Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about "Gas condensate working-up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fast pyrolysis processor which produces low oxygen content, liquid bio-oil

InactiveUS8574404B1Reduce amountLightweight productionDirect heating destructive distillationBiofuelsOxygen contentLow oxygen

In this fast pyrolysis processor the reaction conditions are tailored to minimize the production of gas, while using calcined limestone to provide the heat for fast pyrolysis of biomass and to lower the acidity and oxygen content of the liquid bio-oil which is produced.

Owner:SINCLAIR DOUGLAS STEWART

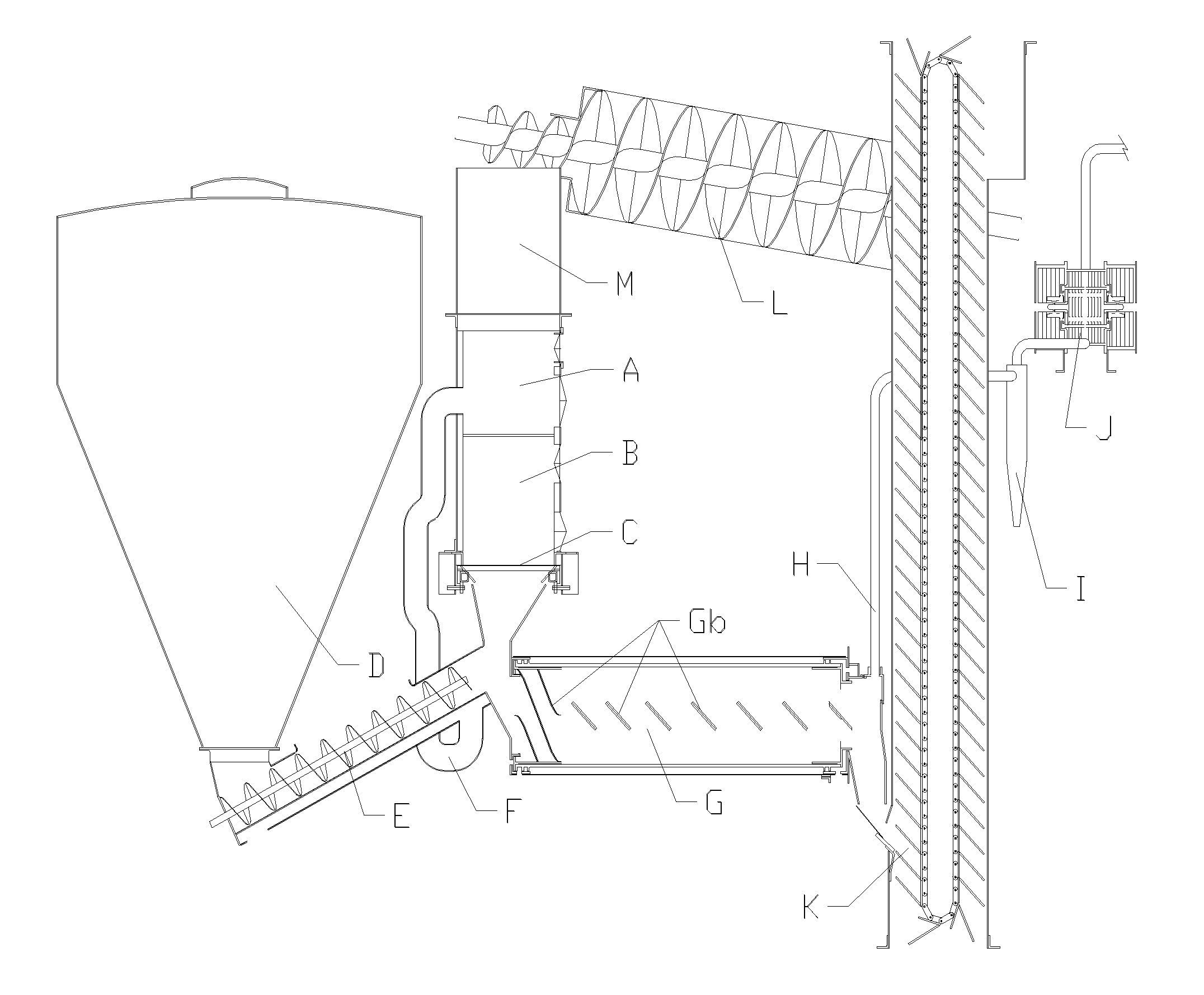

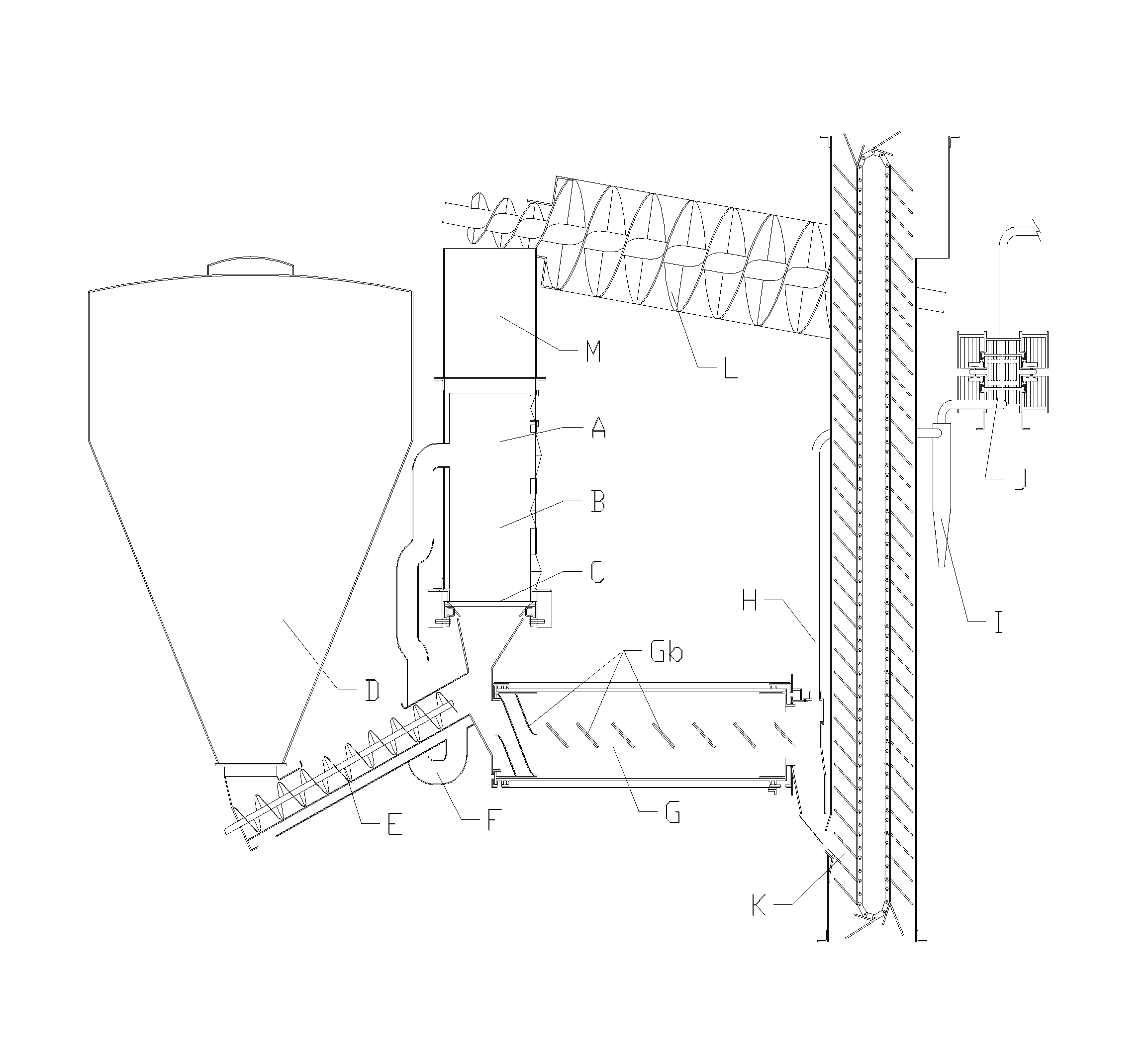

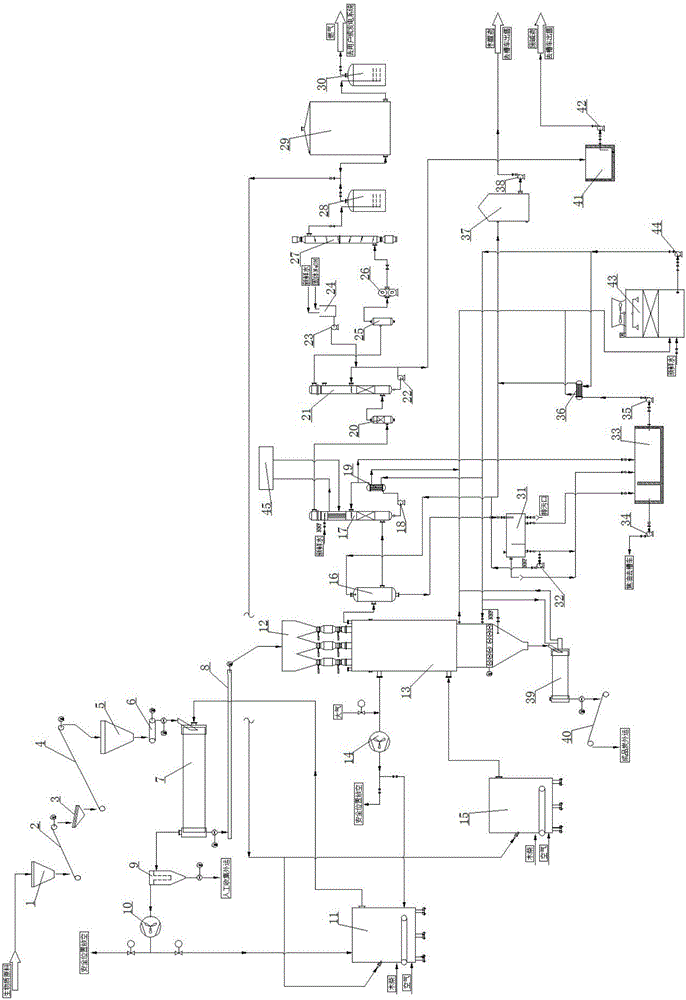

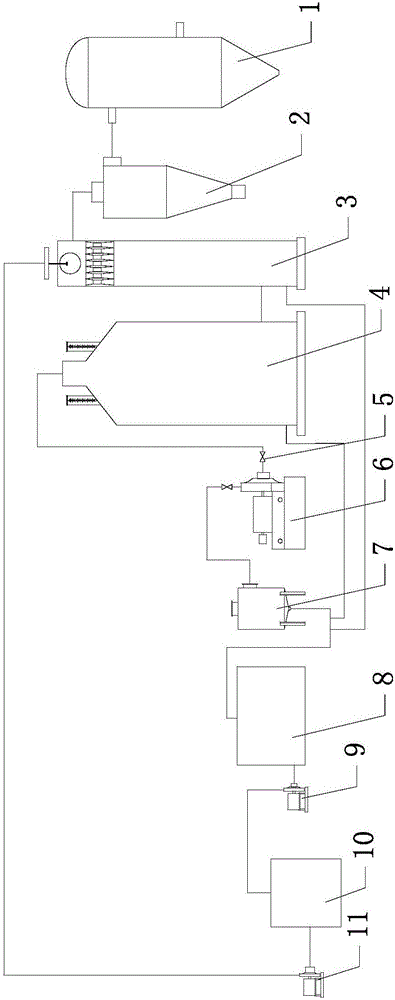

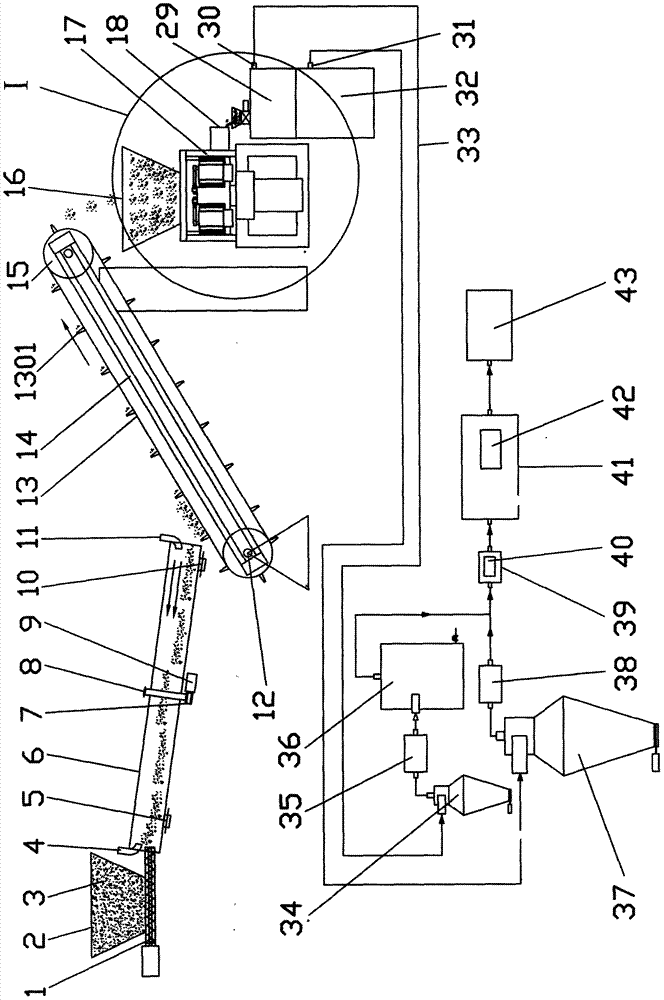

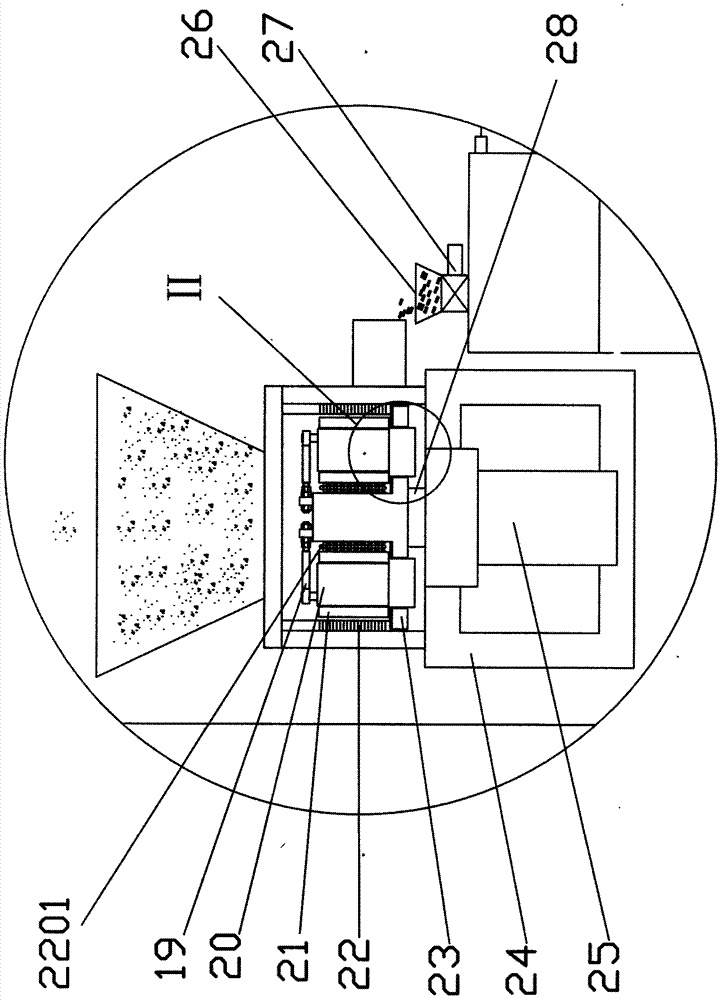

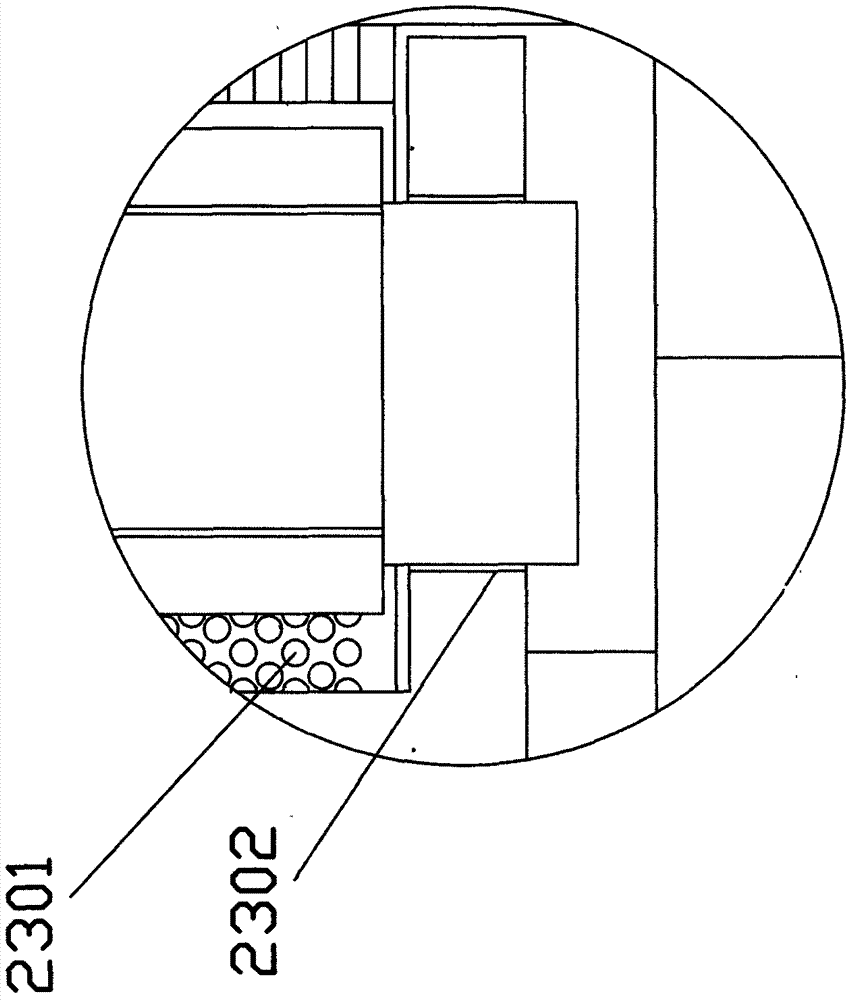

Biomass pyrolysis polygeneration system

InactiveCN106833696AAchieve effective useThe overall structure is simple and reliableBiofuelsPyroligneous acid productionTarProcess engineering

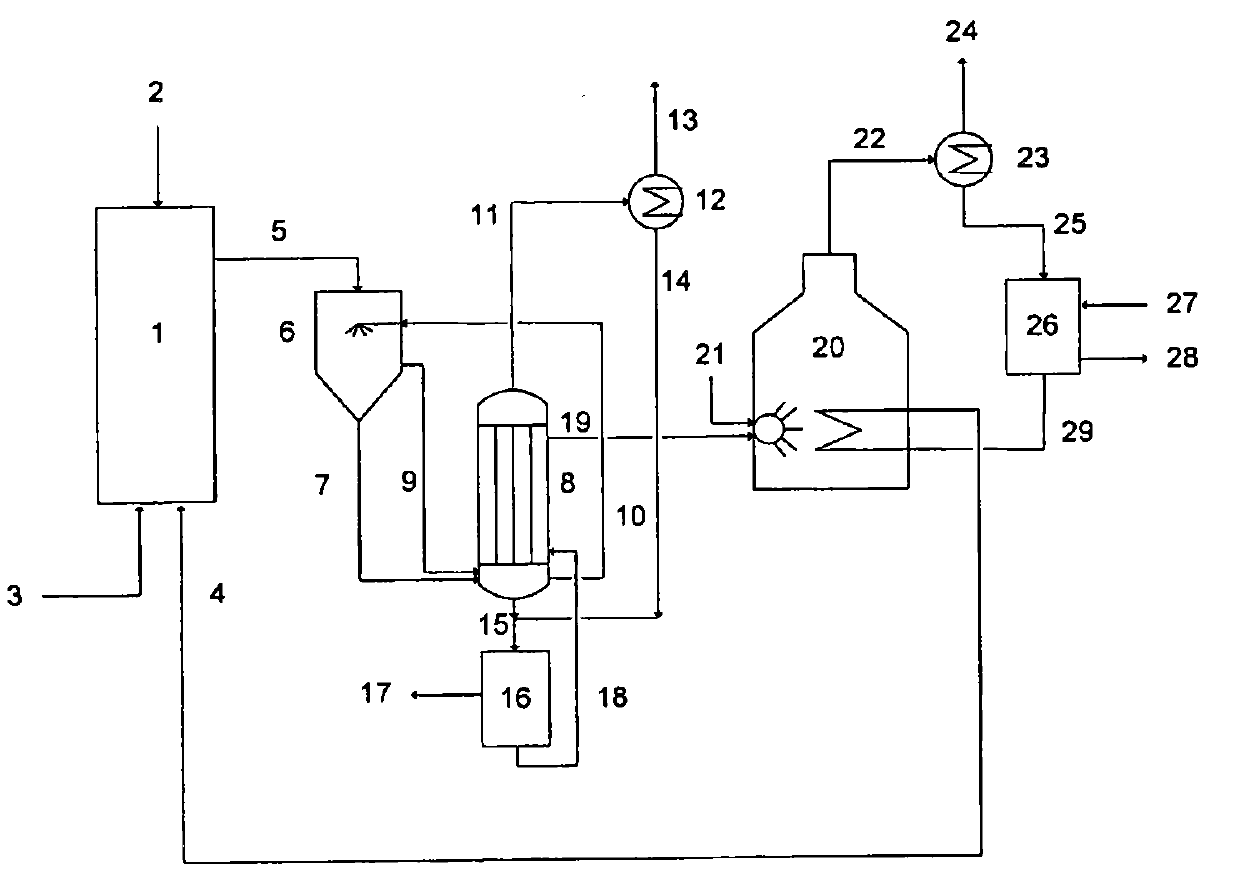

The invention discloses a biomass pyrolysis polygeneration system. A raw material feeding funnel (1), a belt conveyor I (2), a raw material sieving machine (3), a belt conveyor II (4), a drying furnace charging bin (5), a weighing feeder (6) and a drying furnace (7) in the biomass pyrolysis polygeneration system form a biomass drying system; an acid cleaning tank (16), a water cleaning tower (17), a water cleaning separation tank (20), an alkali cleaning tower (21), an alkali cleaning separation tank (25) and an adsorption tower (27) in the biomass pyrolysis polygeneration system form a pyrolysis gas purification system; after being dried, a biomass raw material is sent into a pyrolysis furnace (13); produced fuel gas, tar oil and biomass charcoal are all continuously discharged out from the pyrolysis furnace. The continuous production can be achieved; the process is simple and reliable; the labor intensity is low; the biomass pyrolysis polygeneration system is easy to popularize and apply.

Owner:武汉光谷蓝焰新能源股份有限公司 +1

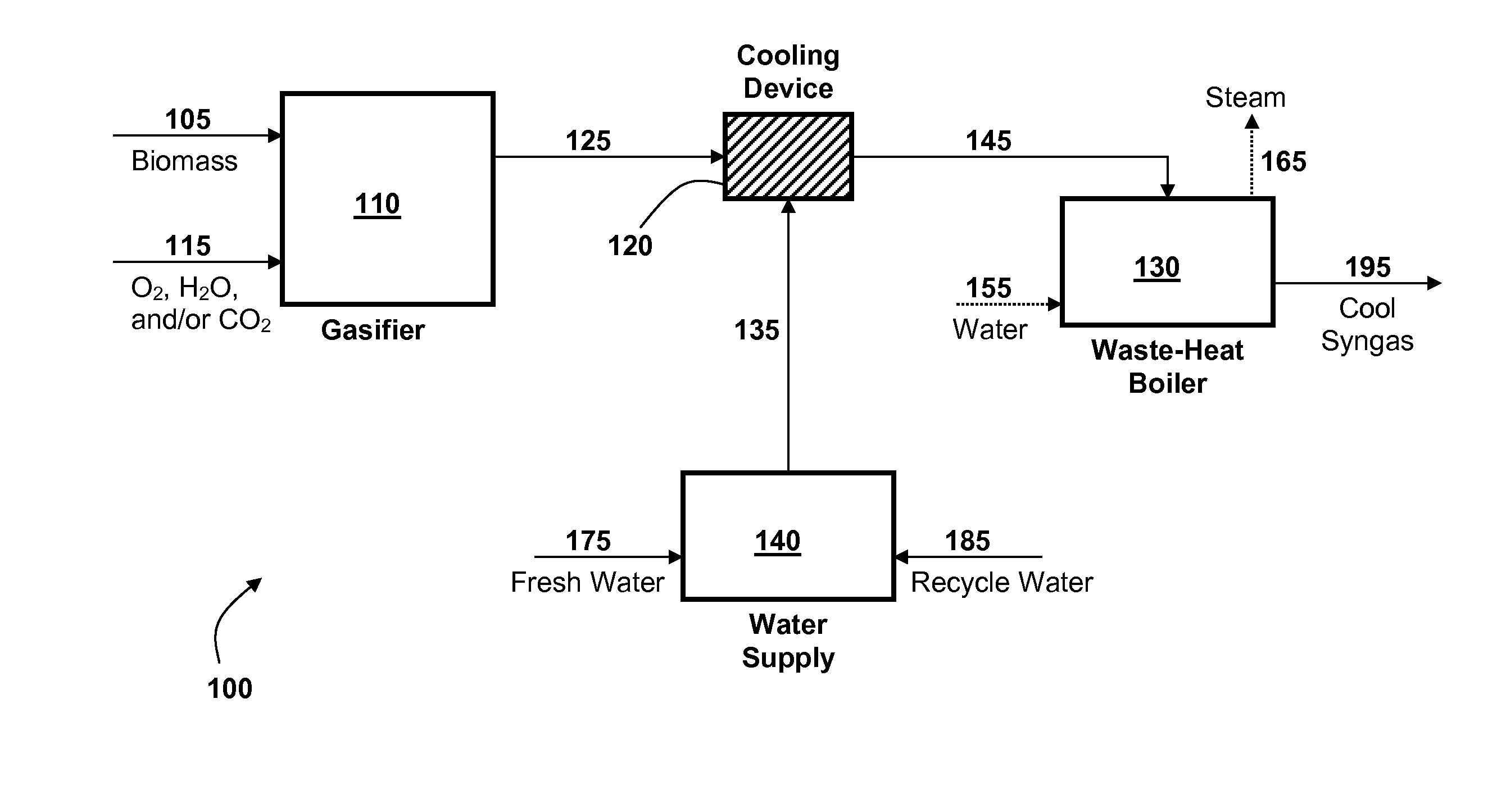

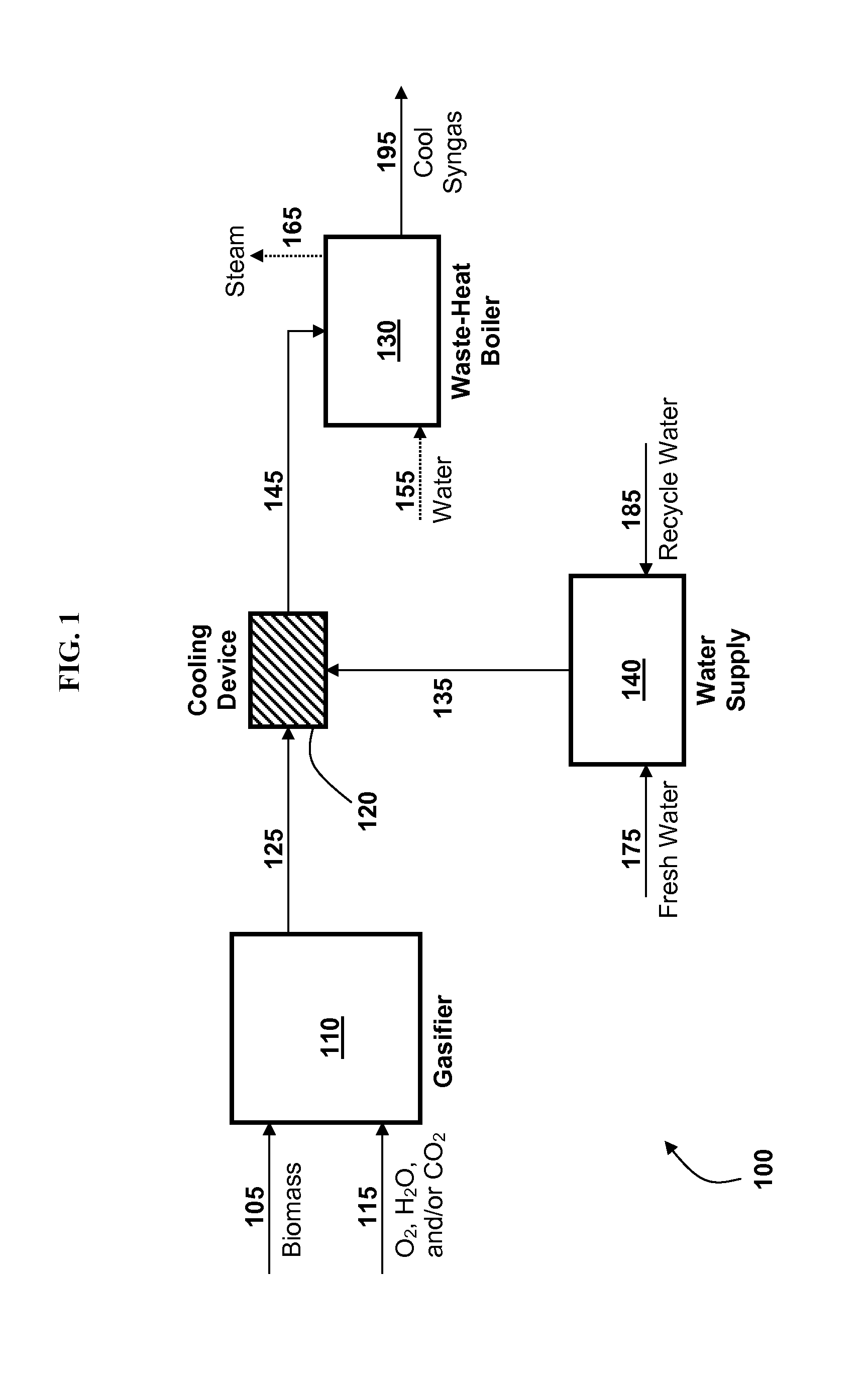

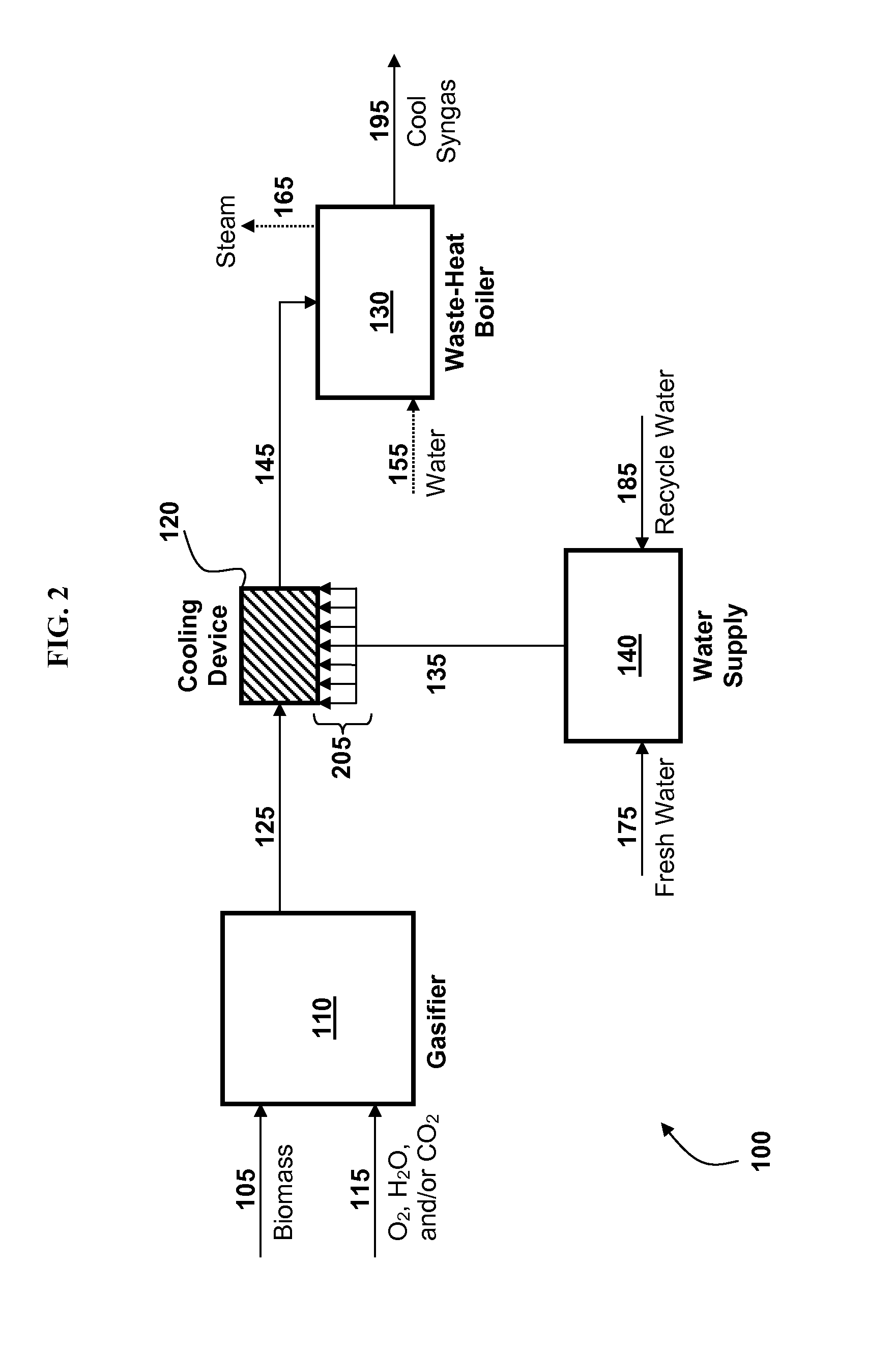

Methods and apparatus for cooling syngas from biomass gasification

InactiveUS20140131622A1Bioreactor/fermenter combinationsBiological substance pretreatmentsLiquid waterEngineering

Improved biomass-gasification methods and apparatus are described, for cooling hot syngas without relying on recycling cool syngas. In some variations, methods are provided for producing cooled syngas from a carbon-containing feedstock, comprising: gasifying the feedstock; feeding hot gas along with liquid water to a cooling device to accomplish humidification, thereby reducing the temperature (but not the enthalpy) of the hot gas; and then feeding the stream to a waste-heat recovery unit to recover energy and produce cool syngas. The invented methods and apparatus can prevent fouling of waste-heat recovery units. Additionally, these methods allow for effective management of tars produced during biomass gasification as well as improved water management.

Owner:MAVERICK SYNFUELS INC FORMERLY MAVERICK BIOFUELS

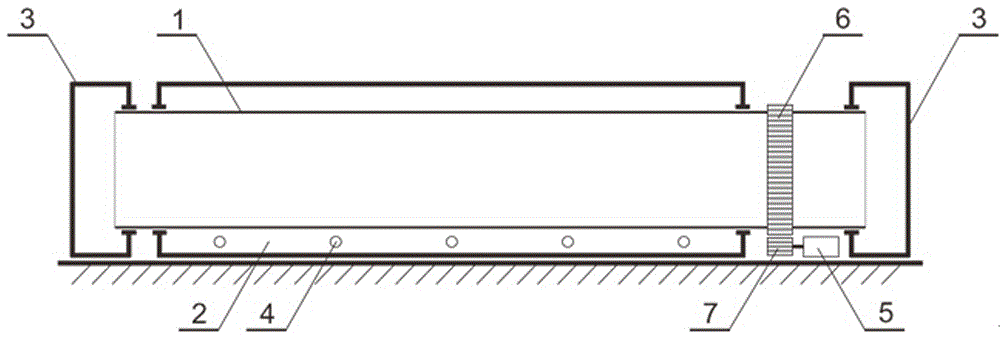

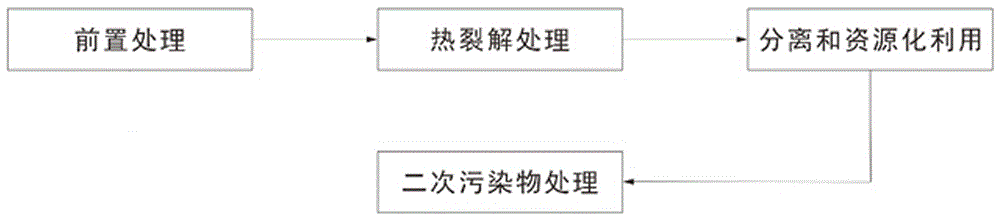

Urban household garbage thermal cracking treatment device and method for conducting urban household garbage thermal cracking with same

InactiveCN105733619AFully lysedGuaranteed uptimeSpecial form destructive distillationGas purification by non-gaseous materials condensationCombustion chamberControl engineering

The invention relates to the technical field of urban household garbage harmless treatment, in particular to an urban household garbage thermal cracking treatment device and a method for conducting urban household garbage thermal cracking with the same. The urban household garbage thermal cracking treatment device mainly comprises a thermal cracking reaction kettle and a combustion chamber, the combustion chamber is internally provided with fuel gas nozzles, kettle heads bear the thermal cracking reaction kettle, the thermal cracking reaction kettle is connected with a motor through a transmission mechanism, and the outer diameter of the thermal cracking reaction kettle is in movable fit connection with the combustion chamber. The method for conducting urban household garbage thermal cracking mainly includes the steps of pretreatment, thermal cracking treatment, separation and recycling utilization and secondary pollutant treatment. The thermal cracking reaction kettle is arranged in the combustion chamber, so that the whole thermal cracking reaction kettle is heated evenly, a high-efficiency thermal conduction state is reached, meanwhile reasonable thermal cracking parameters are selected, full cracking is conducted on urban household garbage, and generation of dioxin is effectively inhibited and completely eradicated.

Owner:YADINGWO ENVIRONMENTAL PROTECTION TECH CO LTD

Device for deep recovering light oil from dry distillation gas

InactiveCN104479725AHigh calorific valueReduce the temperatureDispersed particle filtrationChemical industryWater vaporEconomic benefits

The invention relates to a device for deep recovering light oil from dry distillation gas. According to the device, gaseous light oil and water vapor in dry distillation tail gas are condensed by cooling the dry distillation tail gas, and the light oil is covered so that a gas calorific value is improved and an enterprise can get large economic benefits. Through a high-efficiency heat exchanger and an oil-water separator used by the device, tail gas is cooled only by the one-grade heat exchanger and then is treated by an oil mist filter, the amount of oil recovered by the high-efficiency heat exchanger and the oil mist filter is basically the same as that provided by the contrast file 1, and a cost of the oil mist filter is much lower than that of the high-efficiency heat exchanger. The oil-water separator independently developed by the company has good separation effects and can acquire high-purity light oil only by one-grade oil-water separation. An intermediate oil tank used by the device guarantees maximal recovery of light oil and prevents light oil volatilization possibly appearing in the contrast file 1.

Owner:SHAANXI HANGXING ENERGY TECH

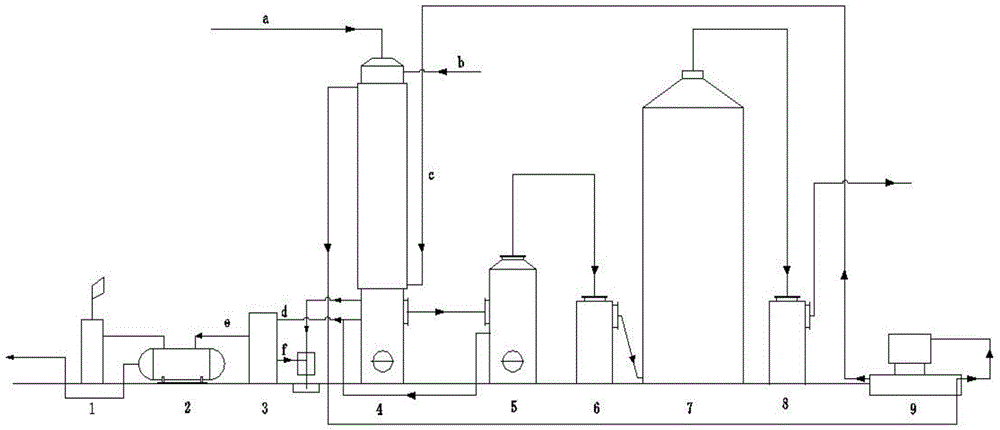

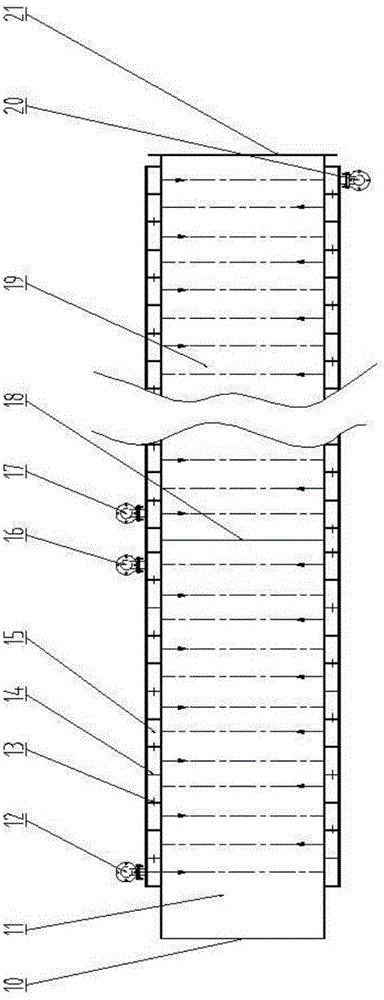

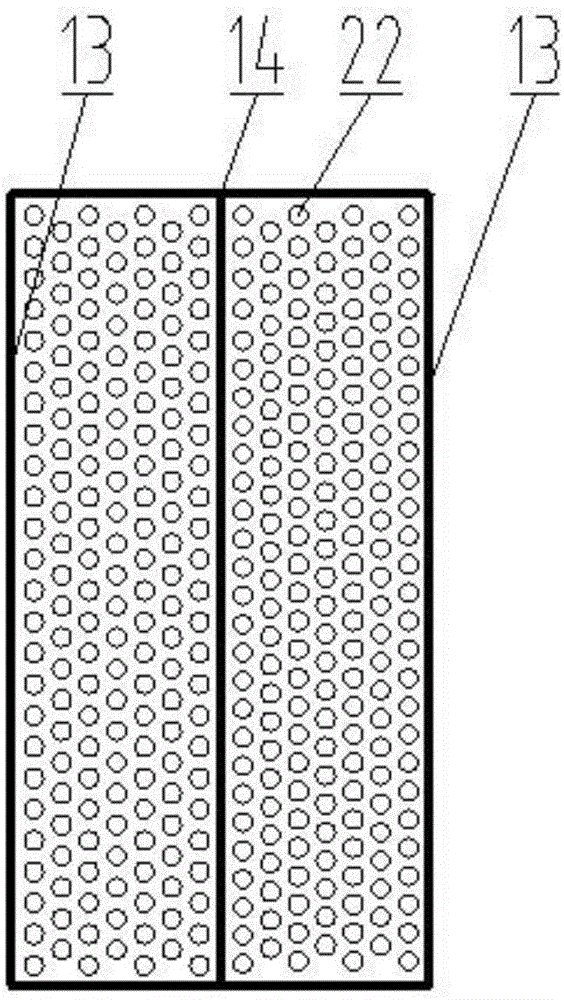

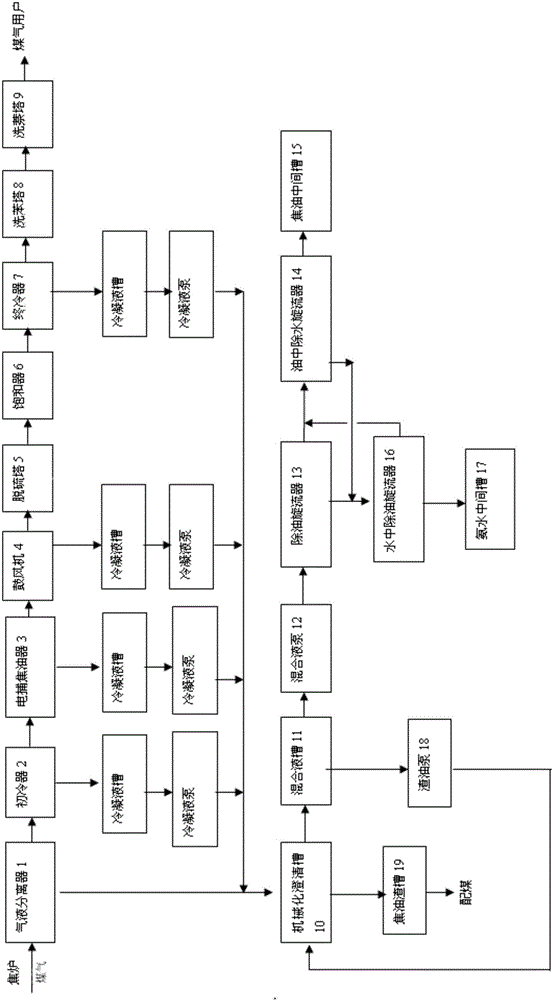

Coke oven gas purification system and condensate treatment subsystem thereof

InactiveCN106010670AShort separation timeEasy to separateWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentEngineeringRotational flow

The invention discloses a condensate treatment subsystem of a coke oven gas purification system. The condensate treatment subsystem comprises a mechanical clarifying tank, a tar residue tank, a mixed liquid tank, a residual oil pump, a mixed liquid pump, an oil removal hydrocyclone, an in-water oil removal hydrocyclone, an ammonia water middle tank, an in-oil water removal hydrocyclone and a tar middle tank; residues, oil and water in condensate produced in the gas purification process are separated in the rotational flow centrifugal sedimentation principle, immediate treatment of the condensate is realized, the separation time is short, the separation effect is better, equipment is reduced, the investment is low, and small areas are occupied. The invention further provides the coke oven gas purification system containing the condensate treatment subsystem.

Owner:SHANDONG IRON & STEEL CO LTD

Method for gasifying solid raw material containing carbon

A method for gasifying solid fuel containing carbon, such as turf, brown coal and hard coal, with the addition of an oxygen-containing gas and steam, wherein the gas condensate accumulating during the washing and cooling of the crude gas is also purified in a manner known per se, subsequently evaporated in the waste heat boiler, the steam is purified by means of thermal catalytic afterburning, the content of water vapor in the flue gas formed in the process is condensed out and the condensate is treated in a boiler feed water conditioning system and evaporated by means of the heat generated in the thermal afterburning, and the steam is supplied as process steam to the gasification of the solid raw materials.

Owner:LURGI

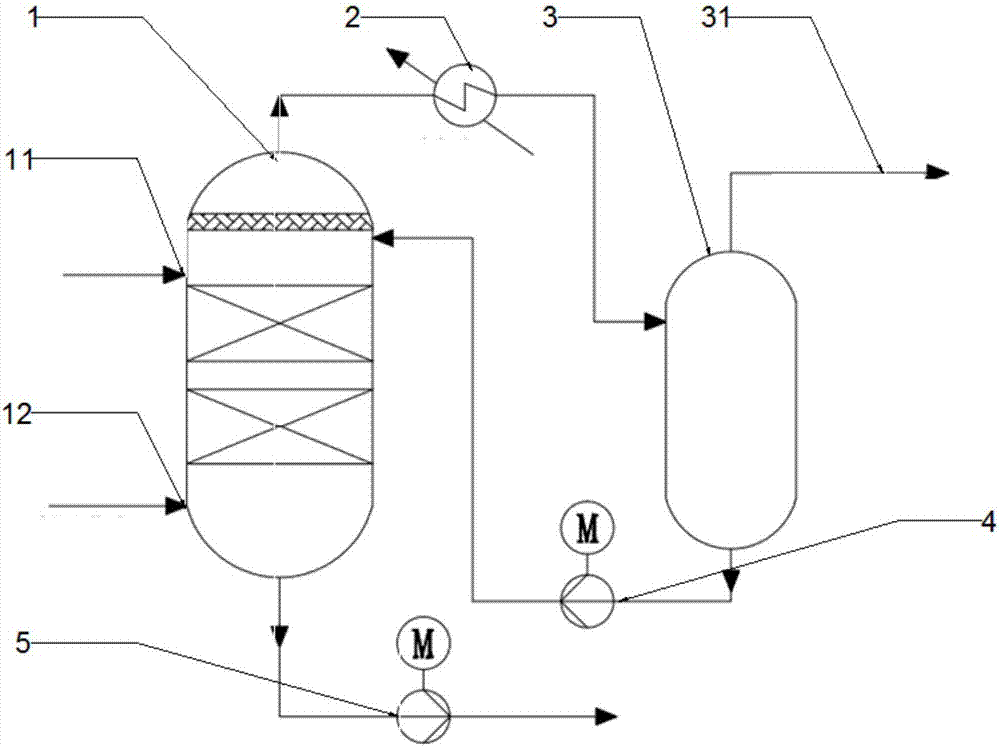

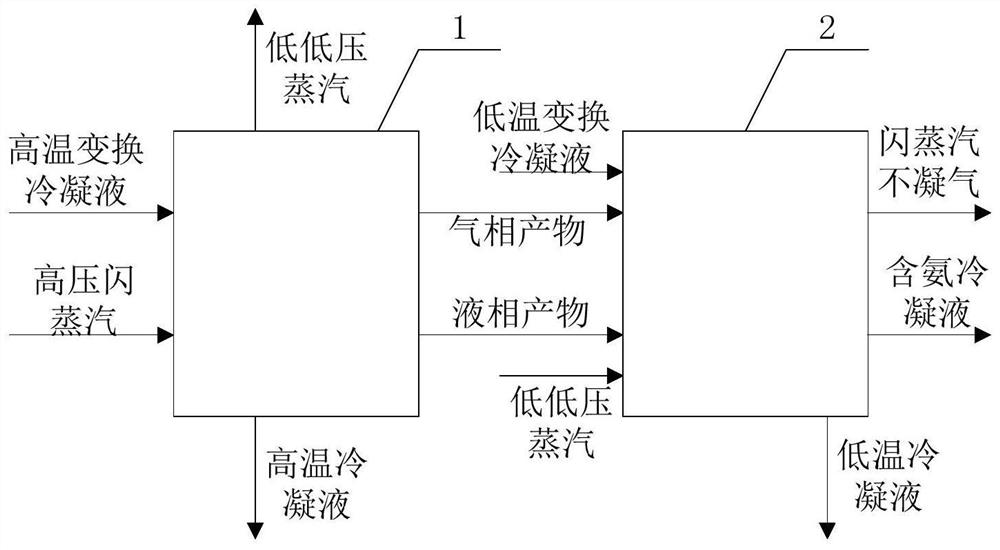

System and method for reducing ammonia nitrogen content

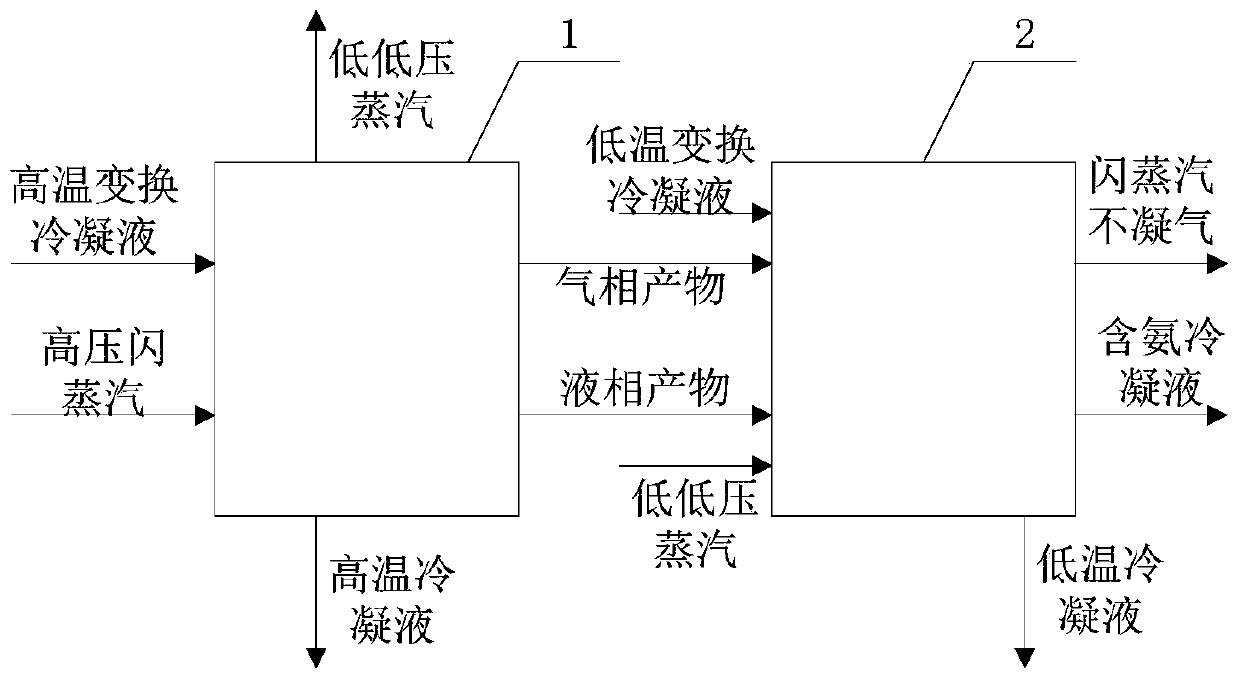

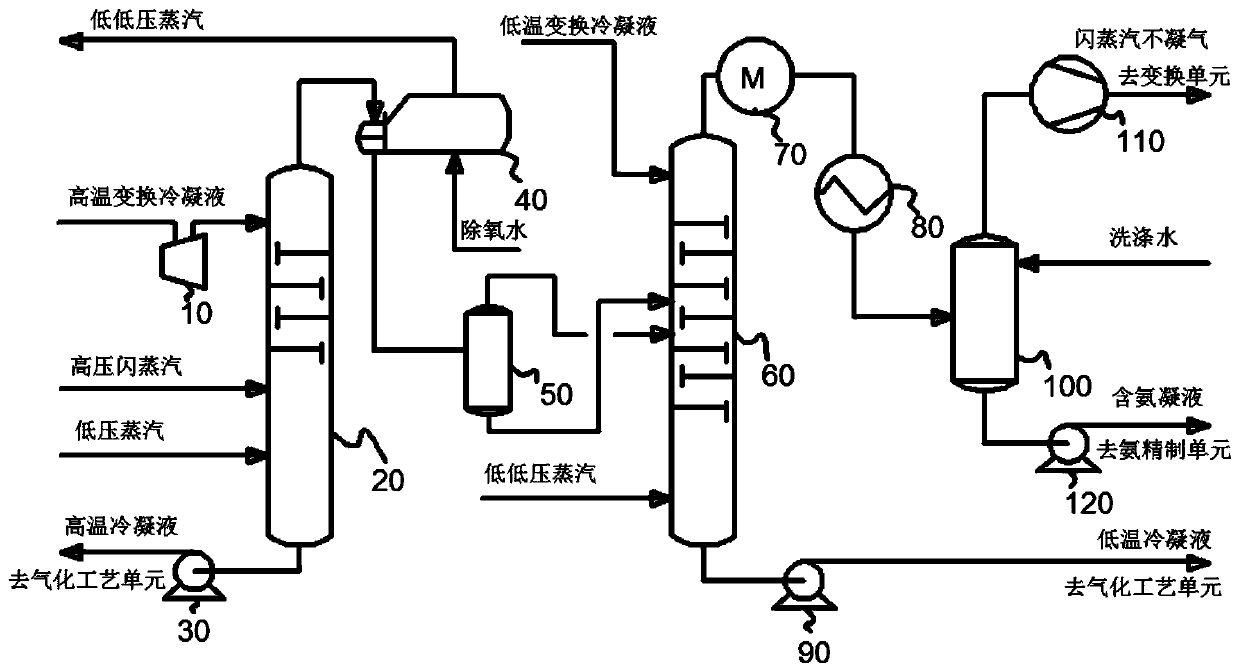

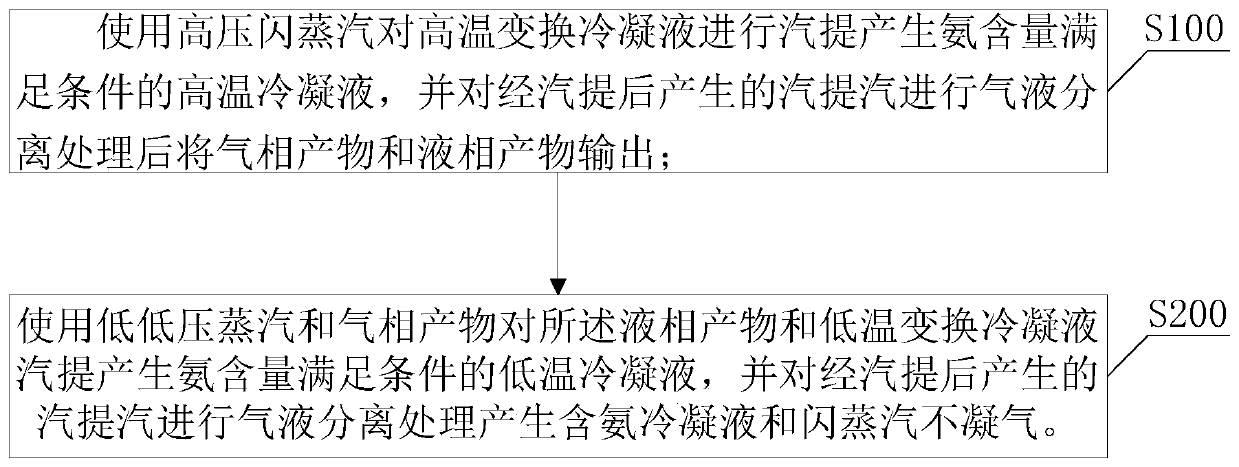

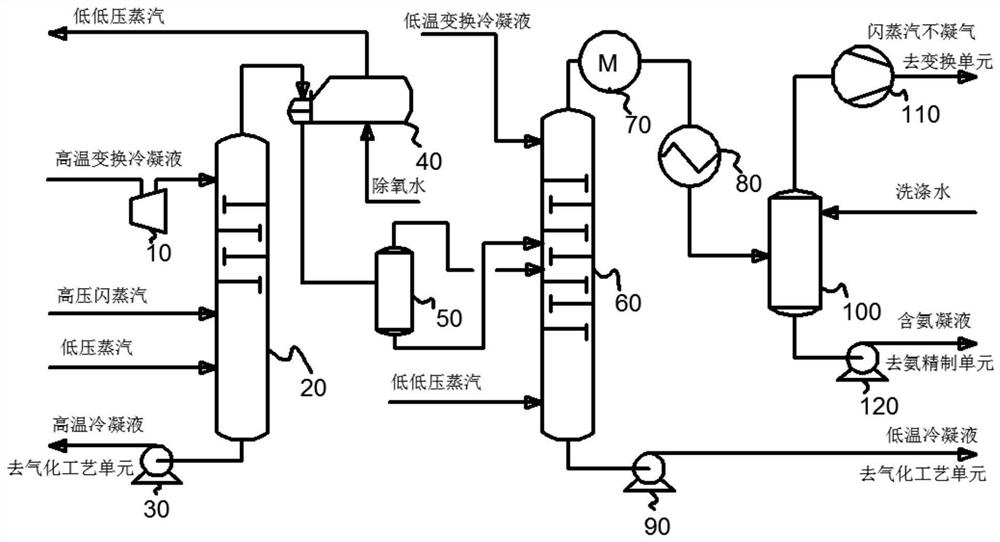

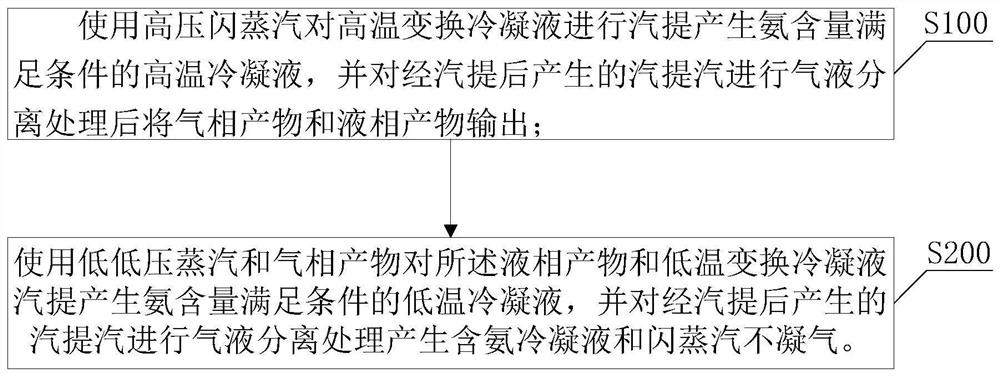

ActiveCN110203986AReduce ammonia nitrogen contentWaste heat can be recoveredSpecific water treatment objectivesWater contaminantsLiquid productGas phase

The invention relates to the technical field of coal gasification and gas shift, and discloses a system and method for reducing the ammonia nitrogen content. The system comprises a high-temperature condensate treatment device and a low-temperature condensate treatment device, wherein the high-temperature condensate treatment device is used for conducting stripping on an input high-temperature shift condensate by using input high-pressure flash steam to generate a high-temperature condensate with the ammonia content meeting conditions, conducting gas-liquid separation on stripping steam generated after stripping and outputting a gas product and a liquid product to the low-temperature condensate treatment device; the low-temperature condensate treatment device is used for conducting stripping on the liquid product and an input low-temperature shift condensate by using input low-pressure steam and the gas product to generate a low-temperature condensate with the ammonia content meeting conditions, and conducting gas-liquid separation on stripping steam generated after stripping to generate an ammonia-containing condensate and flash non-condensable gas. By means of the system, the content of ammonia nitrogen in black water and grey water in a gasification process unit can be reduced, and the content of the ammonia nitrogen in the grey water discharged by the gasification process unit can be reduced to the degree that wastewater is well accepted.

Owner:CHINA SHENHUA COAL TO LIQUID & CHEM CO LTD +1

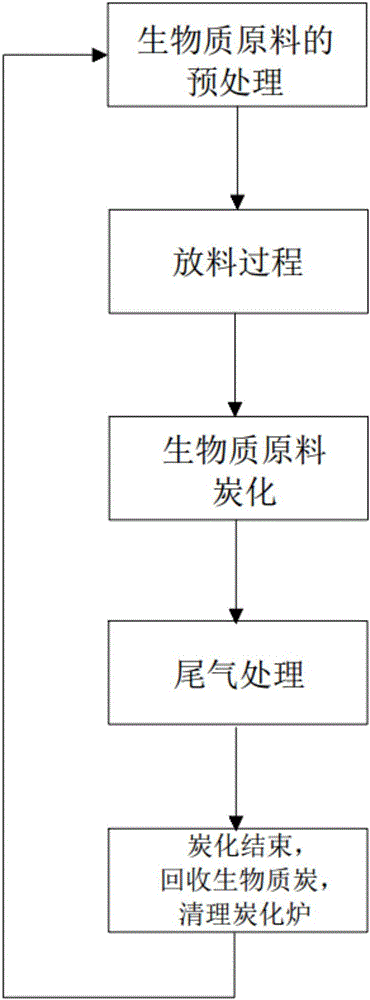

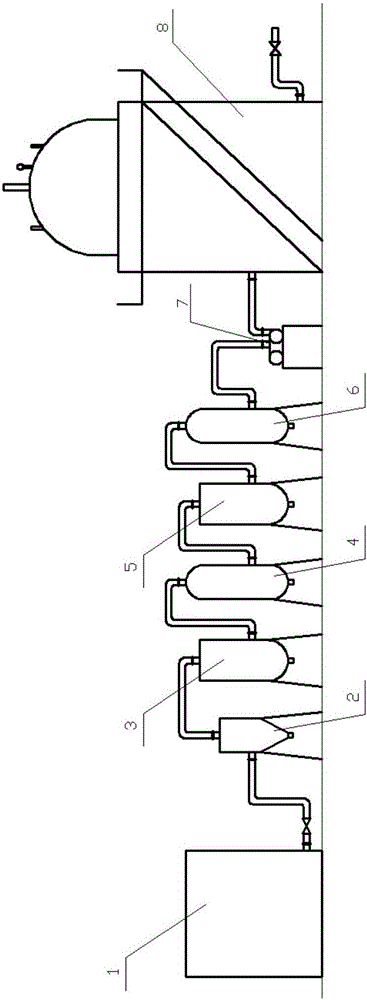

Biomass carbonizing technology and system with high carbon production

InactiveCN106118701AReduce the temperatureSave energyCoke ovensDispersed particle separationResource utilizationHigh carbon

The invention relates to a biomass carbonizing technology with high carbon production, belonging to the technical field of biomass utilization. The biomass carbonizing technology comprises the following steps: (1) pretreating biomass raw materials; (2) discharging; (3) carbonizing the biomass raw materials, and controlling the carbonizing temperature to be 300-500 DEG C and draught air speed to be 11-13 m / s by adopting external heat; (4) performing tail gas treatment; and (5) finishing carbonization. The invention relates to a biomass carbonizing system with high carbon production. The biomass carbonizing system comprises a carbonizing furnace, a cyclone separator, a primary condenser, a primary coke removal device, a secondary condenser, a secondary coke removal device, a roots fan and a gas storage cabinet. The biomass carbonizing technology and system have the technical effects that the technological equipment is simple, the resource utilization rate is high, the carbonization temperature is low, energy resources can be saved, more carbon production and less gas production can be achieved, the pertinence is strong, the production cost is low, and popularization is easy.

Owner:HEBEI TIANSHAN BIOTECH CO LTD

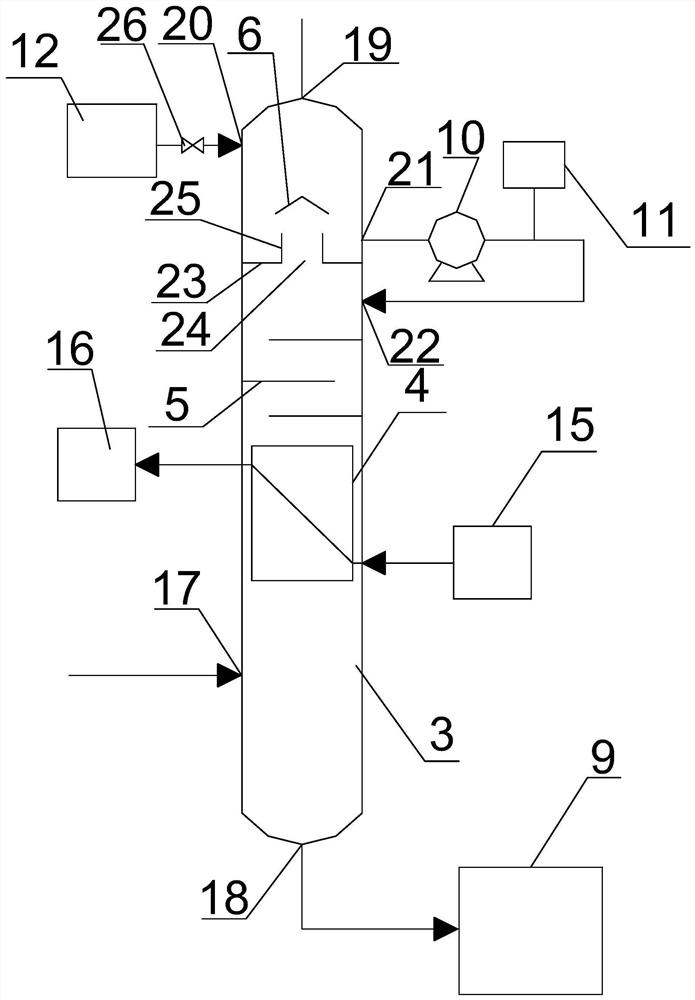

Integral gasification combined circulation (IGCC) power generation technology coal gasification and desulfurization unit-based ammonia-nitrogen removing device and method

PendingCN107129836AReduce total nitrogen contentReduce total ammonia nitrogenWater contaminantsWater/sewage treatmentAmmoniacal nitrogenThermodynamics

The invention discloses an integral gasification combined circulation technology (IGCC) coal gasification and desulfurization unit-based ammonia-nitrogen removing device and method. According to the device, a coal gas condensate inlet is formed in the left upper part of a stripping tower, and low-pressure steam inlet is formed in the left lower part of the stripping tower; the top nozzle of the stripping tower is connected with the upper nozzle of a stripping gas cooler through a pipeline, and the bottom nozzle of the stripping tower is connected with the inlet of a stripping water pump through a pipeline; the outlet of the stripping water pump is connected with a gasification device through a pipeline; the lower nozzle of the stripping gas cooler is connected with the left upper nozzle of a gas-liquid separation tank through a pipeline; the upper nozzle of the gas-liquid separation tank is connected with a sulfur removing and reclaiming device through an ammonia-containing acid gas pipeline; the bottom nozzle is connected with the inlet of a condensate return pump through a pipeline; and the outlet of the condensate return pump is connected with the right upper nozzle of the stripping tower through a pipeline. The device has the beneficial effects that the ammonia-nitrogen accumulation of a desulfurizing agent MDEA solution system can be reduced, the coal gasified gas desulfurizing agent MDEA solution degradation speed can be retarded, and the service cycle can be prolonged.

Owner:HUANENG TIANJIN COAL GASIFICATION POWER CO LTD

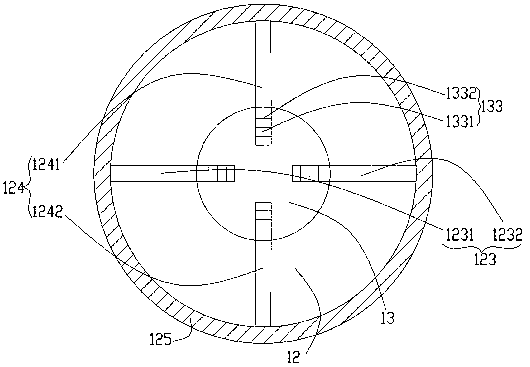

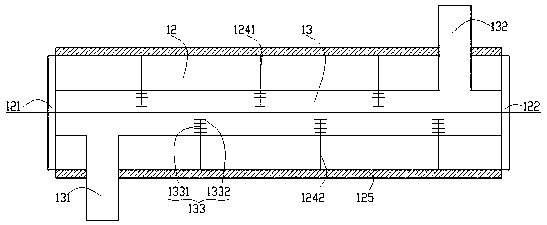

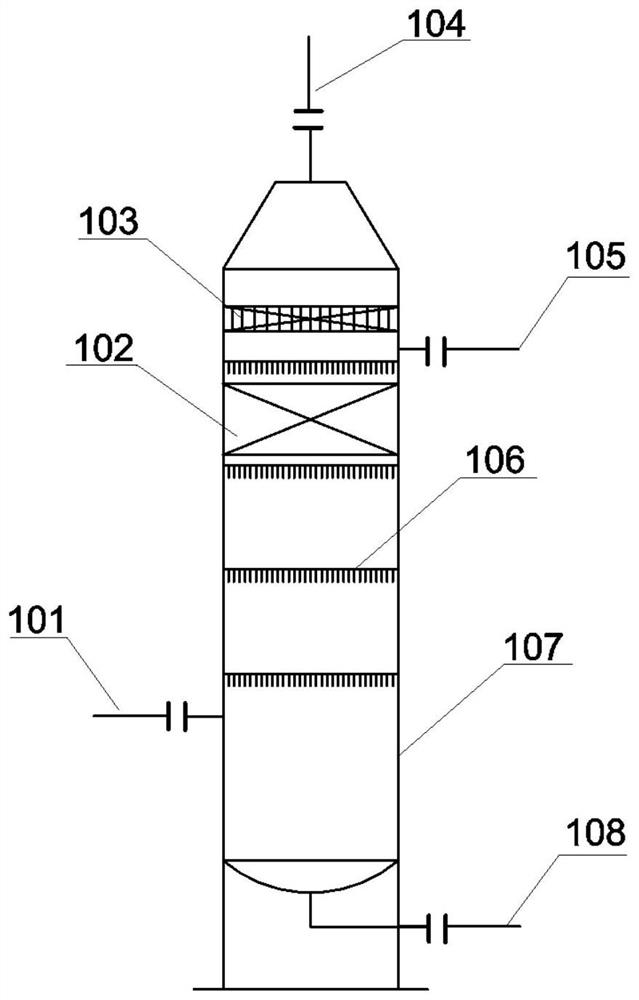

Ammonia washing tower and anti-corrosion shift gas ammonia washing device and process using same

PendingCN112246075AImprove solubilityFast absorptionGas treatmentGeneral water supply conservationPhysical chemistryChilled water

The invention belongs to an ammonia washing tower and an anti-corrosion shift gas ammonia washing device and process using the ammonia washing tower. The device comprises a pre-process shift gas pipeline, and the pre-process shift gas pipeline is connected with a shift gas inlet of an ammonia washing tower through a water cooler shell pass; the ammonia washing tower sequentially comprises a flashevaporation section, a cooling section, an ammonia washing section and a pre-washing analysis section from bottom to top, a shift gas inlet is formed in one side of the flash evaporation section, anda flash evaporation condensate outlet is formed in the bottom of the flash evaporation section; the cooling section comprises a chilled water cooler; the ammonia washing section comprises a pluralityof layers of float valve trays and a gas distribution cap assembly; a shift gas outlet is formed in the top of the pre-washing analysis section; a desalted water inlet is formed in one side of the pre-washing analysis section. The device has the advantages that ammonia gas can be uniformly absorbed in the ammonia washing section on the premise of improving the solubility of the ammonia gas, and the pH of condensate is neutral after the ammonia gas, carbon dioxide and other acidic gases are dissolved in water, so that the acidic environment in the ammonia washing tower is changed, and internalparts or linings of the ammonia washing tower are prevented from being corroded.

Owner:HENAN XINLIANXIN FERTILIZER

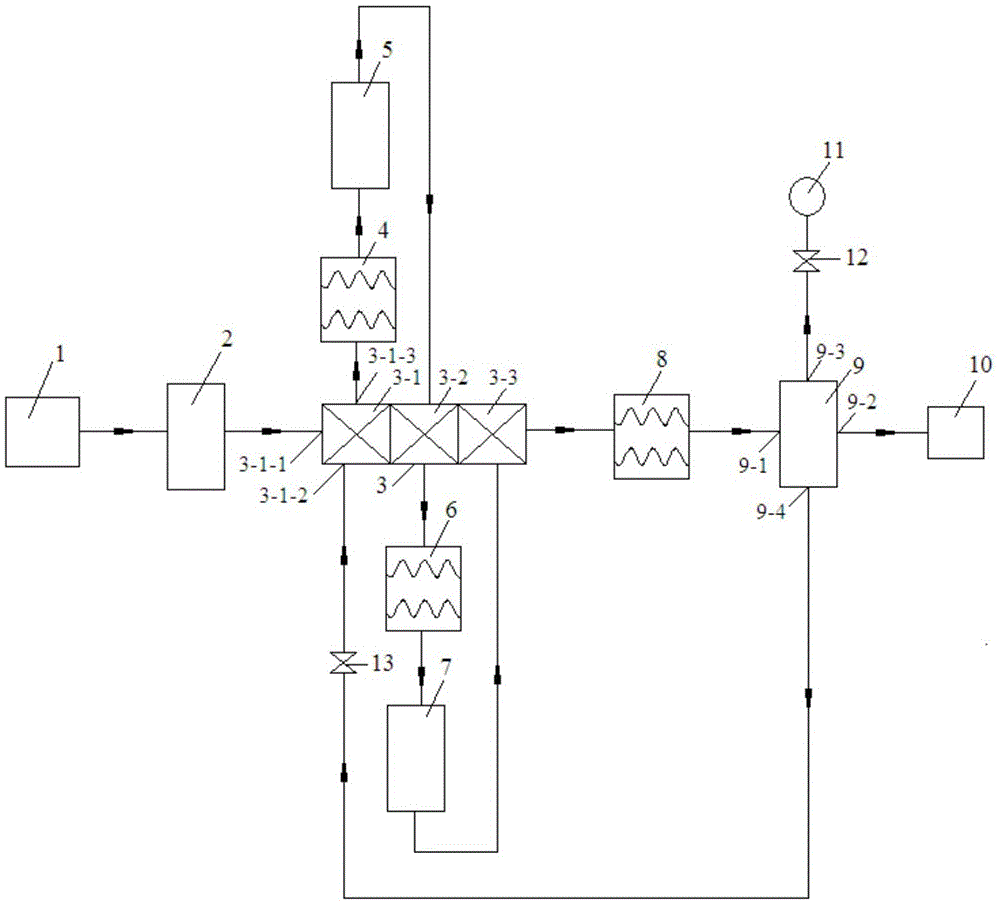

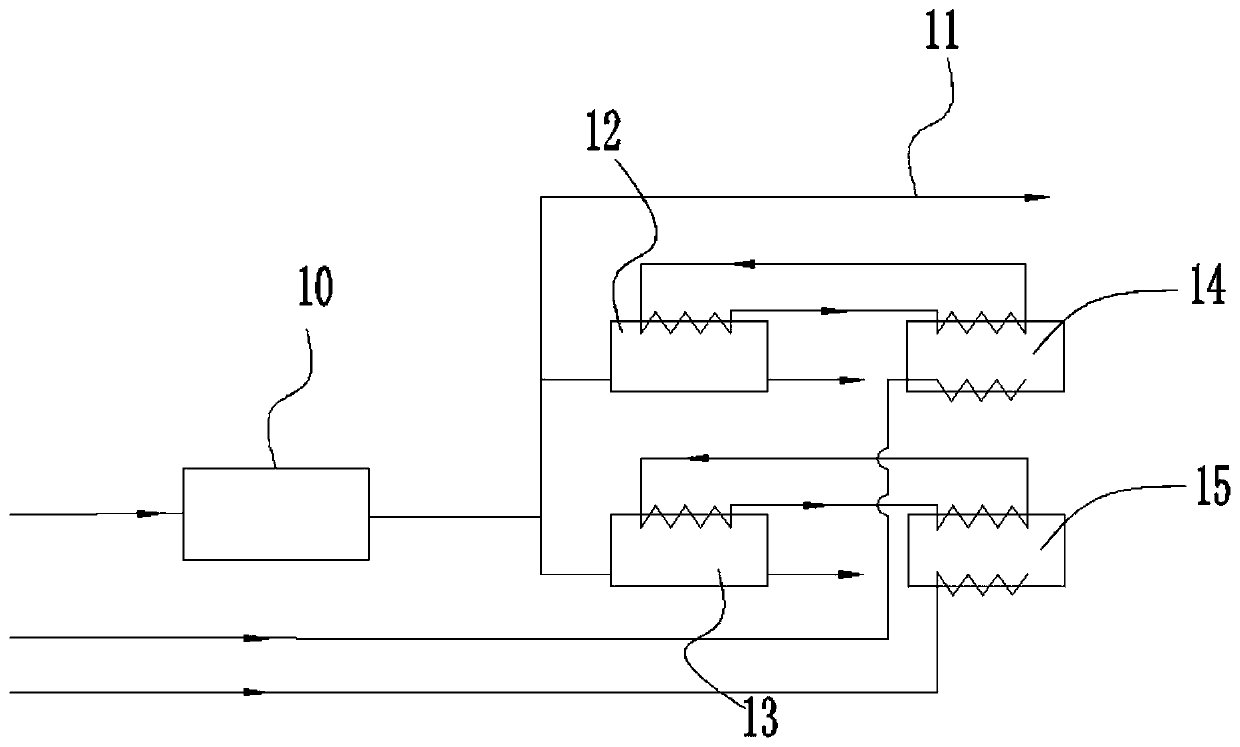

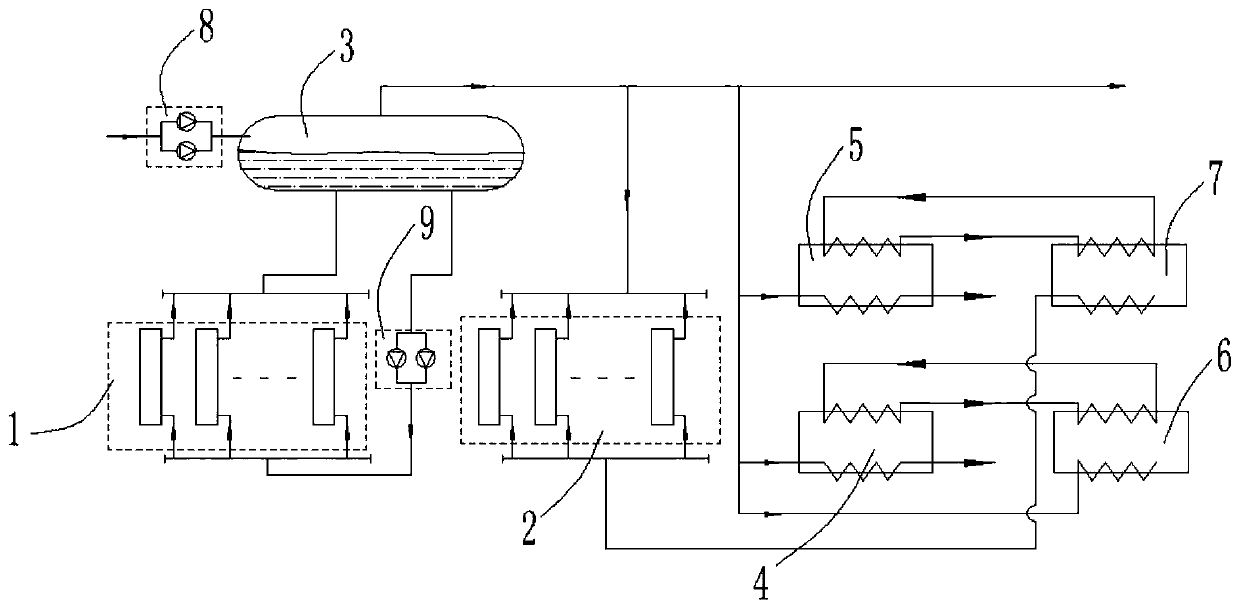

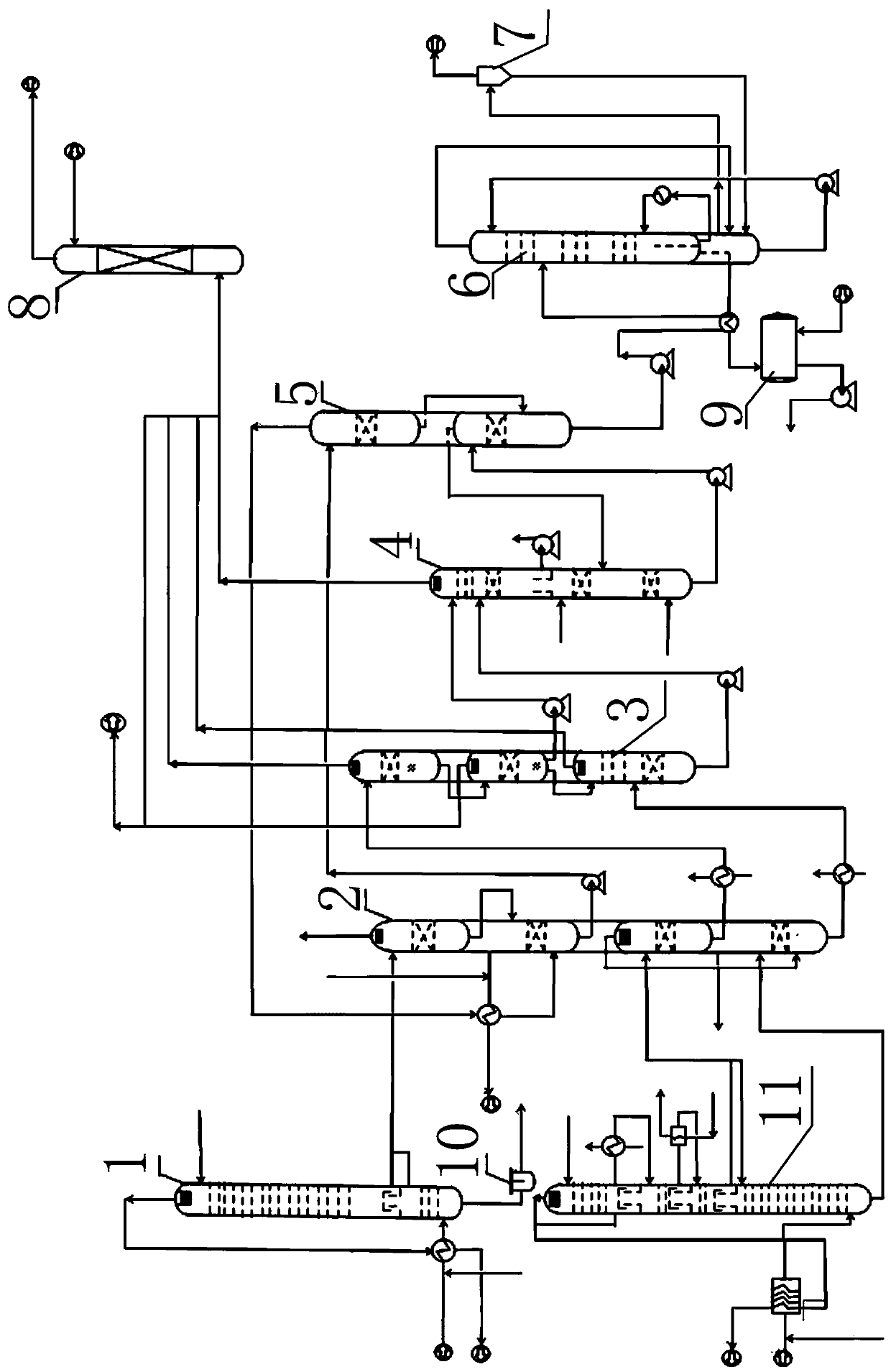

Process method for using coal gas pressurization device for pressurizing coal gas

InactiveCN105542872AEasy to pressurizeImprove cooling effectGas purification by non-gaseous materials condensationGas condensate working-upCooling effectGas cooler

The present invention discloses a process method for using a coal gas pressurization device for pressurizing coal gas, relates to a process for pressurizing coal gas, and aims to solve the problems that a coal gas pressurization device used in the process for synthesis of methanol from coal gas is poor in pressurizing effect, poor in cooling effect and does not apply to large gas flow working conditions. The process method is as follows: water coal gas in a water coal gas tank is treated by a first separator, a coal gas pressurizing compressor I section, a first gas cooler, a second separator, a coal gas pressurizing compressor II section, a second gas cooler, a third separator, a coal gas pressurizing compressor III section, a third gas cooler and a fourth separator, and then enters a temperature swing adsorption device to complete the process method for using the coal gas pressurization device for pressurizing the coal gas. The process method for using the coal gas pressurization device for pressurizing the coal gas can be obtained.

Owner:QITAIHE BAOTAILONG COAL CHEM IND

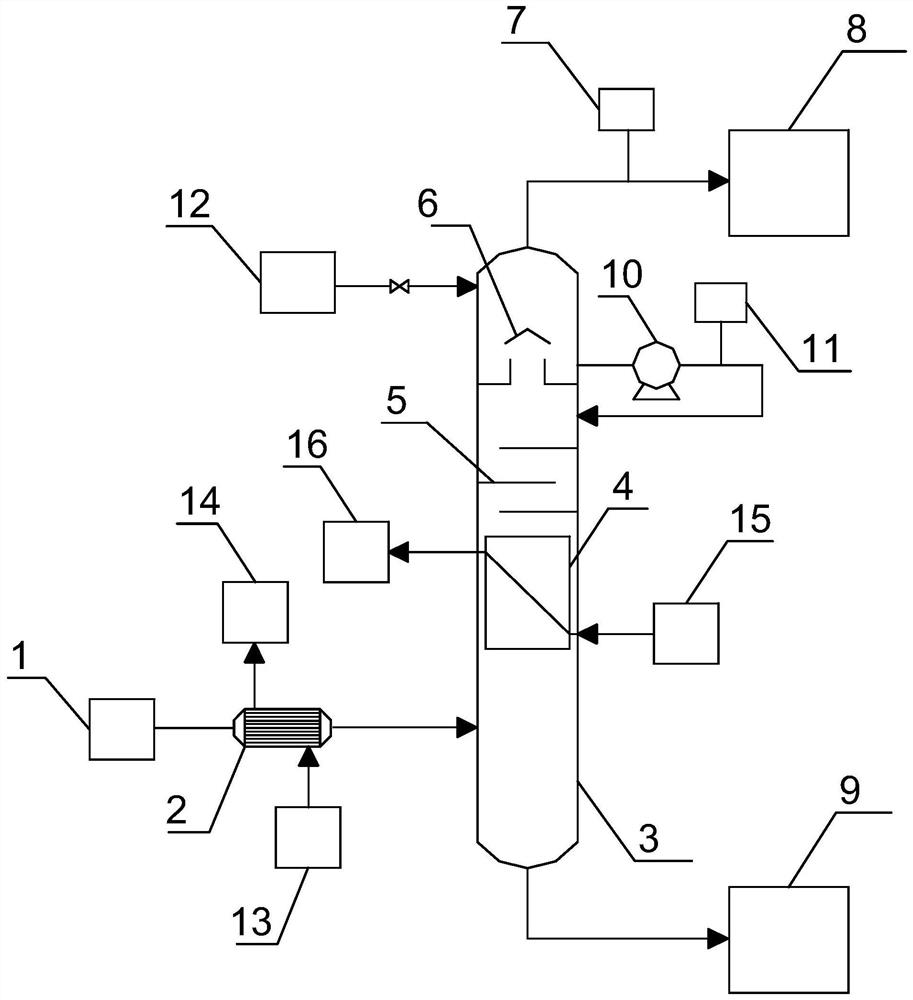

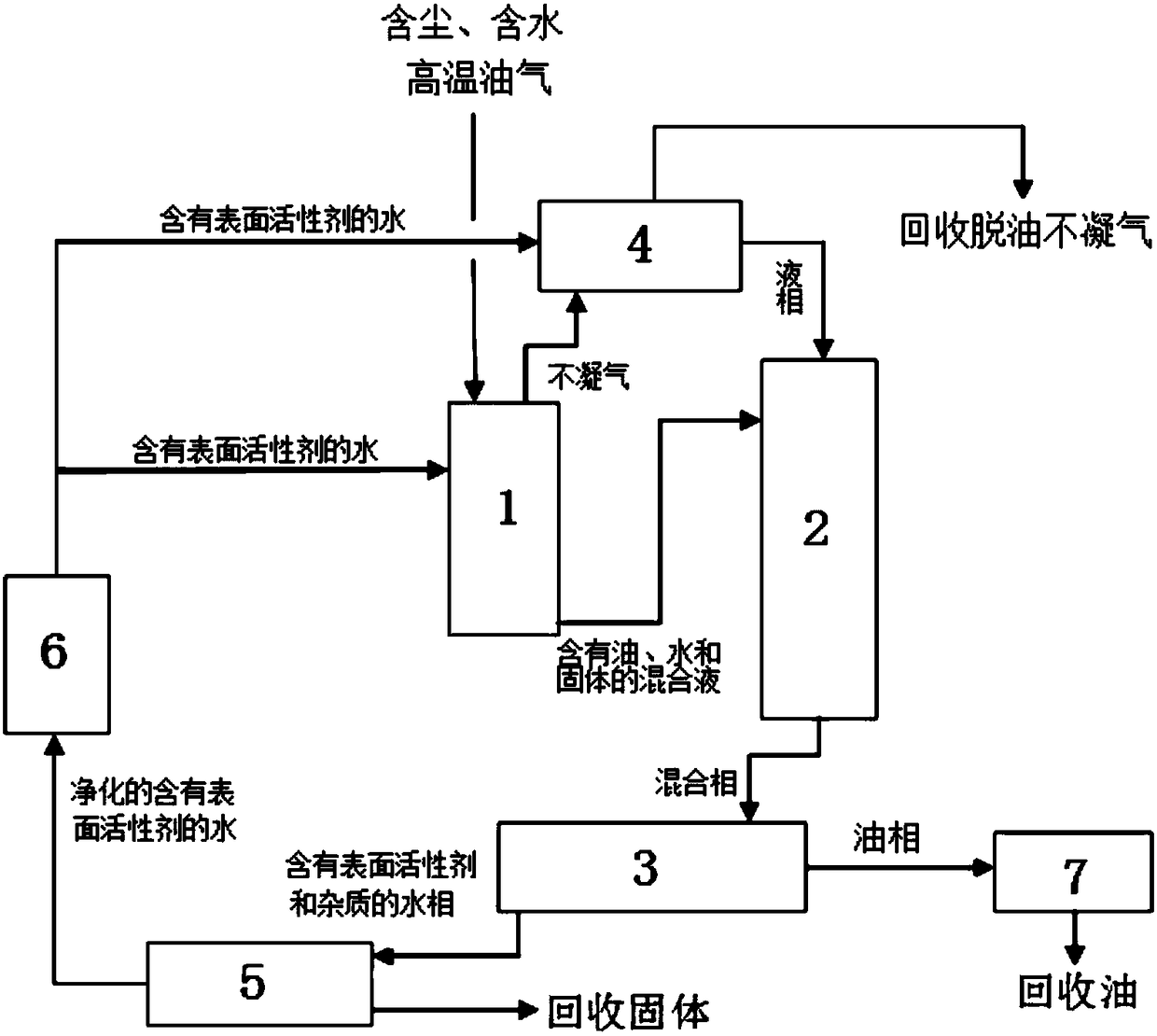

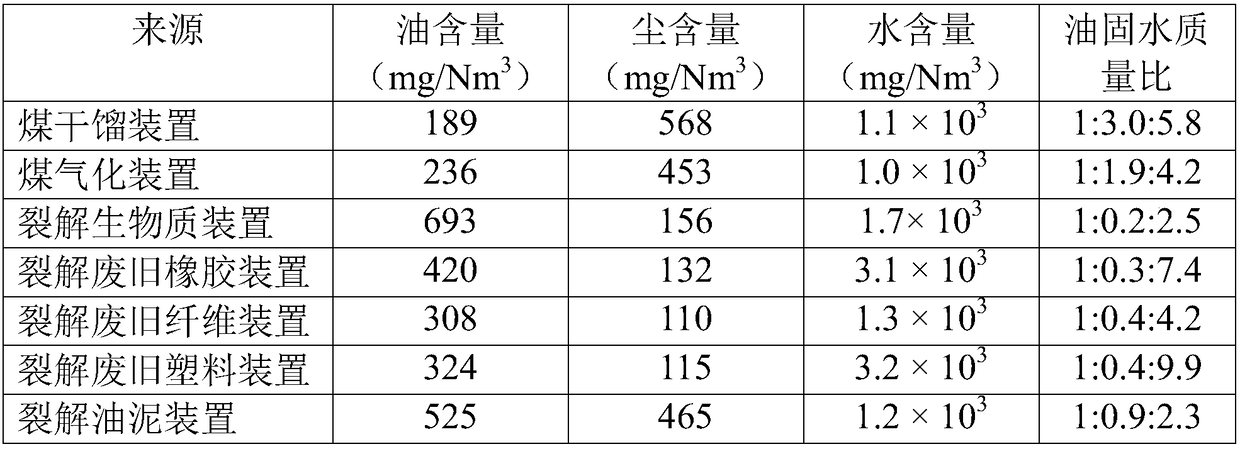

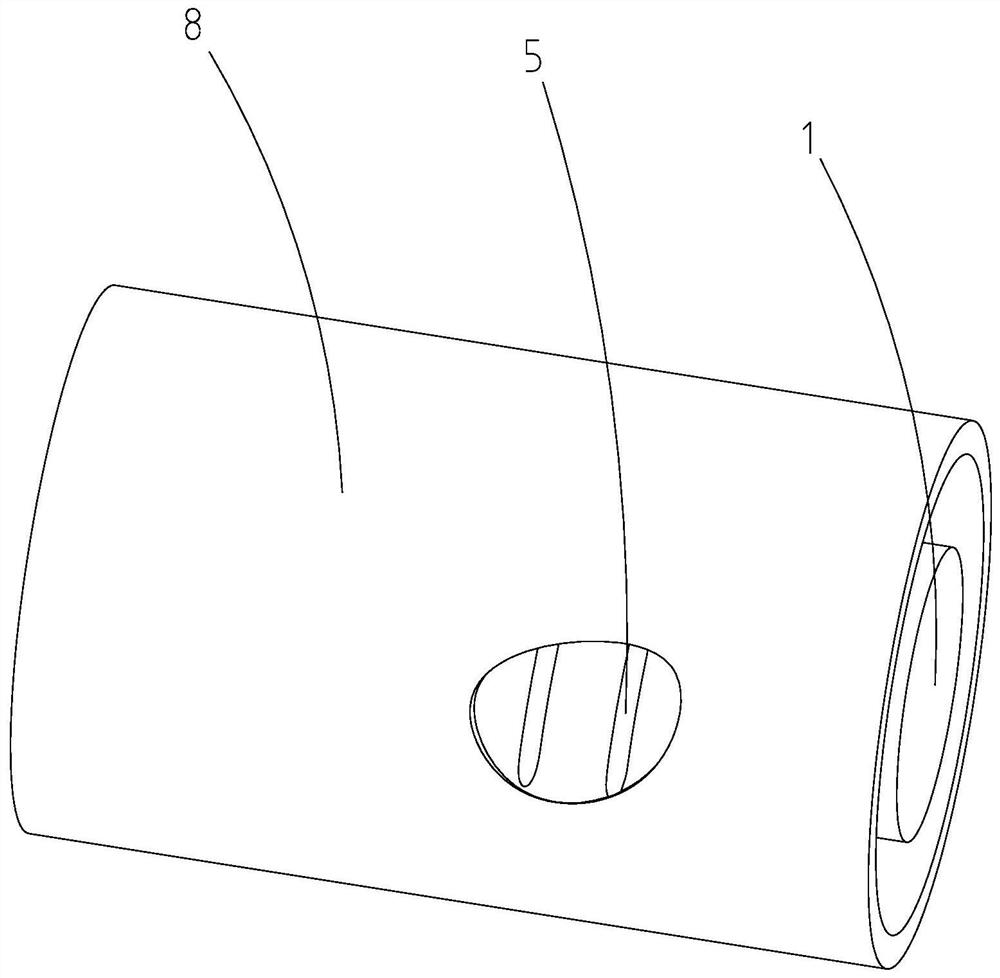

Method and system for purifying dust-containing and water-containing high-temperature oil gas to recover oil

ActiveCN109504469AEfficient removalGas purification by non-gaseous materials condensationGas contaminants removalFiberSolid content

The invention relates to the field of dust-containing and water-containing high-temperature oil gas purification, and discloses a method and a system for purifying dust-containing and water-containinghigh-temperature oil gas to recover oil. The method for purifying the dust-containing and water-containing high-temperature oil gas to recover the oil comprises the following steps: (1) surfactant-containing water is enabled to be in contact with the dust-containing and water-containing high-temperature oil gas to carry out condensation, so that noncondensable gas and a mixture containing oil, water and solid are obtained; (2) the mixture obtained in step (1) is introduced into a fiber liquid film contactor to carry out mutual contact, so that a mixed phase is obtained, wherein the fiber liquid film contactor comprises a cylinder, and the cylinder is loaded with fibers; and (3) the obtained mixed phase is subjected to standing for sedimentation in an oil-water separation tank, so that anoil phase and a water phase containing the surfactant and impurities are obtained. The method disclosed by the invention can be adopted to effectively remove solid impurities and water in the dust-containing and water-containing high-temperature oil gas, obtaining recovered oil with solid content less than 0.001 percent and water content less than 0.1 percent, and the purified recovered oil can bedirectly refined and processed.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

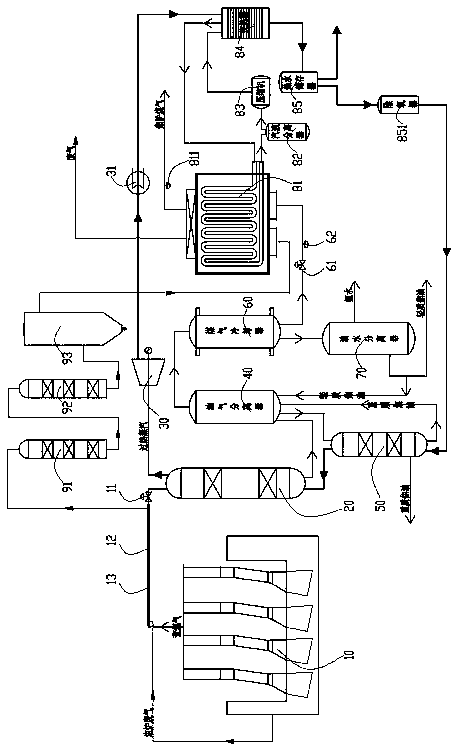

Coke oven raw gas and waste gas waste heat recycling system

PendingCN111336487AFull recoveryFull reuseLiquid degasificationDispersed particle filtrationEngineeringEnergy conservation

The invention discloses a coke oven raw gas and waste gas waste heat recycling system. The coke oven raw gas and waste gas waste heat recycling system comprises a coke oven, a high-temperature waste heat boiler, a waste gas purifying device, a steam turbine, an oil-gas separator, a low-temperature waste heat boiler, a coal gas cooler, an oil-water separator and a low-temperature waste heat recycling device. According to the scheme adopted by the invention, the high-temperature waste heat boiler, the low-temperature waste heat boiler and the low-temperature waste heat recycling device are simultaneously arranged, so that raw gas high-temperature sensible heat, heavy tar low-temperature waste heat and 60-100-DEG C raw gas low-temperature waste heat are effectively recycled and reutilized, and a great deal of heavy tar and light tar in raw gas further can be recycled, and therefore, profits are created and the yield is increased for enterprises, and economic and social benefits are very good; raw gas is further conveyed into a first smoke gas pipeline to perform heat exchange with coke oven waste gas in a second smoke gas pipeline, so that high-temperature sensible heat in the raw gasis partially recycled and reutilized; and in a coke oven waste gas denitration process, a heater does not need to additionally arrange, so that coke oven waste gas investment and treatment cost is greatly reduced, and energy conservation and consumption reduction of coking enterprises are facilitated.

Owner:平罗县阳光焦化有限公司

Crude gas waste heat recycling and use system and method

PendingCN110240949AEfficient recyclingAvoid wastingEnergy inputIncreasing energy efficiencyEvaporationEconomic benefits

The invention discloses a crude gas waste heat recycling and use system and method. The crude gas waste heat recycling and use system comprises a waste heat recycling system and a waste heat use system, wherein the waste heat recycling system comprises a saturated steam heat exchanger group, a superheated steam heat exchanger group, a steam pocket with a steam-water separator, a circulation water pump group and a water supply pump group; and the waste heat use system comprises a condensed ammonium hydroxide heater, a condensed rich oil heater, an ammonia evaporation tower and a debenzolization tower. The crude gas waste heat recycling and use system and the waste heat recycling and use method disclosed by the invention are not only environment-friendly and energy-saving, but also remarkable in economic benefit, both the waste heat utilization rate of a company can be increased, and carbon emission and waste gas discharge can be reduced, and in addition, steam can be supplied outside to make economic values.

Owner:WUHAN FRONT IND EQUIP TECH

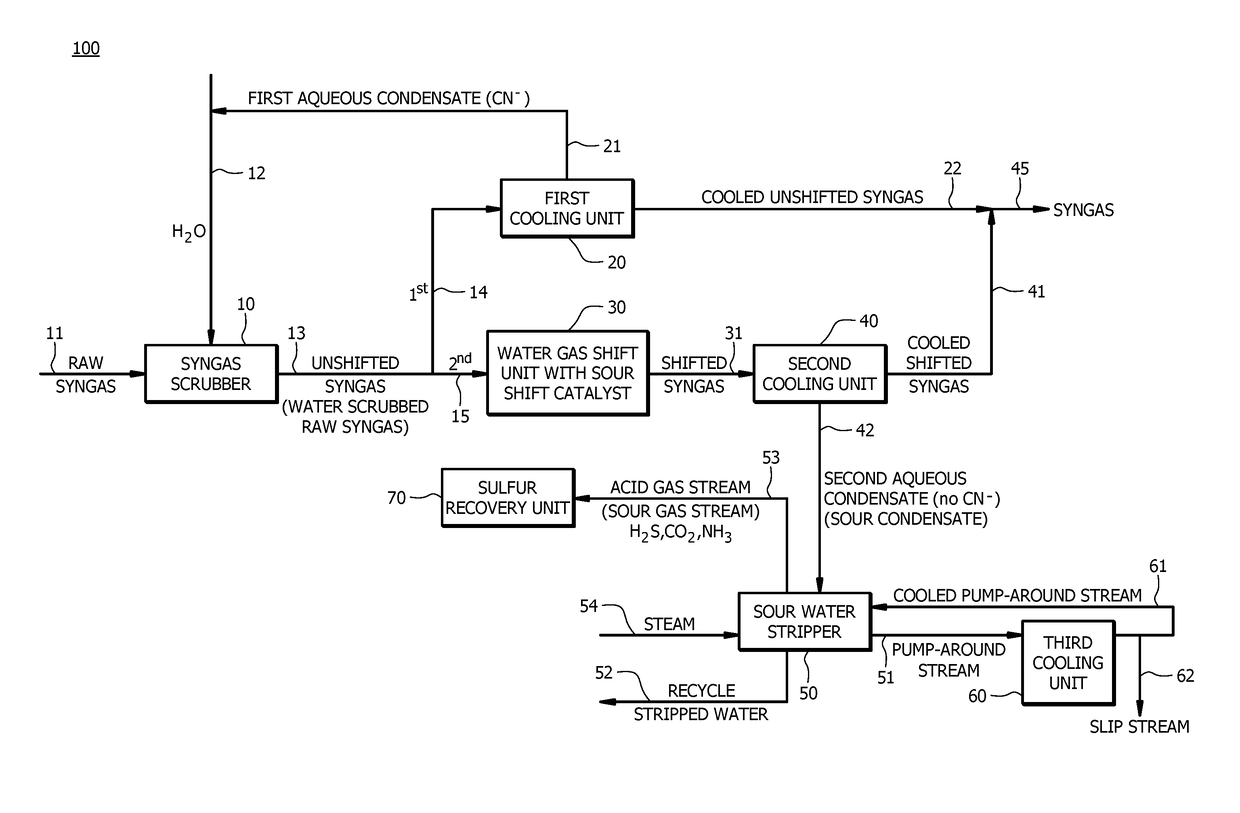

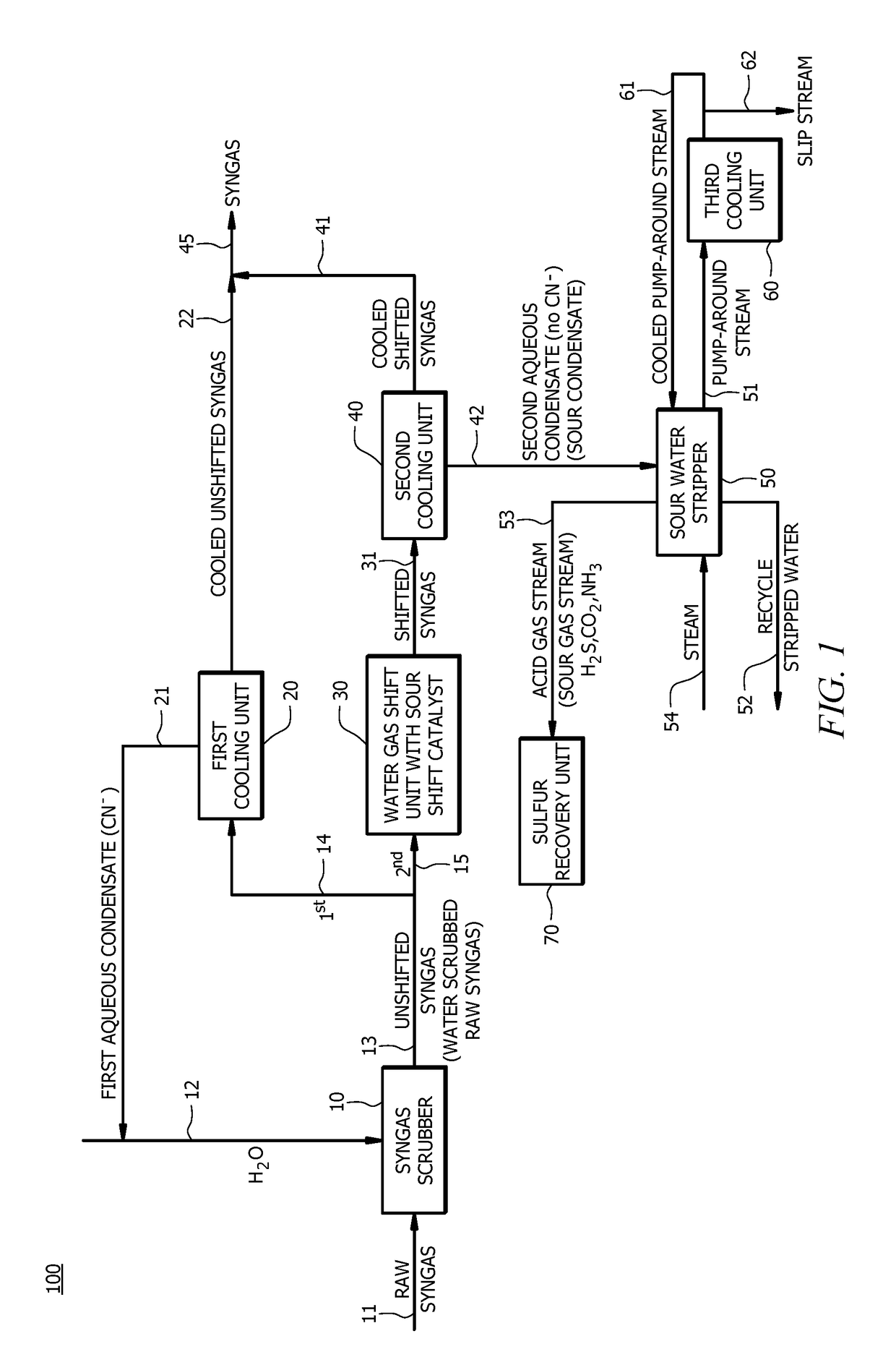

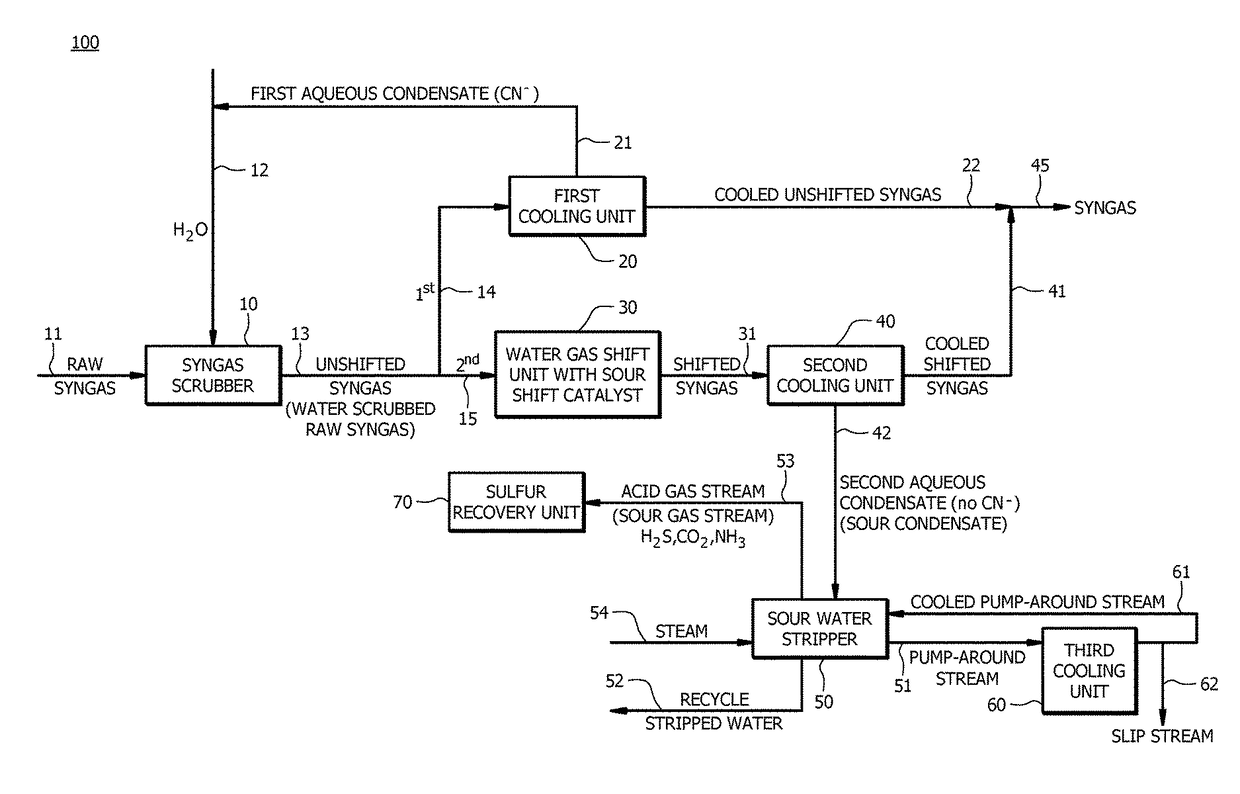

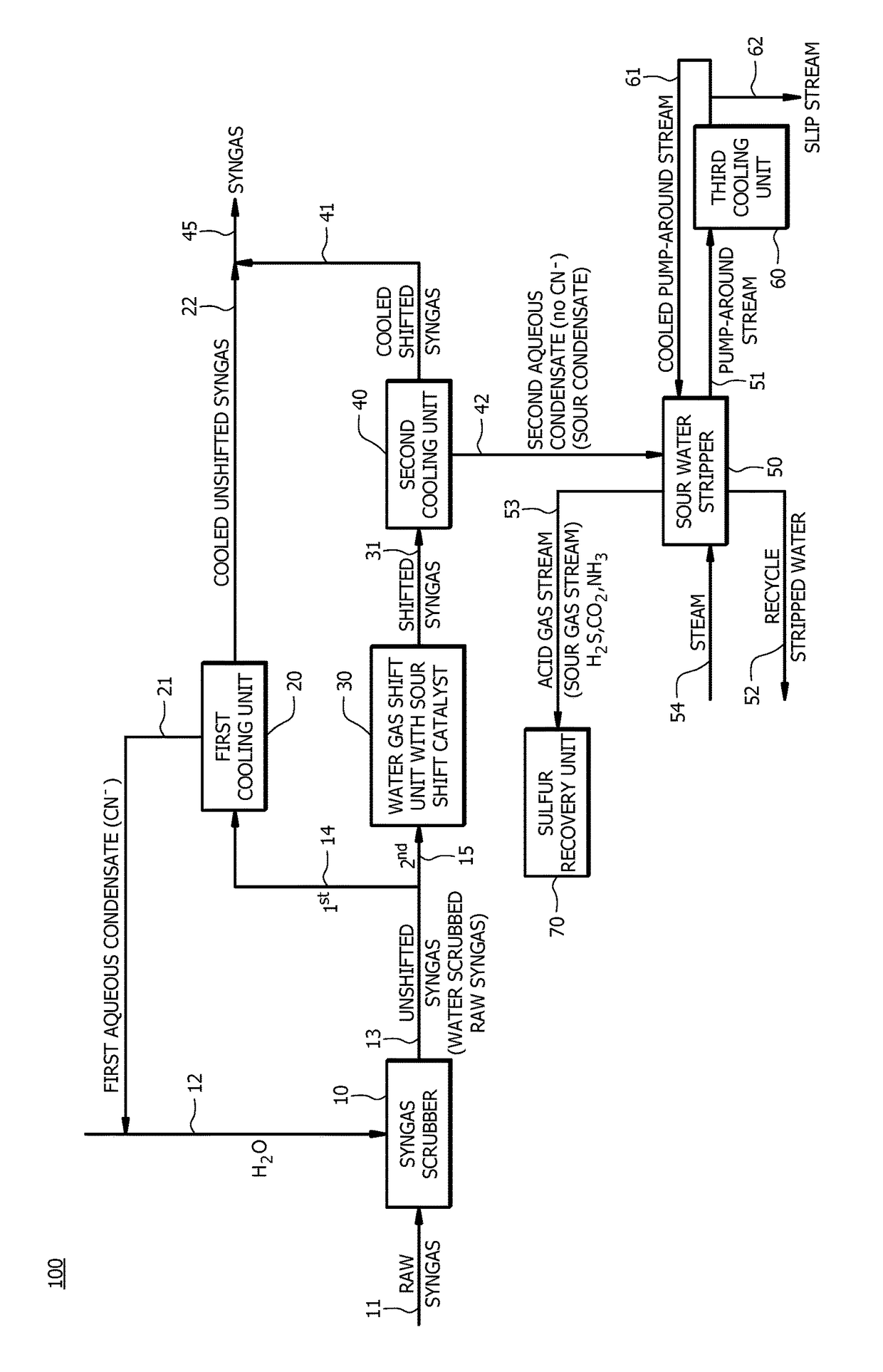

Novel method for avoiding expensive sour water stripper metallurgy in a gasification plant

A method of producing syngas comprising receiving raw syngas from a gasification unit; introducing the raw syngas and water to a syngas scrubber to produce unshifted syngas; introducing a first portion of unshifted syngas to a first cooling unit to produce cooled unshifted syngas and a first aqueous condensate comprising cyanide in an amount of 5-200 ppmw; recycling the first aqueous condensate to the syngas scrubber; introducing a second portion of unshifted syngas to a water gas shift unit to produce shifted syngas; introducing the shifted syngas to a second cooling unit to produce cooled shifted syngas and a second aqueous condensate comprising cyanide in an amount of less than 2.5 ppmw; contacting the cooled shifted syngas with the cooled unshifted syngas to produce modified syngas; and introducing the second aqueous condensate to a sour water stripper to produce stripped water and an acid gas comprising H2S, CO2, and ammonia.

Owner:FLUOR TECH CORP

Oil-based mud treatment device and oil-based mud treatment method

ActiveCN114853301AEasy dischargeReduce viscositySolid waste disposalSludge treatment by pyrolysisProcess engineeringWaste treatment

The invention discloses an oil-based mud treatment device and an oil-based mud treatment method.The oil-based mud treatment device comprises a hammer mill, a solid waste treatment mechanism and a pyrolysis gas separation treatment mechanism, and the hammer mill is used for hammer milling and pyrolysis of oil-based mud to obtain solid waste and pyrolysis gas; the solid waste treatment mechanism is communicated with a solid waste outlet of the hammer mill and is used for crushing and discharging the solid waste; and the pyrolysis gas separation treatment mechanism is communicated with the pyrolysis gas outlet of the hammer mill and is used for separating oil and water in the pyrolysis gas. The oil-based mud can be pyrolyzed, the viscosity of the solid waste is reduced to prevent the conveying pipe from being blocked, and the oil in the pyrolysis gas is recycled to prevent the environment from being polluted.

Owner:CHANGZHOU UNIV

Low-rank coal low-temperature pyrolysis tar gas recycling equipment

InactiveCN106047423ASimple structureReasonable stepsCombination devicesGas purification by non-gaseous materials condensationCycloneElectricity

The invention relates to the field of low-rank coal low-temperature pyrolysis, in particular to low-rank coal low-temperature pyrolysis tar gas recycling equipment. The low-rank coal low-temperature pyrolysis tar gas recycling equipment comprises a high-temperature electric dust remover, a high-temperature cyclone separator, a cooling tower, an electric tar trapper, an induced draft fan, a rotary trapping collector, a tar collecting pond, a tar delivery pump, a tar storage tank and a tar cooling pump which are sequentially arranged from the right to the left at intervals. Two high-temperature electromagnetic valves are respectively arranged on pipelines, the induced draft fan and the electric tar trapper are communicated with each other via the corresponding pipeline, and the induced draft fan and the rotary trapping collector are communicated with each other via the corresponding pipeline. The low-rank coal low-temperature pyrolysis tar gas recycling equipment has the advantages that the low-rank coal low-temperature pyrolysis tar gas recycling equipment is simple in structure and easy to operate, steps are reasonable, methods for matching high-temperature electric dust removal and high-temperature cyclone with each other are adopted, accordingly, dust in tar gas can be deeply removed, and the dust removal efficiency can be improved for the tar gas by means of secondary dust removal; the tar gas can be cooled by the aid of tar cooling methods instead of water cooling methods, accordingly, the purity of tar can be guaranteed, requirements of people can be effectively met, and problems in the prior art can be solved.

Owner:朱绍辉

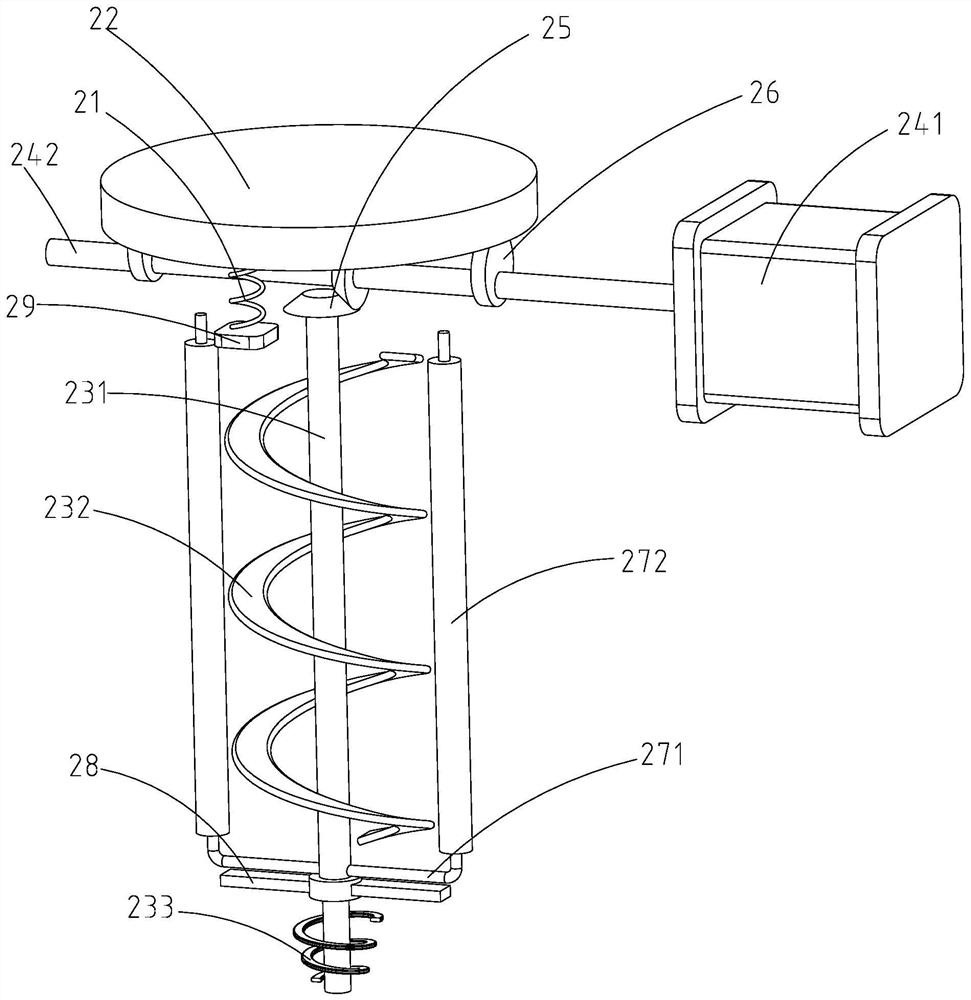

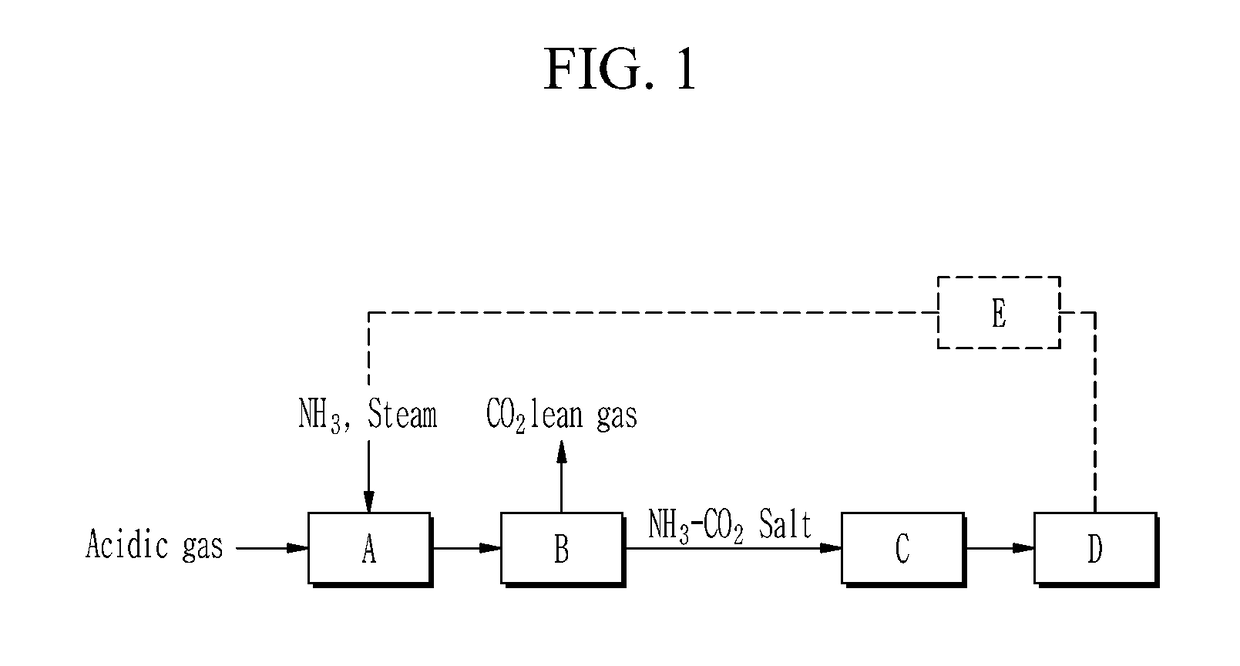

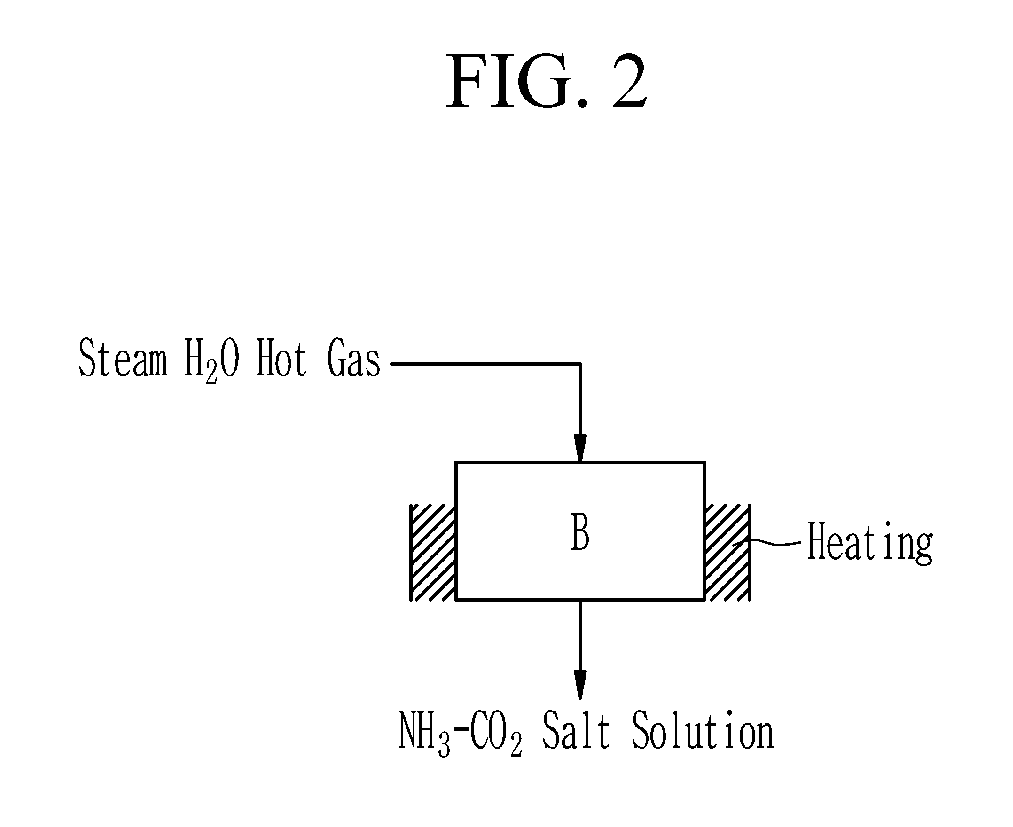

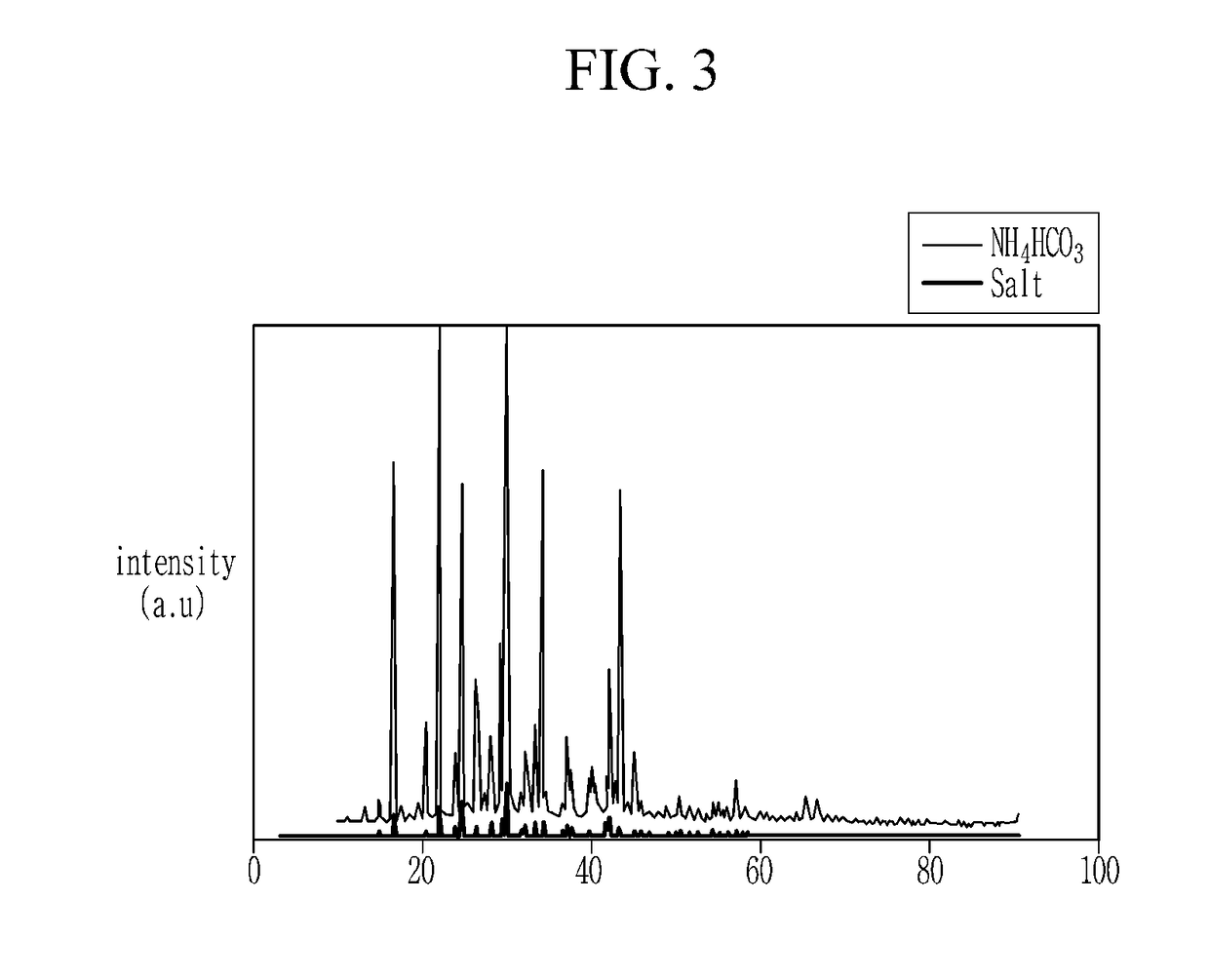

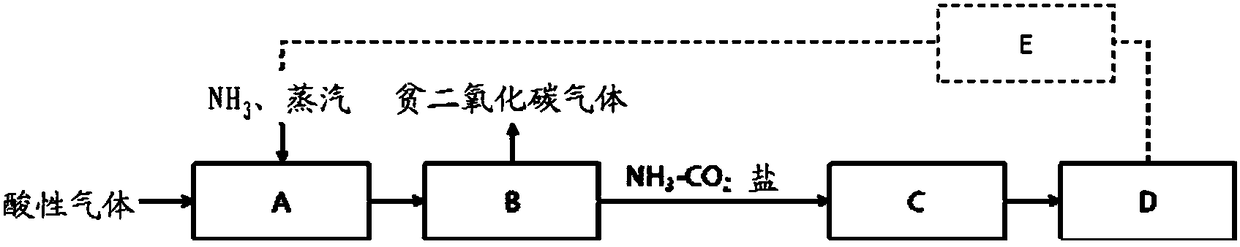

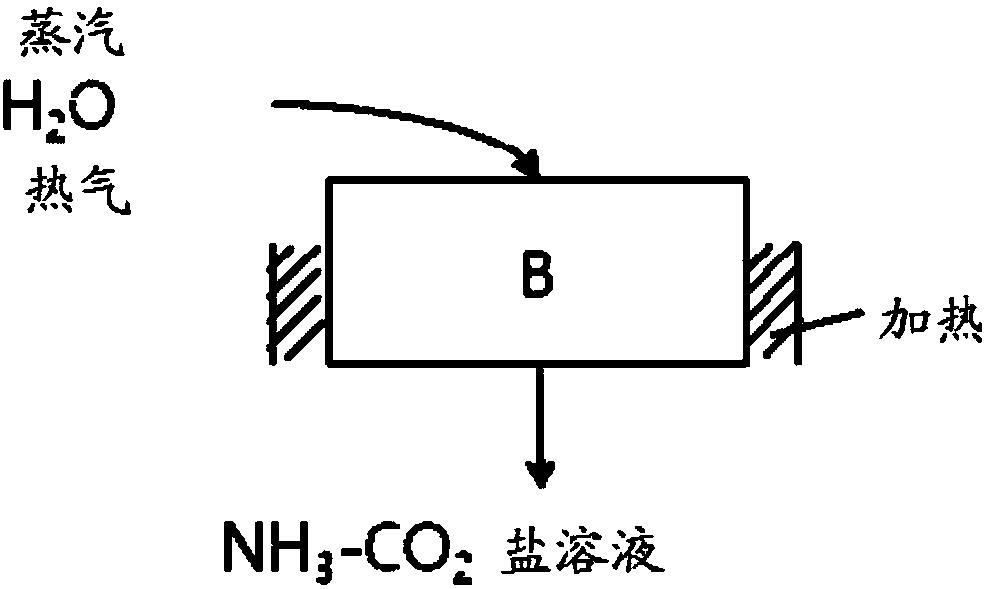

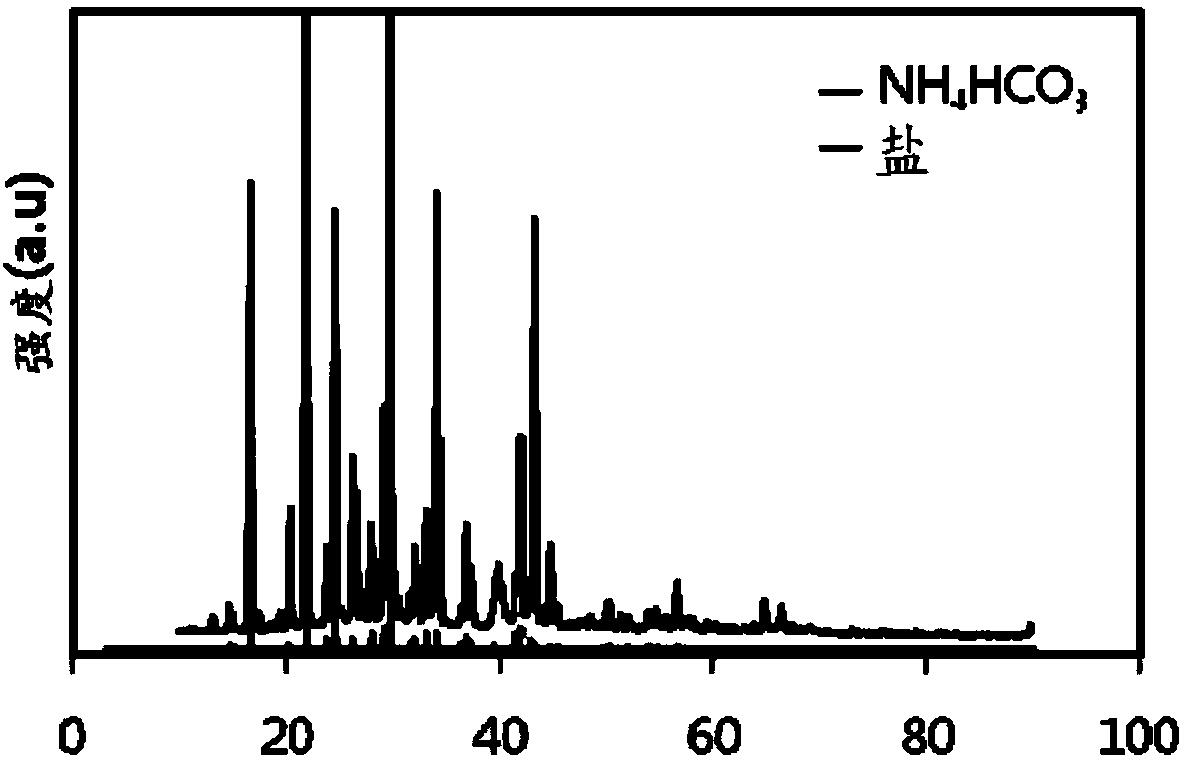

Method for removing carbon dioxide in acidic gas and apparatus therefor

InactiveUS20180361315A1Efficient separationIncrease efficiency economicalGas treatmentDispersed particle separationSlurryCoke oven

Provided is a method for removing carbon dioxide in acidic gas and an apparatus therefor. A method for removing carbon dioxide in acidic gas includes: purifying coke oven gas to prepare acidic gas; injecting ammonia into the acidic gas and adjusting a molar ratio of carbon dioxide to ammonia in an entire mixed stream to 0.5 or more; indirectly cooling the mixed stream to form a salt; removing the salt in a form of slurry; heating the salt in the removed slurry to decompose the salt into carbon dioxide gas, ammonia gas, and water; and recovering the decomposed ammonia gas.

Owner:POHANG IRON & STEEL CO LTD

Equipment for the mechanical separation of oil and bitumen from gas condensates

An apparatus for the mechanical separation of oil and tar from gas condensate, which comprises a tank which is equipped with a container to be traversed by gas condensate, which contains metallurgical coke, and with parallel plate separators, wherein partitions divide the container volume into compartments in which the oil and the tar settle from the gas condensate under the influence of gravity.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

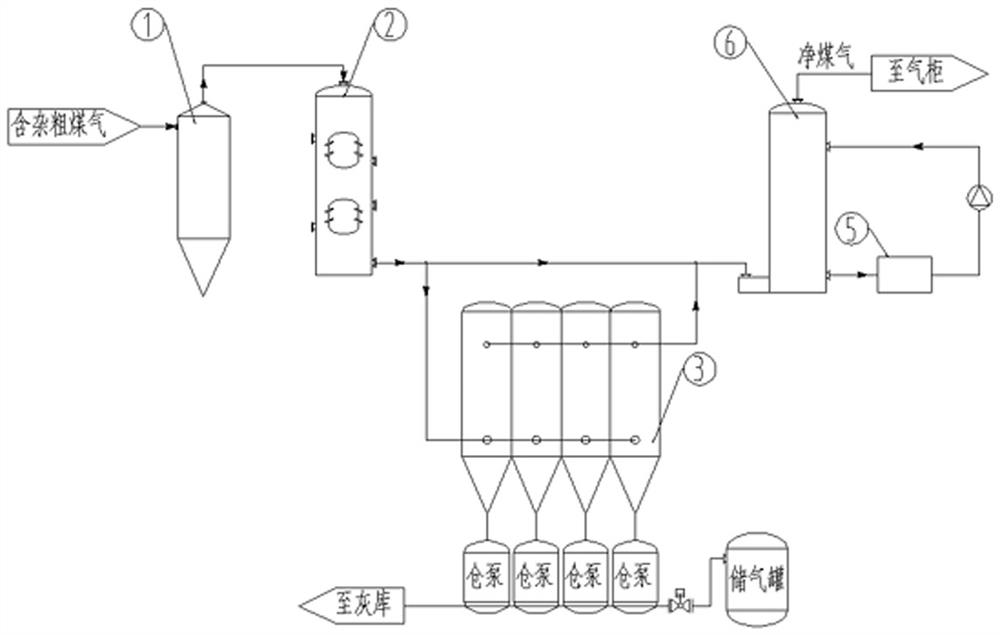

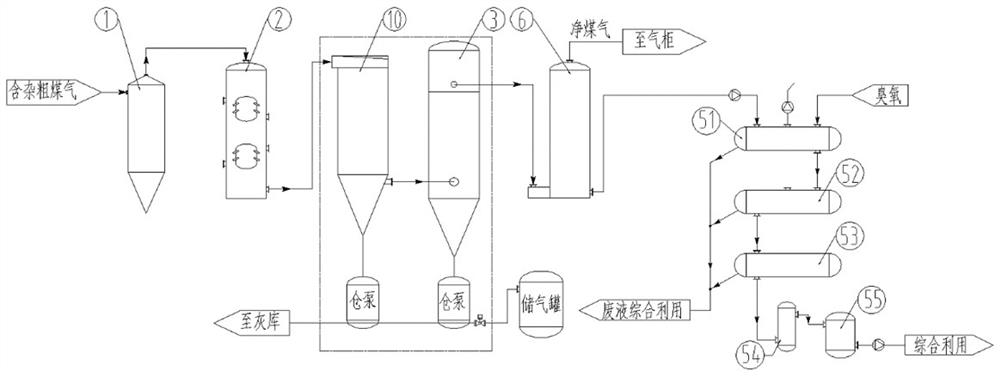

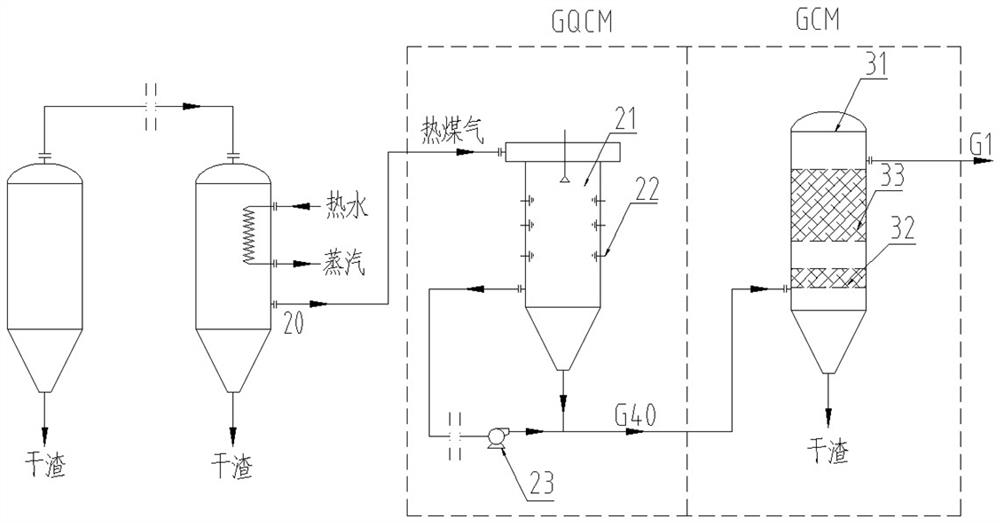

A coal-to-gas multi-pollutant purification and treatment system

ActiveCN112226250BSimple ingredientsLess corrosiveEnergy inputGas contaminants removalGas solidHazardous substance

The present invention provides a coal-to-gas multi-pollutant purification and treatment system, which is suitable for upgrading, purifying, converting and utilizing crude gas containing miscellaneous gases, which includes a process for upgrading and purifying synthetic gas and a process for multi-channel flexible treatment of incremental waste water; The crude gas containing impurities is removed from the primary effect gas-solid separation device and then enters the waste heat exchanger for waste heat recovery. After heat exchange, the gas enters the gas quality control and improvement module for gas modification and upgrading. The gas is input to the high-efficiency gas purification module for gas-solid separation to further remove dust and colloids in the gas. The invention effectively removes the impurities and harmful substances in the synthetic gas, and at the same time, the removal rate of the harmful water-soluble gas exceeds 90%, reduces the corrosivity of the water body, and can realize the goal of subsequent graded treatment.

Owner:上海境业环保能源科技股份有限公司

Device and method for treating low-temperature methanol-washing hydrocarbon-containing exhaust gas

PendingCN110295067AAchieve reuseSimple structureGas contaminants removalGas condensate working-upHeat regenerationChemistry

The invention discloses a device and method for treating low-temperature methanol-washing hydrocarbon-containing exhaust gas, relates to the technical field of coal chemical industry, and involves low-temperature methanol washing. The device includes a coke-oven gas absorption tower, a shift gas absorption tower, a flash column, a carbon dioxide product tower, a hydrogen sulfide concentration tower, a nitrogen stripping tower, a heat regeneration tower, an acid gas separation device, a tail gas water-washing tower and a buffer tank; the upper portion of the flash column is a coke-oven gas treatment section, and the lower portion is a shift gas treatment section; the lower portion of the coke-oven gas absorption tower is connected with the upper portion of flash column, and the coke-oven gas treatment section is connected with the nitrogen stripping tower, the lower portion of the shift gas absorption tower is connected with the lower portion of the flash column, and the shift gas processing section is connected with the carbon dioxide product tower, the hydrogen sulfide concentration tower and the nitrogen stripping tower successively; the nitrogen stripping tower is connected withthe heat regeneration tower, and the heat regeneration tower is connected with the acid gas separation device and the buffer tank. The hydrocarbon-containing flash steam in the coke-oven gas processcan be enriched and recycled, the reuse of waste gas is achieved, and the equipment investment and the operation cost are reduced.

Owner:山西焦煤集团飞虹化工股份有限公司

Production line for preparing liquefied coal gas from mushroom waste materials

PendingCN107353937ASolve pollutionPromote environmental protectionGas purification by catalytic conversionGasification processes detailsProduction lineWood gas generator

The invention provides a production line for preparing liquefied coal gas from mushroom waste materials. The production line comprises a mushroom waste material curing molding set, a coal gas generator, purification equipment, a catalyzing device, a liquefying set and a liquefied coal gas storage tank; and a technological process of carrying out drying, curing and granulation, gasification, purification, catalysis, liquefying and the like on the mushroom waste materials is adopted and the mushroom waste materials are finally transformed into single-component clean liquefied coal gas, so that the environment pollution problem caused by the mushroom waste materials is solved and the environment-protection performance and the economic performance are prominent.

Owner:张娜娜

System for reducing ammonia nitrogen content and method for reducing ammonia nitrogen content

ActiveCN110203986BReduce ammonia nitrogen contentSpecific water treatment objectivesWater contaminantsAmmoniacal nitrogenFluid phase

The invention relates to the technical field of coal gasification and gas conversion, and discloses a system for reducing ammonia nitrogen content and a method for reducing ammonia nitrogen content. The system includes: a high-temperature condensate treatment device, which is used to use the input high-pressure flash steam to strip the input high-temperature shift condensate to produce a high-temperature condensate with ammonia content that meets the conditions, and to strip the stripped steam generated after stripping. After the gas-liquid separation process, the gas-phase products and liquid-phase products are output to the low-temperature condensate treatment device; the low-temperature condensate treatment device is used to use the input low-pressure steam and gas-phase products to strip the liquid-phase products and the input low-temperature shift condensate Produce low-temperature condensate with ammonia content meeting the conditions, and perform gas-liquid separation on the stripping steam generated after stripping to produce ammonia-containing condensate and flash steam non-condensable gas. The invention can reduce the ammonia nitrogen content in the black water and gray water of the gasification process unit, and reduce the ammonia nitrogen content of the gray water discharged from the gasification process unit to the level that the sewage can be better accepted.

Owner:CHINA SHENHUA COAL TO LIQUID & CHEM CO LTD +1

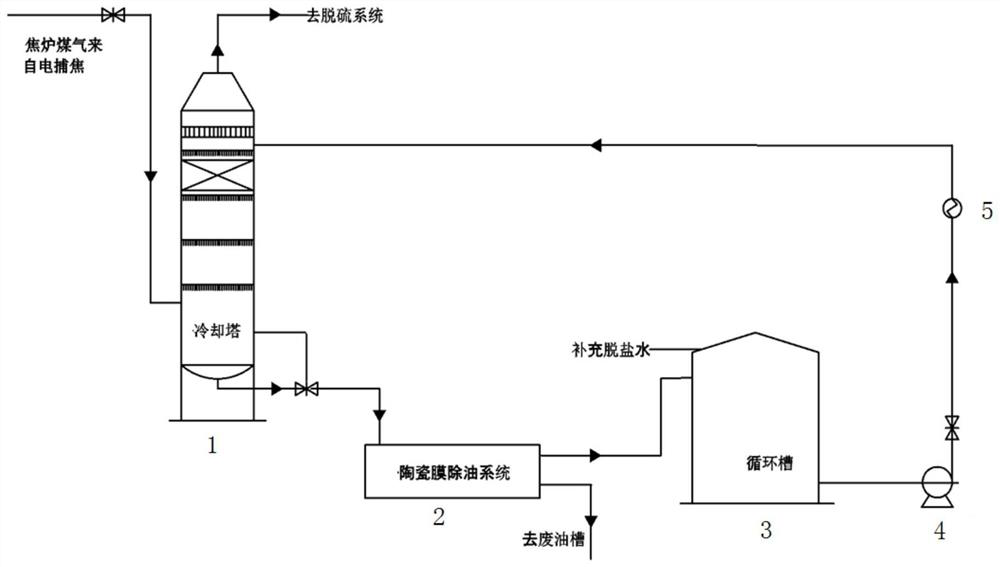

Coke oven gas complex iron cooling pretreatment system and method before desulfurization

PendingCN114250087ASolving Water Balance ProblemsGuarantee continuous and stable operationGas purification by non-gaseous materials condensationGas contaminants removalCooling towerThermodynamics

The invention relates to a cooling pretreatment system and method before desulfurization of coke oven gas complex iron, the system comprises a cooling tower, a ceramic membrane oil removal system, a circulating tank, a circulating pump and a heat exchanger, the cooling tower is a partially hollow tower filled with a layer of filler and a plurality of liquid distributors; according to the system and the method, the coke oven gas subjected to electric coke catching can be cooled, impurities such as tar dust and naphthalene in the coke oven gas subjected to electric coke catching can be deeply removed, and the problem of water balance in a coke oven gas desulfurization system is solved; and the problem that sulfur foams become virtual and even foam due to the fact that impurities such as tar dust and naphthalene are accumulated in the system in coke oven gas complex iron desulfurization is solved, the requirement of complex iron desulfurization for deep purification of the impurities in the coke oven gas is met, and the purpose that the desulfurization system normally floats and separates the sulfur foams and operates continuously and stably is achieved.

Owner:LINHUAN COKING

Method for avoiding expensive sour water stripper metallurgy in a gasification plant

A method of producing syngas comprising receiving raw syngas from a gasification unit; introducing the raw syngas and water to a syngas scrubber to produce unshifted syngas; introducing a first portion of unshifted syngas to a first cooling unit to produce cooled unshifted syngas and a first aqueous condensate comprising cyanide in an amount of 5-200 ppmw; recycling the first aqueous condensate to the syngas scrubber; introducing a second portion of unshifted syngas to a water gas shift unit to produce shifted syngas; introducing the shifted syngas to a second cooling unit to produce cooled shifted syngas and a second aqueous condensate comprising cyanide in an amount of less than 2.5 ppmw; contacting the cooled shifted syngas with the cooled unshifted syngas to produce modified syngas; and introducing the second aqueous condensate to a sour water stripper to produce stripped water and an acid gas comprising H2S, CO2, and ammonia.

Owner:FLUOR TECH CORP

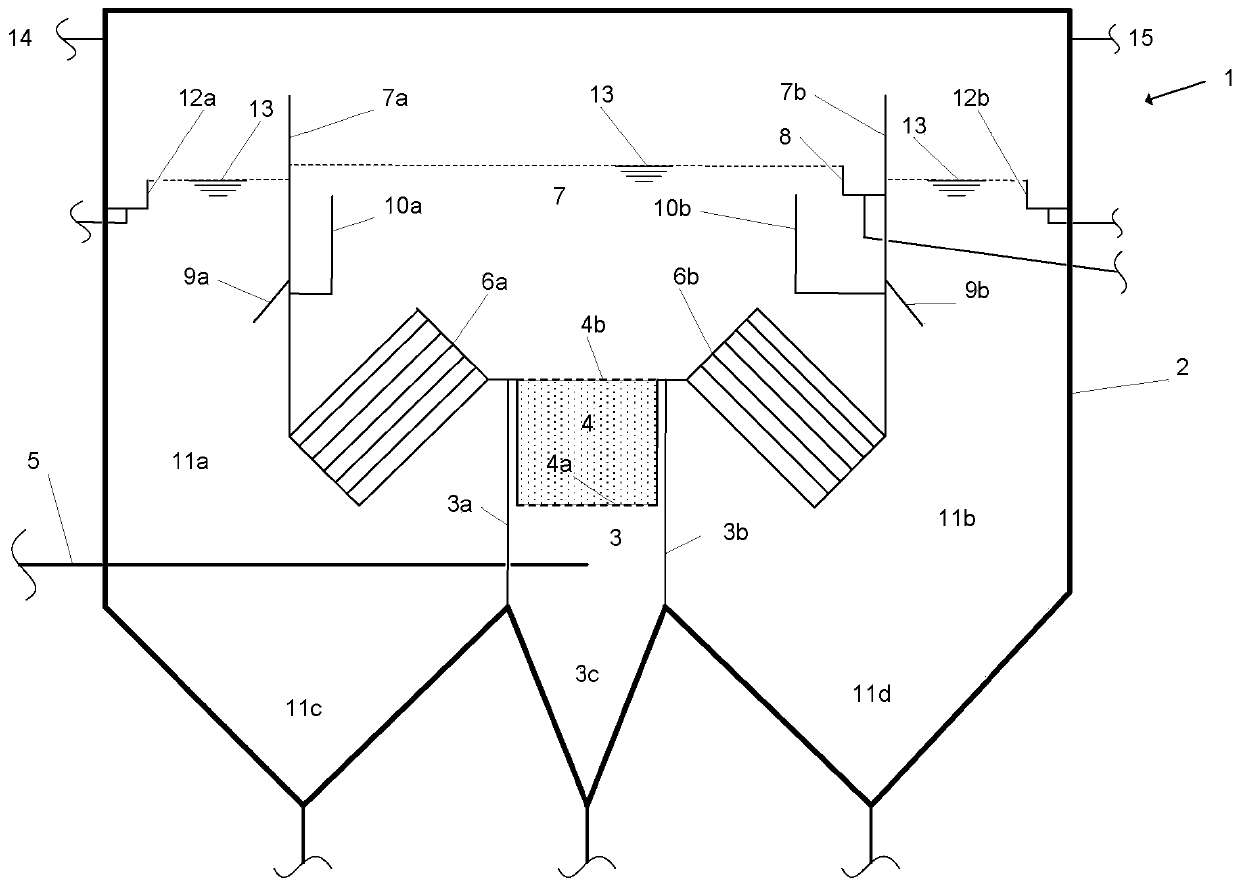

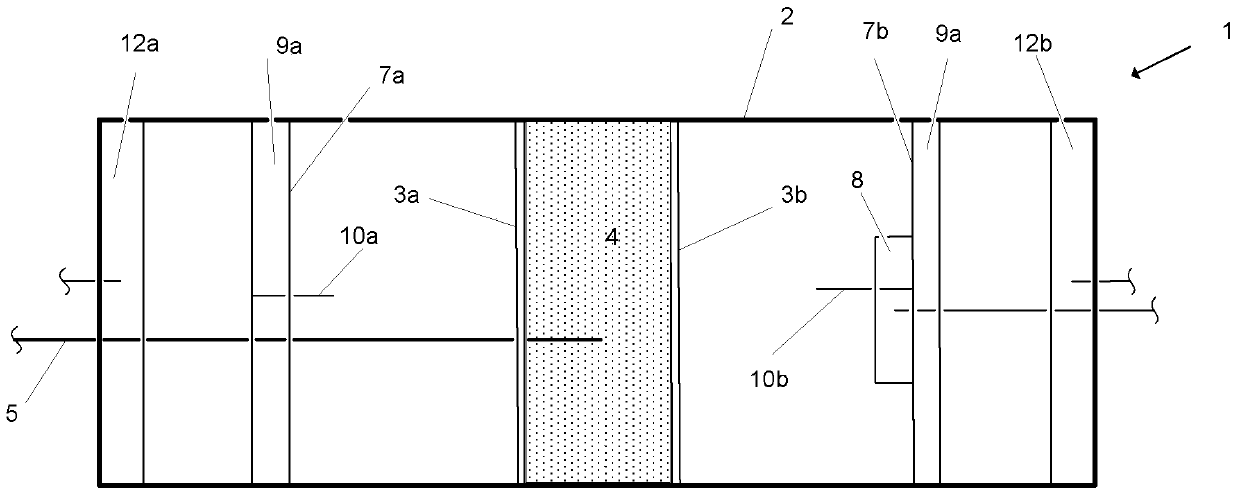

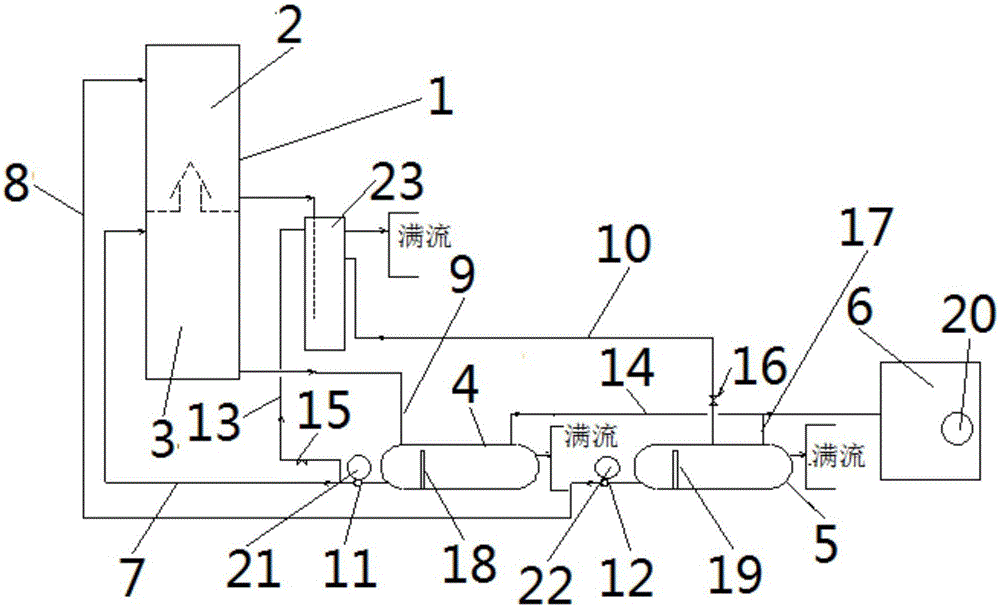

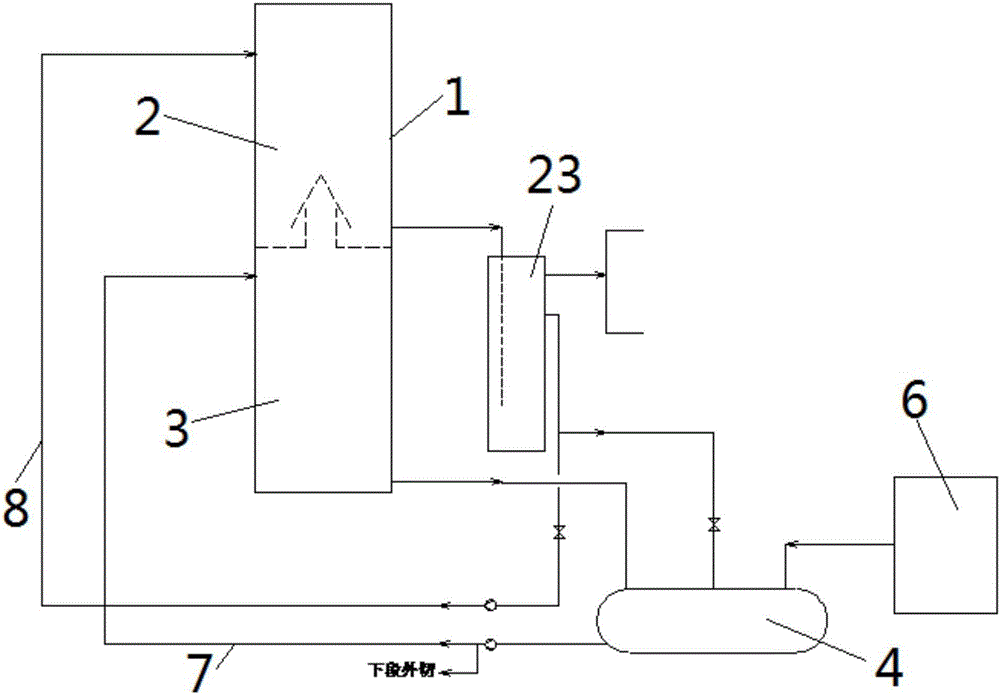

Primary cooler naphthalene-washing device

ActiveCN106753594AStable and efficient workSimple structureGas contaminants removalGas condensate working-upCooling towerEngineering

The invention provides a primary cooler naphthalene-washing device which is applied in the technical field of coke oven parts in iron and steel smelting companies. A primary cooler body (1) of the primary cooler naphthalene-washing device comprises a primary cooler body upper segment (2) and a primary cooler body lower segment (3), wherein a naphthalene-washing slot I (4) and a naphthalene-washing slot II (5) of the primary cooler naphthalene-washing device communicate with an oil supplement component (6); the naphthalene-washing slot I (4) communicates with the primary cooler body lower segment (3); the naphthalene-washing slot II (5) communicates with the primary cooler body upper segment (2). The primary cooler naphthalene-washing device provided by the invention has a simple structure, the temperature of coal gas passing through the primary cooler body can be lowered, the water consumption in a coal gas cooling process is lowered, the production and running cost is lowered, blocking of the primary cooler naphthalene-washing device is reduced, the resistance of the primary cooler body is kept controllable, stable running of the primary cooler naphthalene-washing device is ensured, the cleaning frequency of a primary cooler is lowered, the service life of the device is prolonged, and the filler replacing frequency of a final cooling tower is lowered.

Owner:MAANSHAN IRON & STEEL CO LTD

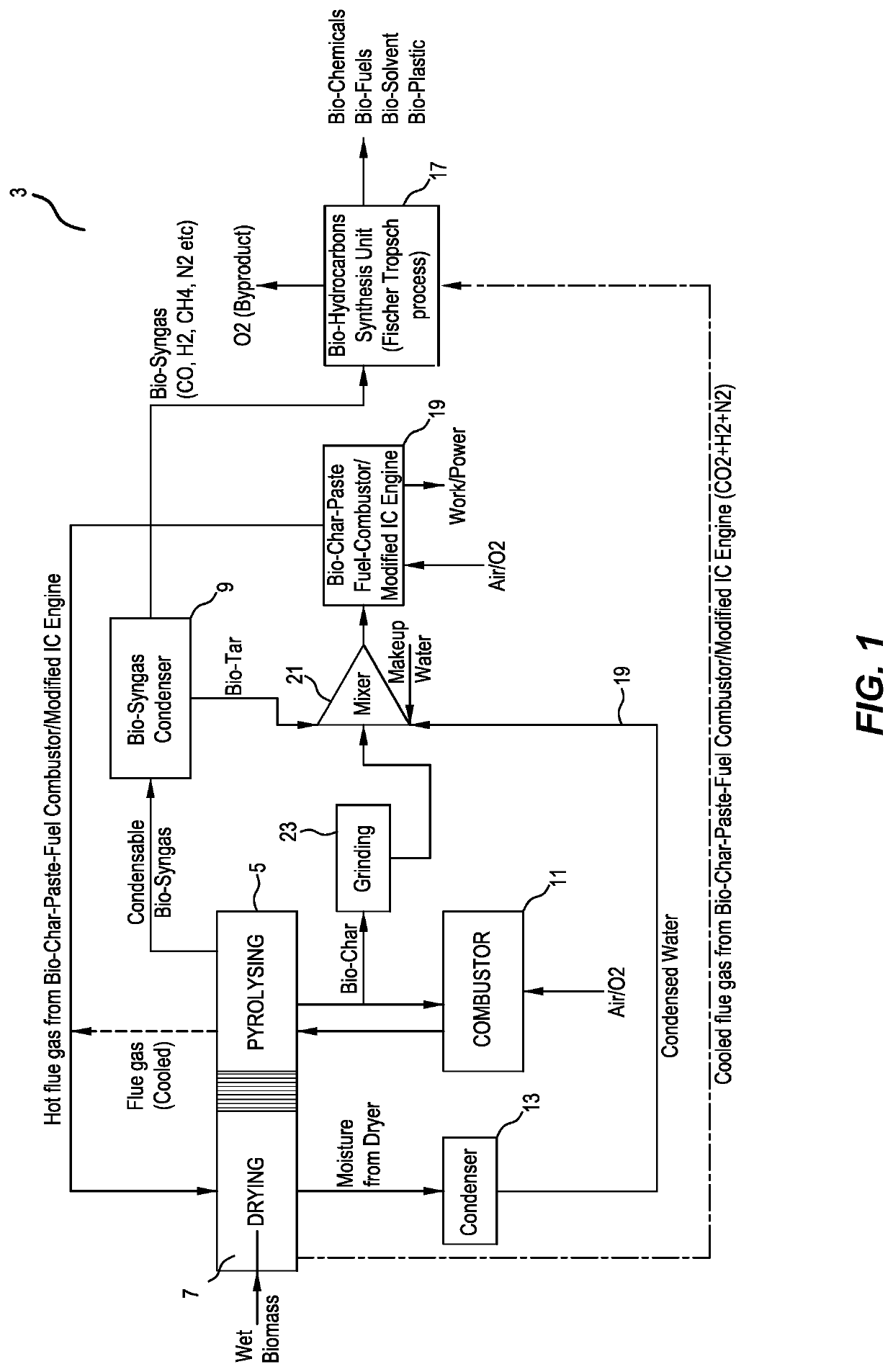

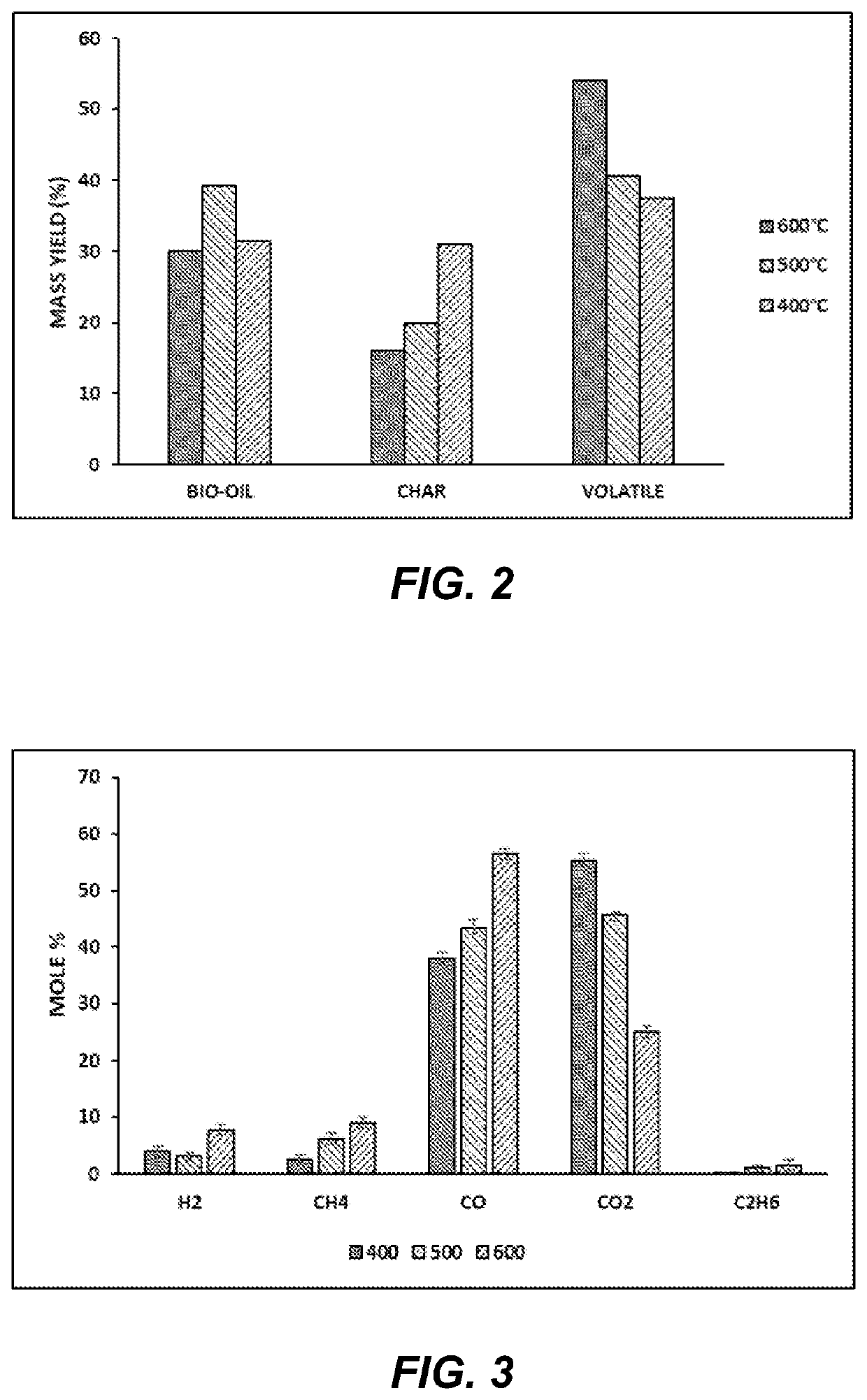

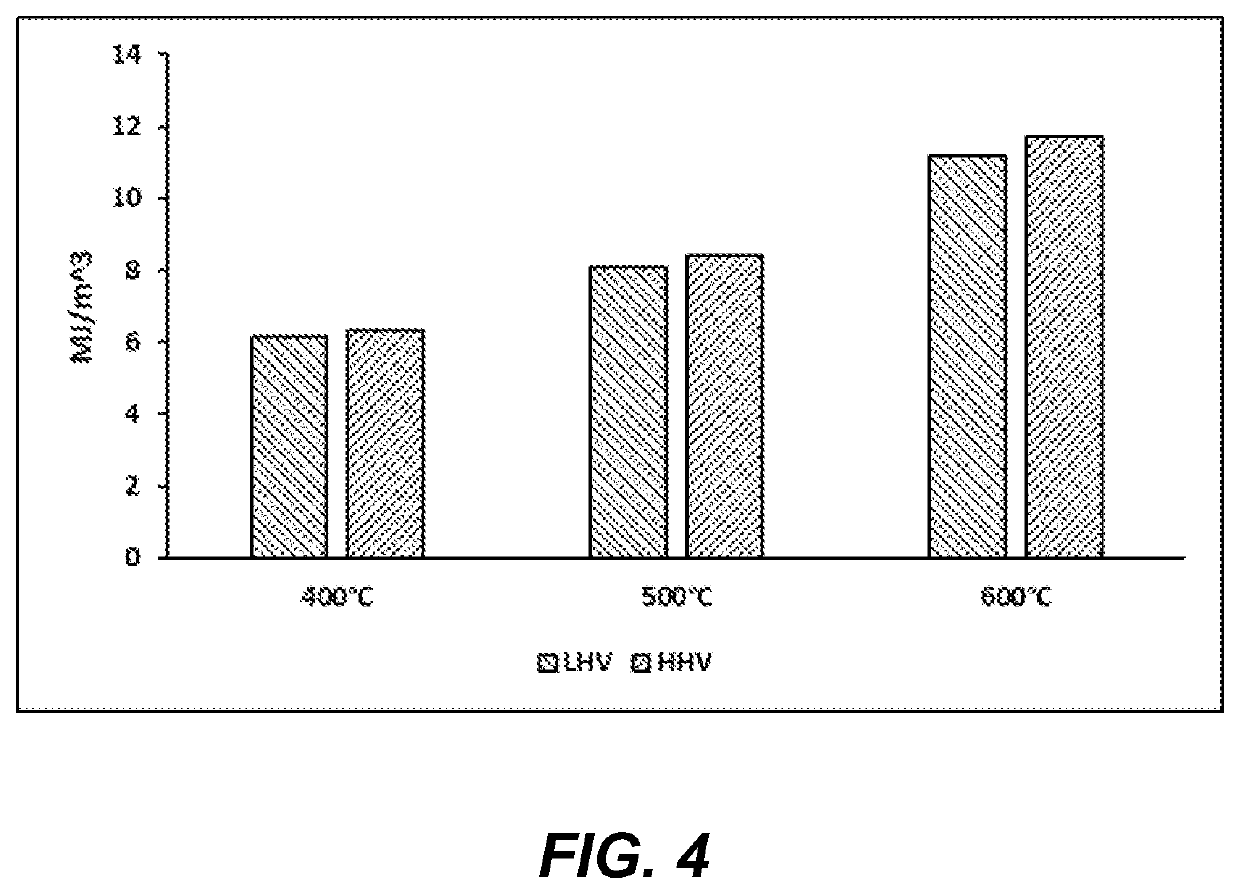

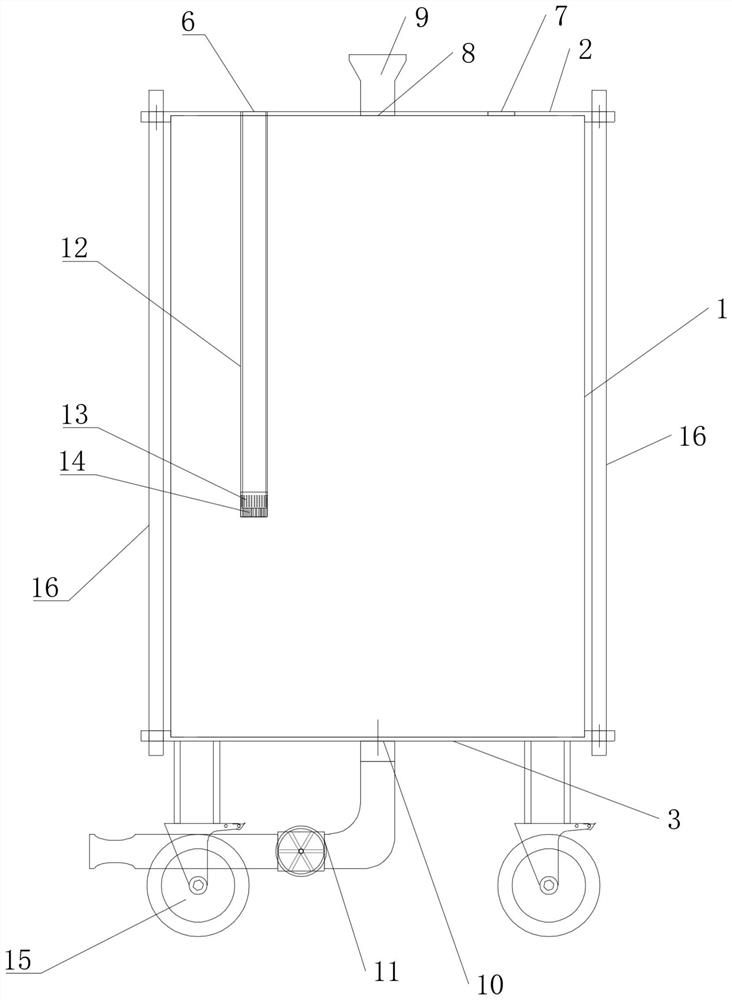

Production of products from biomass

PendingUS20220306940A1Maximising production and recoveryMaximize processingCombustible gas catalytic treatmentLiquid hydrocarbon mixture recoveryBiofuelEnvironmental engineering

Owner:HERMAL BIO ENERGY INT PTY LTD

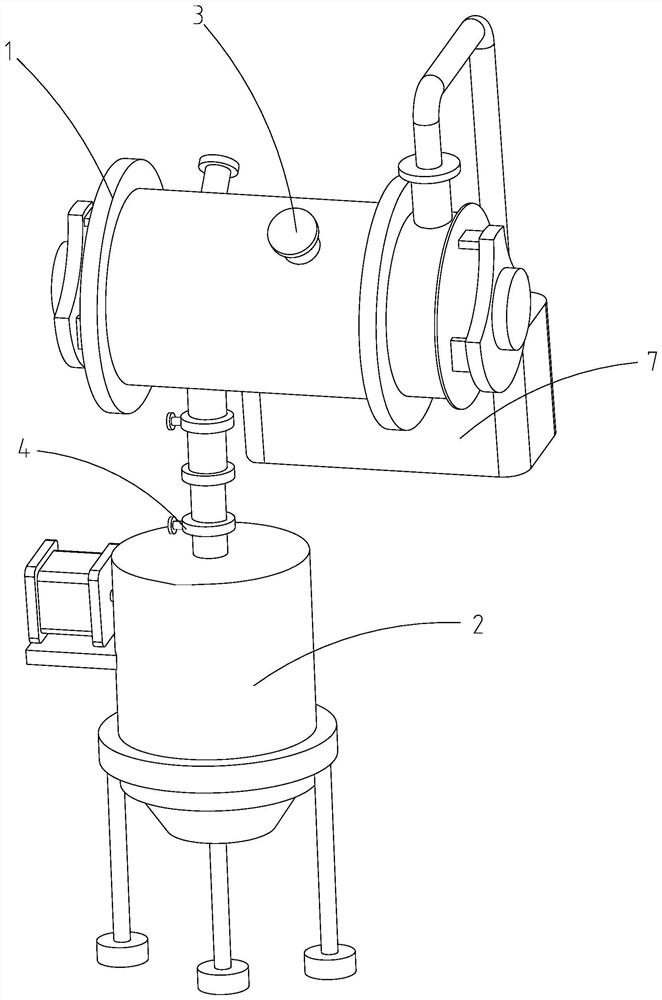

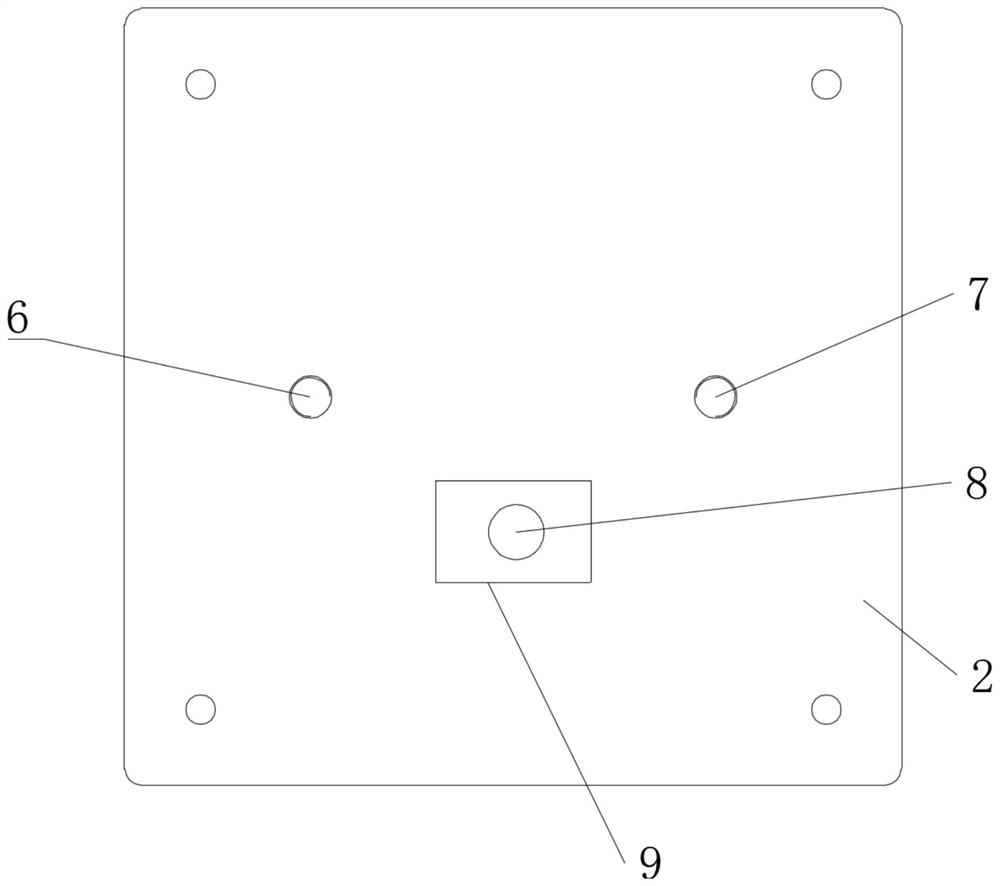

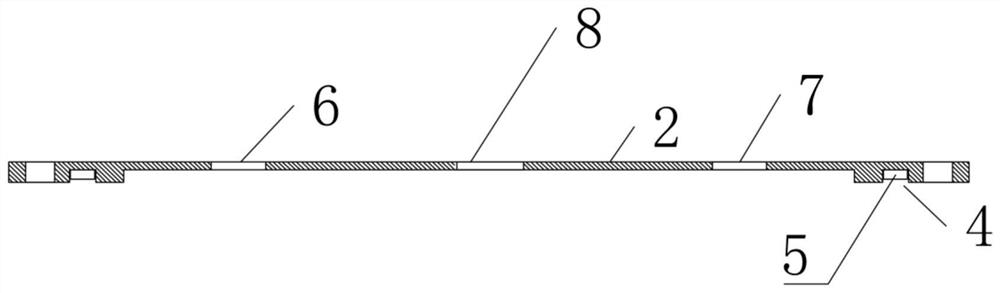

Washing device for Lurgi coal gasifier outlet sample gas pretreatment system

PendingCN113604257ASafe entryEasy accessGas purification by non-gaseous materials condensationGas contaminants removalPressure stabilizationMonitoring system

The invention relates to the technical field of gasification furnaces, in particular to a washing device for a Lurgi coal gasifier outlet sample gas pretreatment system, which comprises a tank body with an open upper end and an open lower end , an upper flange cover and a lower flange cover, circumferential ring grooves are formed in the positions, corresponding to the edges of openings in the upper end and the lower end of the tank body, of the lower side face of the upper flange cover and the upper side face of the lower flange cover respectively, the upper flange cover and the lower flange cover are connected through a long screw rod, an air inlet, an air outlet and a water inlet which are communicated with the interior of the tank body are formed in the upper flange cover, and an air inlet pipe is arranged in the tank body. The upper end of the air inlet pipe is communicated with the air inlet, a water inlet ball valve is arranged at the position, corresponding to the water inlet, of the upper flange cover, the oil removal and pressure stabilization effects can be well achieved, and measurement sample gas is provided for a subsequent online monitoring system.

Owner:浙江赫能环境科技有限公司

Method for removing carbon dioxide in acidic gas and apparatus therefor

InactiveCN108290112AEfficient separationImprove economyGas treatmentDispersed particle separationCoke ovenSlurry

The present invention relates to a method for removing carbon dioxide in acidic gas and an apparatus therefor. An embodiment of the present invention provides a method for removing carbon dioxide in acidic gas, the method comprising the steps of: purifying coke gas to prepare acidic gas; introducing ammonia into the acidic gas and then regulating the molar ratio of carbon dioxide to ammonia to 0.5or higher in the entire mixture stream; indirectly cooling the mixture stream to produce salt; removing the salt in the form of a slurry; heating the salt in the removed slurry to decompose the sameinto carbon dioxide gas, ammonia gas, and water; and collecting the decomposed ammonia gas.

Owner:POHANG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com