Preparation method of multilayer transparent conductive film, film prepared thereby, and application thereof

A transparent conductive film and powder technology, which is applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of difficult to obtain low resistivity GZO film and high cost, and achieve good film adhesion, Ease of control and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] see figure 1 , showing a method for preparing a multilayer transparent conductive film according to an embodiment of the present invention, which includes the following steps:

[0018] S01: Ga 2 o 3 Powder and ZnO powder are mixed and sintered as GZO target material, the Ga 2 o 3 The mass ratio of the powder to the ZnO powder is 1 / 99 to 1 / 19;

[0019] S02: Provide Cu target material;

[0020] S03: Put the GZO target material and the Cu target material into the magnetron sputtering chamber, vacuumize, and alternately sputter the GZO layer and the Cu layer on the substrate to obtain a sandwich-structured GZO-Cu-GZO transparent conductive film.

[0021] In step S01, the Ga 2 o 3 The powder and the ZnO powder are uniformly mixed, for example, sintered at a temperature of 900° C. to 1350° C. to obtain a GZO ceramic target. Preferably, Ga 2 o 3 The mass ratio of the powder to the ZnO powder is 1 / 80 to 1 / 40, more preferably Ga 2 o 3 The mass ratio of the powder to...

Embodiment 1

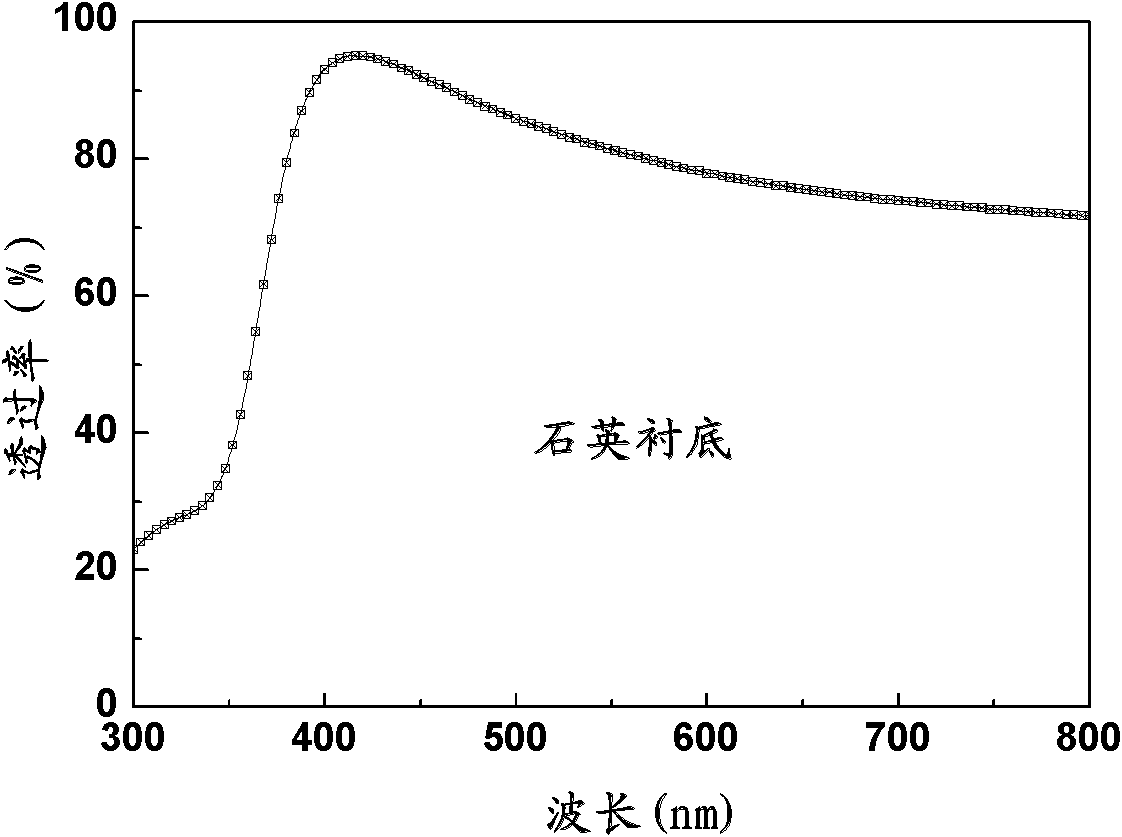

[0029] Use Ga 2 o 3 :ZnO=1:66 (mass ratio) powder, after uniform mixing, sintered at 1250°C at high temperature to form a Φ60×2mm ceramic target, and put it into a vacuum chamber together with a custom-made Cu target (Φ50×3mm). Then, the quartz substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water, dried with high-purity nitrogen, and placed in a vacuum chamber. The distance between the target and the substrate was set to 50 mm. Use a mechanical pump and a molecular pump to evacuate the cavity to 6.0×10 -4 Pa, the argon gas of 20 sccm is introduced, and the pressure is adjusted to 1.0 Pa. The sputtering power of the GZO target was 100W, and the sputtering power of the Cu target was 60W. The thickness of the three layers of the obtained GZO-Cu-GZO film is 50nm, 10nm and 80nm respectively, the sheet resistance is 15Ω / □, and the average transmittance of visible light is 85%.

Embodiment 2

[0031] Use Ga 2 o 3 :ZnO=1:66 (mass ratio) powder, after uniform mixing, sintered at 1250°C at high temperature to form a Φ60×2mm ceramic target, and put it into a vacuum chamber together with a custom-made Cu target (Φ50×3mm). Then, the quartz substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water, dried with high-purity nitrogen, and placed in a vacuum chamber. The distance between the target and the substrate was set to 50 mm. Use a mechanical pump and a molecular pump to evacuate the cavity to 6.0×10 -4 Pa, the argon gas of 20 sccm is introduced, and the pressure is adjusted to 1.0 Pa. The sputtering power of the GZO target was 100W, and the sputtering power of the Cu target was 60W. The thickness of the three layers of the obtained GZO-Cu-GZO thin film is 70nm, 5nm, 80nm respectively, the sheet resistance is 300Ω / □, and the average transmittance of visible light is 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com