Dyestripping method, dyestripping device and dyestripping equipment

A film device and drive device technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of affecting the safety of wafers, affecting the quality of dicing films, and consuming tapes, so as to achieve a safe and reliable tearing process. The operation of tearing the film is simple and easy, and the effect of reducing the use of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

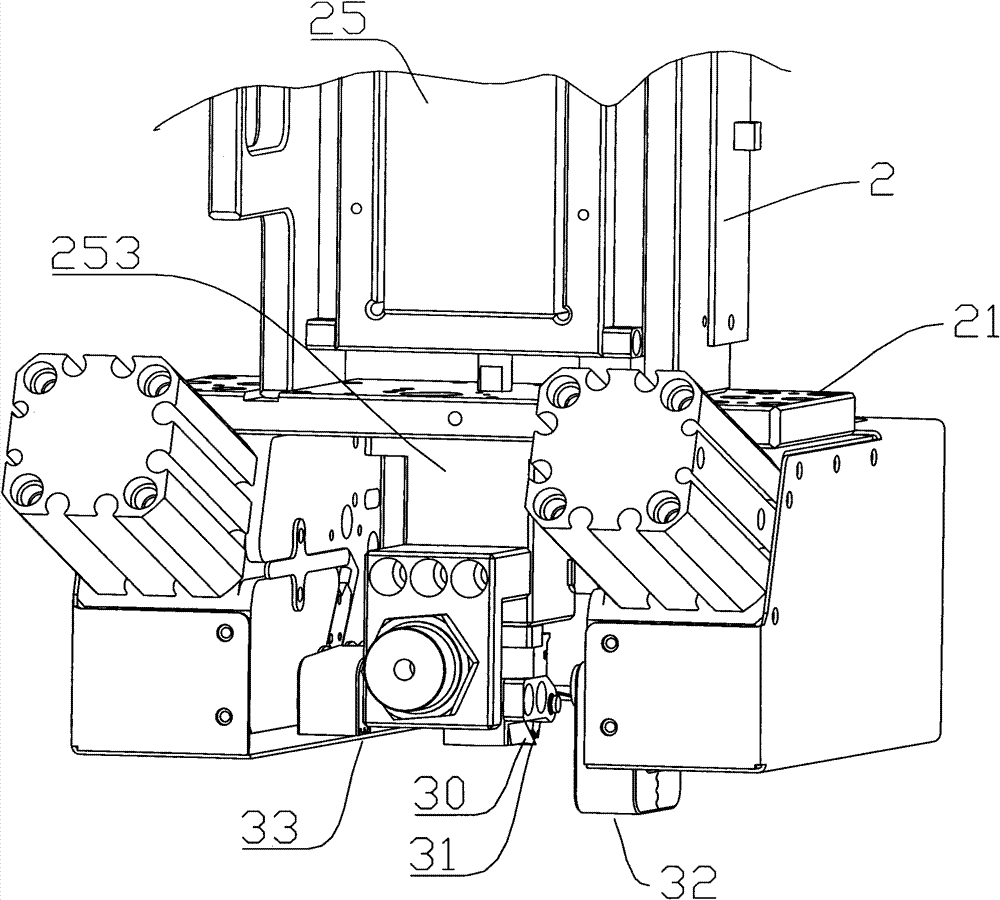

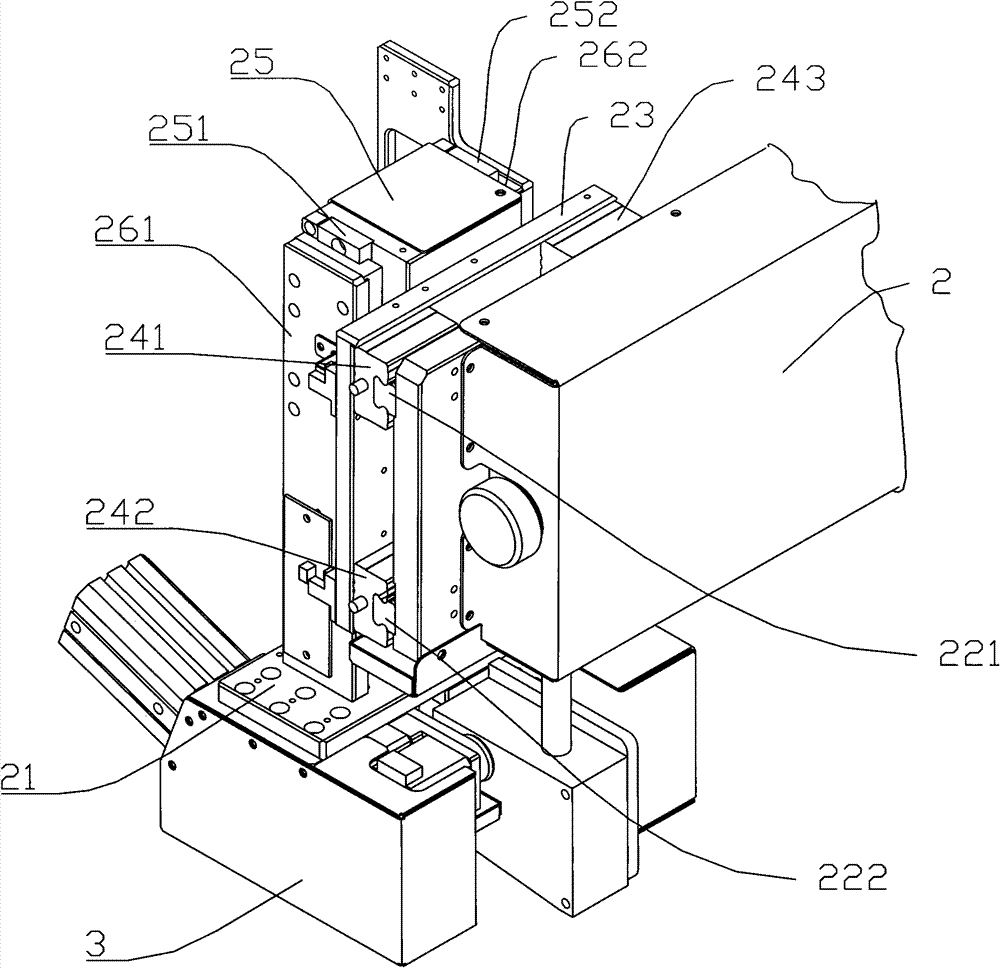

[0048] The present invention is described in detail below in conjunction with accompanying drawing:

[0049] Such as figure 1As shown, the film tearing equipment includes a beam 1, and two parallel first guide rails (11, 12) are arranged on the beam 1. One end of the mechanical arm 2 cooperates with the two first guide rails (11, 12), and can move along the two first guide rails (11, 12). The movement of the mechanical arm 2 along the two first guide rails (11, 12) can be driven by known driving methods. The other end of mechanical arm 2 is equipped with film tearing device 3. A wafer carrying device 5 is provided below the film tearing device 3 for placing and fixing the wafer when tearing the film. A wafer carrier 5 is mounted on the base 4 . The wafer carrying device 5 can be fixedly installed on the base 4 ; it can also be movably installed on the base 4 , which can be realized by using a known installation method.

[0050] When tearing the film, the wafer 6 is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com