Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Achieve large area deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Piston with (Ti, Al)N multilayer heat insulating and wear resisting super-thick coating on surface and preparation method and application of piston

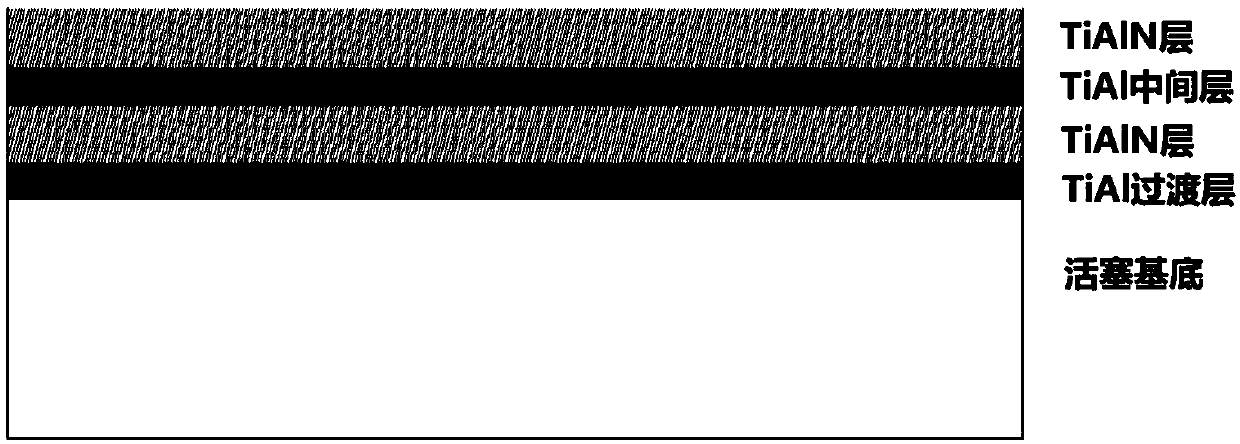

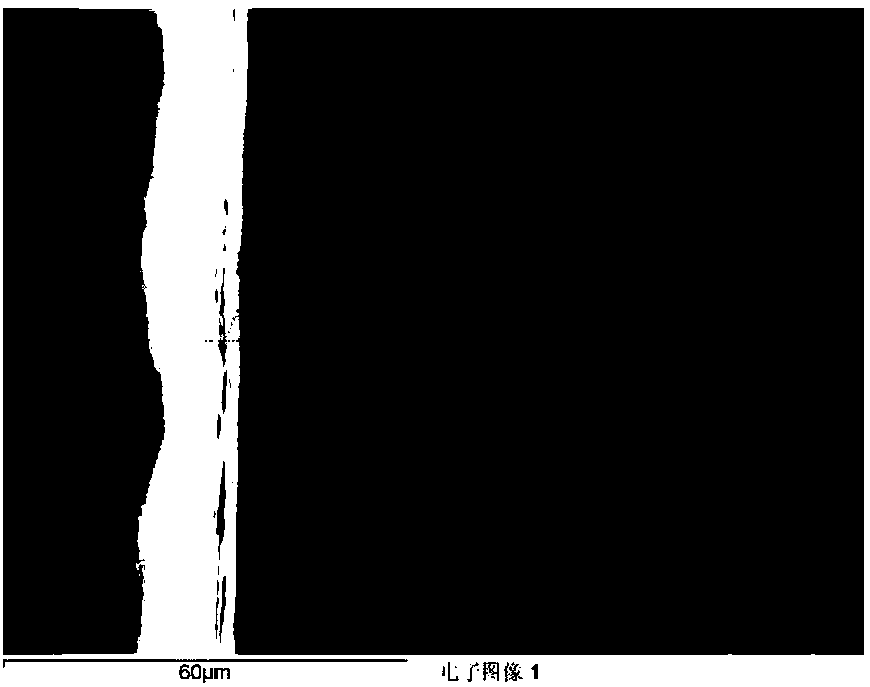

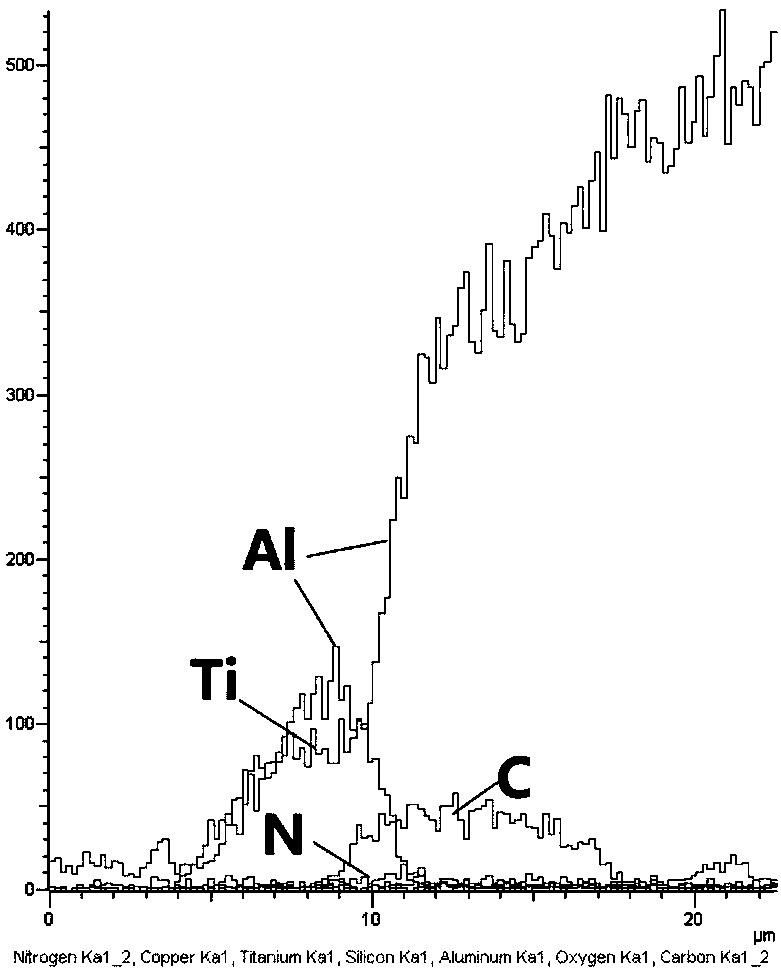

ActiveCN107604312AImprove wear resistanceImprove antioxidant capacityVacuum evaporation coatingSputtering coatingPistonInternal combustion engine

The invention relates to a piston with a (Ti, Al)N multilayer heat insulating and wear resisting super-thick coating on the surface and a preparation technology and application of the piston. The structure of the piston comprises two schemes. According to the first scheme, the piston comprises a base, a TiAl transition layer and a TiAlN clad layer, and the TiAl transition layer evenly wraps the base; and the TiAlN clad layer evenly wraps the TiAl transition layer. According to the second scheme, the piston comprises a base, a first TiAl transition layer, a first TiAlN clad layer, a second TiAltransition layer and a second TiAlN clad layer, and the piston structurally comprises the base, the first TiAl transition layer, the first TiAlN clad layer, the second TiAl transition layer and the second TiAlN clad layer in sequence. According to application of the piston, the piston is used for an internal combustion engine. The designed piston surface has heat insulation performance, wear resistance, oxidation resistance and heat shock resistance, and the service life of the piston is effectively prolonged.

Owner:XIANGTAN UNIV

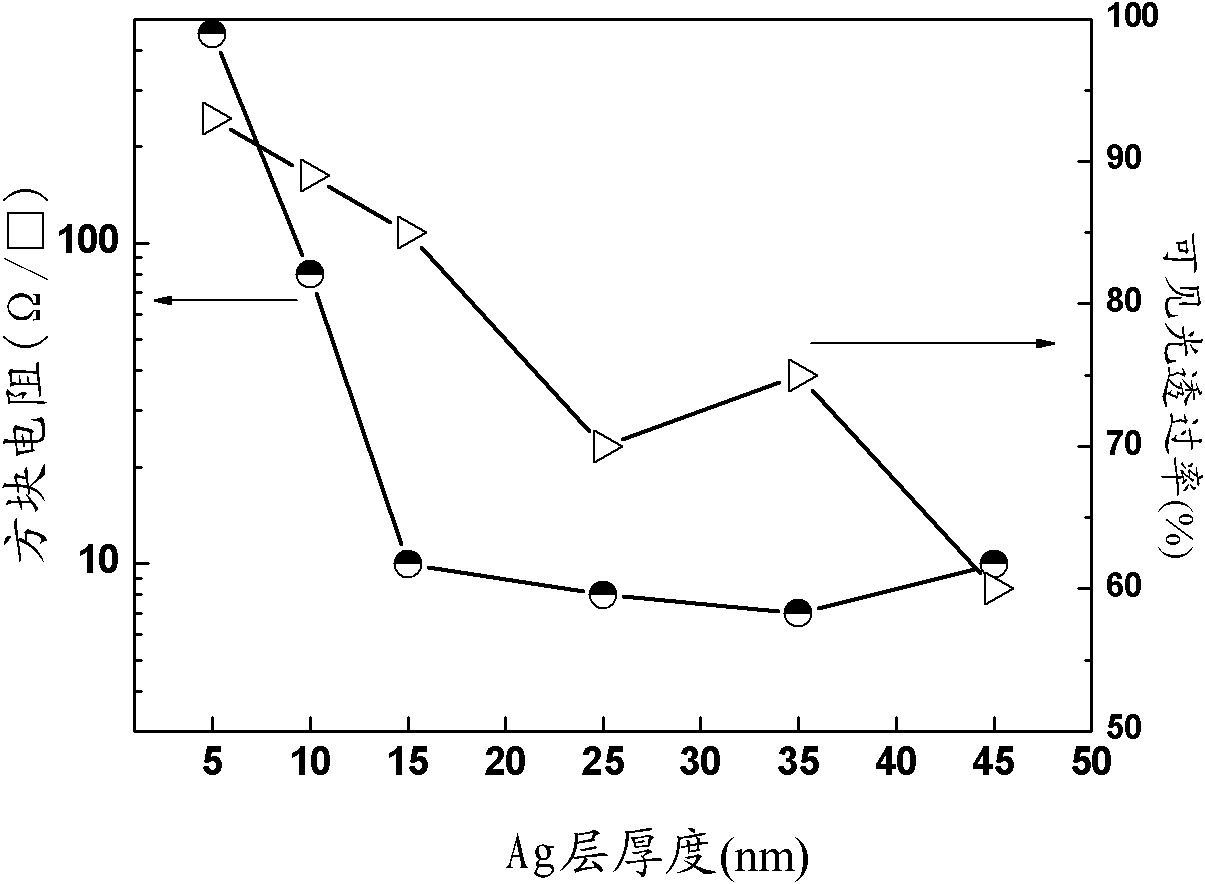

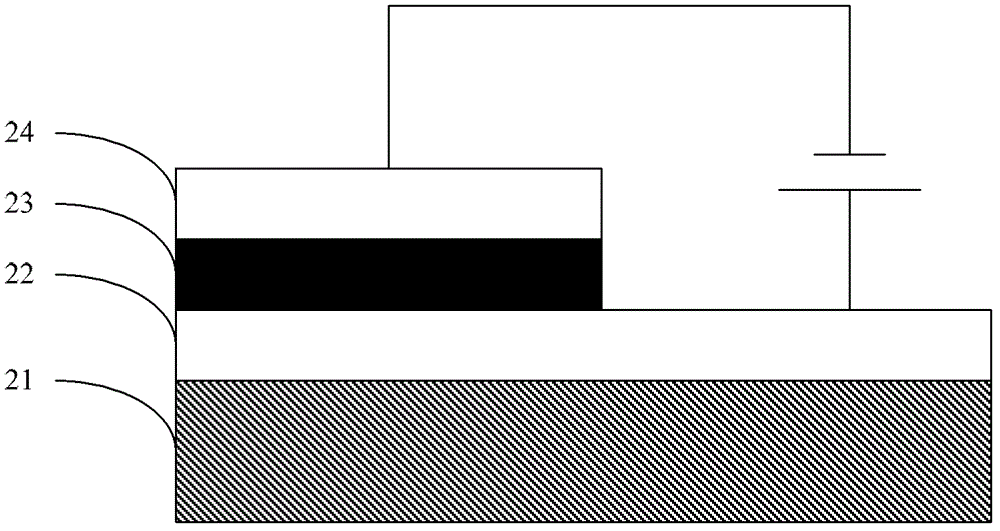

Preparation method of multilayer transparent conductive thin film as well as prepared thin film and application thereof

InactiveCN102134699AIncrease deposition rateConductiveVacuum evaporation coatingSputtering coatingSemiconductor materialsElectrically conductive

The invention relates to the field of preparing semiconductor materials and provides a preparation method of a multilayer transparent conductive thin film as well as a prepared thin film and an application thereof. The method comprises the following steps: mixing SiO2 powder with ZnO powder and sintering to serve as an SZO target, wherein the mass ratio of the SiO2 powder to the ZnO powder is 2 / 199-1 / 6; providing an Ag target; and putting the SZO target and the Ag target into a magnetic-control sputtering cavity, orderly sputtering a first SZO layer, an Ag layer and a second SZO layer on a substrate so as to obtain an SZO-Ag-SZO transparent conductive thin film which is of a sandwich structure. The invention also provides the multilayer transparent conductive thin film obtained by using the method and the application of the film in semiconductor photoelectric devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Preparation method of multilayer transparent conductive film, film prepared thereby, and application thereof

InactiveCN102134704AIncrease deposition rateLower substrate temperatureVacuum evaporation coatingSputtering coatingSemiconductor materialsSemiconductor

The invention relates to the preparation field of semiconductor material, and provides a preparation method of a multilayer transparent conductive film, the film prepared thereby, and the application thereof. The preparation method comprises the steps of: mixing Ga2O3 powder and ZnO powder, sintering the mixture and taking the product as GZO target material, wherein the mass ratio between the Ga2O3 powder and ZnO powder is 1 / 99-1 / 19; providing Cu target material; putting the GZO target material and the Cu target material into a magnetron sputtering cavity; vacuumizing and alternately sputtering a GZO layer and a Cu layer on a substrate; and finally obtaining the GZO-Cu-GZO transparent conductive film with a sandwich structure. The invention also provides the multilayer transparent conductive film prepared by the method, and the application of the film in a semiconductor photoelectric device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Chemical preparation technology of Cu(InAl)Se2 film

InactiveCN102723399AReduce consumptionEasy to operateFinal product manufactureSemiconductor devicesWater bathsSolar cell

The invention relates to a chemical preparation technology of a Cu(InAl)Se2 film. The technology is a preparation method of chemical deposition. The method is characterized by: taking soda-lime glass as a substrate; firstly, using a radio frequency (RF) magnetron sputtering method to sputter molybdenum (Mo) metal so as to make a back electrode on the substrate; then, using a chemical bath deposition (CBD) method to deposit a CIAS film on the Mo back electrode. Through using the CBD method to prepare the CIAS film, material consumption is small; expensive vacuum equipment is not needed; a toxic gas does not need to be processed and the large area deposition can be realized. A forbidden band width of the prepared CIAS film is 1.44eV, which is an optimal band gap of a single-junction solar cell. And a luminous absorption coefficient is greater than 10<6>cm<-1>.

Owner:YUNNAN NORMAL UNIV

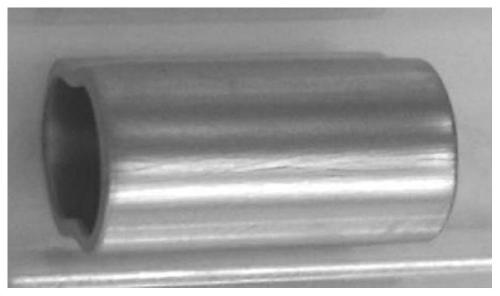

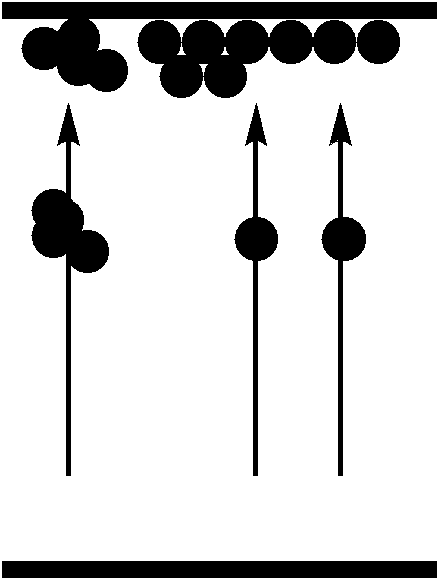

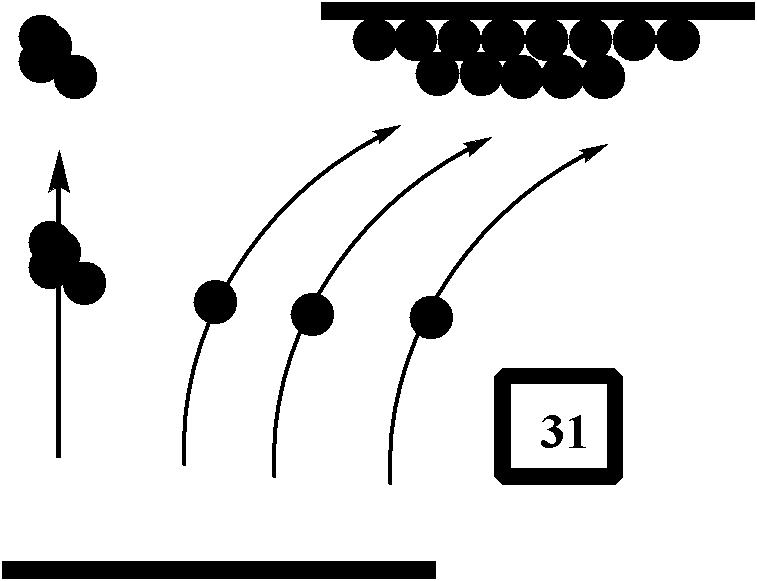

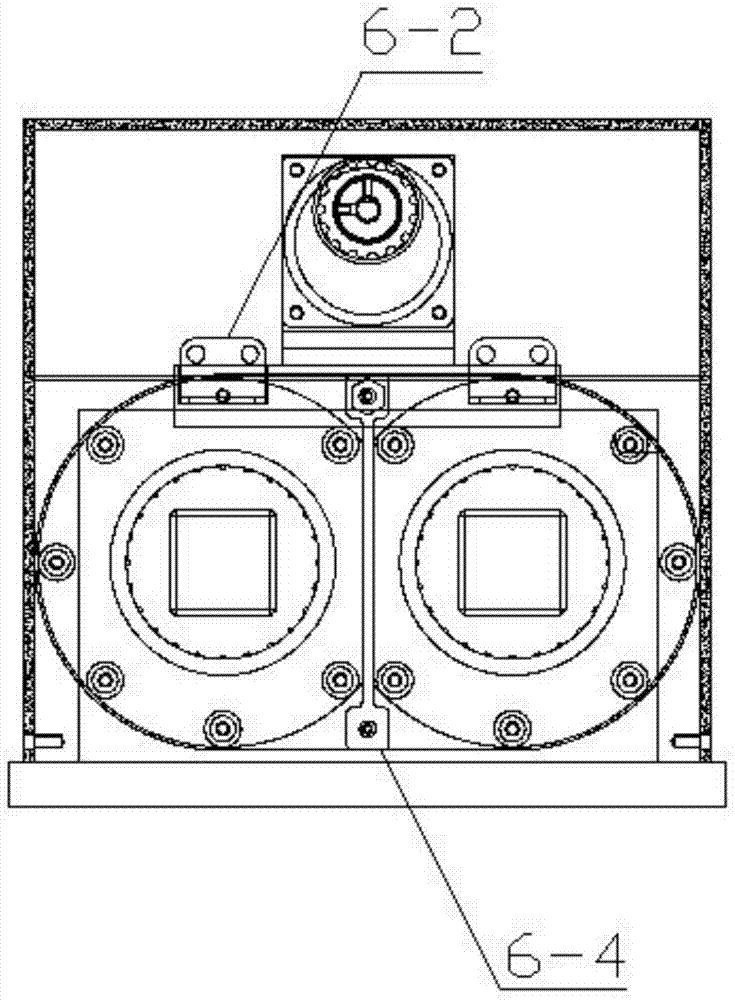

Novel twin external rotating cathode

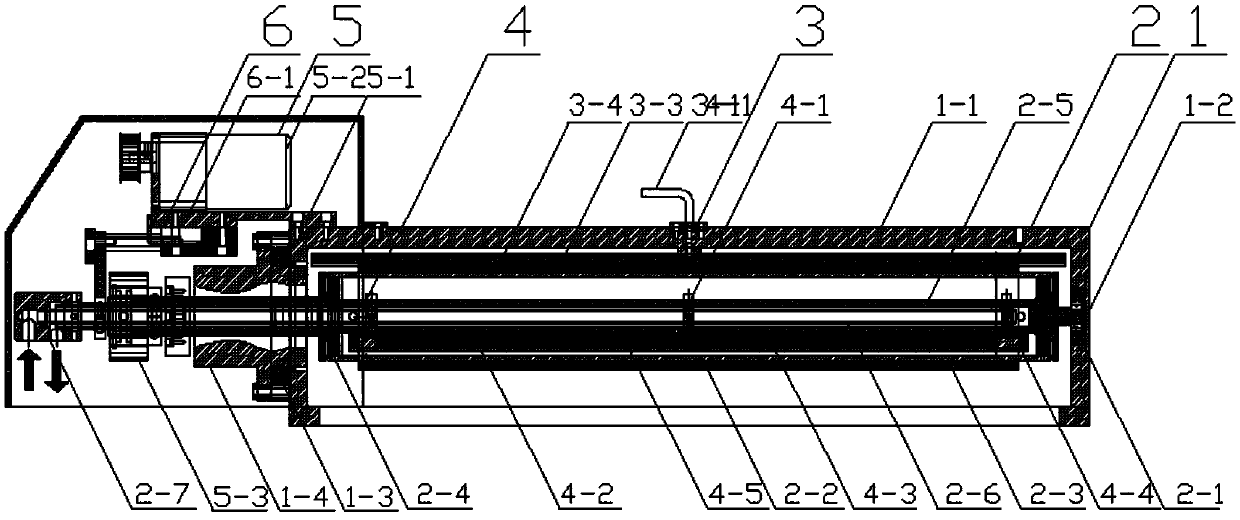

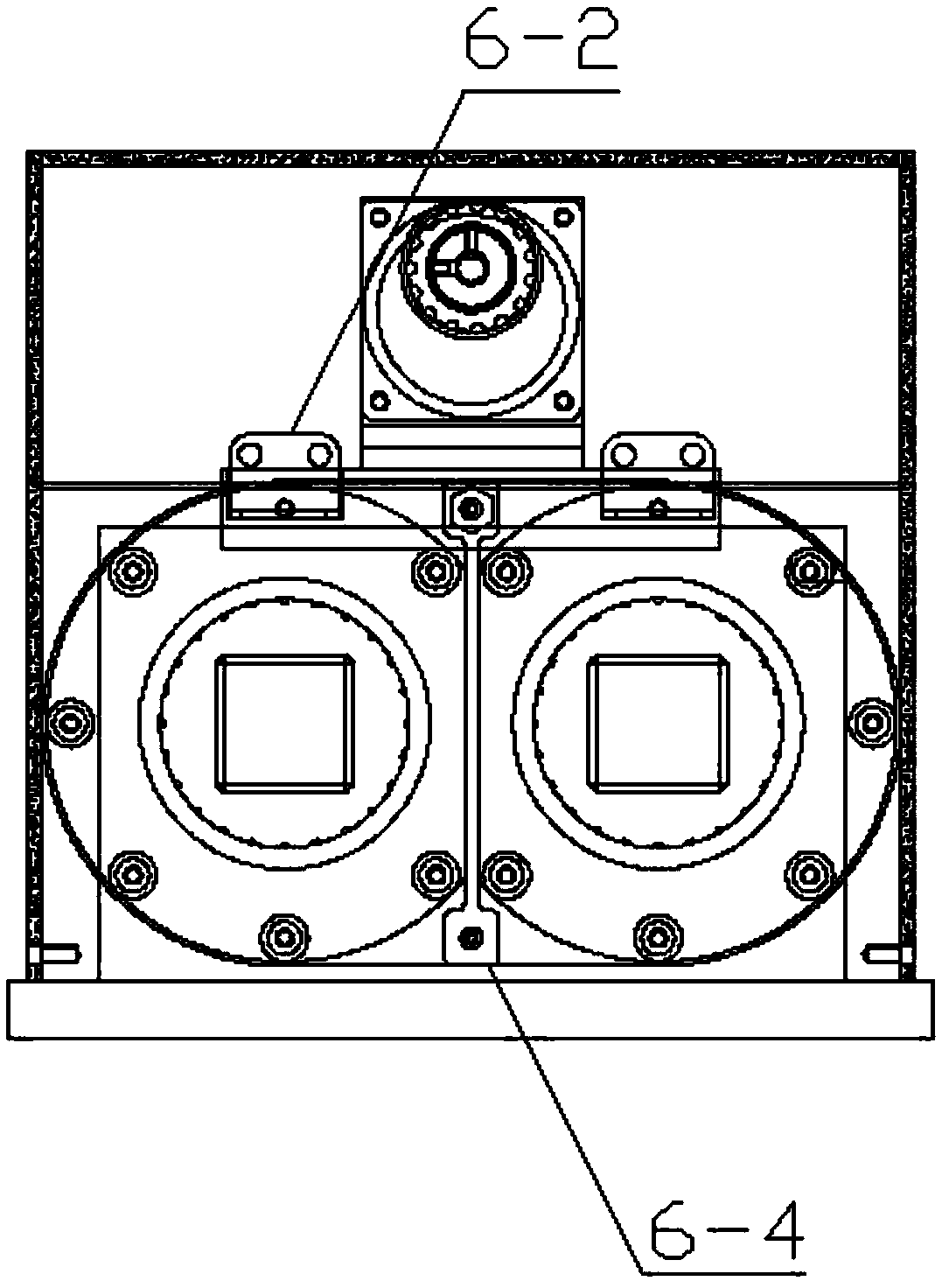

ActiveCN105506568AThe repeatability of the film layer process is goodEnhanced Plasma DensityVacuum evaporation coatingSputtering coatingEngineeringSettling

The invention discloses a novel twin external rotating cathode, which comprises a common target sleeve, a twin cooling water system, a common technical gas inlet system, a twin weight equalizer system, a common rotary power system, a twin electric power access system, a twin observation window and a common security protection hood, wherein a motor of the common rotary power system drives the common target sleeve to rotate at the same speed through a synchronous belt synchronizing wheel; the common technical gas inlet system introduces working gas to keep the vacuum in the working vacuum degree; and the twin electric power access system is used for accessing corresponding high voltage, so that the gas is ionized into plasma, thereby carrying out magnetron sputtering coating in a balanced magnetic field provided by the twin weight equalizer system. By adopting the linear twin rotating cathode design, the novel large-area twin external rotating cathode has the characteristics of high deposition rate, wide uniform settling region, high target utilization ratio and high technical stability, and can implement continuous target face self-cleaning and arbitrary-angle installation.

Owner:WUHAN KERUIDA VACUUM TECH CO LTD

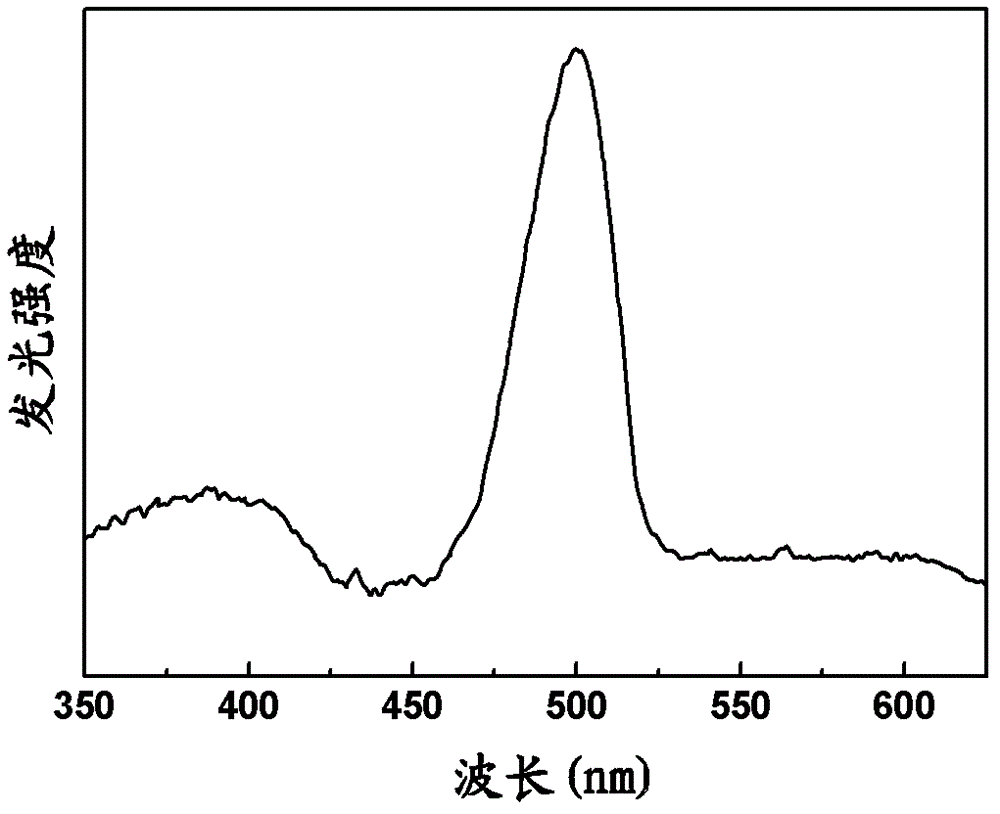

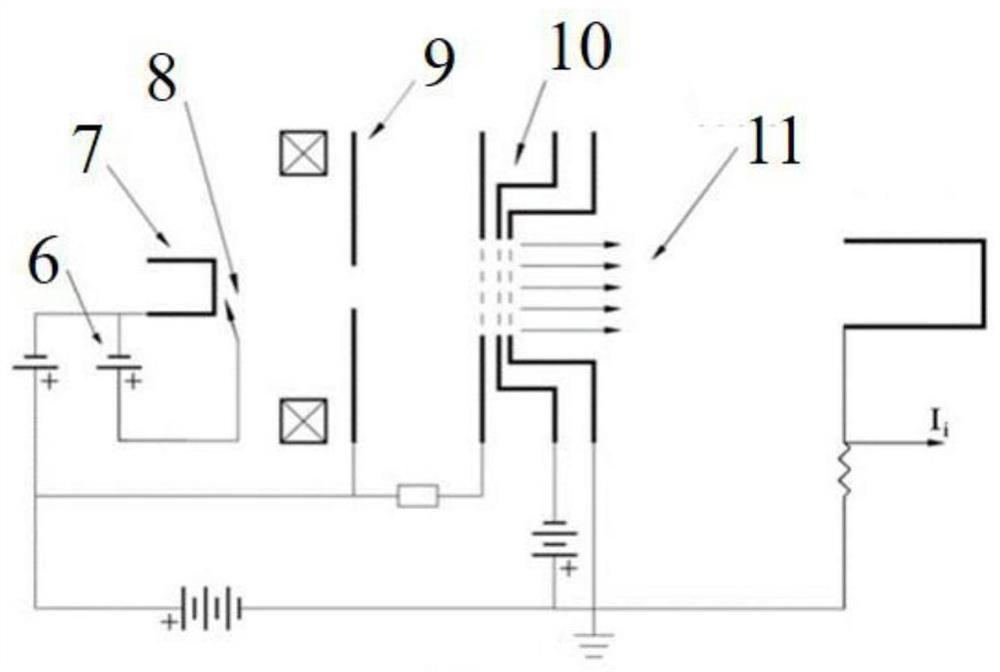

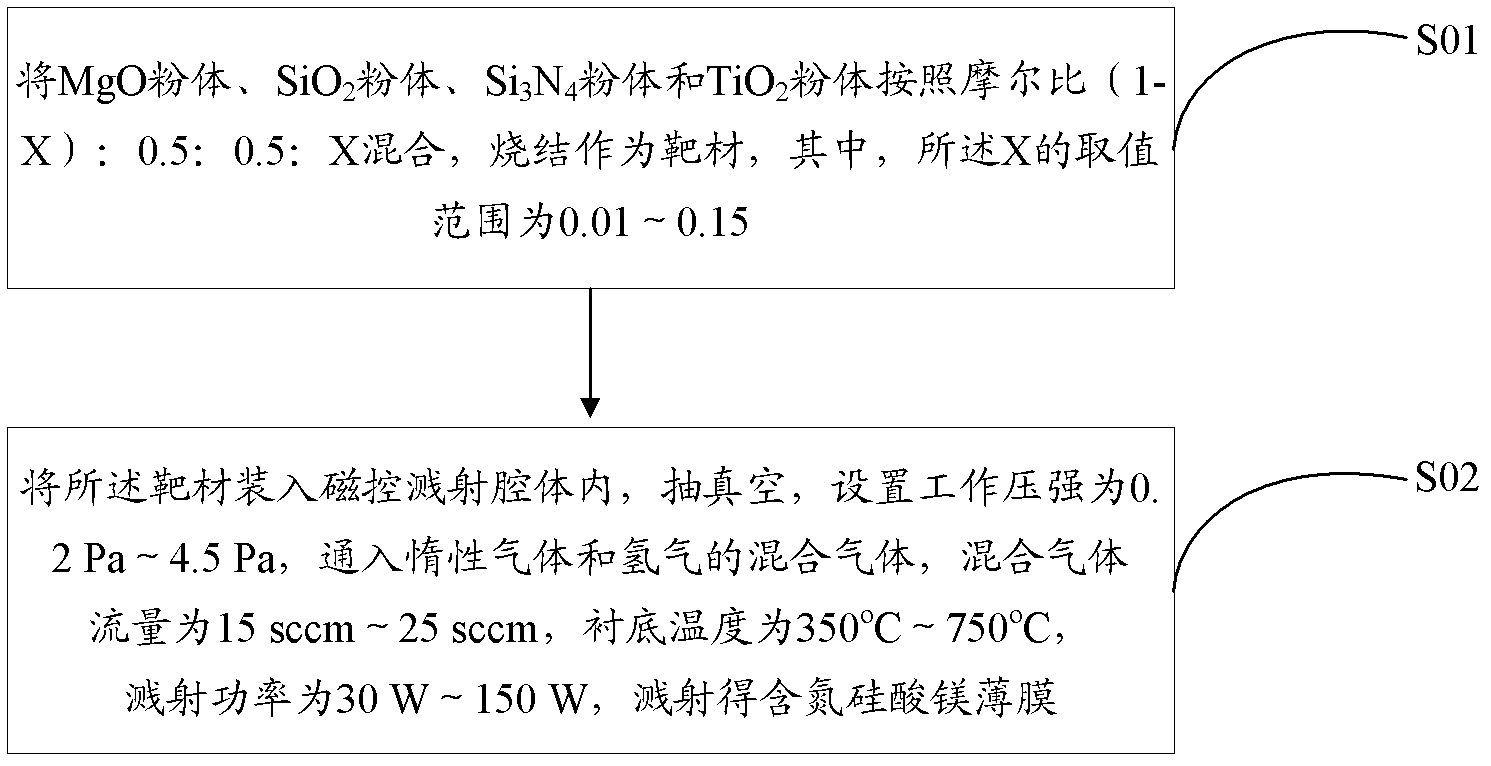

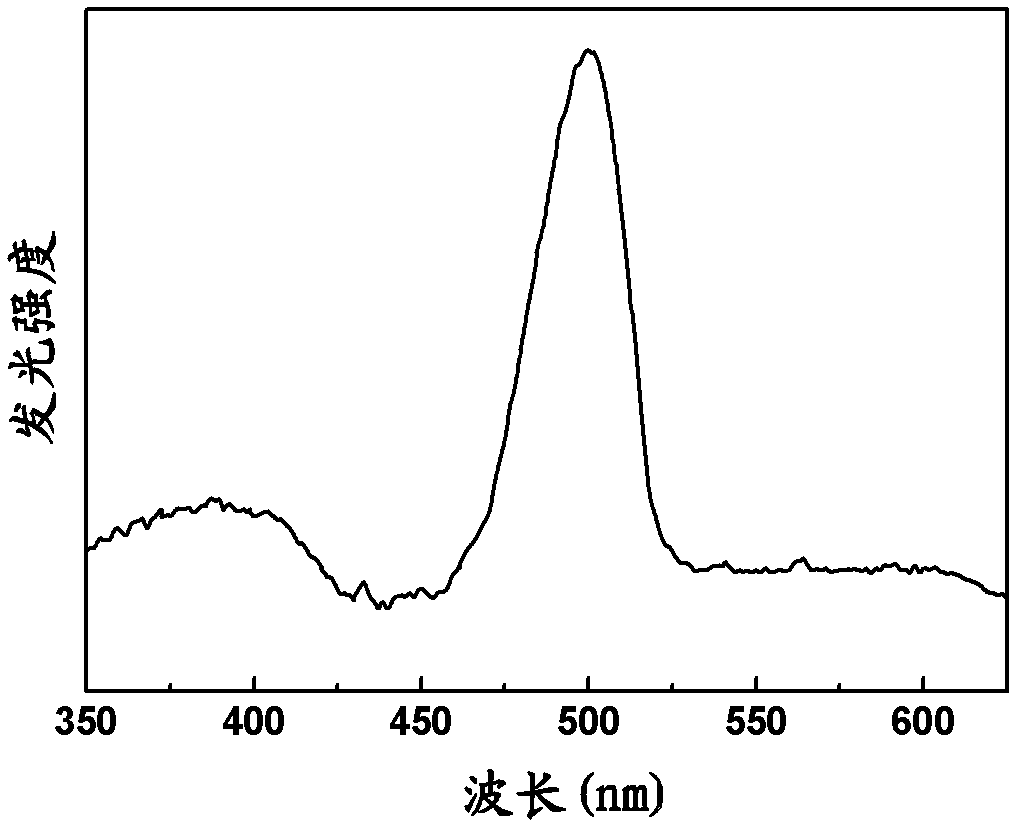

Nitrogenous magnesium silicate film, and preparation method and application thereof

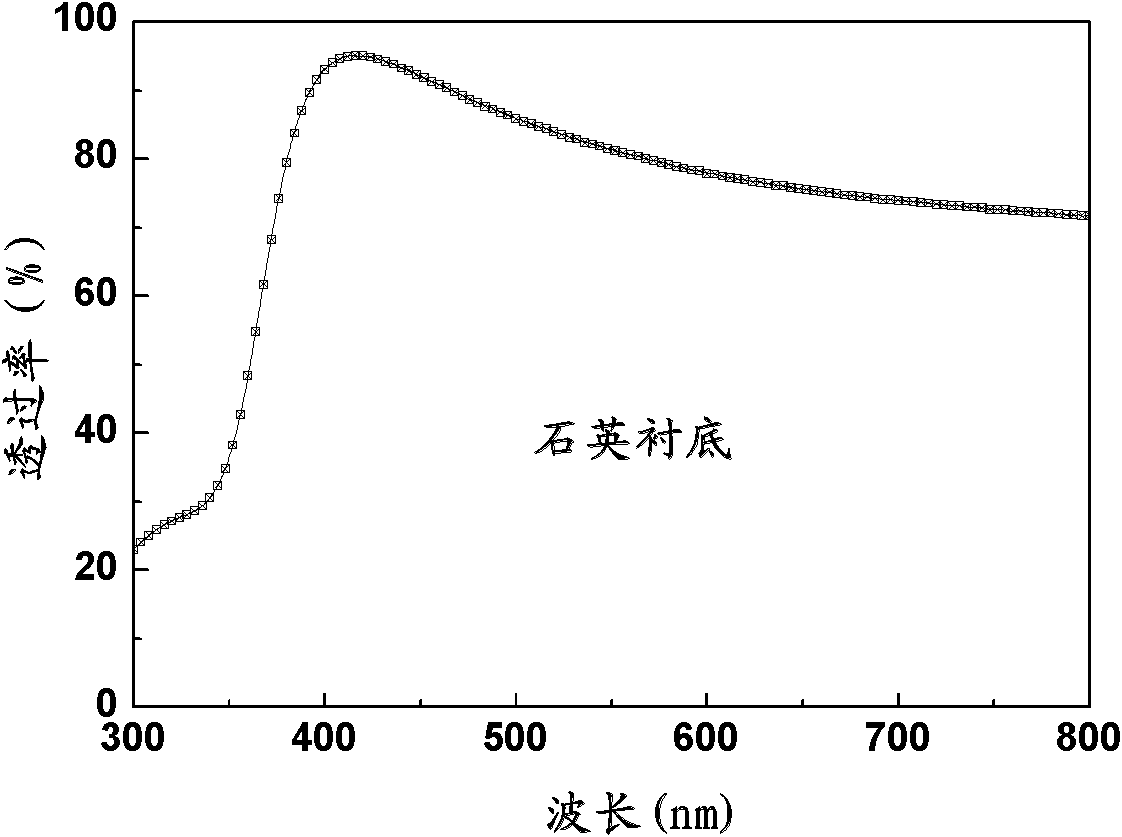

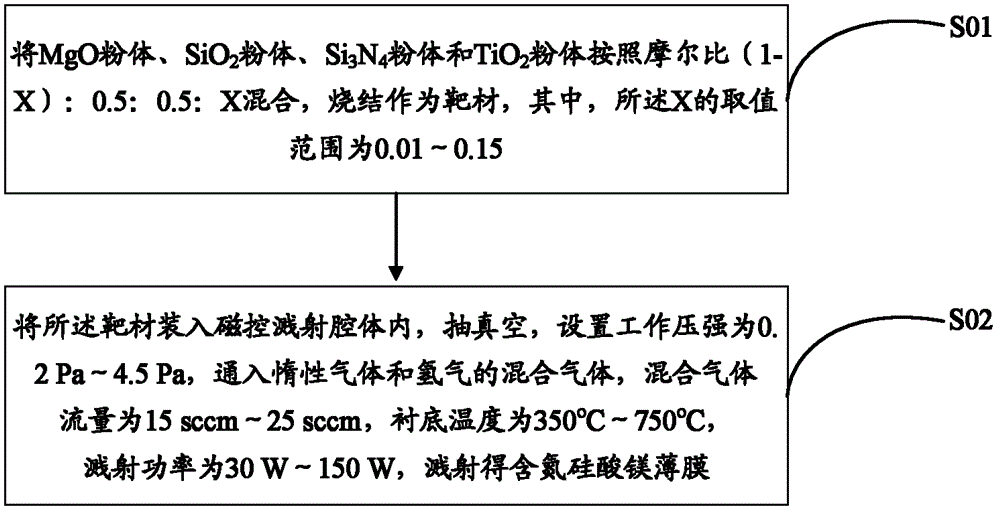

ActiveCN102796517AImprove stabilitySolution to short lifeLuminescent compositionsTi dopingSemiconductor materials

The invention relates to the field of preparation of semiconductor materials, and provides a nitrogenous magnesium silicate film which is a titanium-doped nitrogenous magnesium silicate film of which the general formula is Mg1-XSi2O2N2:XTi4+, wherein X-0.01-0.15. The invention also provides a preparation method of the nitrogenous magnesium silicate film, which comprises the following steps: mixing MgO powder, SiO2 powder, Si3N4 powder and TiO2 powder, and sintering to obtain a target; and filling the target into a magnetron sputtering chamber, vacuumizing, setting working parameters, and sputtering to obtain the nitrogenous magnesium silicate film. The invention also provides application of the nitrogenous magnesium silicate film in electroluminescent devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

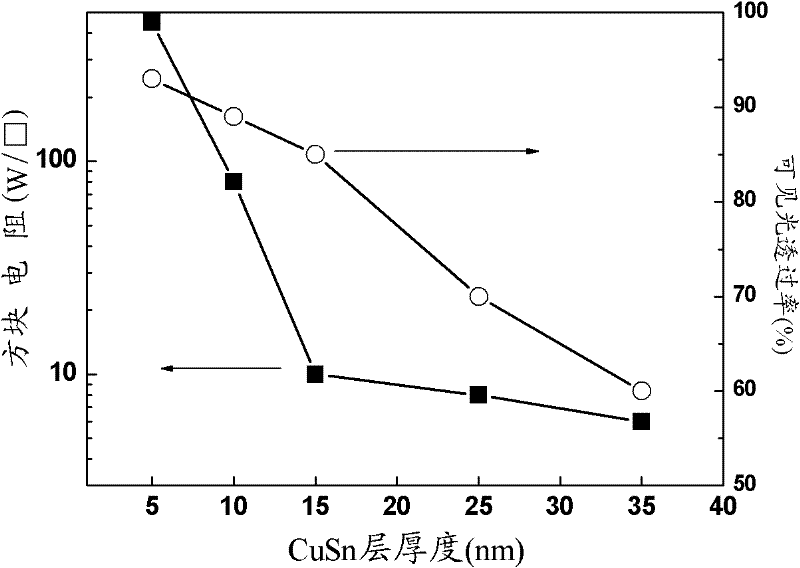

Preparation method of multilayer transparent conductive thin film as well as prepared thin film and application thereof

InactiveCN102650034AIncrease deposition rateLow substrate temperatureVacuum evaporation coatingSputtering coatingElectrically conductiveSemiconductor materials

The invention relates to the field of preparing semiconductor materials and provides a preparation method of a multilayer transparent conductive thin film as well as a prepared thin film and an application thereof. The method comprises the following steps: mixing SiO2 powder with ZnO powder and sintering to serve as an SZO target, wherein the mass ratio of the SiO2 powder to the ZnO powder is 1 / 199-1 / 9; providing a CuSn target, wherein the mass ratio of the Cu to the Sn is 7 / 3-19 / 1; and putting the SZO target and the CuSn target into a magnetic-control sputtering cavity, orderly sputtering an SZO layer and a CuSn layer on a substrate so as to obtain an SZO-CuSn-SZO transparent conductive thin film which is of a sandwich structure. The invention further provides the multilayer transparent conductive thin film obtained by using the method and the application of the film in semiconductor photoelectric devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Coating layer for high-efficient combination of nuclear reactor and preparation method of coating layer

PendingCN110106467AImprove corrosion resistanceMeeting the requirements for accident-resistant cladding materialsVacuum evaporation coatingSputtering coatingNuclear reactor coreThermal spraying

The invention discloses a coating layer for high-efficient combination of a nuclear reactor. The coating layer is deposited on the external surface of matix materials used for the nuclear reactor, andthe coating layer successively includes a Zr-Cr or Ti-Cr transition layer and a Cr deposition layer from internal to external; the preparation method of the coating layer adopts a physical vapor deposition method, a thermal spraying method, a cooling spraying method, a laser cladding method, an electrochemical plating or a chemical vapor deposition method, and preferably adopts an arc ion platingof the physical vapor deposition method. According to the coating layer, zirconium alloy matrix materials are coated with the coating layer to obtain cladding materials with good ability of corrosionresistance, membrane-matrix cooperative deformation and high temperature and oxidation resistance; and the cladding materials are accident resistance fuel cladding materials with a promising development prospect, and high-temperature mechanical properties of coated cladding materials taking N36 as a matrix are better.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for producing silicon doping zinc oxide film, produced film and application thereof

InactiveCN102650035AIncrease deposition rateImprove crystal qualityFinal product manufactureVacuum evaporation coatingSemiconductor materialsSilicon

The invention relates to the field of semiconductor material production, and provides a method for producing a silicon doping zinc oxide film, a produced film and an application thereof, wherein the method comprises the following steps that: SiO2 powder and ZnO powder are mixed and sintered to be used as an SZO target, and the mass ratio of SiO2 to ZnO is 1:199-1:66; and the SZO target is contained in a magnetron sputtering cavity, the cavity is vacuumized, sputtering parameters are set, and a silicon doping zinc oxide film is sputtered onto a substrate. The invention further provides the silicon doping zinc oxide film which is produced by the method and the application of the silicon doping zinc oxide film on semiconductor photoelectric devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Shaving blade with multi-layer strengthening coating and preparation method of shaving blade

PendingCN111763945ASolve technical problems such as weak bonding force and easy coating peeling offHigh hardnessVacuum evaporation coatingSputtering coatingStructural engineeringMagnetic filtration

The invention discloses a shaving blade with a multi-layer strengthening coating and a preparation method of the shaving blade. A blade base with a blade edge is prepared by adopting a composite technology of magnetic filtration cathode vacuum arc deposition and MEVVA source injection, and a strengthening layer and a lubricating layer are arranged on the blade base, wherein the strengthening layeris composed of a plurality of nanometer layers with different hardness and comprises a Ti transition layer, a TiN transition layer and a Ti-doped DLC layer which are sequentially arranged from insideto outside, and the lubricating layer is a polytetrafluoroethylene layer. Multiple transition layers such as the Ti transition layer and the TiN transition layer are introduced between the blade basematerial and the DLC film layer, meanwhile, Ti ions are injected into MEVVA source ions, the surface hardness of a shaver can be enhanced, the interface lattice effect can be optimized, the internalstress of the coating can be effectively relieved, the bonding force between the coating and the base is effectively improved, the workpiece hardness and wear resistance are improved, and the frictioncoefficient is reduced so that the service life of the workpiece can be prolonged.

Owner:北京市辐射中心

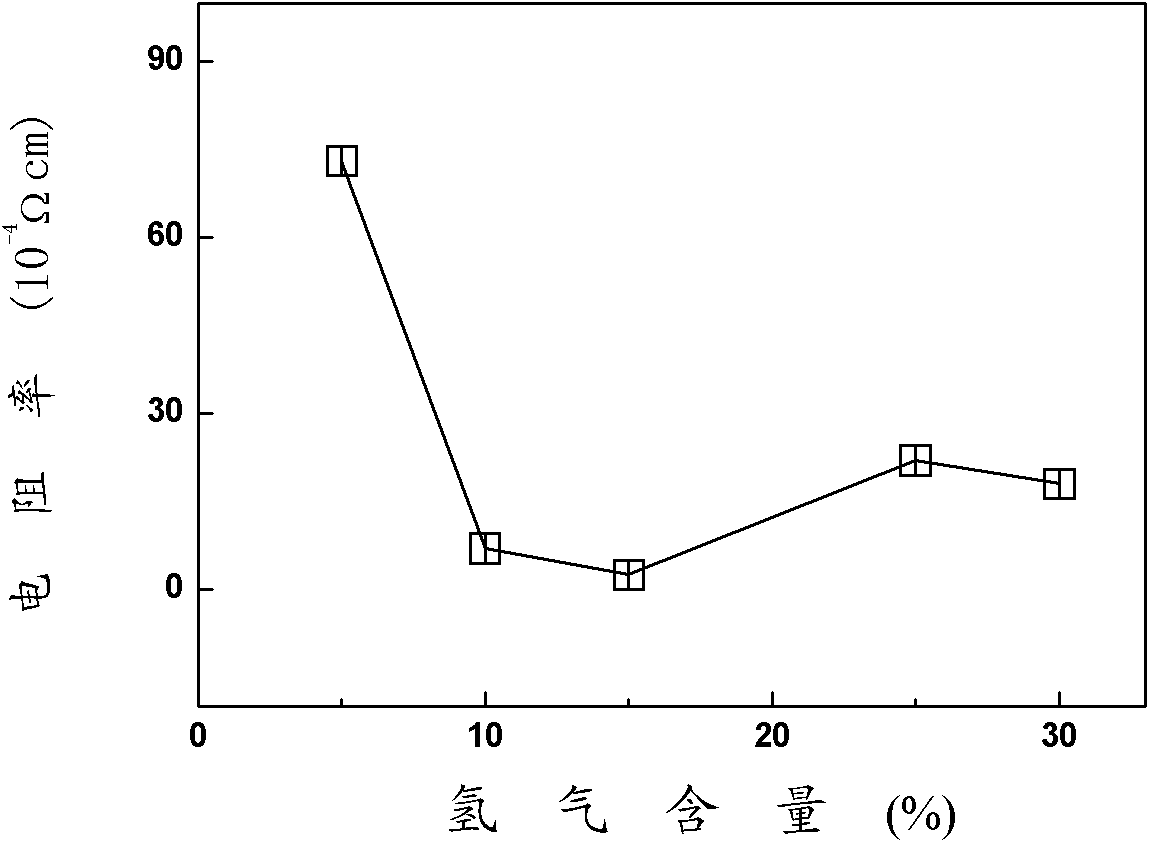

Gallium-doped zinc oxide film, and preparation method and application thereof

InactiveCN102691037AIncrease deposition rateGood adhesionVacuum evaporation coatingSputtering coatingSemiconductor materialsPhysical chemistry

The invention relates to the field of semiconducting material preparation, and provides a preparation method of a gallium-doped zinc oxide film. The method comprises the following steps: mixing Ga2O3 powder and ZnO powder with the mass ratio of Ga2O3 powder to ZnO powder being 1 / 1999 to 1 / 99, and sintering the mixture as a GZO target material; filling the GZO target material into a magnetron sputtering cavity, carrying out vacuumizing, with the working pressure set as 0.2 Pa to 1.5 Pa, the inert gas flow as 15sccm to 35sccm, and sputtering power of the GZO layer as 60 to 160 W, and sputtering to obtain the gallium-doped zinc oxide film; and annealing the above prepared gallium-doped zinc oxide film, with the annealing atmosphere being a mixed gas of an inert gas and hydrogen gas, wherein the molar volume percentage content of the hydrogen gas in the mixed gas is 5% to 30% and the annealing temperature is 200 DEG C to 600 DEG C. The invention further provides the gallium-doped zinc oxide film prepared by the method and an application of the gallium-doped zinc oxide film in semiconductor photoelectric devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Preparation method of room temperature ferromagnetic hydrogen and hafnium co-doped indium oxide film

ActiveCN107742604BDense grainImprove uniformitySemiconductor/solid-state device manufacturingMagnetizationHafnium

Provided is a preparation method of hydrogen and hafnium co-doped indium oxide film having room-temperature ferromagnetism. A direct-current magnetron sputtering method is adopted. An In2O3 ceramic target accounting for 1.5-10% of the doping amount of hafnium oxide (HfO2) by weight is used as a target material, monocrystalline silicon serves as a substrate, high-purity argon (Ar) having the purityof 99.99% or above serves as sputtering gas, hydrogen (H2) is introduced in the sputtering process to serve as doping source for deposition, and the hydrogen and hafnium co-doped indium oxide film having different magnetization characteristics is obtained.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

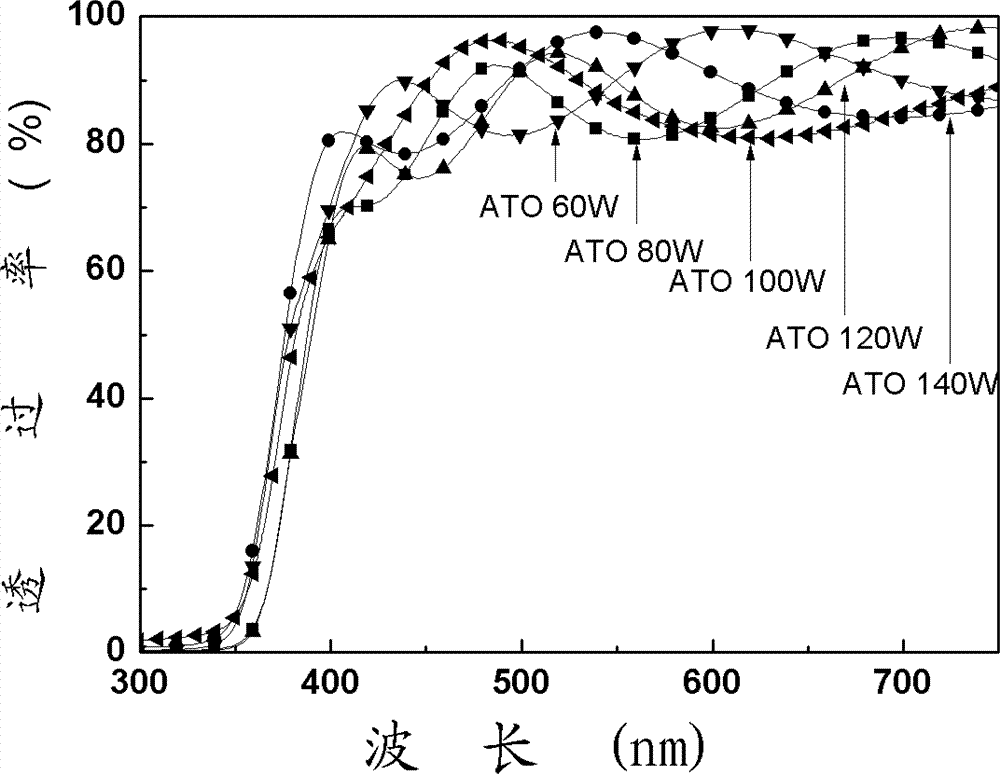

Multielement composite transparent conductive film and preparation method and application thereof

InactiveCN102465271BIncrease deposition rateGood adhesionVacuum evaporation coatingSputtering coatingSemiconductor materialsPhysical chemistry

The invention provides a multielement composite transparent conductive film and a preparation and application thereof, relating to the field of preparation of semiconductor materials. The preparation method comprises the following steps of: preparing an AZO target: mixing Al2O3 powder with ZnO powder to obtain a mixture and sintering the mixture to be used as the target, wherein the molar weight ratio of Al2O3 to ZnO is 1 / 120-1 / 35; preparing an ATO target: mixing Sb2O3 powder with SnO2 powder to obtain a mixture and sintering the mixture to be used as the target, wherein the molar weight ratio of Sb2O3 to SnO2 is 1 / 9-1 / 4; and depositing a film: feeding the AZO target and the ATO target into a magneto-controlled sputtering chamber, vacuumizing and setting the following parameters, namely, the substrate temperature is 500-800 DEG C, the inert gas flow is 15sccm-25sccm, the pressure intensity is 0.2-1.6Pa, the sputtering powers of the AZO target and the ATO target are respectively 60-160W, and the deposition time is 40-240min.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

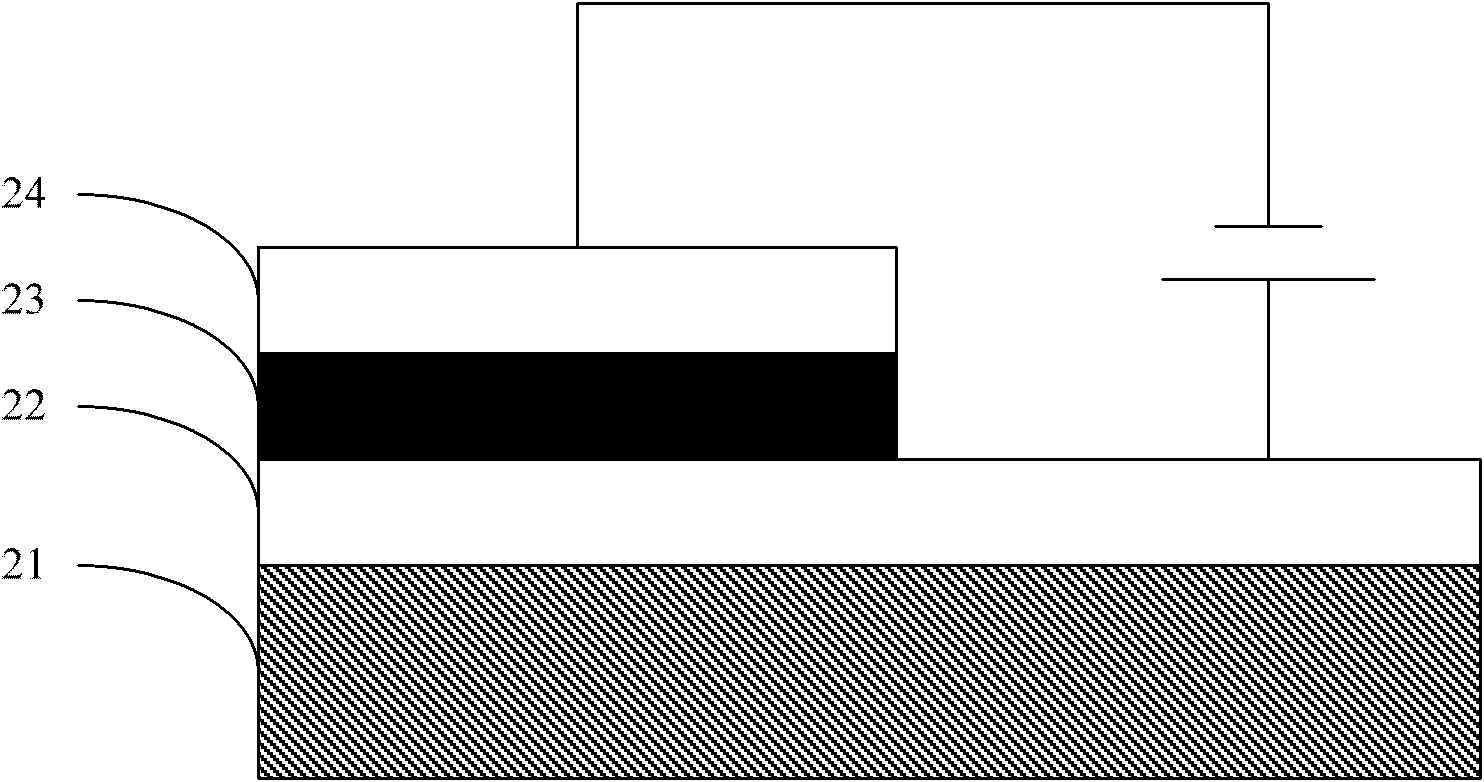

A kind of p-type camsno amorphous oxide semiconductor thin film and preparation method thereof

ActiveCN106711193BImprove material propertiesAchieve large area depositionTransistorSemiconductor/solid-state device manufacturingPhysical chemistryThin membrane

The invention discloses a p-type CaMSnO amorphous oxide semiconductor thin film, wherein the valence of Ca is +2, M is one of VIIIB group transition metals Fe, Co and Ni, the valence of M is +3, and Ca and M are combined with O to form a p-type conductive substrate of the material; and the valence of Sn is +2, p-type conduction is also formed in the substrate at the same time, and the Sn is provided with a spherical electron orbit and highly overlapped with electron cloud in an amorphous state so as to play a role of a hole transmission channel. The invention further provides a method for preparing the p-type CaMSnO amorphous oxide semiconductor thin film, which comprises the steps of firstly preparing a CaCoSnO ceramic piece according to a sintering method, and preparing a p-type CaMSnO amorphous oxide semiconductor thin film by taking the CaCoSnO ceramic piece as a target material according to a pulse laser deposition method, wherein the hole concentration is in a range of 10<12>cm<-3> to 10<14>cm<-3>. The thin film prepared according to the method can be applied to a P-type amorphous thin-film transistor.

Owner:ZHEJIANG UNIV

P-type ZnRhMo amorphous oxide semiconductor film and preparation method thereof

ActiveCN106711200AImprove material propertiesControl of p-type conductivityTransistorSemiconductor/solid-state device manufacturingTransmission channelTransmittance

The invention discloses a p-type ZnRhMo amorphous oxide semiconductor film. In ZnRhMo, Zn is Zn(+2), Rh is Rh(+3), and the two are combined with O to form a p-type conductive basal body of a material, wherein M is one from Cu, Ni and Sn and is at a suboxidation chemical state, i.e., when M is Cu, the M is Cu(+1), when M is Ni, the M is Ni(+2), and when M is Sn, the M is Sn(+2); and M is doped in the basal body to form p-type conduction, M acts with Zn and Rh to form a space network structure, and the three communicate with one another at an amorphous state to function as a cavity transmission channel. The invention further discloses a method for preparing the p-type ZnRhMo amorphous oxide semiconductor film. By taking a sintered ZnRhCuO ceramic chip as a target material, a p-type ZnRhCuO amorphous film is prepared by use of a pulse laser depositing method, the cavity concentration is 10<13> to 10<15>cm<-3>, and the visible light transmittance is greater than or equal to 87%. The p-type ZnRhMo amorphous oxide semiconductor film disclosed by the invention can be applied to a p-type amorphous film transistor.

Owner:ZHEJIANG UNIV

Nitrogenous magnesium silicate film, and preparation method and application thereof

ActiveCN102796517BImprove stabilitySolution to short lifeLuminescent compositionsSemiconductor materialsMetallurgy

The invention relates to the field of preparation of semiconductor materials, and provides a nitrogenous magnesium silicate film which is a titanium-doped nitrogenous magnesium silicate film of which the general formula is Mg1-XSi2O2N2:XTi4+, wherein X-0.01-0.15. The invention also provides a preparation method of the nitrogenous magnesium silicate film, which comprises the following steps: mixing MgO powder, SiO2 powder, Si3N4 powder and TiO2 powder, and sintering to obtain a target; and filling the target into a magnetron sputtering chamber, vacuumizing, setting working parameters, and sputtering to obtain the nitrogenous magnesium silicate film. The invention also provides application of the nitrogenous magnesium silicate film in electroluminescent devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

A kind of p-type crmcuo amorphous oxide semiconductor thin film and preparation method thereof

ActiveCN106711201BImprove material propertiesAchieve large area depositionTransistorSemiconductor/solid-state device manufacturingRadio frequency magnetron sputteringPhysical chemistry

The invention discloses a p-type amorphous oxide semiconductor thin film. The p-type amorphous oxide semiconductor thin film is CrMCuO, and the thin film is amorphous and has p-type conductivity, wherein Cr is of +3 valence; M is one of Zn, Mg and Mn elements and is of +2 valence, and Cr and M are jointly combined with O to form a p-type conductive matrix of the CrMcuO thin film; Cu is of +1 valence, Cu, Cr and M co-act to form spatial network structures, and the spatial network structures are connected with each other in an amorphous state to achieve the effect of a hole transport channel. The invention further provides a preparation method of the p-type CrMgCuO amorphous oxide semiconductor thin film. The p-type CrMgCuO amorphous thin film is prepared by using a CrMgCuO ceramic chip as the target, adopting a radio-frequency magnetron sputtering method and using Ar-O2 as a working gas. The prepared thin film can be used for p-type amorphous thin film transistor.

Owner:ZHEJIANG UNIV

A kind of p-type lamsno amorphous oxide semiconductor film and preparation method thereof

ActiveCN106711228BImprove material propertiesAchieve large area depositionTransistorSemiconductor/solid-state device manufacturingElectron holeChemical physics

Owner:ZHEJIANG UNIV

Chemical preparation technology of Cu(InAl)Se2 film

InactiveCN102723399BReduce consumptionEasy to operateFinal product manufactureSemiconductor devicesWater bathsSolar cell

The invention relates to a chemical preparation technology of a Cu(InAl)Se2 film. The technology is a preparation method of chemical deposition. The method is characterized by: taking soda-lime glass as a substrate; firstly, using a radio frequency (RF) magnetron sputtering method to sputter molybdenum (Mo) metal so as to make a back electrode on the substrate; then, using a chemical bath deposition (CBD) method to deposit a CIAS film on the Mo back electrode. Through using the CBD method to prepare the CIAS film, material consumption is small; expensive vacuum equipment is not needed; a toxic gas does not need to be processed and the large area deposition can be realized. A forbidden band width of the prepared CIAS film is 1.44eV, which is an optimal band gap of a single-junction solar cell. And a luminous absorption coefficient is greater than 10<6>cm<-1>.

Owner:YUNNAN NORMAL UNIV

A kind of p-type nimsno amorphous oxide semiconductor thin film and preparation method thereof

InactiveCN106702326BImprove material propertiesControl of p-type conductivityVacuum evaporation coatingSputtering coatingHigh resistanceStandard electrode potential

The invention discloses a p-type NiMSnO amorphous oxide semiconductor film, the element M in the NiMSnO has low standard electrode potential and high binding energy with O, an oxide formed by the M and the O is a high-resistance oxide, the forbidden band width of the oxide is larger than 3 eV, and the M is any one of Be, Mg, Ca, Sr, Ba, B, Al, Ga, In, Sc, Y, Si, Ge, Hf, Zr, Mn, Fe, Nb, V, Sc, Rh or Co; in addition, Ni is +2 valence and is a matrix element in the p-type NiMSnO amorphous oxide, and the Ni is combined with the O to form the p-type conduction characteristic of the NiMSnO; the M is combined with the O in a matrix and is served as a control element of hole concentration; and Sn is +2 valence and combined with the O to play a role of a hole transmission channel. The invention furthermore discloses a preparation method of the p-type NiMSnO amorphous oxide semiconductor film. A NiGaSnO ceramic wafer is served as a target material, a pulse laser deposition method is adopted, the hole concentration of the prepared p-type NiMSnO amorphous oxide semiconductor film is 10<12>-10<14>m<3>, and visible light transmittance is larger than or equal to 80%. The film material provided by the invention can be used for a p-type amorphous film transistor.

Owner:ZHEJIANG UNIV

Piston with (ti,al)n multi-layer heat-insulating and wear-resistant ultra-thick coating on the surface, its preparation method and application

ActiveCN107604312BImprove wear resistanceImprove antioxidant capacityVacuum evaporation coatingSputtering coatingInternal combustion engineMaterials science

The invention relates to a piston with a (Ti, Al)N multilayer heat insulating and wear resisting super-thick coating on the surface and a preparation technology and application of the piston. The structure of the piston comprises two schemes. According to the first scheme, the piston comprises a base, a TiAl transition layer and a TiAlN clad layer, and the TiAl transition layer evenly wraps the base; and the TiAlN clad layer evenly wraps the TiAl transition layer. According to the second scheme, the piston comprises a base, a first TiAl transition layer, a first TiAlN clad layer, a second TiAltransition layer and a second TiAlN clad layer, and the piston structurally comprises the base, the first TiAl transition layer, the first TiAlN clad layer, the second TiAl transition layer and the second TiAlN clad layer in sequence. According to application of the piston, the piston is used for an internal combustion engine. The designed piston surface has heat insulation performance, wear resistance, oxidation resistance and heat shock resistance, and the service life of the piston is effectively prolonged.

Owner:XIANGTAN UNIV

Gallium-doped zinc oxide film, and preparation method and application thereof

InactiveCN102691037BIncrease deposition rateGood adhesionVacuum evaporation coatingSputtering coatingSemiconductor materialsPhysical chemistry

The invention relates to the field of semiconducting material preparation, and provides a preparation method of a gallium-doped zinc oxide film. The method comprises the following steps: mixing Ga2O3 powder and ZnO powder with the mass ratio of Ga2O3 powder to ZnO powder being 1 / 1999 to 1 / 99, and sintering the mixture as a GZO target material; filling the GZO target material into a magnetron sputtering cavity, carrying out vacuumizing, with the working pressure set as 0.2 Pa to 1.5 Pa, the inert gas flow as 15sccm to 35sccm, and sputtering power of the GZO layer as 60 to 160 W, and sputtering to obtain the gallium-doped zinc oxide film; and annealing the above prepared gallium-doped zinc oxide film, with the annealing atmosphere being a mixed gas of an inert gas and hydrogen gas, wherein the molar volume percentage content of the hydrogen gas in the mixed gas is 5% to 30% and the annealing temperature is 200 DEG C to 600 DEG C. The invention further provides the gallium-doped zinc oxide film prepared by the method and an application of the gallium-doped zinc oxide film in semiconductor photoelectric devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

A kind of p-type cunsno amorphous oxide semiconductor thin film and preparation method thereof

ActiveCN106711199BImprove material propertiesControl of p-type conductivityTransistorVacuum evaporation coatingCrystallographyRadio frequency magnetron sputtering

The invention discloses a p-type CuNSnO amorphous oxide semiconductor thin film, wherein N element is not a group III element, has low standard potential and has high binding energy with O, the formed oxide is a high-resistance oxide, the band gap of the oxide is greater than 3 eV, and the N is any one of Si, Ge, Hf, Zr, Mg, Mn, Fe, Nb, V, Sr, Ba, Rh, Co, and Ca; the Cu is +1 valence copper, is the matrix element of a material, and combines with O to form p-type conductive property of the material; the N combines with O and serves as a control element of hole concentration in a matrix; and the Sn is +2 valence stannum, combines with O to form p-type conductive property, has a spherical electron orbit, has highly-coincided electron cloud in an amorphous state, and serves as a hole transmission channel. The invention further discloses a method for preparing the p-type CuNSnO amorphous oxide semiconductor thin film, which adopts a CuSrSnO ceramic chip as a target, and adopts an RF magnetron sputtering method. The hole concentration of the prepared p-type CuNSnO amorphous oxide semiconductor thin film reaches a range from 10<13> to 10<15> cm<-3>. The p-type CuNSnO amorphous oxide semiconductor thin film disclosed in the invention can be applied to a p-type amorphous thin film transistor.

Owner:ZHEJIANG UNIV

Multielement composite transparent conductive film and preparation method and application thereof

ActiveCN102465273BGood adhesionReduce the temperatureVacuum evaporation coatingSputtering coatingSemiconductor materialsMetallurgy

The invention provides a multielement composite transparent conductive film and a preparation and application thereof, relating to the field of preparation of semiconductor materials. The preparation method comprises the following steps of: preparing an AZO target: mixing Al2O3 powder with ZnO powder to obtain a mixture and sintering the mixture to be used as the target, wherein the molar weight ratio of Al2O3 to ZnO is 1 / 90-1 / 50; preparing an ATO target: mixing Sb2O3 powder with SnO2 powder to obtain a mixture and sintering the mixture to be used as the target, wherein the molar weight ratioof Sb2O3 to SnO2 is 1 / 7-1 / 5; and depositing a film: feeding the AZO target and the ATO target into a magneto-controlled sputtering chamber, vacuumizing and setting the substrate temperature to be 500-800 DEG C, and loading a negative bias on the substrate, wherein the inert gas flow is 15sccm-25sccm, the pressure intensity is 0.2-1.6Pa, the sputtering powers of the AZO target and the ATO target are respectively 60-160W, and the deposition time is 40-240min.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Multielement-doped strontium phosphate luminescent film, and preparation method and applications thereof

InactiveCN102796984BWide luminous rangeImprove thermal stabilityVacuum evaporation coatingSputtering coatingField emission deviceCathode ray

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Multielement composite transparent conductive film and preparation method and application thereof

InactiveCN102465271AIncrease deposition rateGood adhesionVacuum evaporation coatingSputtering coatingSemiconductor materialsMetallurgy

The invention provides a multielement composite transparent conductive film and a preparation and application thereof, relating to the field of preparation of semiconductor materials. The preparation method comprises the following steps of: preparing an AZO target: mixing Al2O3 powder with ZnO powder to obtain a mixture and sintering the mixture to be used as the target, wherein the molar weight ratio of Al2O3 to ZnO is 1 / 120-1 / 35; preparing an ATO target: mixing Sb2O3 powder with SnO2 powder to obtain a mixture and sintering the mixture to be used as the target, wherein the molar weight ratio of Sb2O3 to SnO2 is 1 / 9-1 / 4; and depositing a film: feeding the AZO target and the ATO target into a magneto-controlled sputtering chamber, vacuumizing and setting the following parameters, namely, the substrate temperature is 500-800 DEG C, the inert gas flow is 15sccm-25sccm, the pressure intensity is 0.2-1.6Pa, the sputtering powers of the AZO target and the ATO target are respectively 60-160W, and the deposition time is 40-240min.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

A kind of p-type znrhmo amorphous oxide semiconductor thin film and preparation method thereof

ActiveCN106711200BImprove material propertiesControl of p-type conductivityTransistorSemiconductor/solid-state device manufacturingPhysical chemistryTransmittance

The invention discloses a p-type ZnRhMo amorphous oxide semiconductor film. In ZnRhMo, Zn is Zn(+2), Rh is Rh(+3), and the two are combined with O to form a p-type conductive basal body of a material, wherein M is one from Cu, Ni and Sn and is at a suboxidation chemical state, i.e., when M is Cu, the M is Cu(+1), when M is Ni, the M is Ni(+2), and when M is Sn, the M is Sn(+2); and M is doped in the basal body to form p-type conduction, M acts with Zn and Rh to form a space network structure, and the three communicate with one another at an amorphous state to function as a cavity transmission channel. The invention further discloses a method for preparing the p-type ZnRhMo amorphous oxide semiconductor film. By taking a sintered ZnRhCuO ceramic chip as a target material, a p-type ZnRhCuO amorphous film is prepared by use of a pulse laser depositing method, the cavity concentration is 10<13> to 10<15>cm<-3>, and the visible light transmittance is greater than or equal to 87%. The p-type ZnRhMo amorphous oxide semiconductor film disclosed by the invention can be applied to a p-type amorphous film transistor.

Owner:ZHEJIANG UNIV

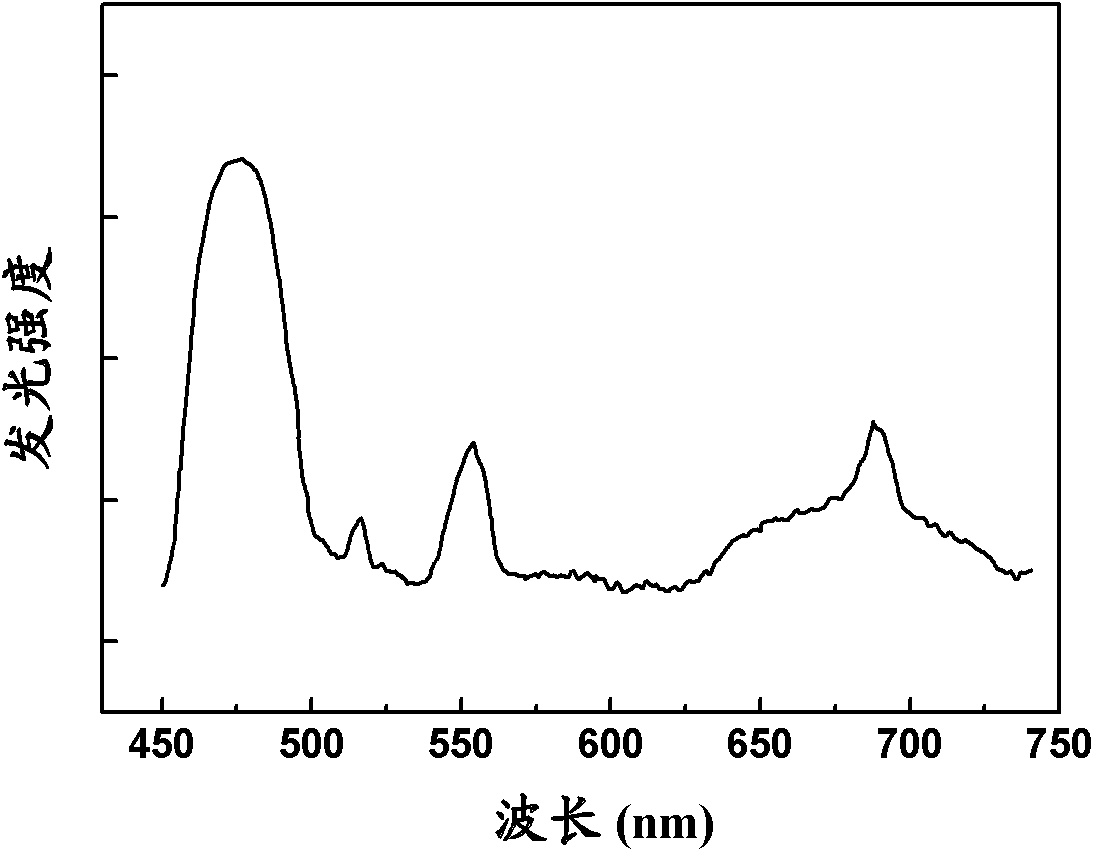

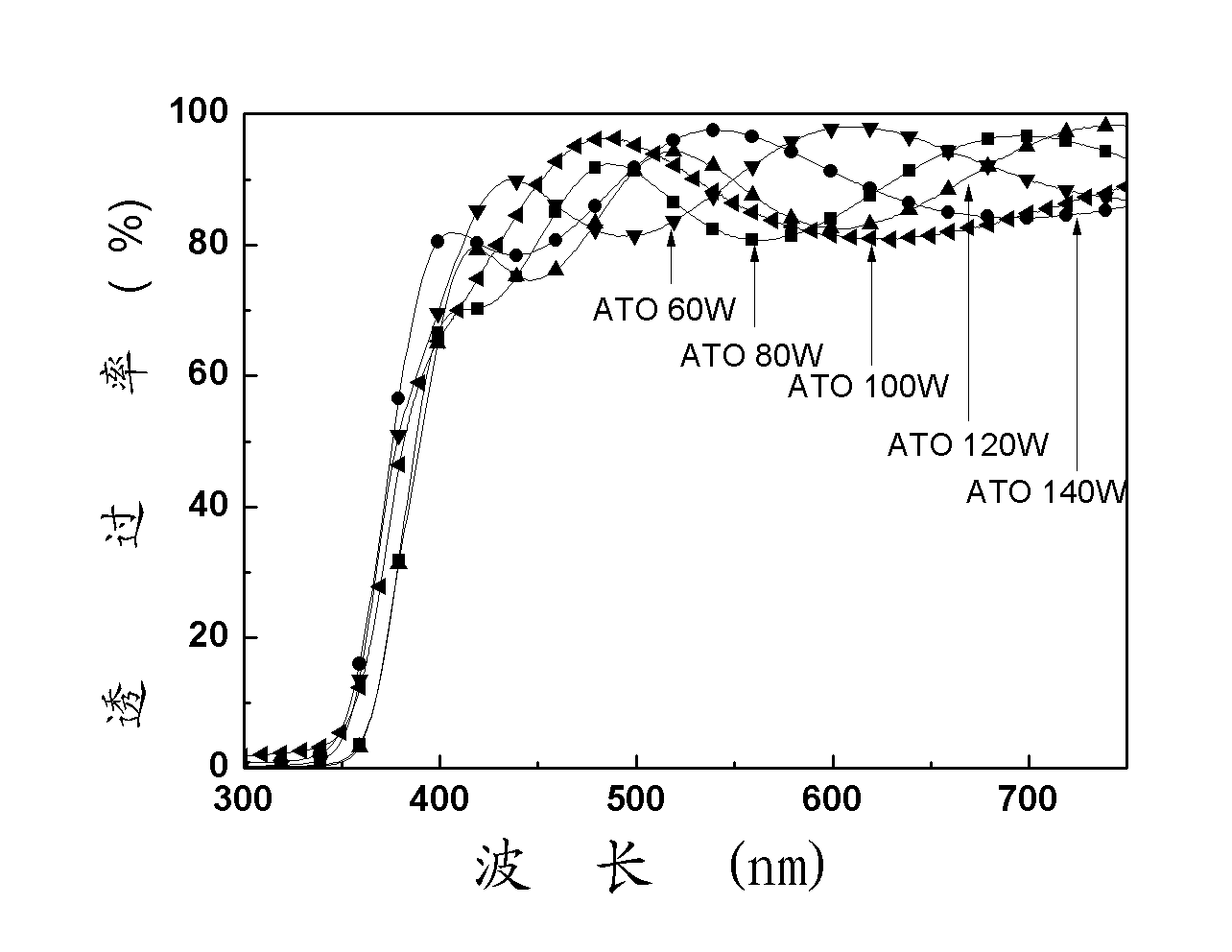

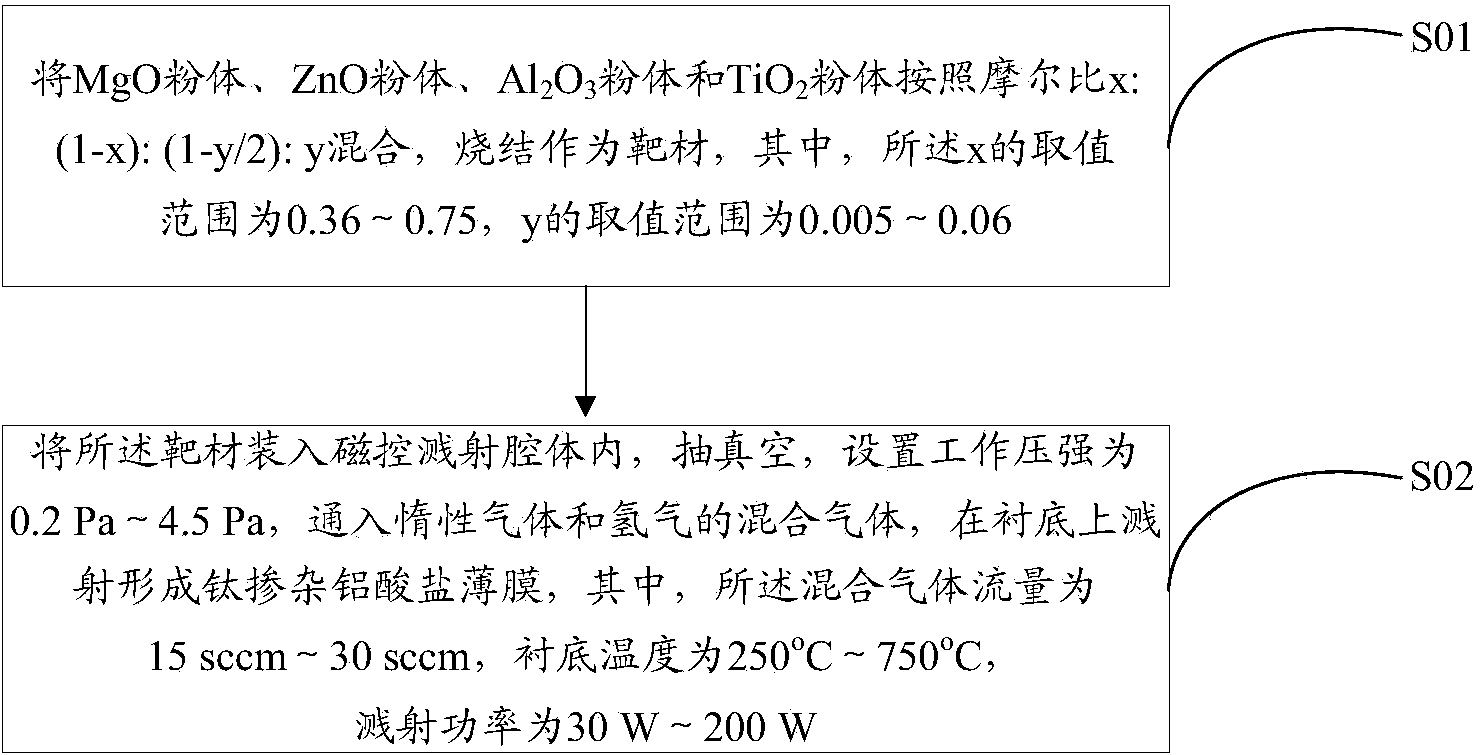

Preparation method and use of titanium-doped zinc-magnesium aluminate film

InactiveCN102787294BImprove stabilityGood chemical stabilityVacuum evaporation coatingSputtering coatingSemiconductor materialsTitanium

The invention relates to the field of semiconductor materials and discloses a titanium-doped zinc-magnesium aluminate film. The titanium-doped zinc-magnesium aluminate film has a general chemical formula of MgxZn1-xAl2-yO4: yTi, wherein x is in a range of 0.36 to 0.75 and y is in a range of 0.005 to 0.06. The invention also provides a preparation method of the titanium-doped zinc-magnesium aluminate film and a use of the titanium-doped zinc-magnesium aluminate film in a semiconductor photoelectric device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Method for producing silicon doping zinc oxide film, produced film and application thereof

InactiveCN102650035BIncrease deposition rateImprove crystal qualityFinal product manufactureVacuum evaporation coatingSemiconductor materialsPhysical chemistry

The invention relates to the field of semiconductor material production, and provides a method for producing a silicon doping zinc oxide film, a produced film and an application thereof, wherein the method comprises the following steps that: SiO2 powder and ZnO powder are mixed and sintered to be used as an SZO target, and the mass ratio of SiO2 to ZnO is 1:199-1:66; and the SZO target is contained in a magnetron sputtering cavity, the cavity is vacuumized, sputtering parameters are set, and a silicon doping zinc oxide film is sputtered onto a substrate. The invention further provides the silicon doping zinc oxide film which is produced by the method and the application of the silicon doping zinc oxide film on semiconductor photoelectric devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

A Novel Twin External Rotating Cathode

ActiveCN105506568BGood process repeatabilityStable jobVacuum evaporation coatingSputtering coatingEngineeringHigh pressure

Owner:WUHAN KERUIDA VACUUM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com