Circulating water filter

A circulating water and filter technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems that the circulation system cannot operate, a large amount of dust, rust, algae agglomeration, frequent replacement, etc. To achieve the effect of ensuring normal and controllable operation, facilitating maintenance and repair, and saving manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

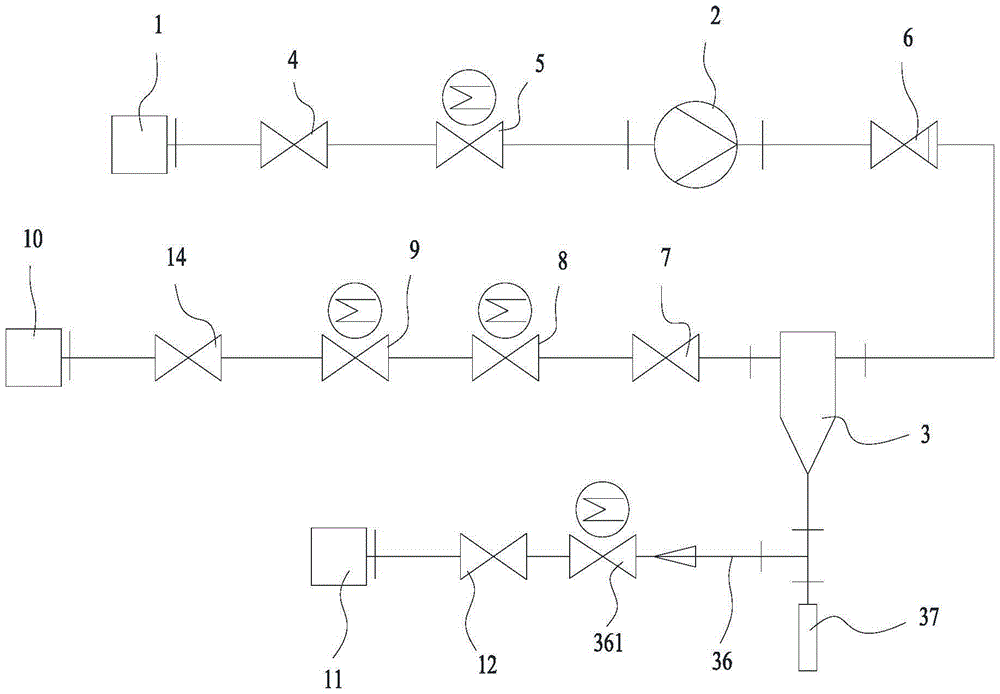

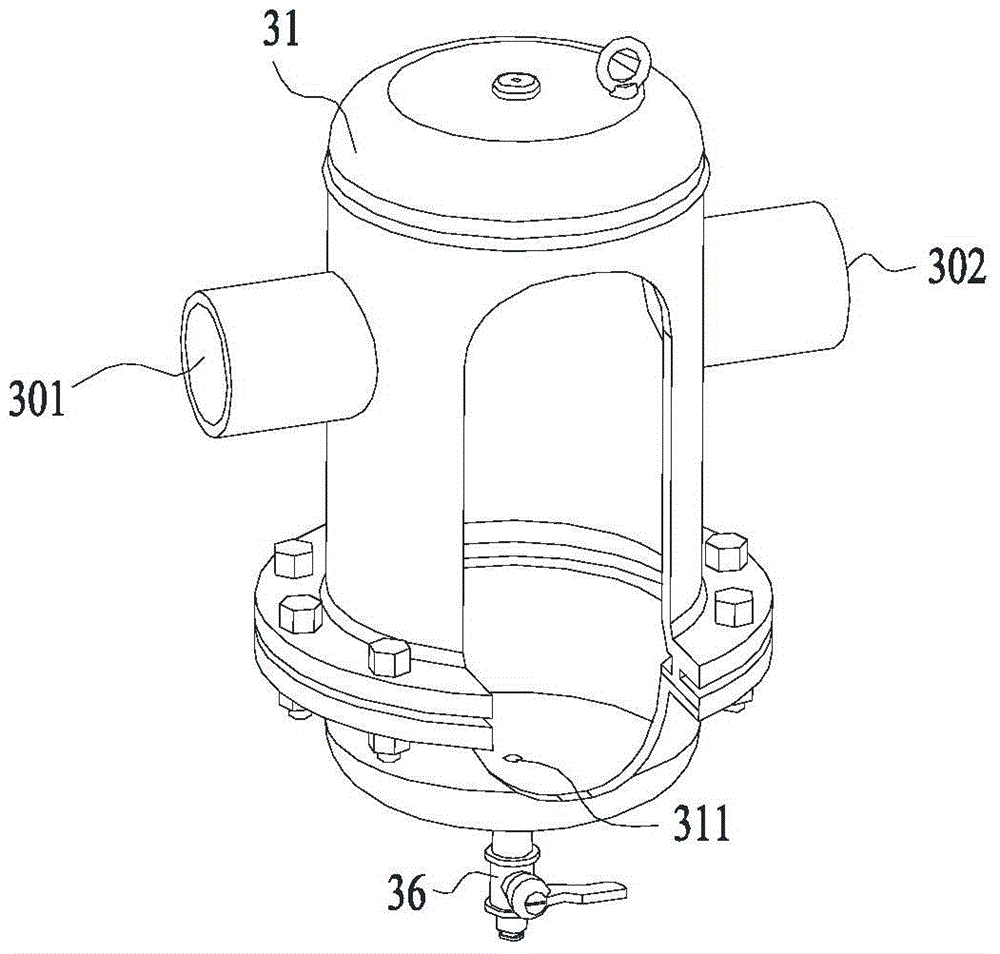

[0024] Such as Figure 1~4 The shown circulating water filter includes a first quick joint 1, a water pump 2, a filter 3 and a second quick joint 10 connected in sequence by pipelines. The filter 3 includes a relatively airtight housing 31, which is pivotally mounted on the housing 31. Inside the cylinder 32 and a plurality of spiral bars 33 spirally wound on the cylinder 32, the side wall of the housing 31 is provided with a filter inlet 301 and a filter outlet 302, the filter inlet 301 and the filter outlet 302 are coaxial, and the filter The inlet 301 communicates with the water pump 2, and the filter outlet 302 communicates with the second quick connector 10; the bottom wall of the housing 31 has a sewage outlet 311, and the sewage outlet 311 is connected with a sewage pipe 36, and the sewage pipe 36 is provided with a first electromagnetic valve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com