Nitrogenous magnesium silicate film, and preparation method and application thereof

A magnesium silicate and thin film technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of expensive rare earth, high cost, scarcity of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

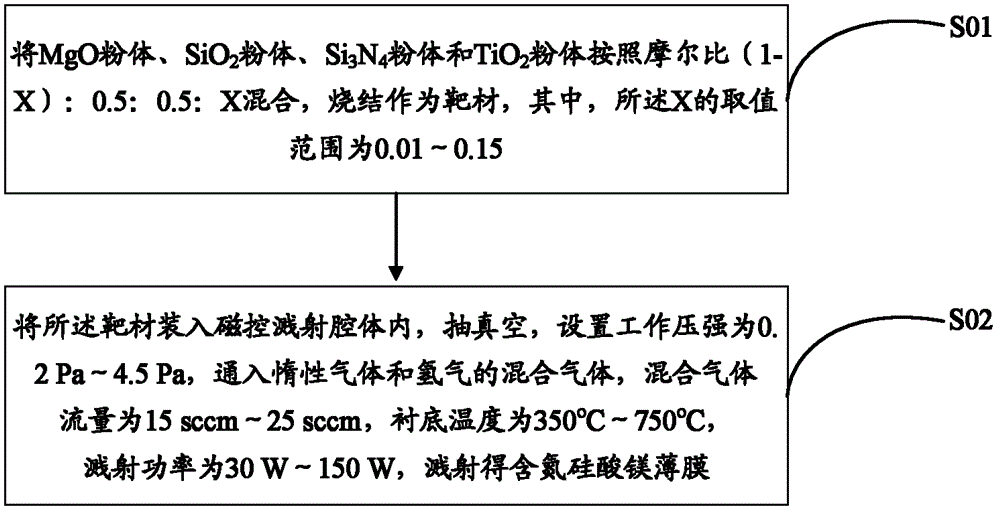

[0019] Another purpose of the embodiment of the present invention is to provide the preparation method of the nitrogen-containing magnesium silicate film of the embodiment of the present invention, please refer to figure 1 , which includes the following steps:

[0020] S01: MgO powder, SiO 2 Powder, Si 3 N 4 Powder and TiO 2 The powder is mixed according to the molar ratio (1-X): 0.5:0.5:X, and sintered as the target material, wherein the value range of X is 0.01-0.15;

[0021] S02: Put the target material into the magnetron sputtering chamber, vacuumize, set the working pressure to 0.2Pa-4.5Pa, feed the mixed gas of inert gas and hydrogen, the flow rate of the mixed gas is 15sccm-30sccm, the substrate temperature The temperature is 350°C-750°C, the sputtering power is 30W-150W, and the nitrogen-containing magnesium silicate film is obtained by sputtering.

[0022] In step S01, MgO powder, SiO 2 Powder, Si 3 N 4 Powder and TiO 2 The powder is mixed evenly according to...

Embodiment 1

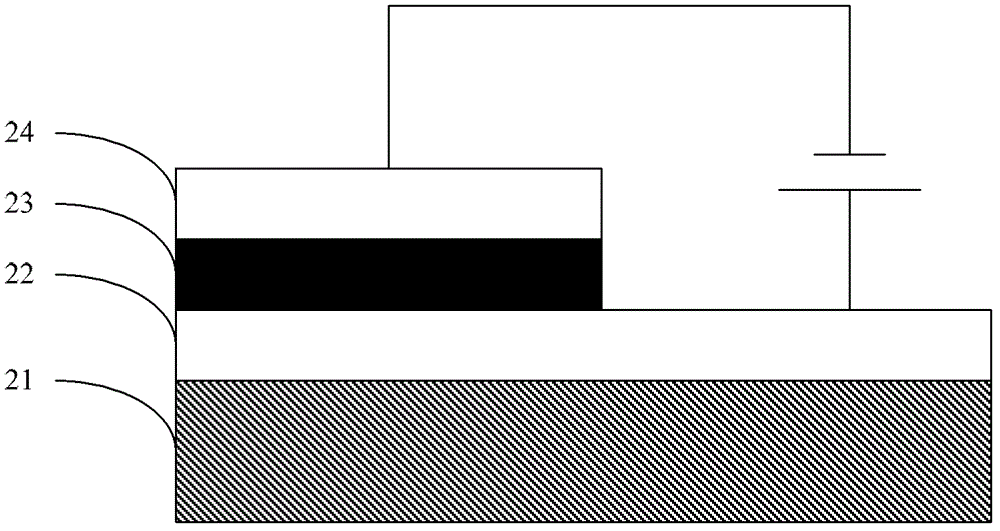

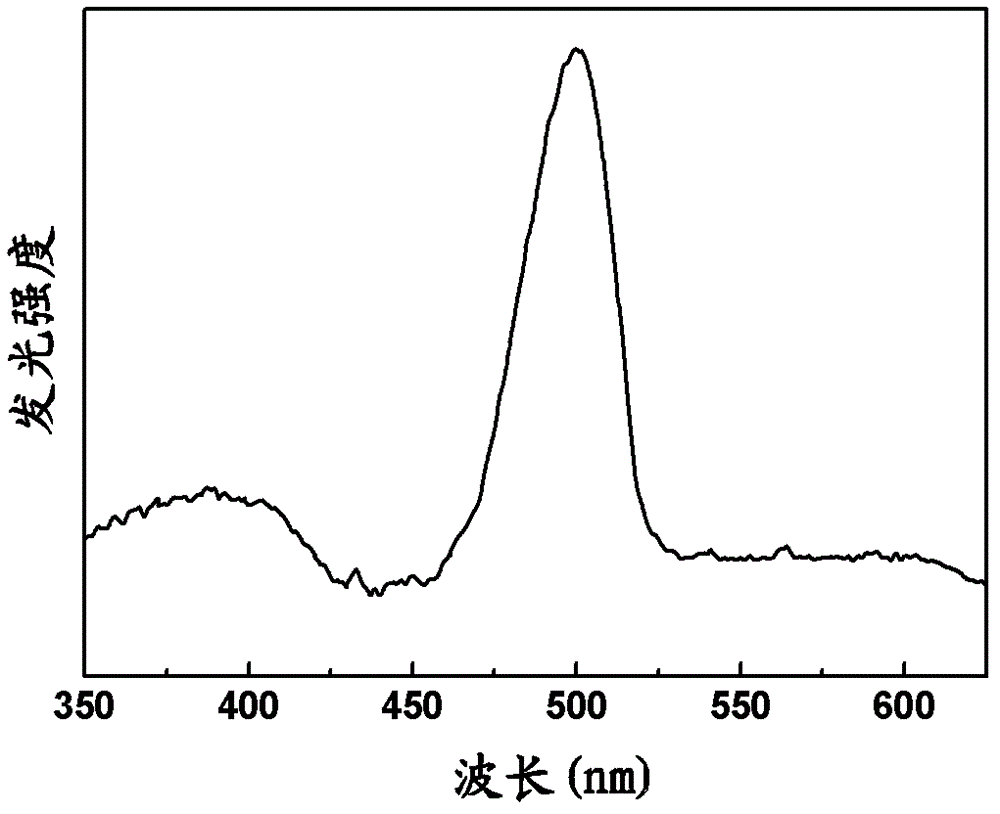

[0028] 7.36g MgO powder with a purity of 99.99%, 6g SiO 2 Powder, 14g Si 3 N 4 Powder and 1.28g TiO 2 After mixing the powder evenly, it is sintered at a high temperature of 1200°C to form a Φ50×2mm ceramic target, and the target is loaded into a vacuum chamber. Then, the glass substrate with ITO was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, and treated with oxygen plasma, and placed in a vacuum chamber. The distance between the target and the substrate was set to 70mm. Use a mechanical pump and a molecular pump to pump the vacuum of the cavity to 7.0×10 -4 Pa, the mixed gas of argon and hydrogen fed into the vacuum chamber, wherein the hydrogen content is 5% (volume ratio), the gas flow rate is 20 sccm, the pressure is adjusted to 1.0 Pa, the substrate temperature is set to 500 ° C, and the sputtering The radiation power was adjusted to 100W, and a nitrogen-containing magnesium silicate film was obtained by sputtering. The o...

Embodiment 2

[0030] 6.8g MgO powder with a purity of 99.99%, 6g SiO 2 Powder, 14g Si 3 N 4 Powder and 2.4g TiO 2 After mixing the powder evenly, it is sintered at a high temperature of 900°C to form a Φ50×2mm ceramic target, and the target is placed in a vacuum chamber. Then, the quartz substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water, dried with high-purity nitrogen, and placed in a vacuum chamber. The distance between the target and the substrate was set to 50mm. Use a mechanical pump and a molecular pump to evacuate the vacuum of the chamber to 1.0×10 -3 Pa, the mixed gas of argon and hydrogen fed into the vacuum chamber, wherein the hydrogen content is 1% (volume ratio), the gas flow rate is 20 sccm, the pressure is adjusted to 0.2 Pa, the substrate temperature is set to 350 ° C, and the sputtering The radiation power was adjusted to 100W, and a nitrogen-containing magnesium silicate film was obtained by sputtering. The obtained nitrogen-con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com