A Novel Twin External Rotating Cathode

A rotating cathode and twinning technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problem of slow formation rate of metal compounds, achieve high target utilization rate, improve deposition rate, and enhance plasma The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

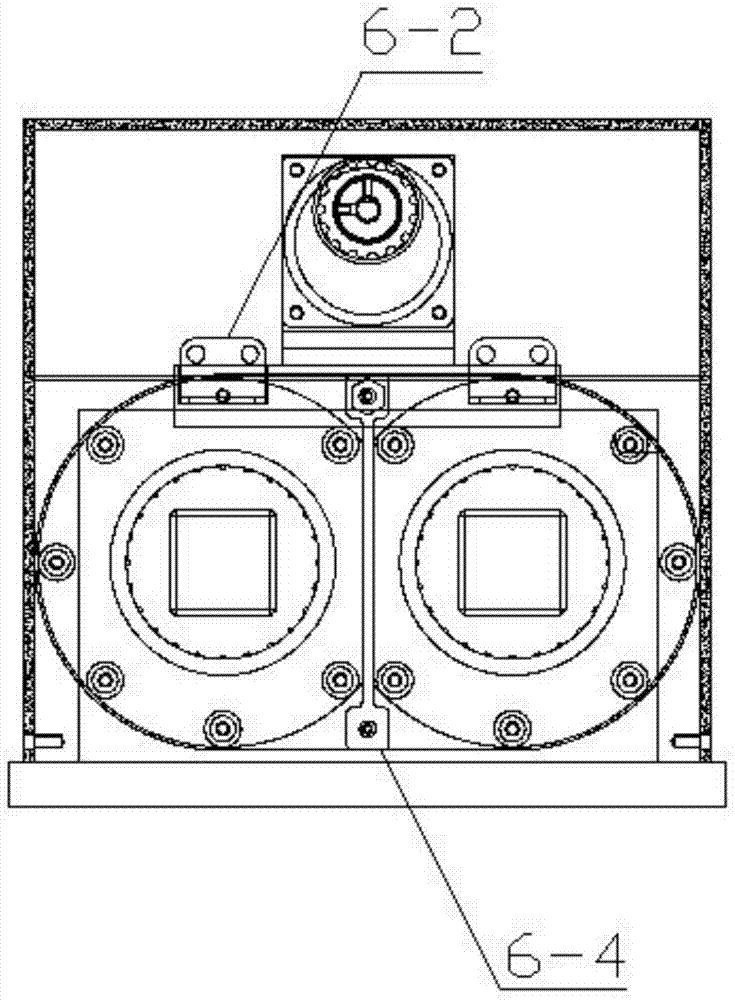

[0043] Such as Figures 1 to 3 The specific implementation of the novel twin external rotating cathodes of the present invention is shown: including a shared target housing (1), a twin cooling water system (2), a shared process air intake system (3), a twin balanced magnetic pole system (4), a shared rotating The power system (5), the twin power access system (6), the twin observation window (7) and the shared safety protection cover (8); the motor of the shared rotating power system (5) drives the shared target through the synchronous belt synchronous wheel The sleeve (1) rotates at the same speed, and the common process air intake system (3) feeds the working gas to maintain the vacuum at the working vacuum degree, and the twin power connection system (6) connects to the corresponding high-voltage power to separate the gas The formed plasma performs magnetron sputtering coating in the balanced magnetic field provided by the twin balanced magnetic pole system (4), and the spu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com