Method and device for drying complex mancozeb

A technology of mancozeb and drying method, which is applied to the combination of methods to dry solid materials, separation methods, drying solid materials, etc., can solve the problems of low output, unstable product quality, and high energy consumption, and achieve improved output and appearance. Bright colors, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

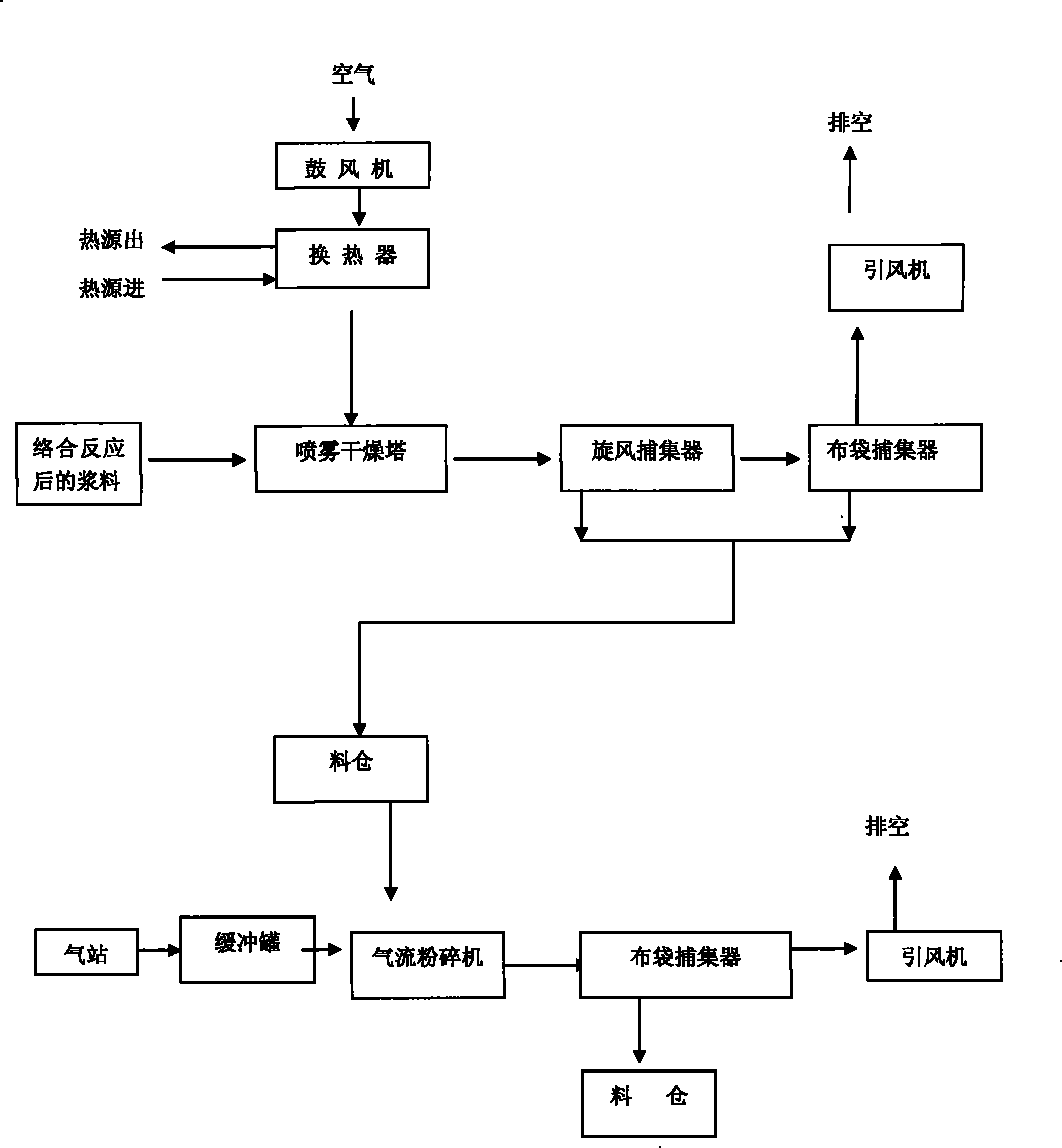

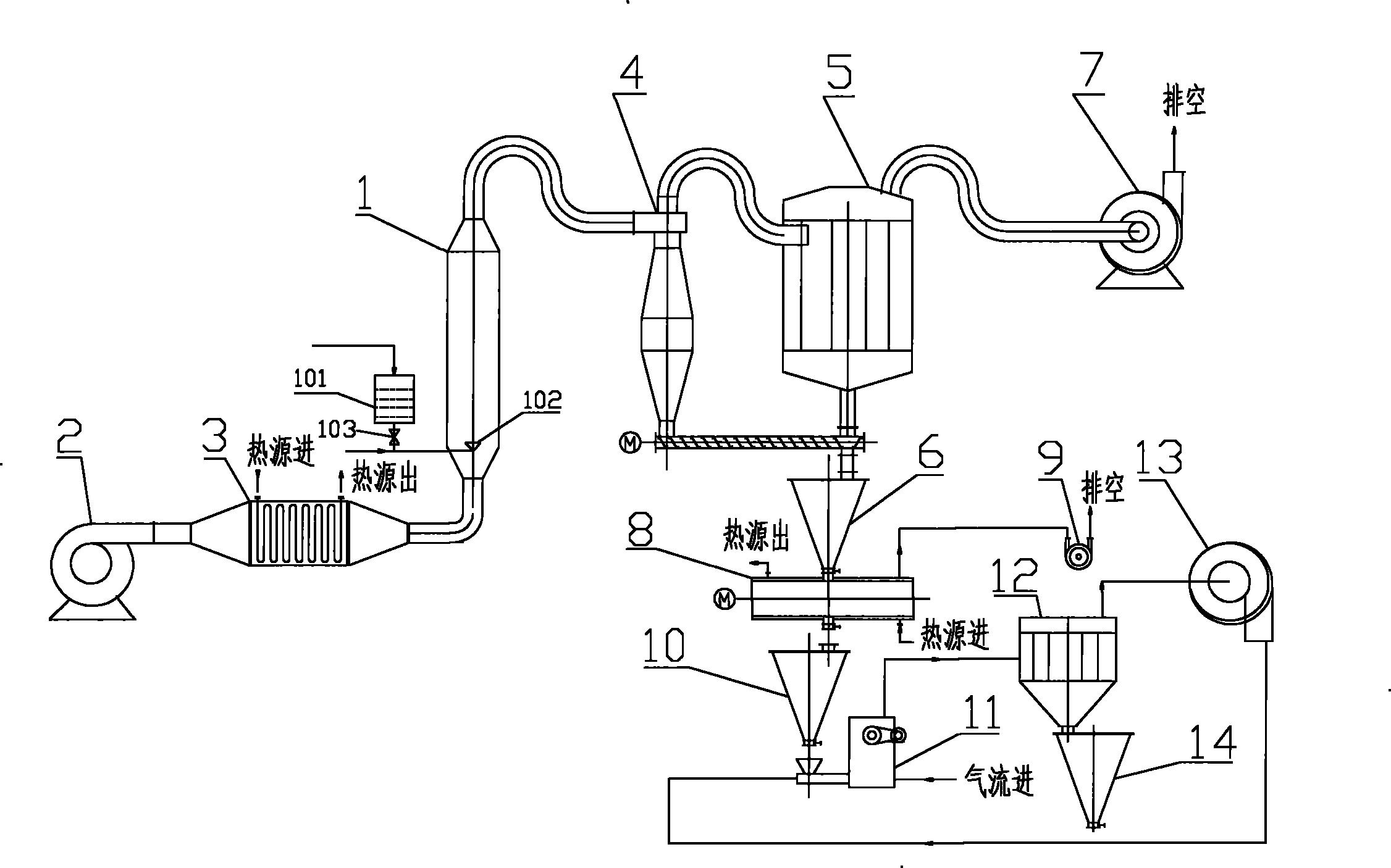

[0014] Combine below figure 1 , image 3 , the present invention is described in detail:

[0015] A drying method for mancozeb in a complex state. Aiming at the characteristics that mancozeb is easy to decompose, flammable, explosive, contains crystal water, difficult to dry at low temperature, easy to catch fire and explode at high temperature, two-stage drying is mainly used 1. Closed circulation airflow pulverization process method, the first stage spray drying: the slurry with good complexation reaction is stored in the metering tank 101, the air flow nozzle 102 is fixed in the middle of the lower part of the spray drying tower 1, the slurry is adjusted by the valve 103, and enters at a uniform speed The nozzle is atomized in the tower under the action of high-speed airflow, and exchanges heat and mass with the air heated by the heat exchanger 3. The cold air of the heat exchanger 3 is introduced by the blower 2, and the drying temperature of the spray drying tower 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com