Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

193 results about "Wood gas generator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A wood gas generator is a gasification unit which converts timber or charcoal into wood gas, a syngas consisting of atmospheric nitrogen, carbon monoxide, hydrogen, traces of methane, and other gases, which - after cooling and filtering - can then be used to power an internal combustion engine or for other purposes. Historically wood gas generators were often mounted on vehicles, but present studies and developments concentrate mostly on stationary plants.

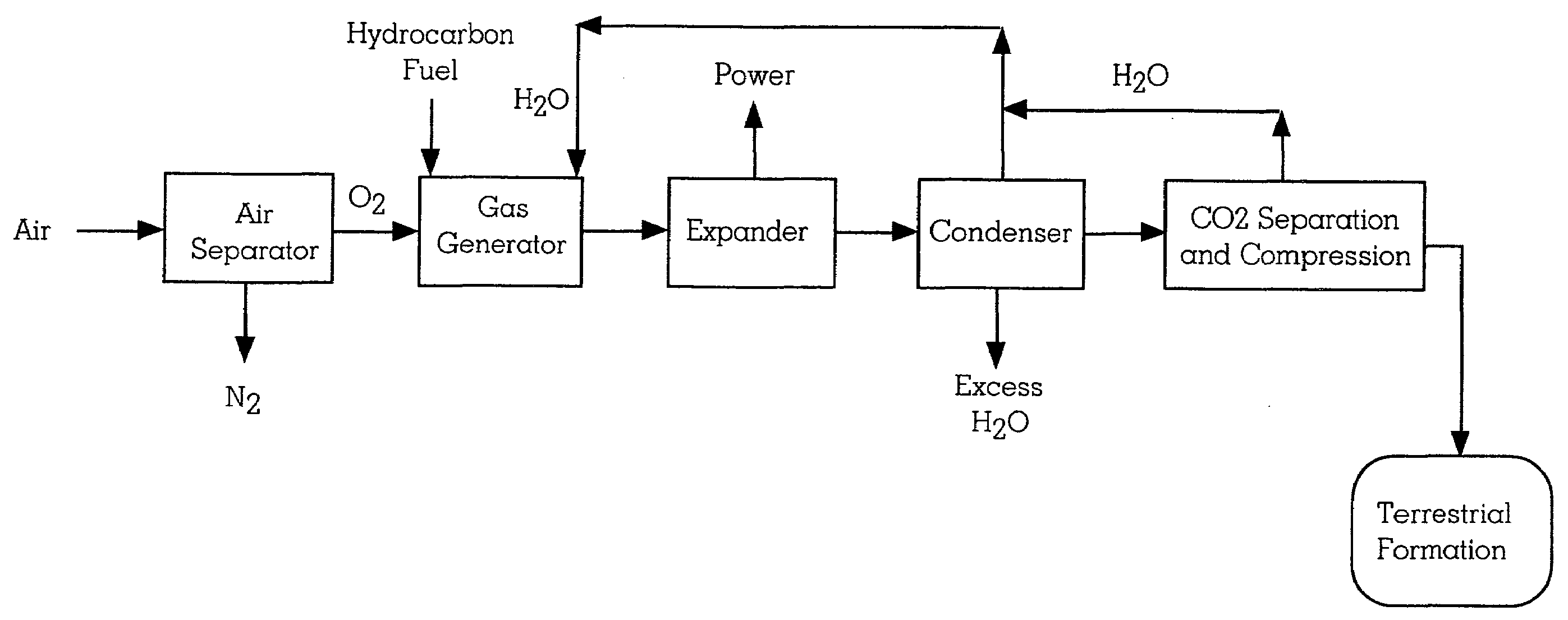

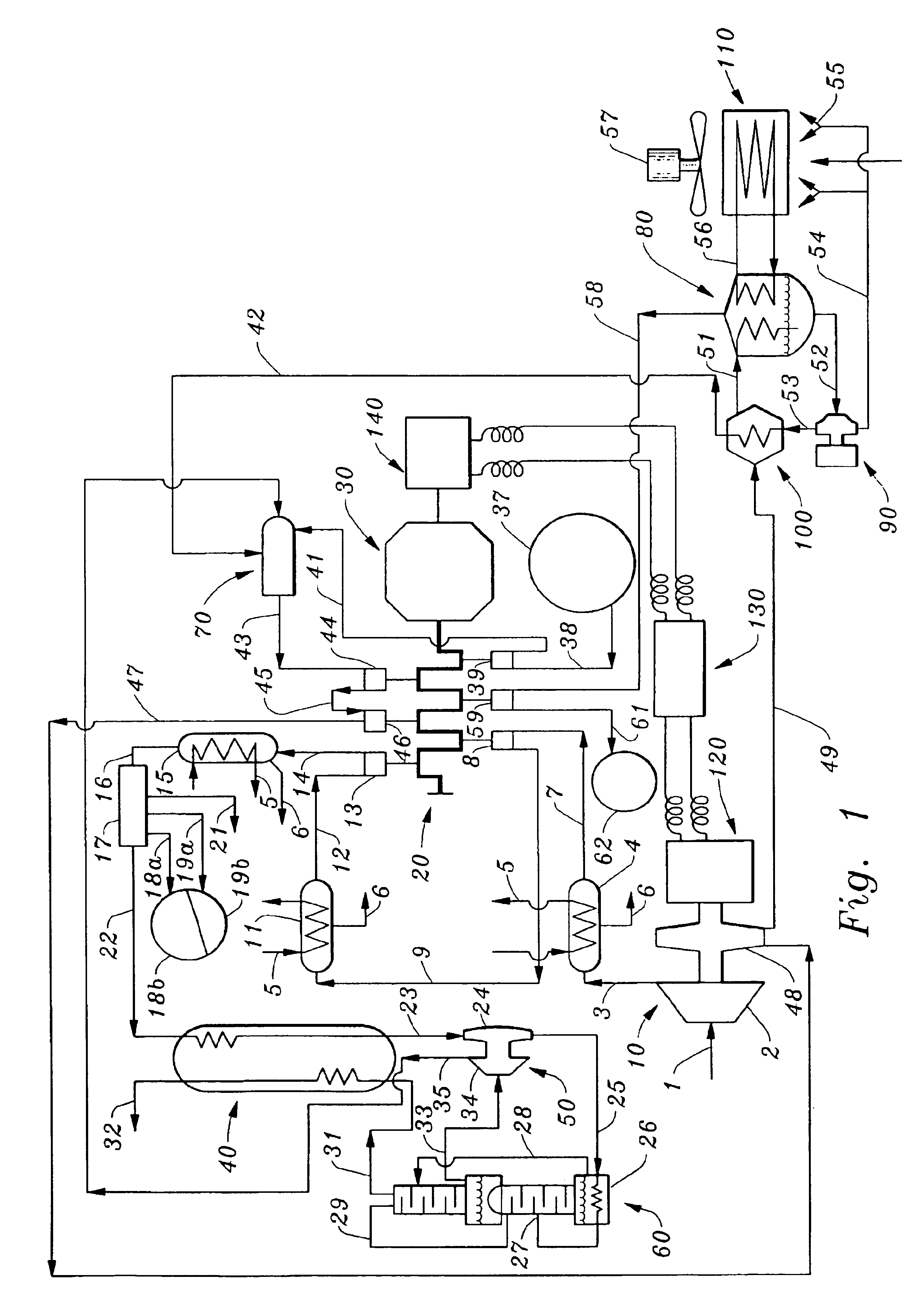

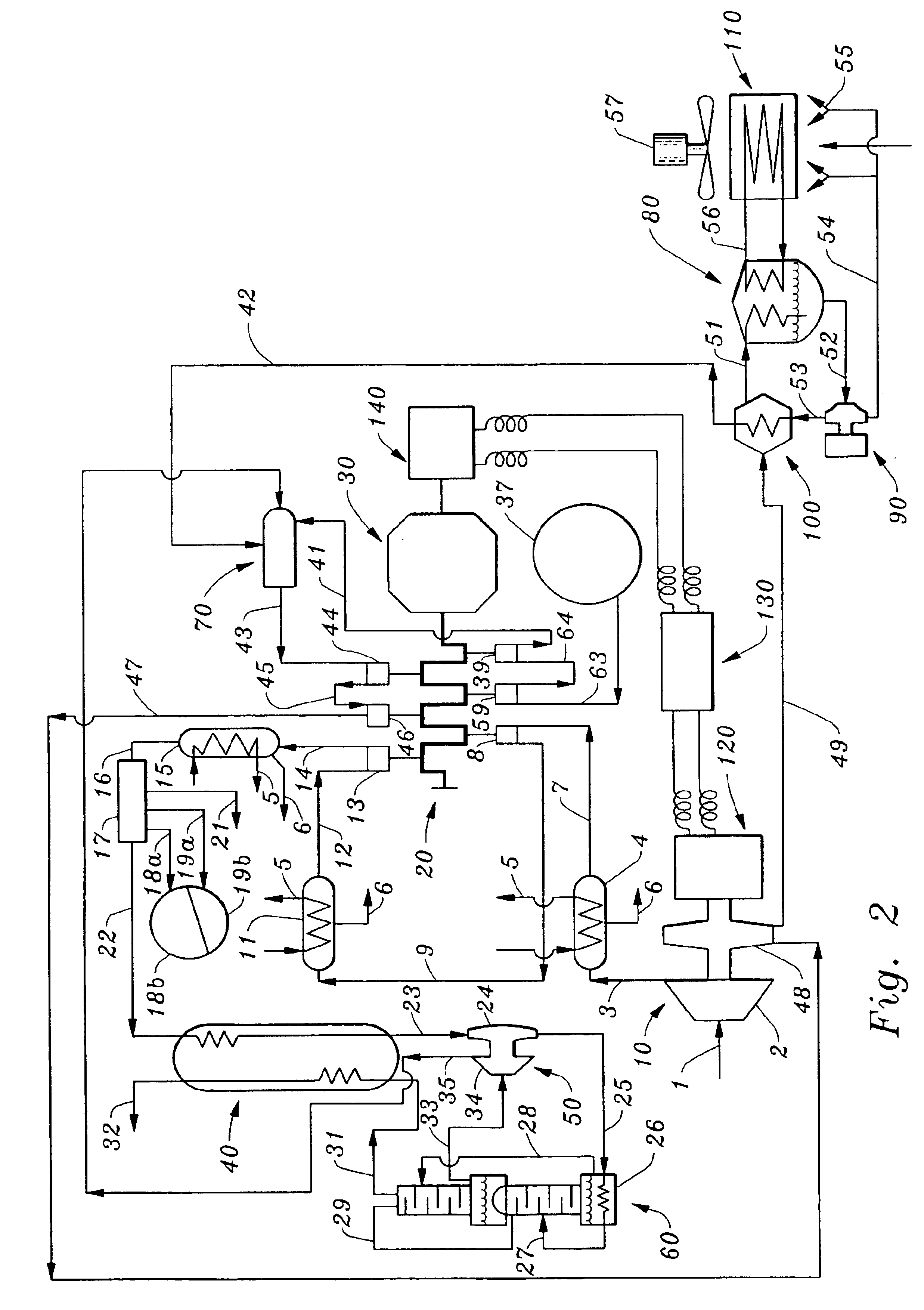

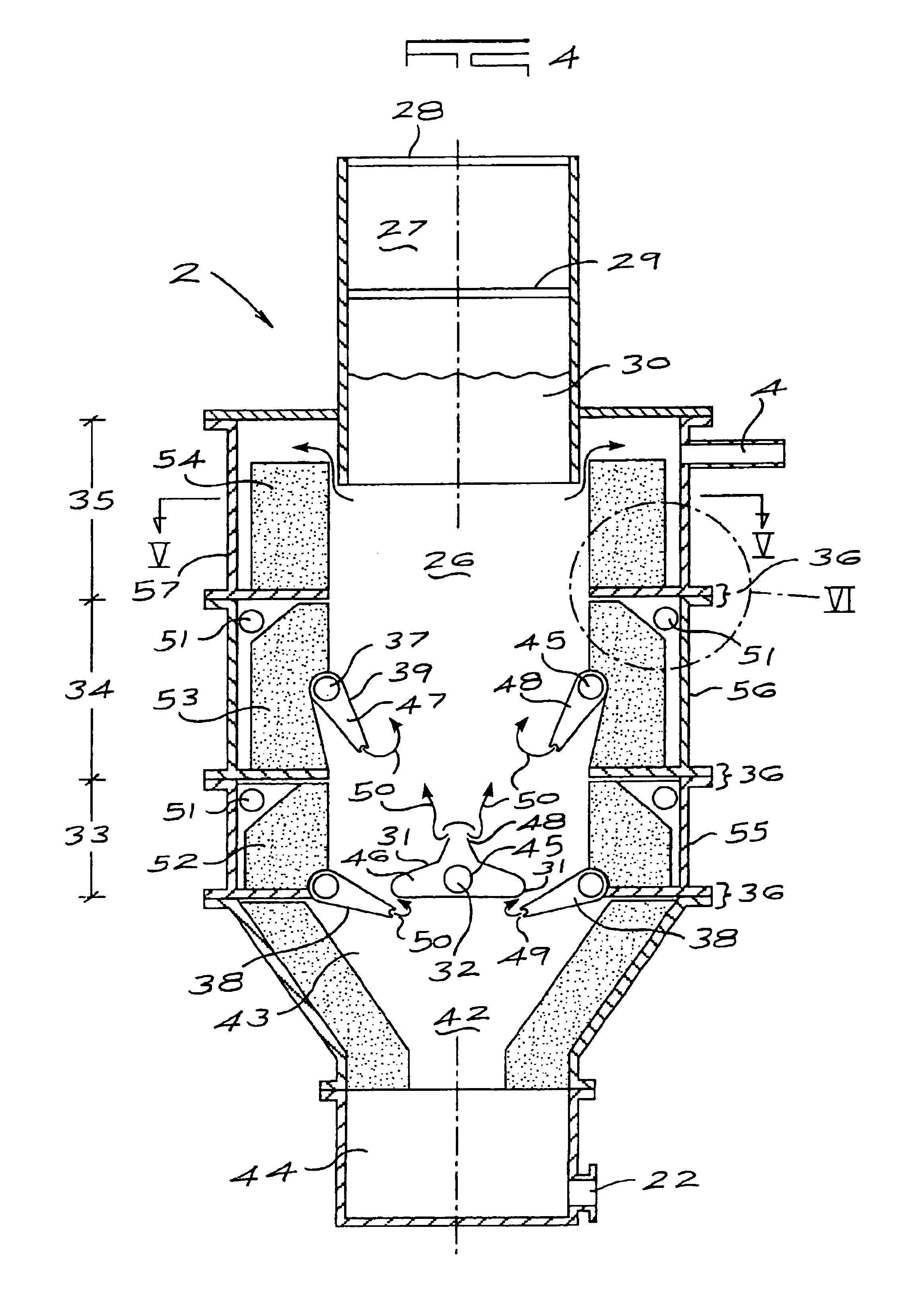

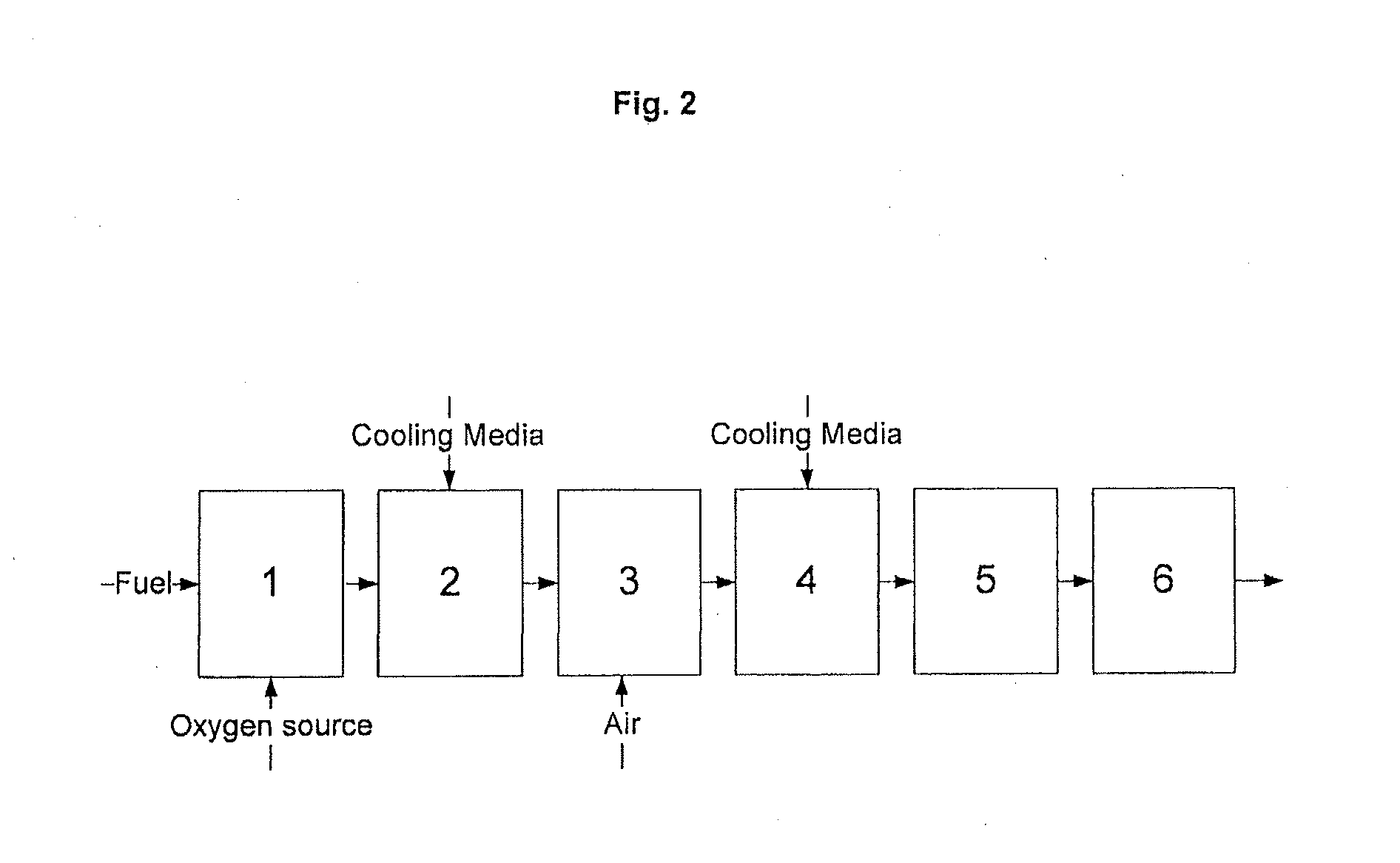

Hydrocarbon combustion power generation system with CO2 sequestration

InactiveUS7043920B2Eliminate needReduce electricity demandReciprocating combination enginesSolidificationAtmospheric airOxygen

A low or no pollution engine is provided for delivering power for vehicles or other power applications. The engine has an air inlet which collects air from a surrounding environment. At least a portion of the nitrogen in the air is removed. The remaining gas is primarily oxygen, which is then routed to a gas generator. The gas generator has inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. The combustion products are then expanded through a power generating device, such as a turbine or piston expander to deliver output power for operation of a vehicle or other power uses. The combustion products are then passed through a condenser where the steam is condensed and the carbon dioxide is collected or discharged. A portion of the water is routed back to the gas generator. The carbon dioxide is compressed and delivered to a terrestrial formation from which return of the CO2 into the atmosphere is inhibited.

Owner:CLEAN ENERGY SYST

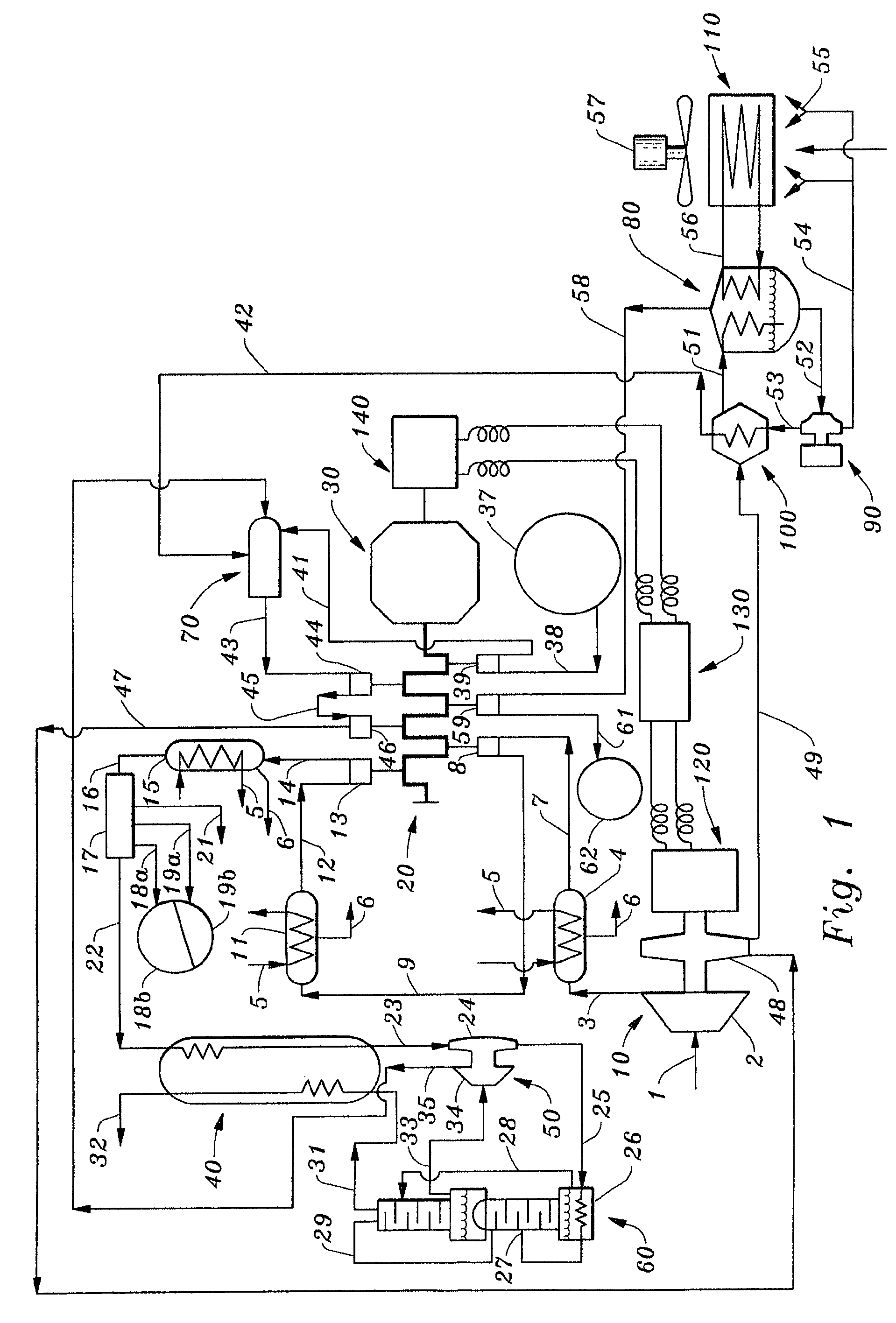

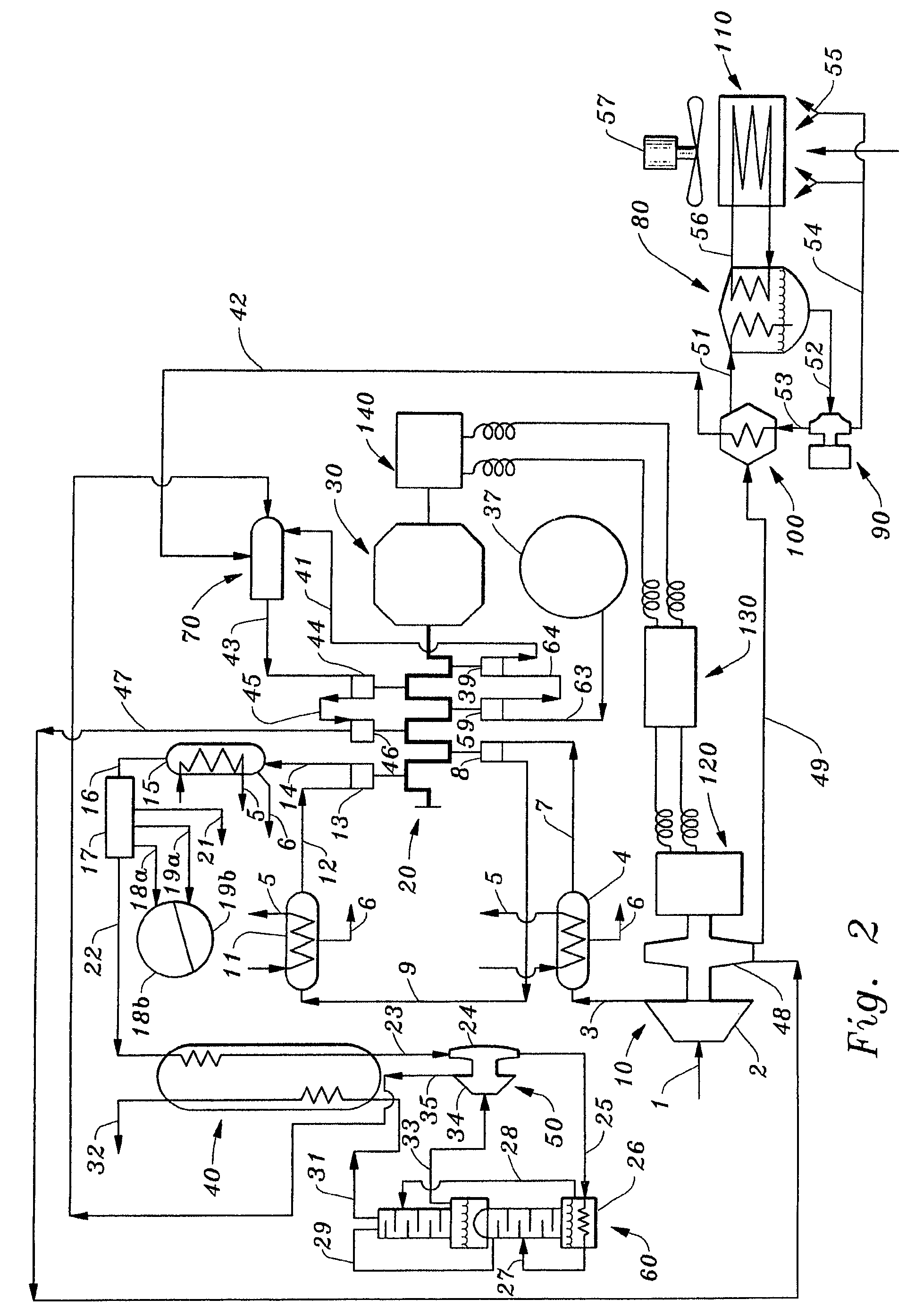

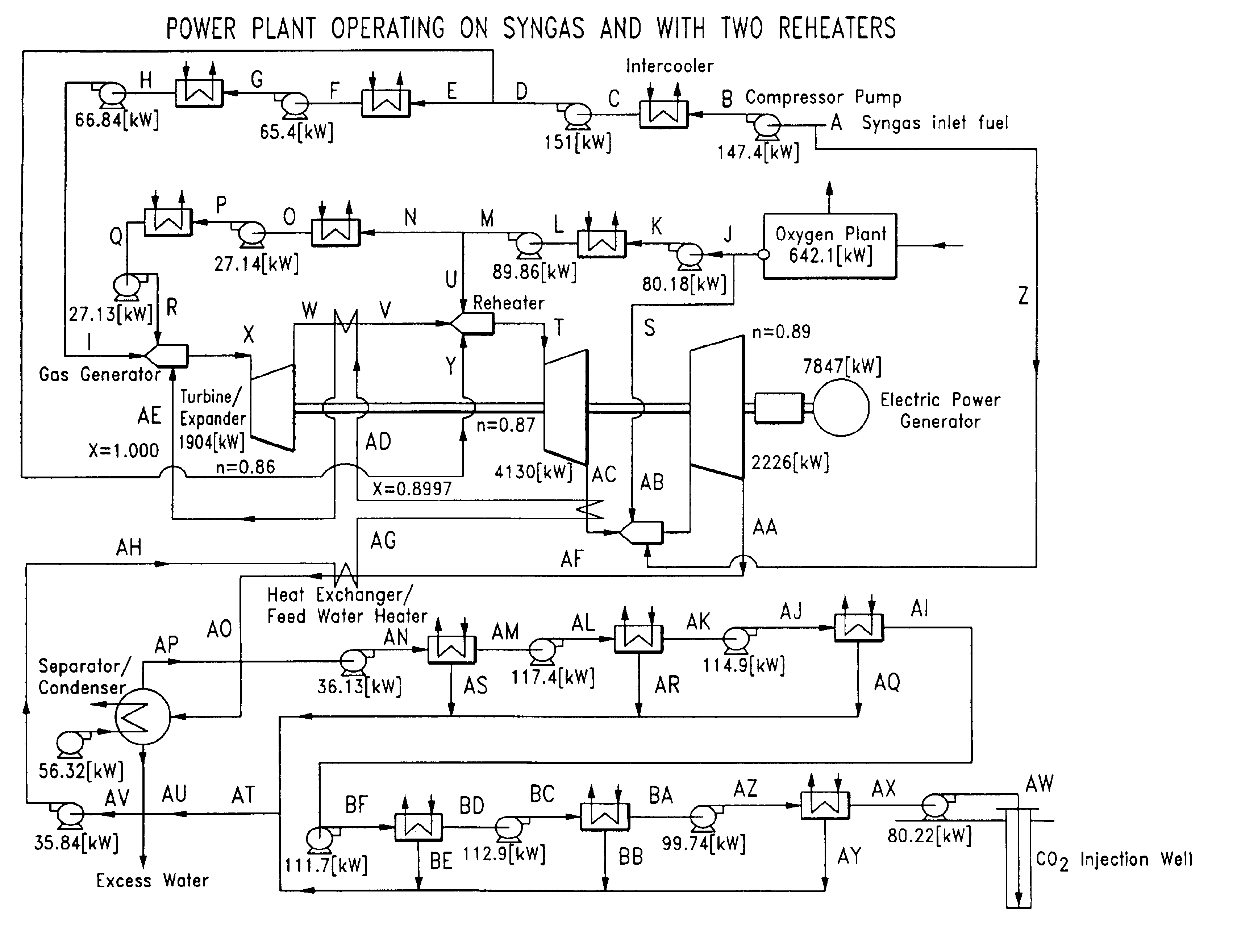

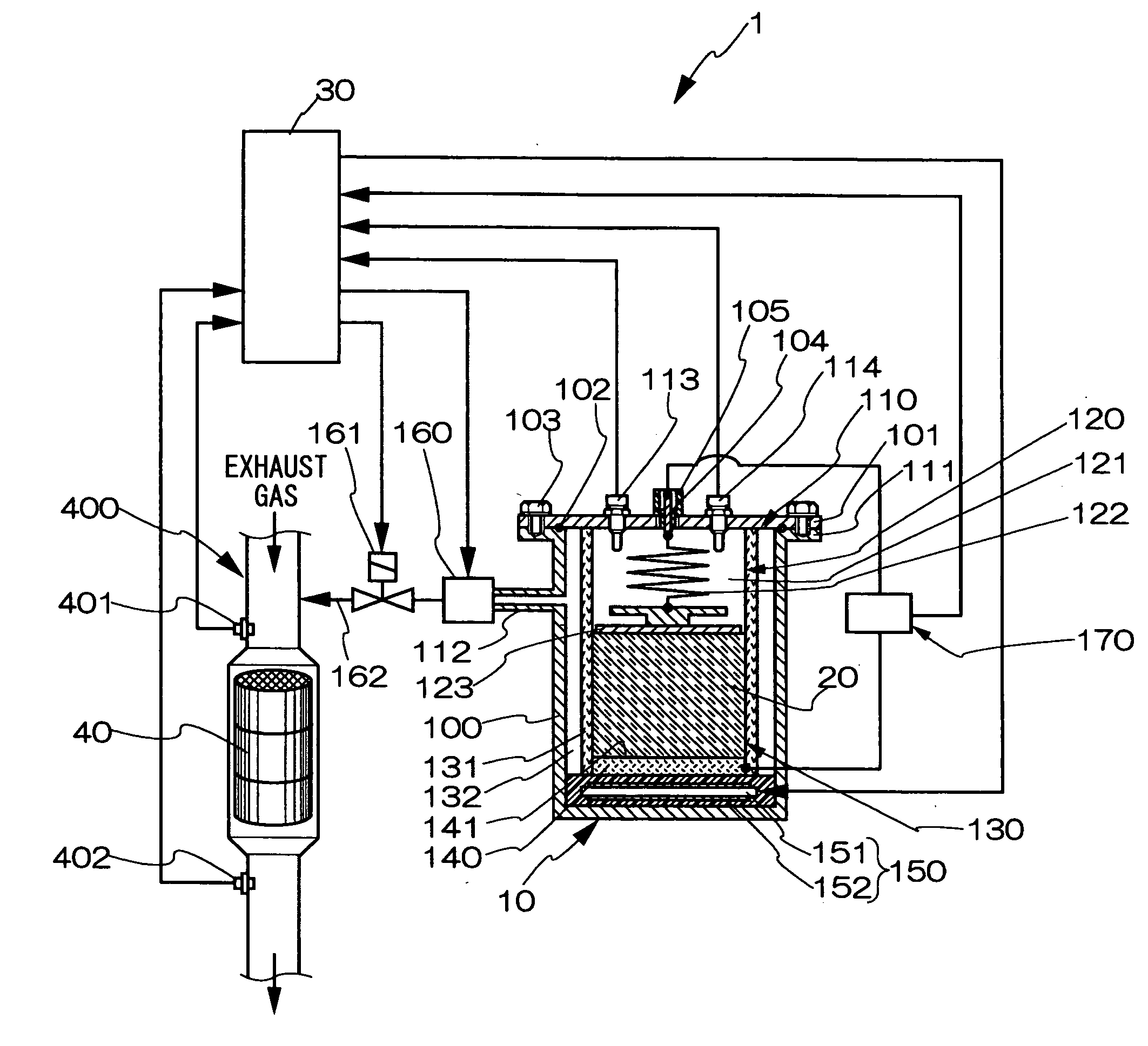

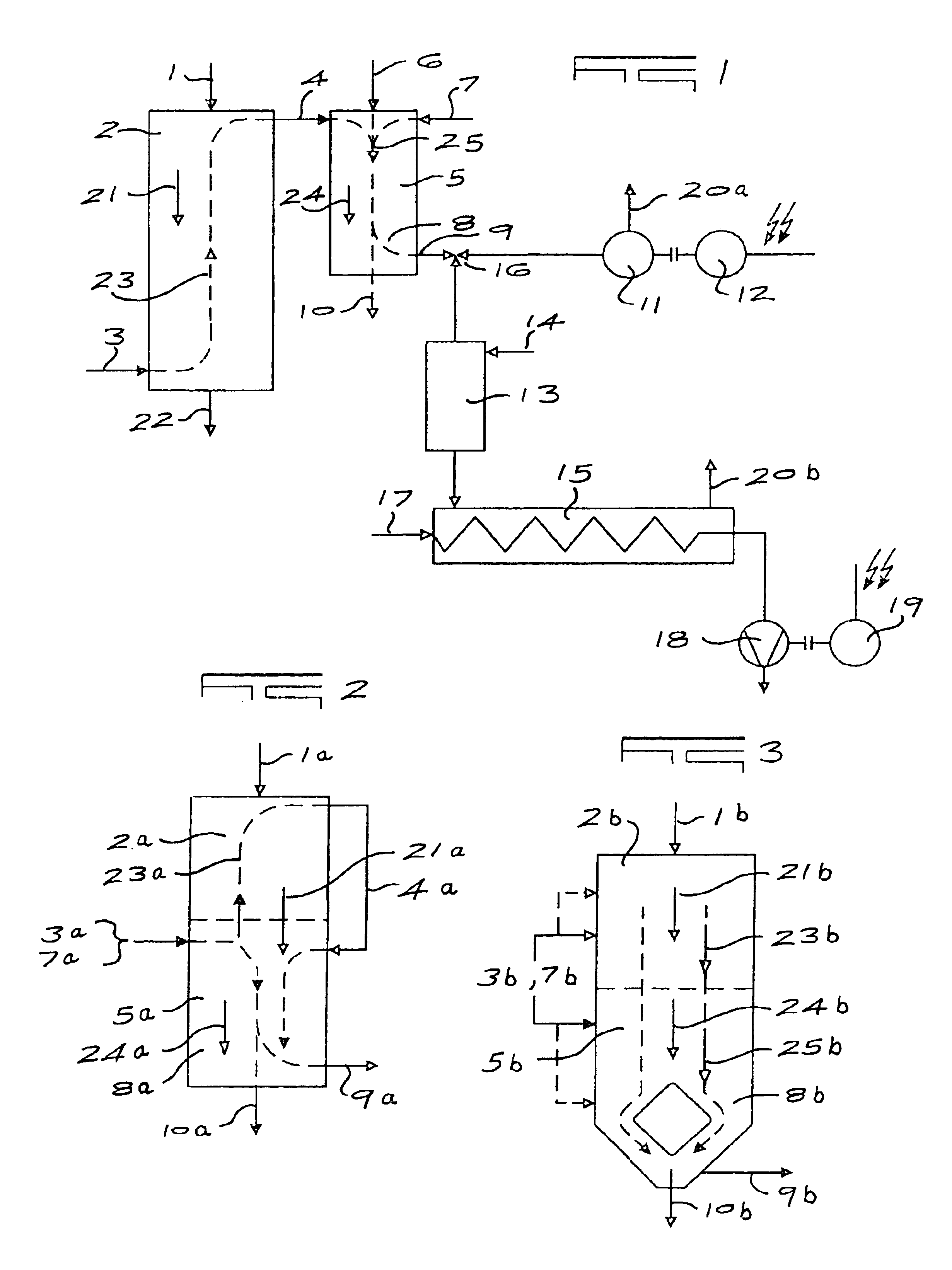

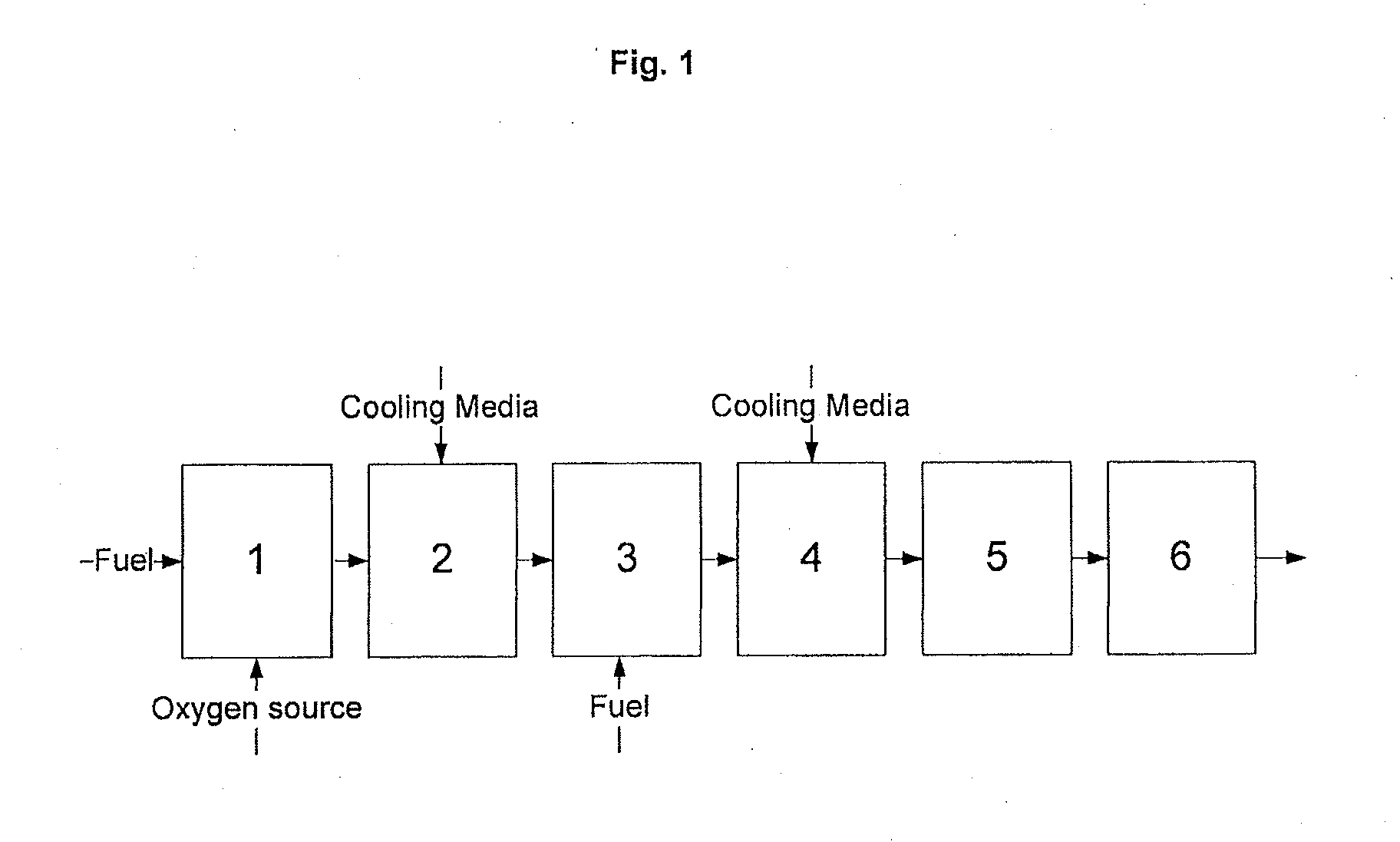

Low pollution power generation system with ion transfer membrane air separation

InactiveUS6945029B2Nitrogen oxideReduce electricity demandSolidificationLiquefactionPollutionCombustion products

A low or no pollution power generation system is provided. The system has an air separator to collect oxygen. A gas generator is provided with inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. Water or other diluents are also delivered into the gas generator to control temperature of the combustion products. The combustion products are then expanded through at least one turbine or other expander to deliver output power. The combustion products are then passed through a separator where the steam is condensed. A portion of the water is discharged and the remainder is routed back to the gas generator as diluent. The carbon dioxide can be conditioned for sequestration. The system can be optimized by adding multiple expanders, reheaters and water diluent preheaters, and by preheating air for an ion transfer membrane oxygen separation.

Owner:CLEAN ENERGY SYST

Gas generating agent composition and gas generator

InactiveUS6517647B1Improve thermal stabilityImprove reliabilityNon-explosive desensitisers/phlegmatisersPressure gas generationSorbentDecomposition

A gas generating composition having an improved thermal stability of a fuel is obtained.A gas generating compostion comprising a gas generating agent containing a non-sodium azide compound fuel and an oxidizing agent, and an adsorbent. Since substances accelerating decomposition of a fuel, such as radicals generating by decomposition of the fuel are adsorbed and kept on the adsorbent, further decomposition of the fuel is inhabited, so that the thermal stability is increased.

Owner:DAICEL CHEM IND LTD

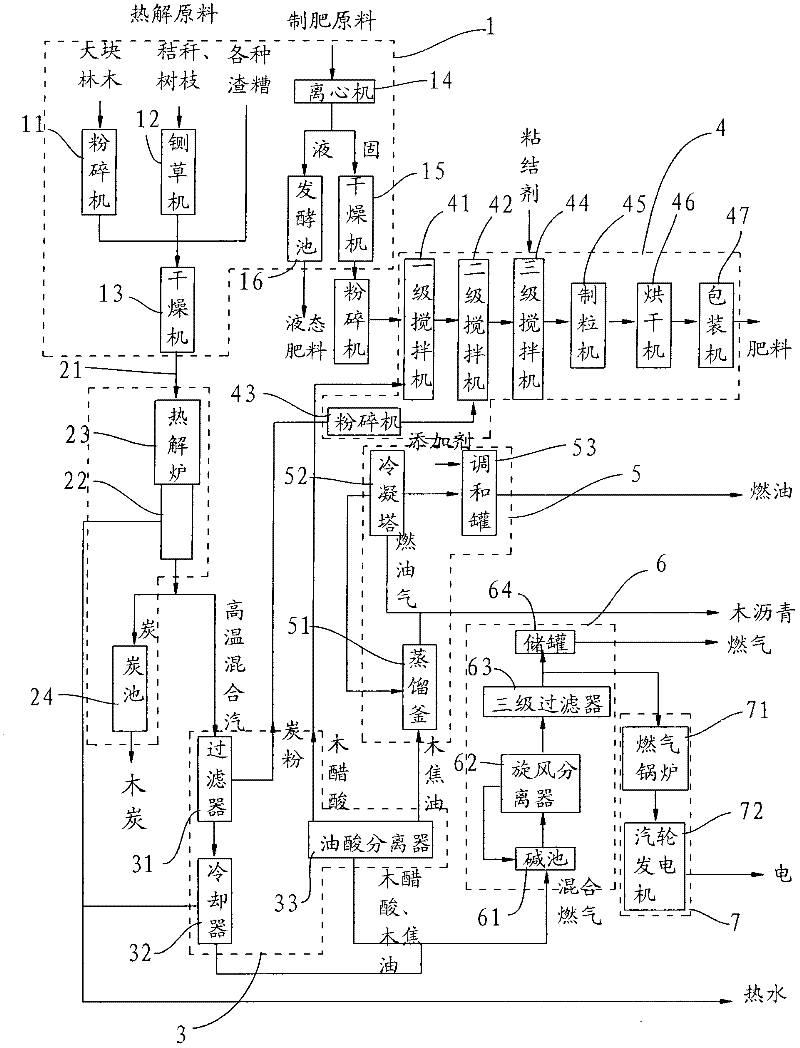

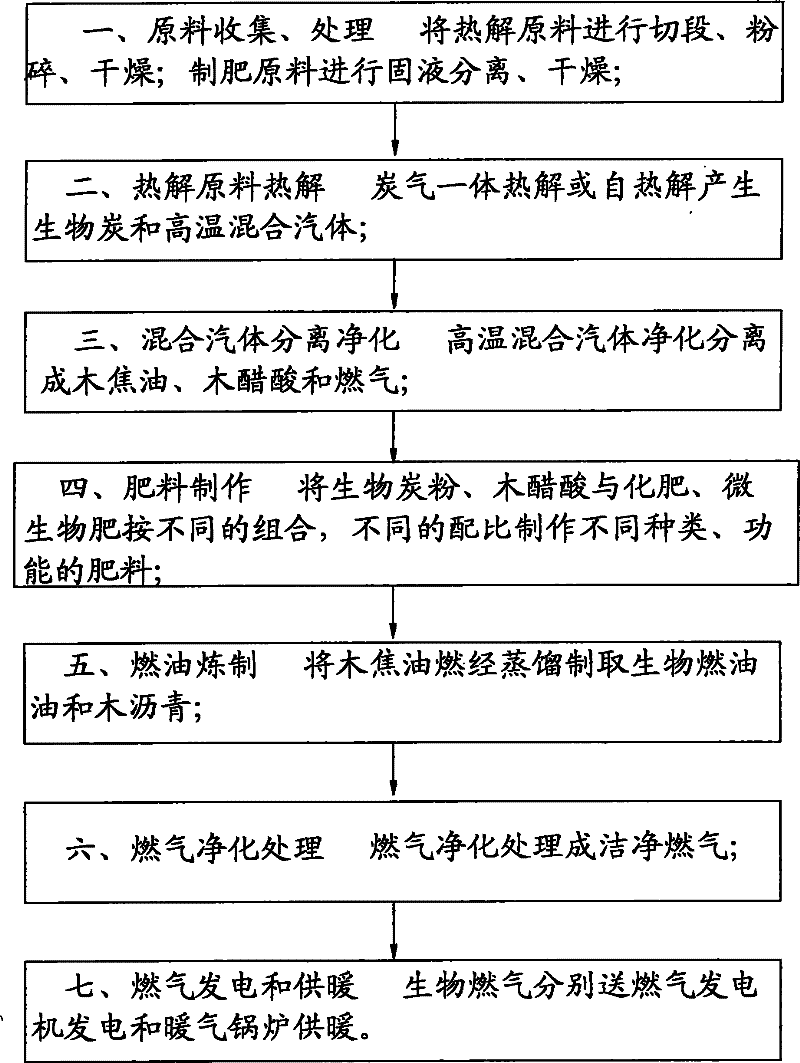

Integrated converting and utilizing co-production method for agricultural waste

InactiveCN102476129AWidely used valueAvoid secondary pollutionSolid waste disposalBiofuelsBiofuelFuel oil

The invention relates to an integrated utilizing technology for agricultural waste and in particular relates to an integrated converting and utilizing co-production method for agricultural waste. The integrated converting and utilizing co-production method comprises the following steps: 1. collecting and processing raw materials; 2. carrying out pyrolysis on the raw materials: generating biochar and high-temperature mixed gas; 3. converting the high-temperature mixed gas: converting the high-temperature mixed gas into wood tar, wood vinegar and fuel gas; 4. manufacturing fertilizers; 5. refining fuel oil: converting the wood tar into biofuel oil and wood pitch; 6. purifying the fuel gas: purifying the fuel gas into clean fuel gas; and 7. converting the fuel gas: respectively sending the biofuel gas into a gas generator, a gas supply pipe network and a heat boiler to covert the biofuel gas into heat energy and electricity energy. The agricultural waste can be converted by multiple levels and are combined to be utilized to obtain straw carbon, fuel gas, heat energy, electricity energy, fertilizers, fuel gas and the like. The use ratio of the agricultural waste reaches 100%. The problem that the agricultural waste is stacked and burnt disorderly can be solved, the pollution problem caused by using chemical fertilizers and pesticides for a long time can be solved, and the problem of utilizing energy, fertilizer and oil in rural areas also can be solved.

Owner:周仁福 +2

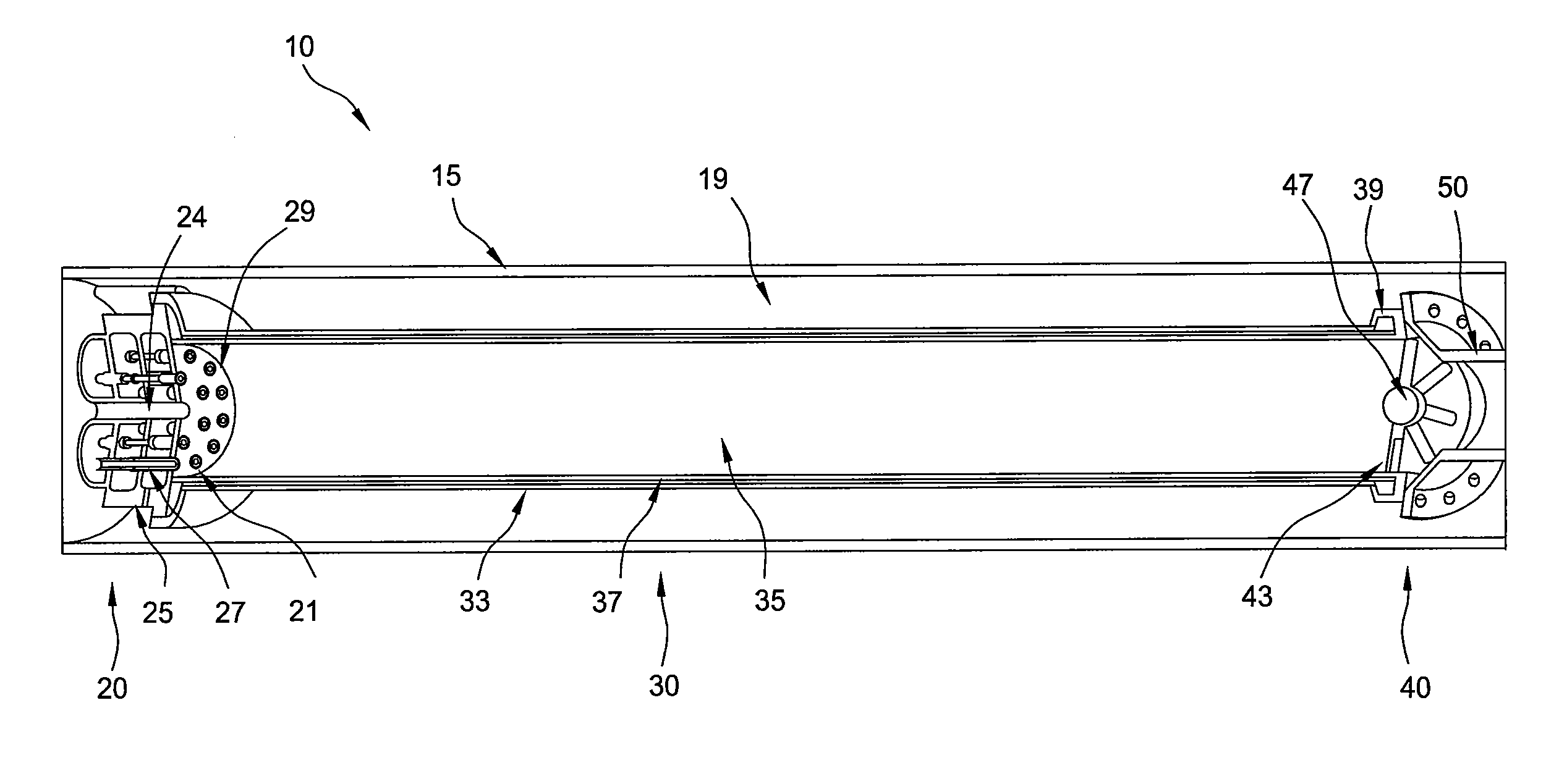

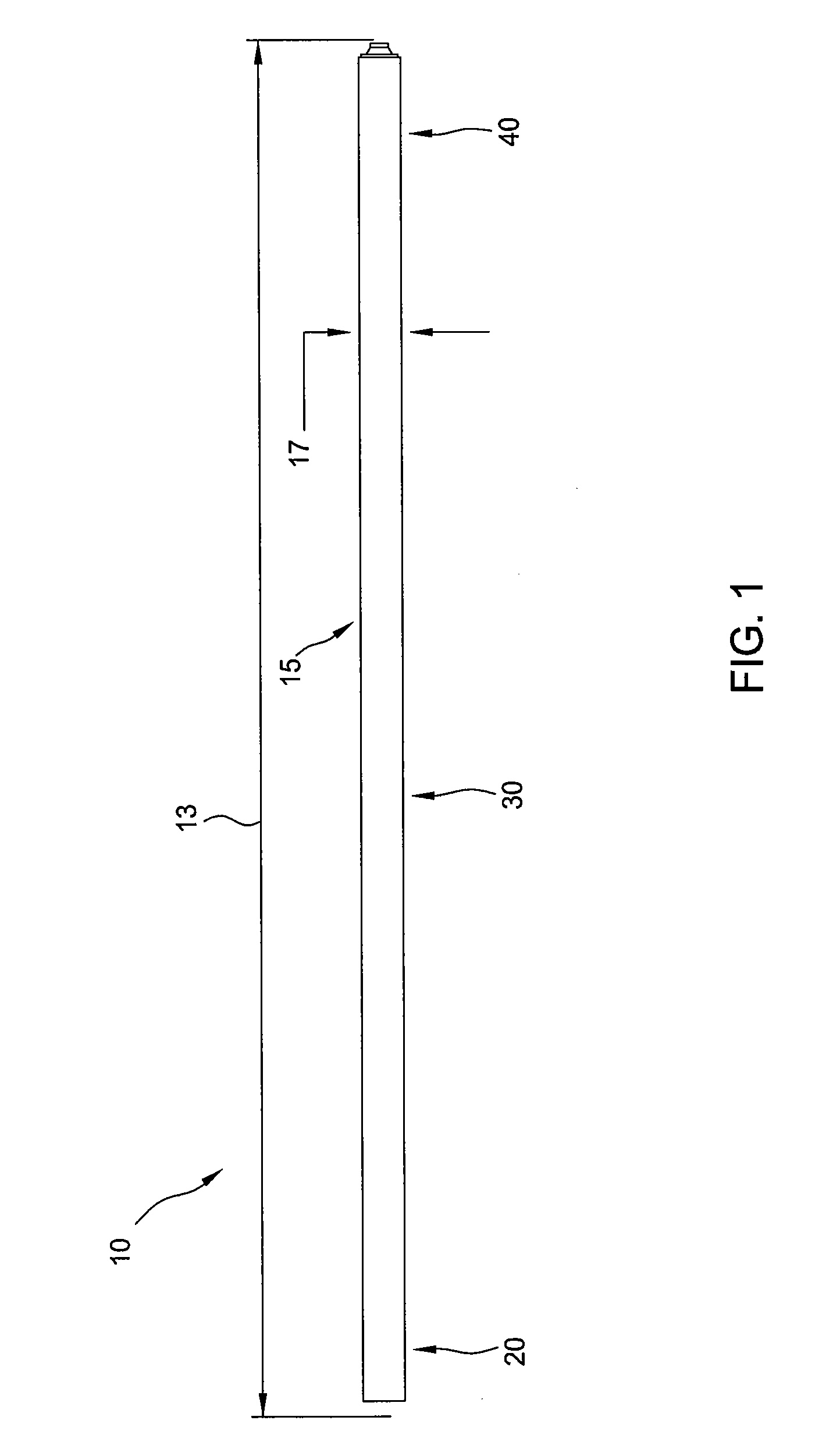

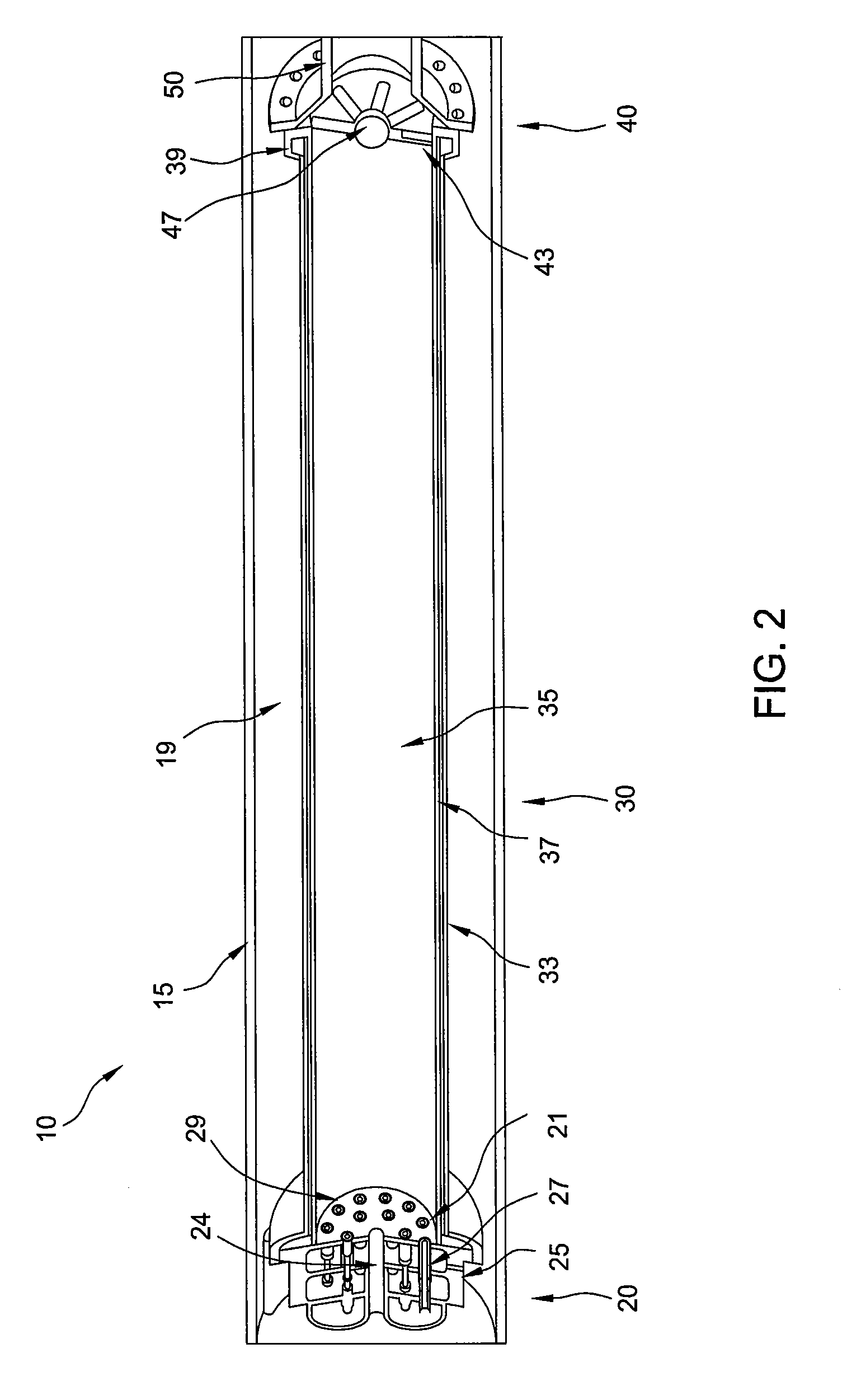

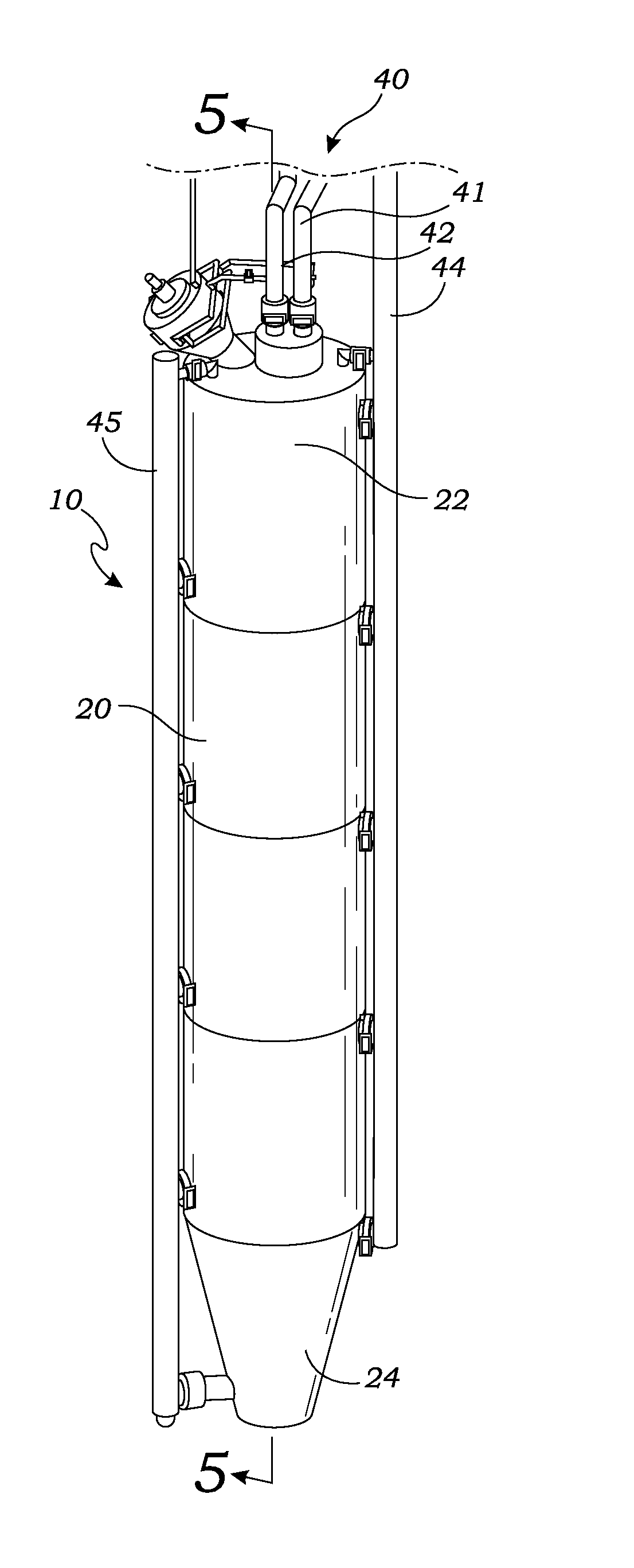

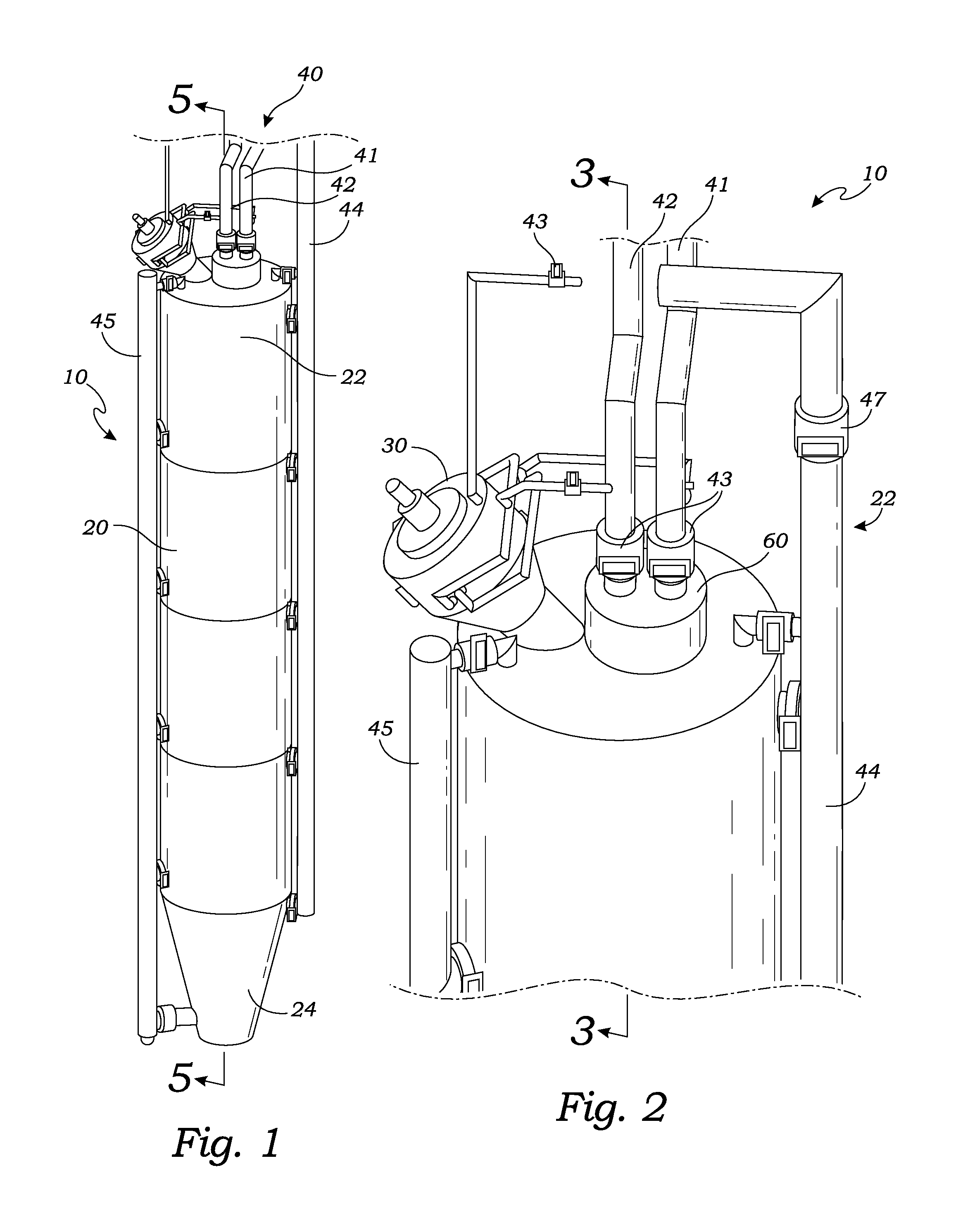

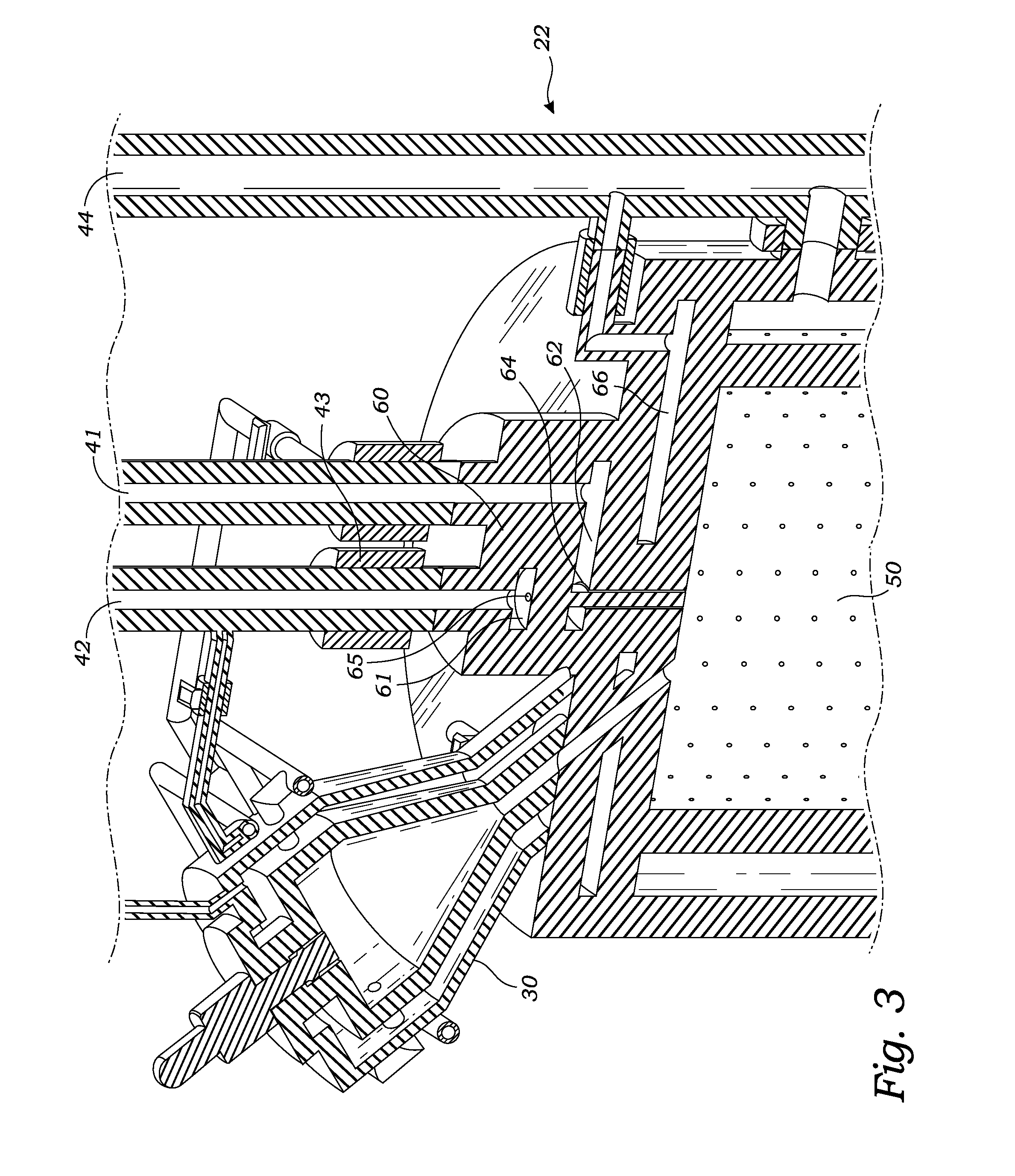

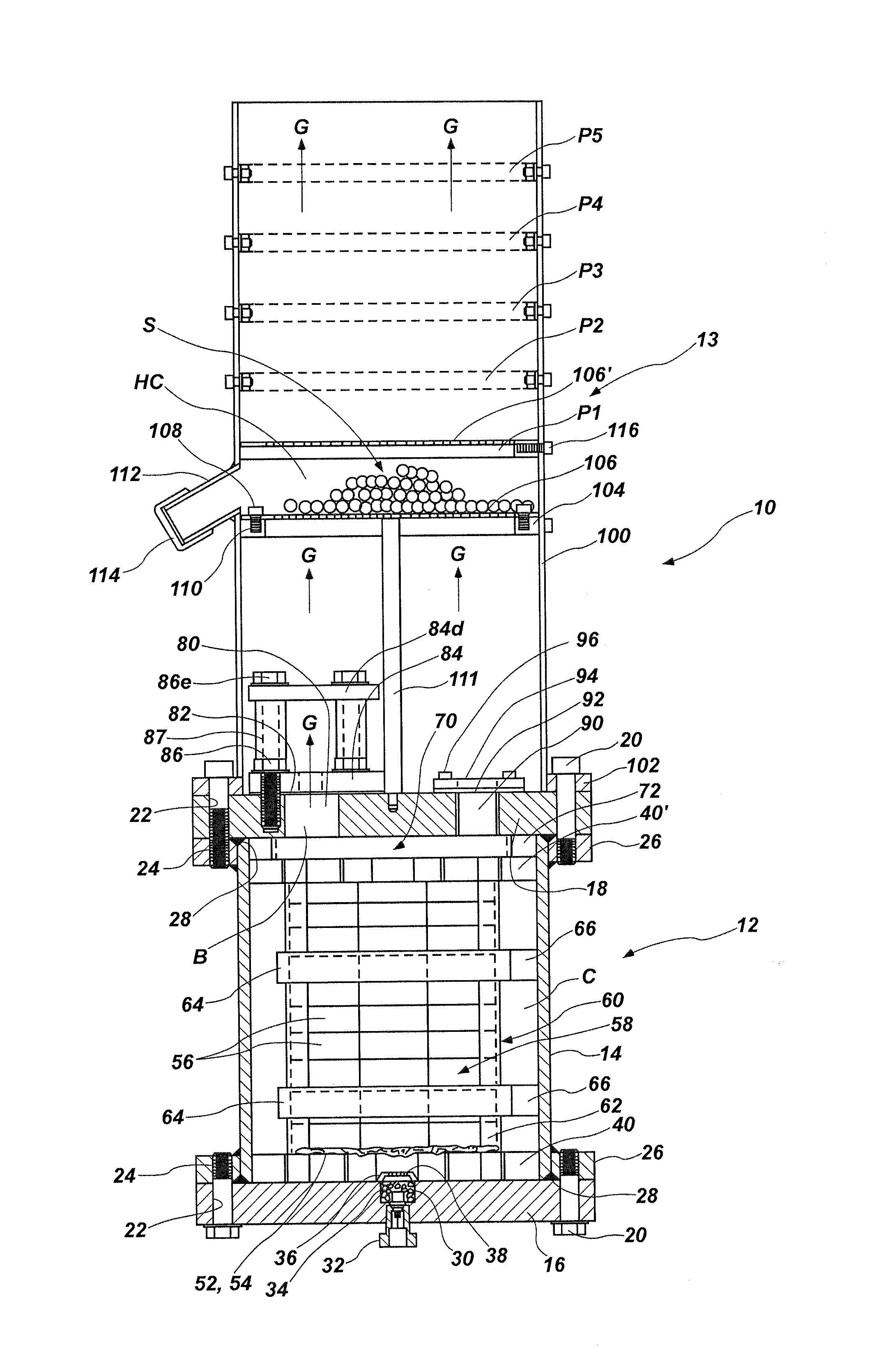

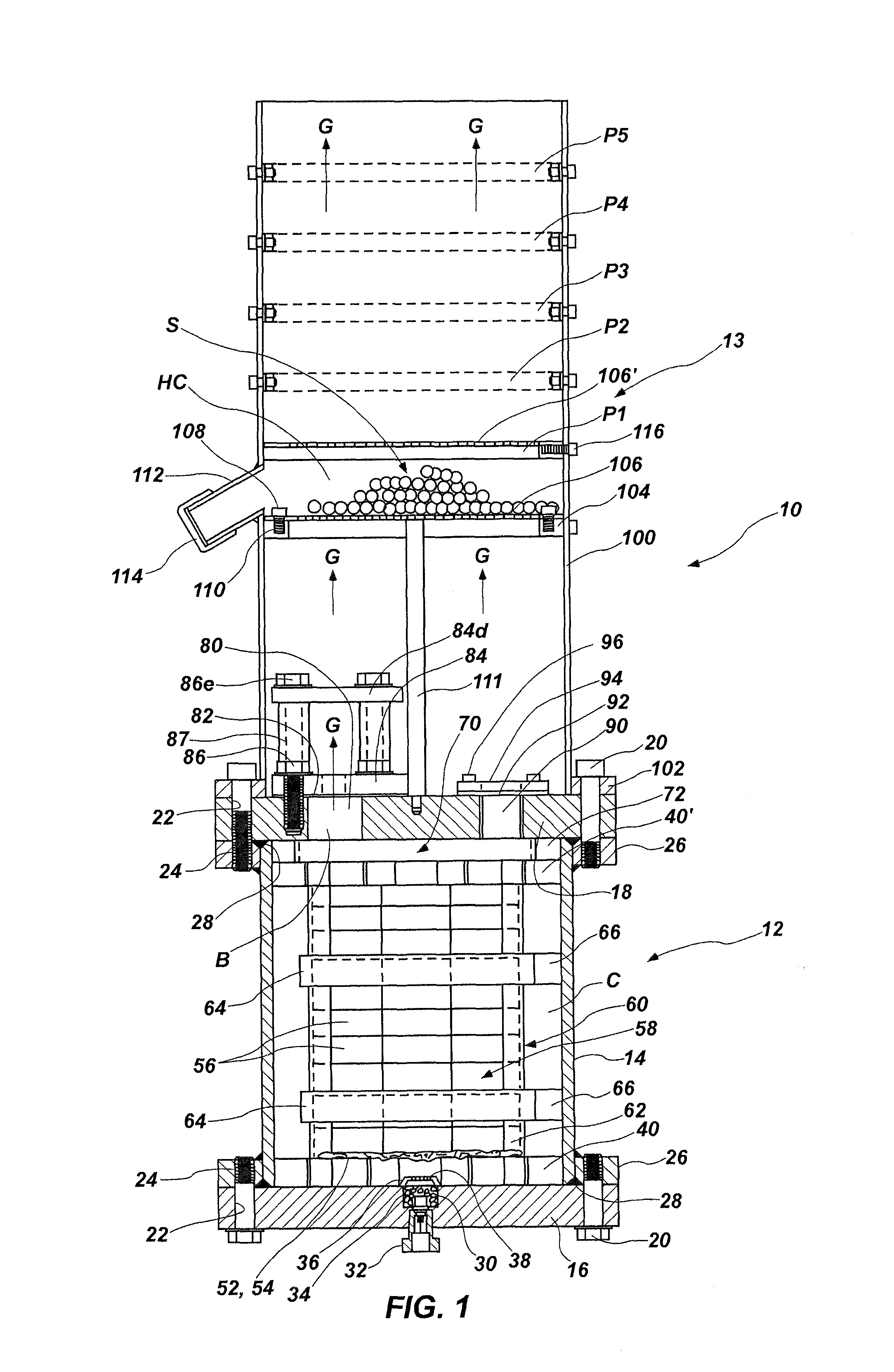

Method and apparatus for a downhole gas generator

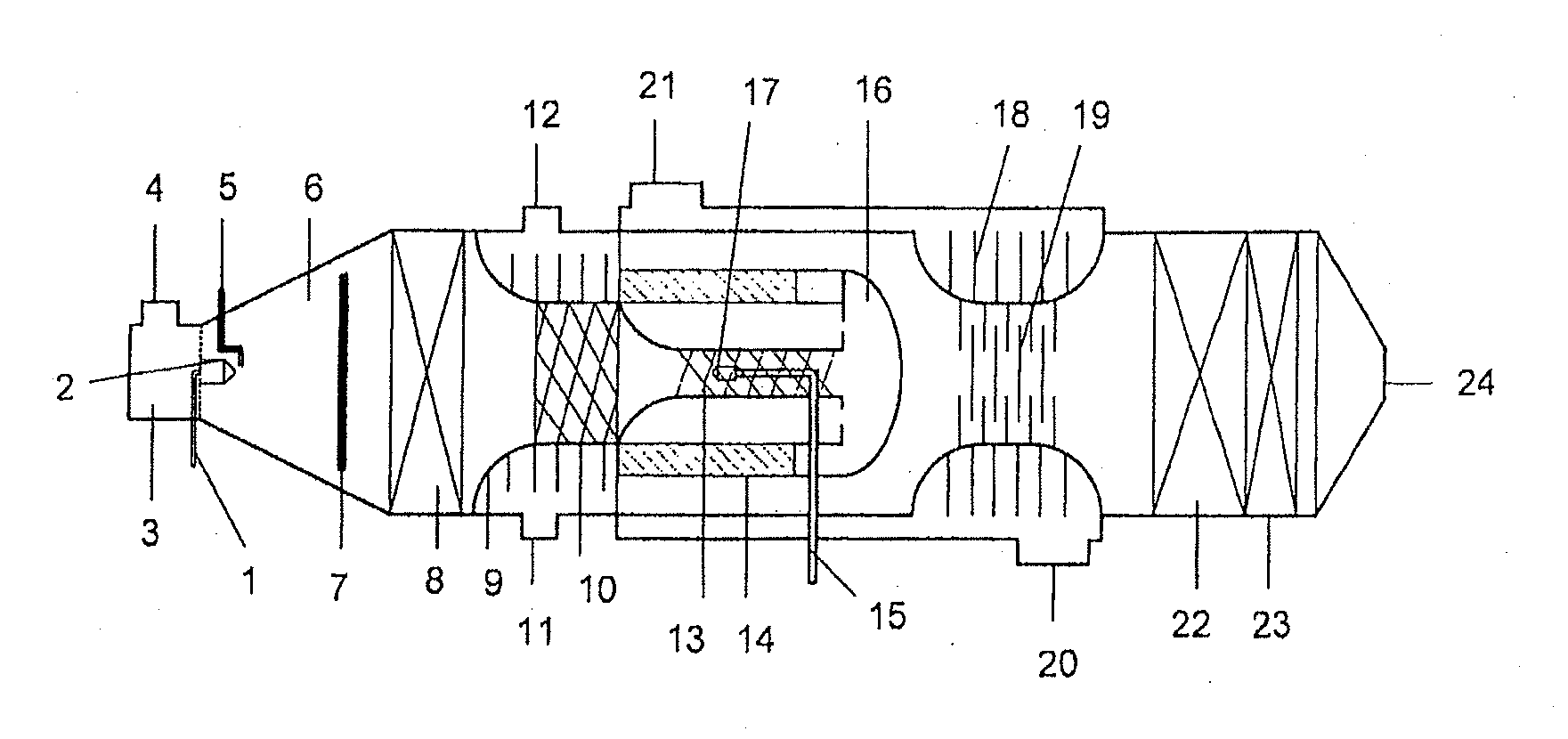

InactiveUS20110127036A1Minimize deposit formationAvoid overall overheatingPipe supportsServomotor componentsCombustion chamberEvaporation

A downhole steam generation apparatus and method of use are provided. The apparatus may include an injection section, a combustion section, and an evaporation section. The injection section may include a housing, injector elements, and injector plate. The combustion section may include a liner having channels disposed therethrough. The evaporation section may include conduits in fluid communication with the channels and the combustion chamber, and a nozzle operable to inject a fluid from the channels to the combustion chamber in droplet form. A method of use may include supplying fuel, oxidant, and fluid to the apparatus; combusting fuel and oxidant in a chamber while flowing the fluid through a plurality of channels disposed through a liner, thereby heating the fluid and cooling the liner; and injecting droplets of the heated fluid into the chamber and evaporating the droplets by combustion of the fuel and the oxidant to produce steam.

Owner:WORLD ENERGY SYST

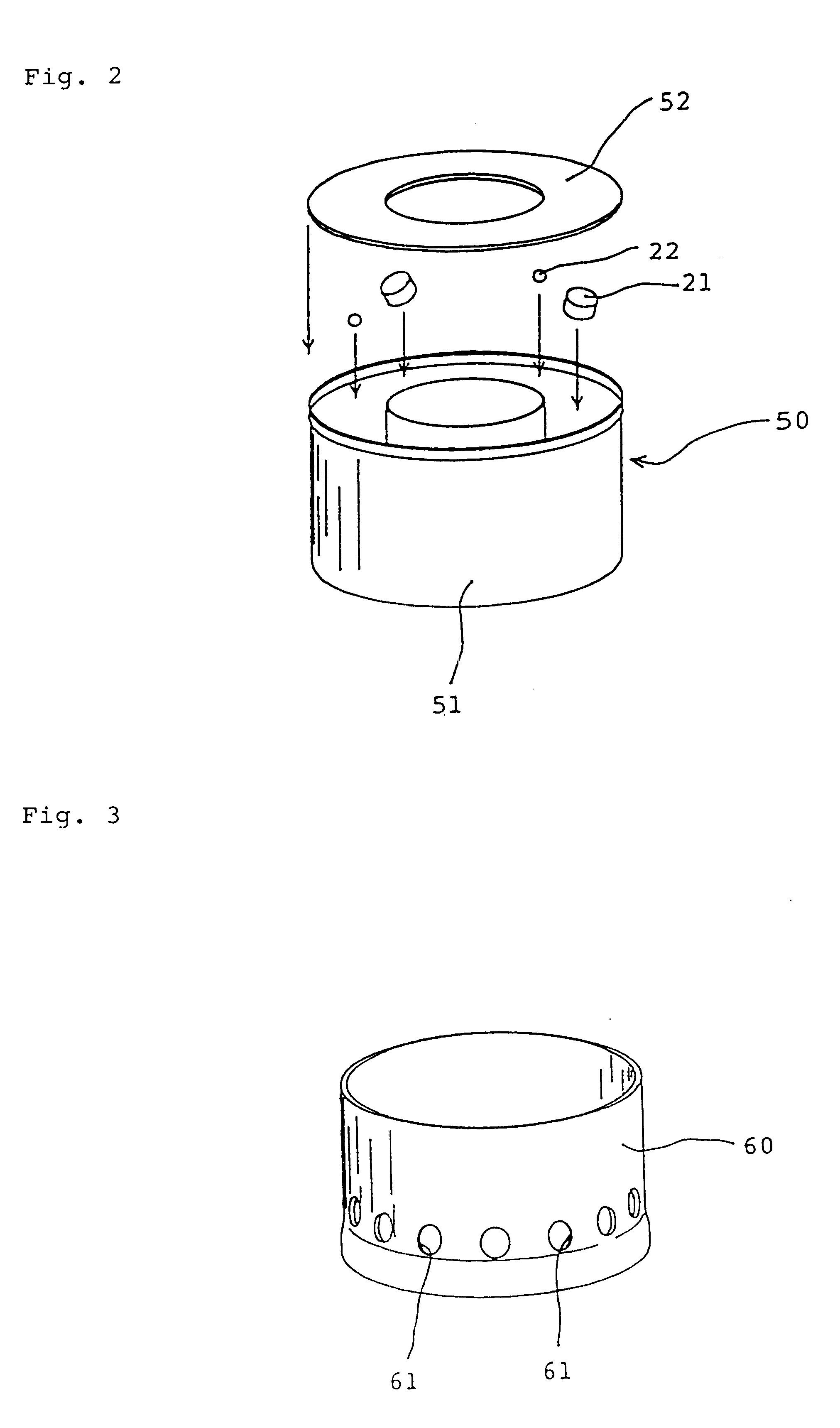

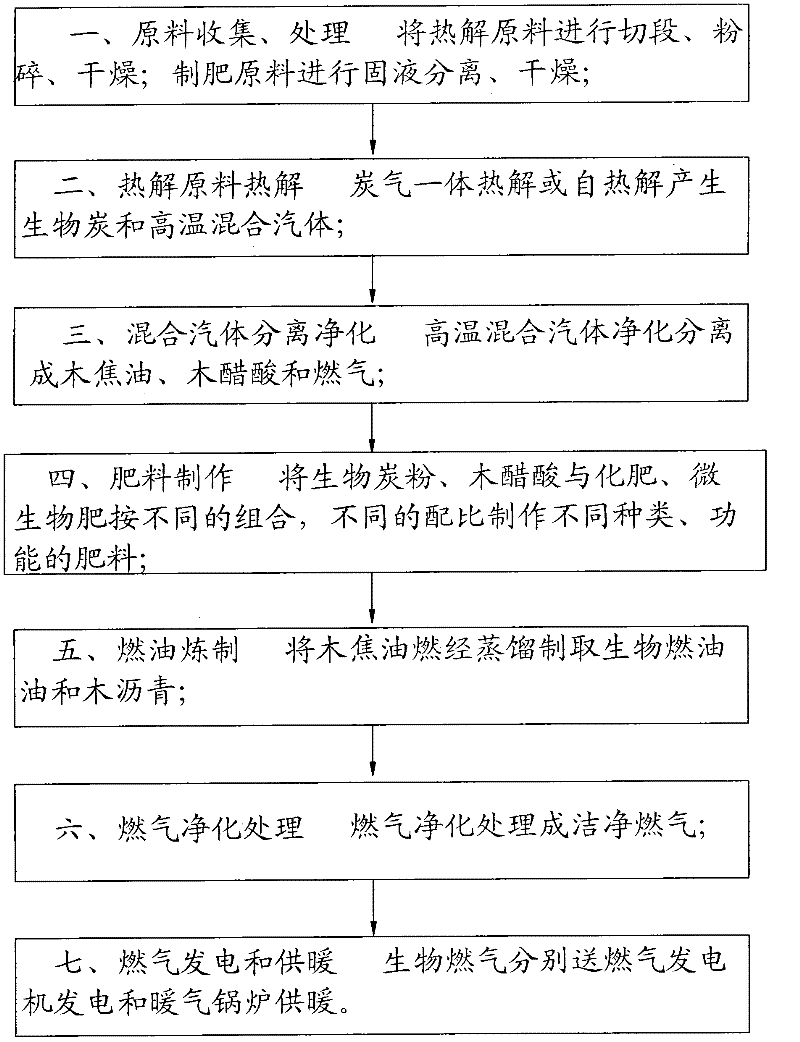

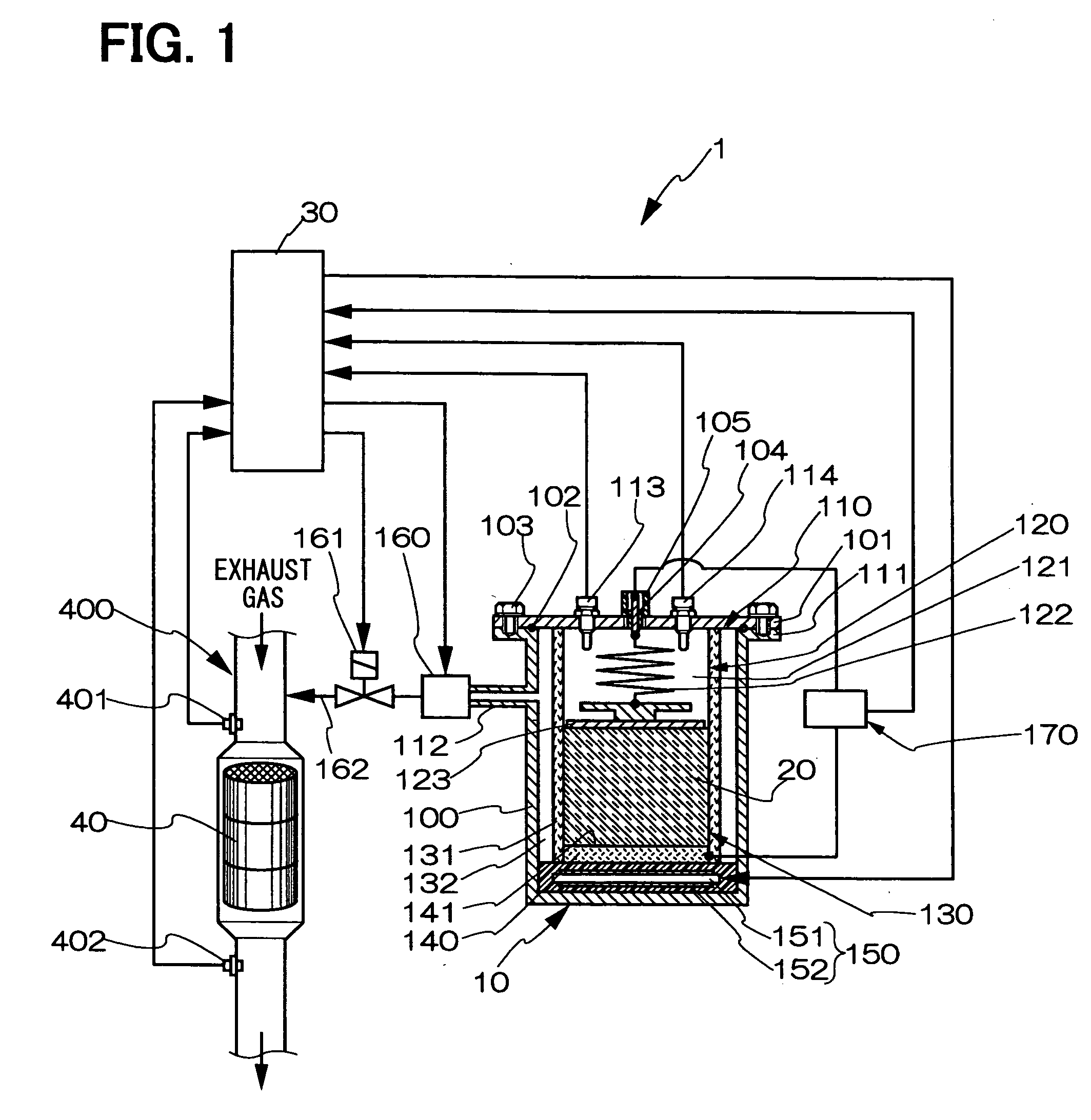

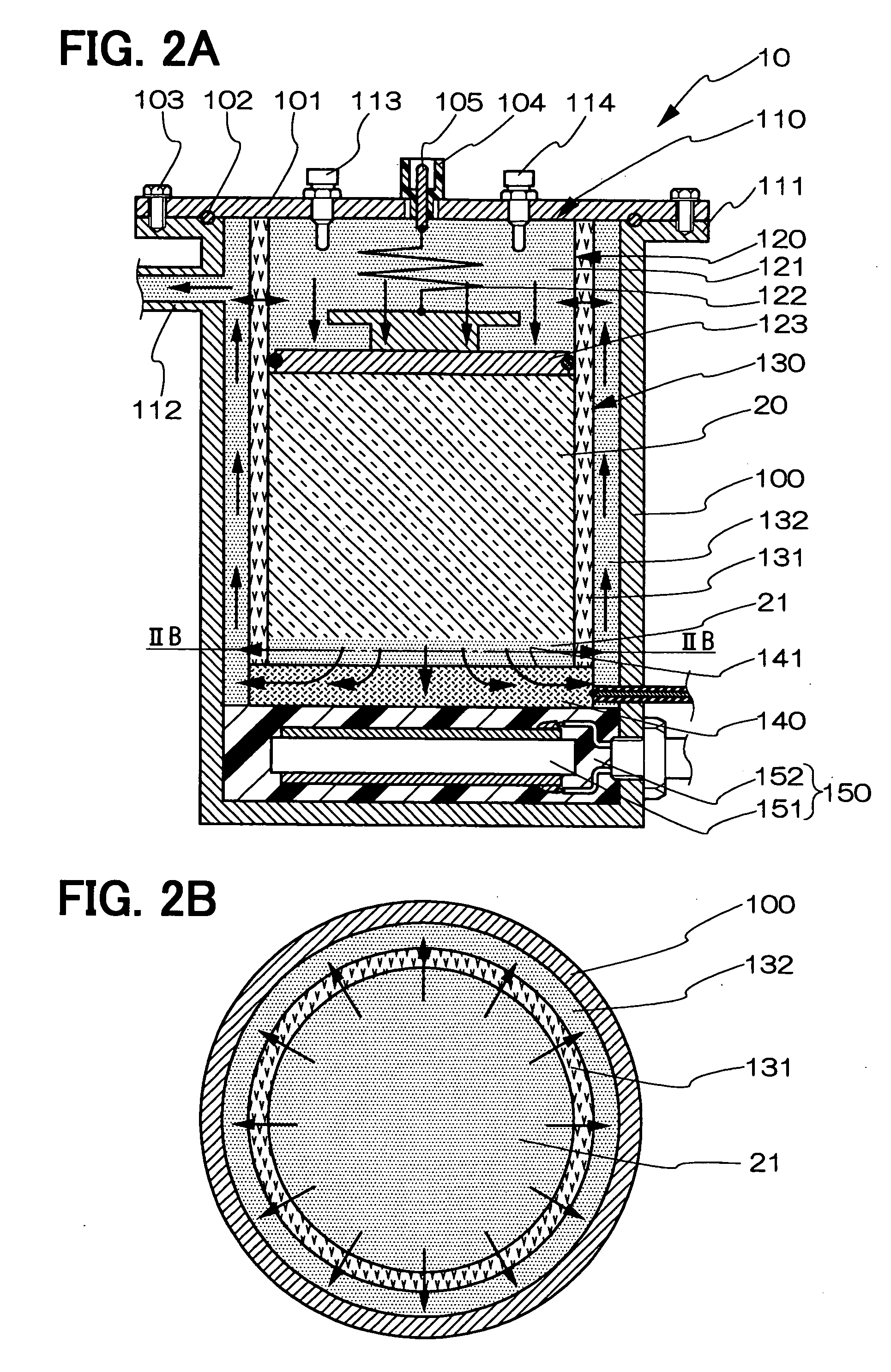

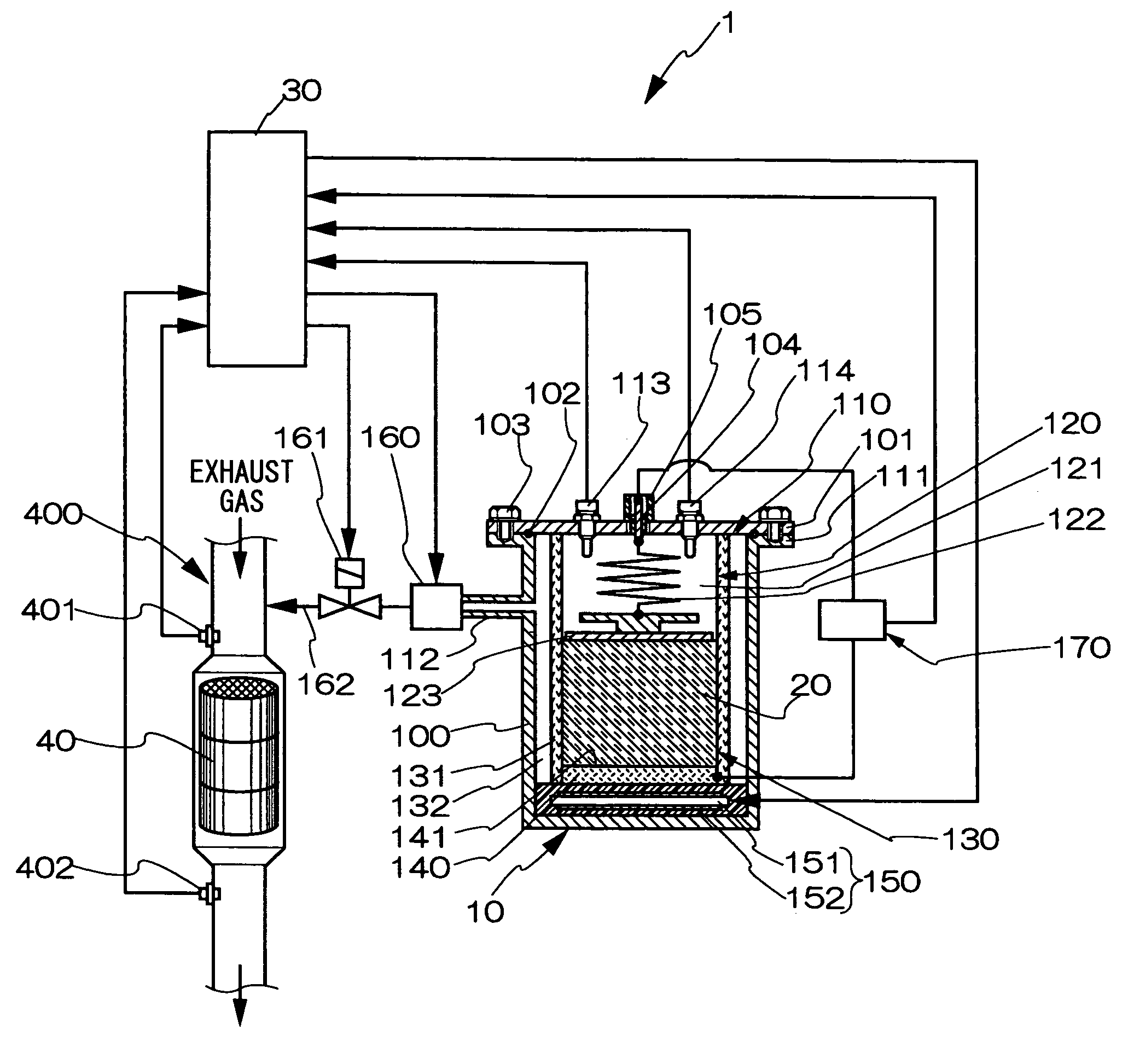

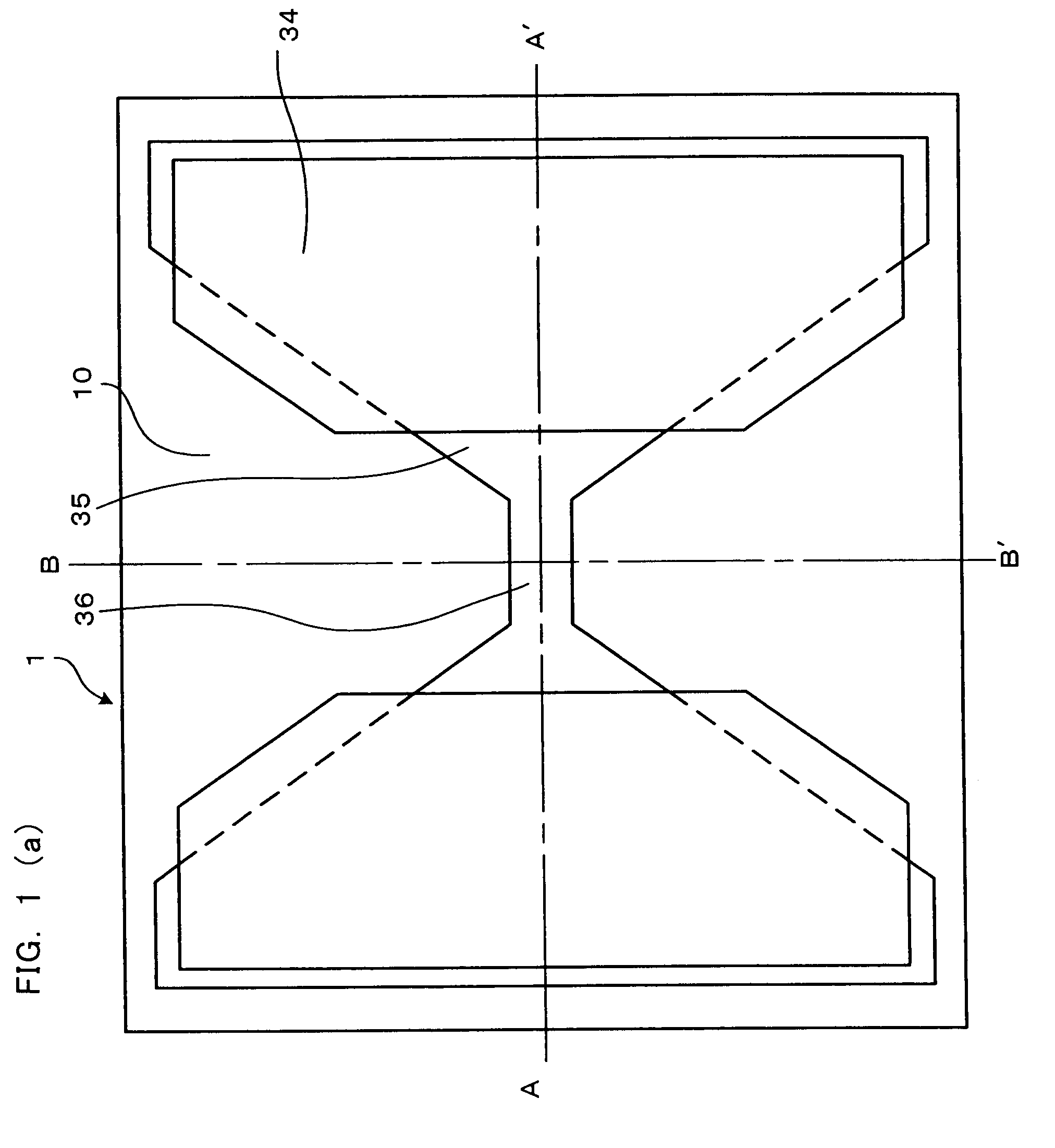

Reducing gas generator and solid reductant SCR system having the generator

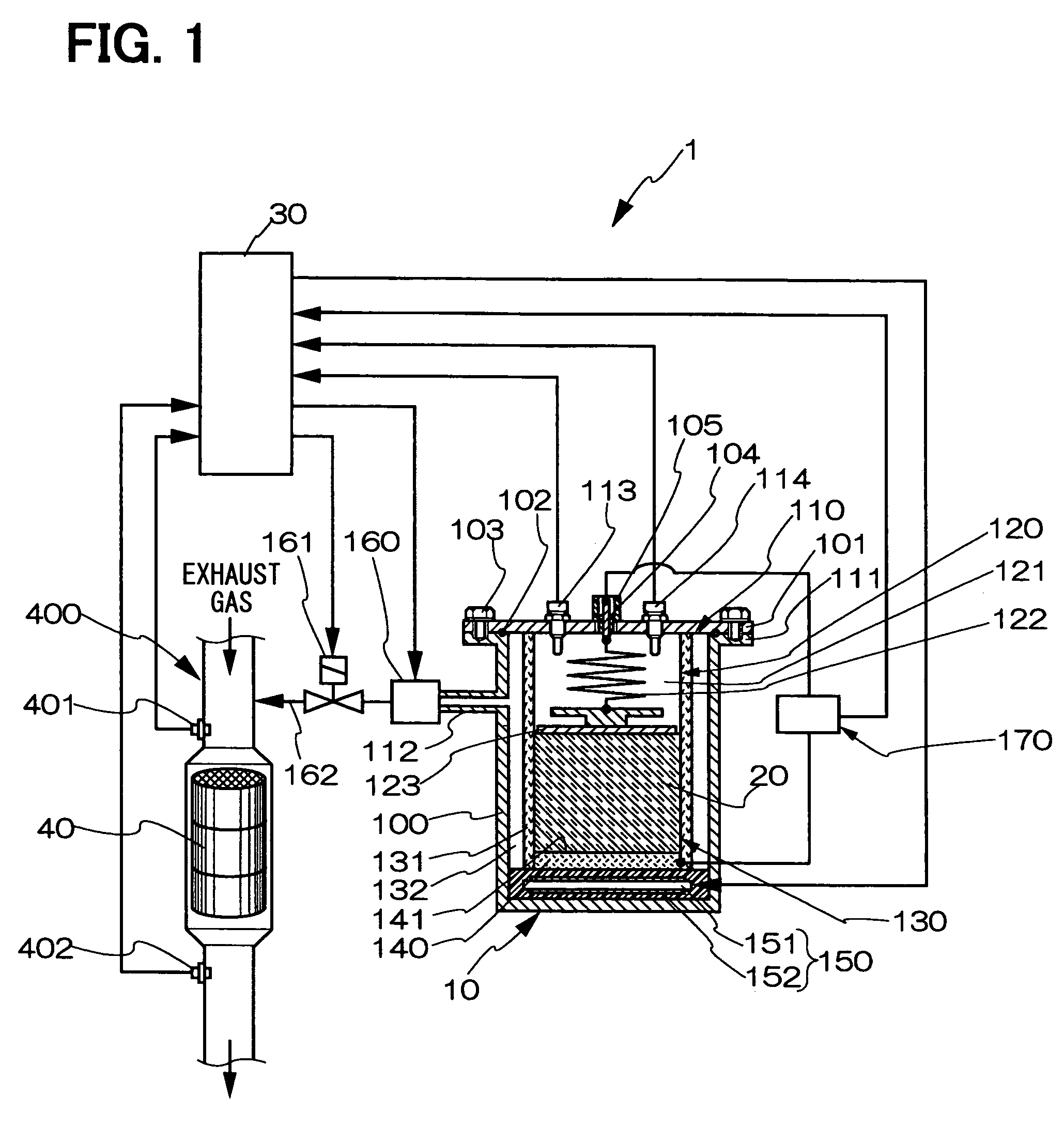

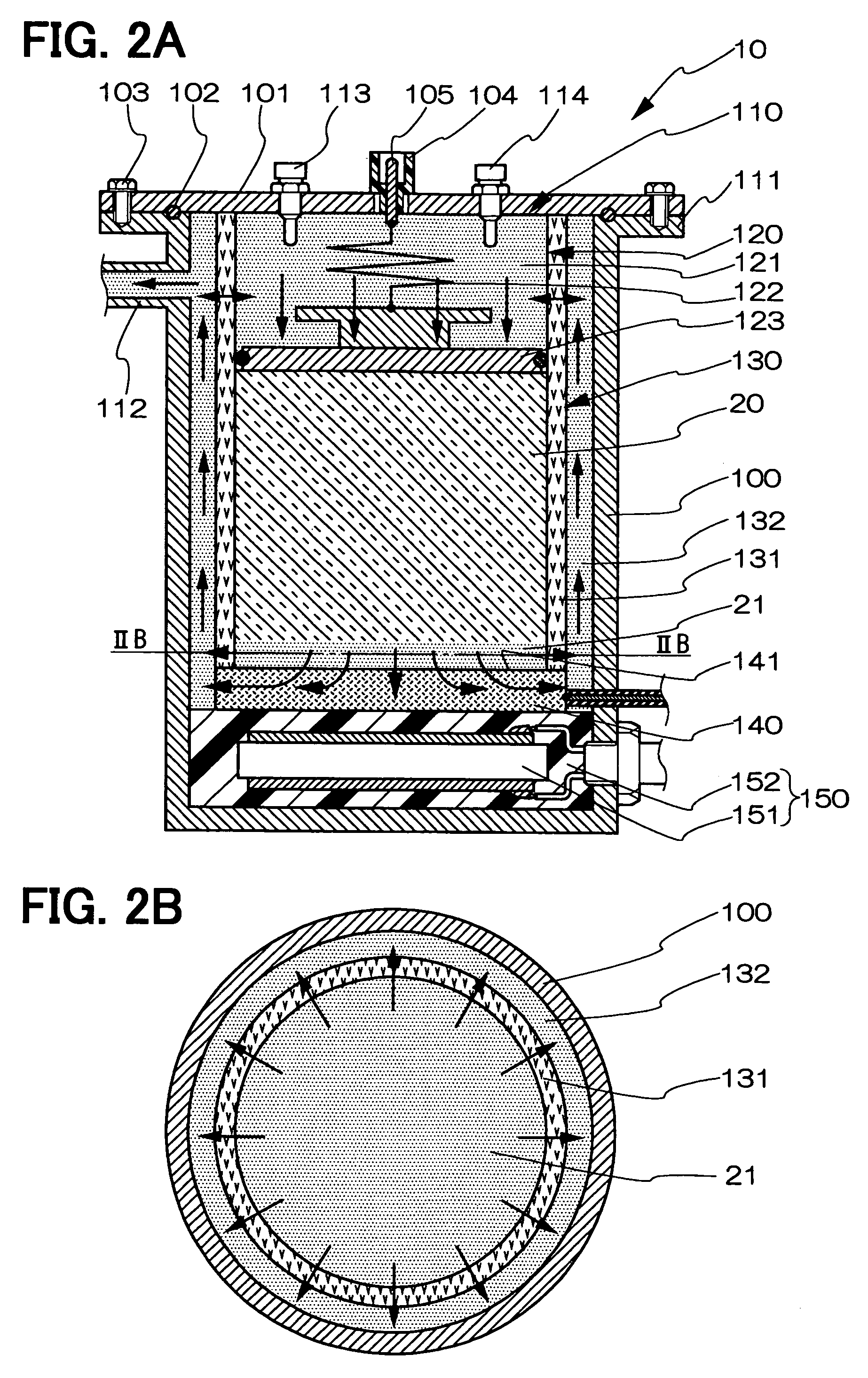

ActiveUS20080260597A1Simple configurationImprove volume efficiencyCombination devicesPressurized chemical processEngineeringWood gas generator

A reducing gas generator generates reducing gas including ammonia. The generator includes a solid reductant and a heat-generating portion. The solid reductant is formed in a columnar shape. A cross-sectional surface of the solid reductant has a constant shape and is perpendicular to a central axis of the solid reductant. The heat-generating portion includes a heat-generating surface opposed to a lower surface of the solid reductant in a vertical direction thereof and in contact with an entire region of the lower surface, and a heating element that heats the heat-generating surface when energized, so that the solid reductant is heated and decomposed to generate the reducing gas.

Owner:DENSO CORP

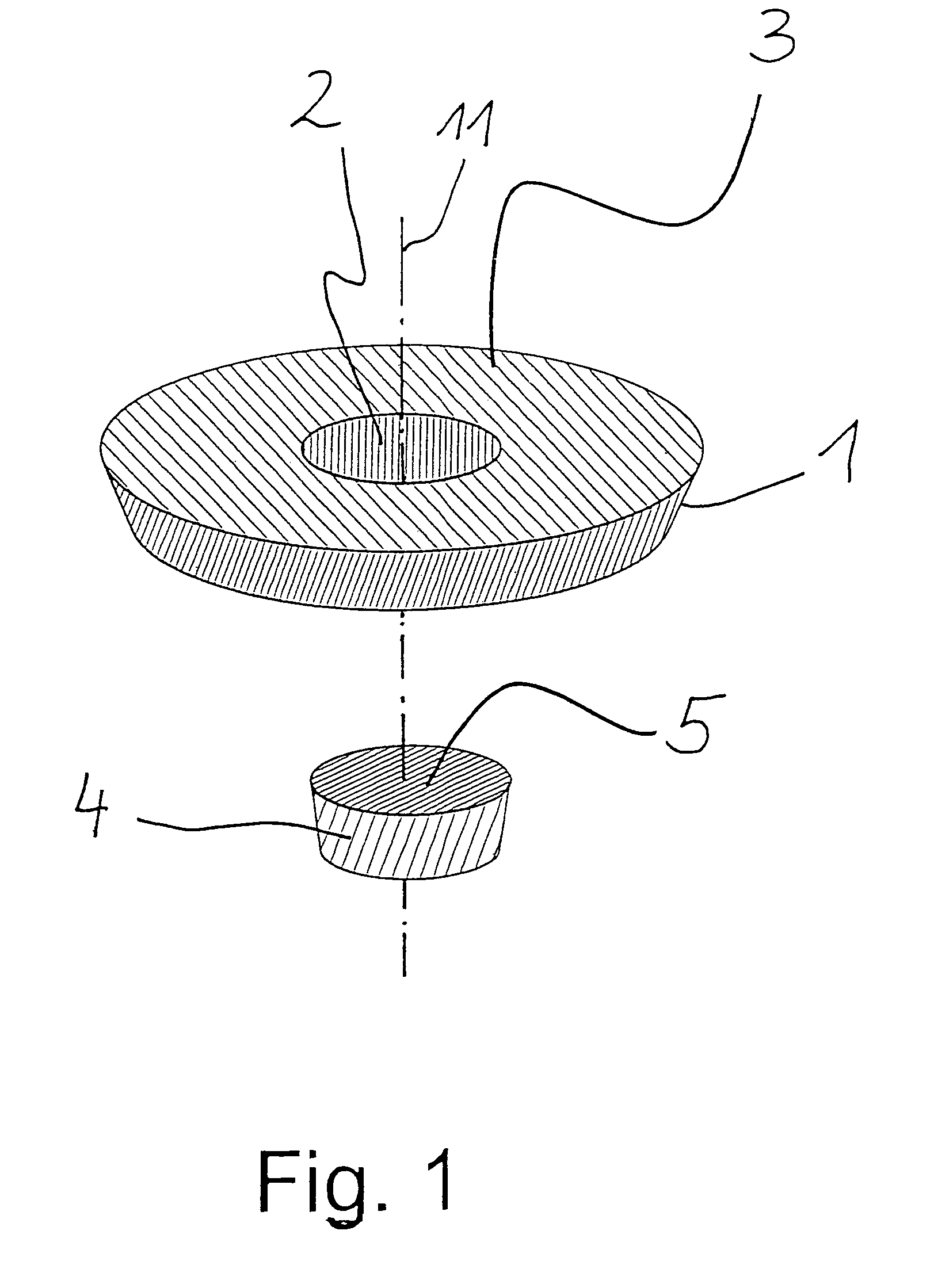

Gas-measuring system with gas sensor and gas generator

ActiveUS7645367B2Minimal fault susceptibility to environmental effectsGuaranteed uptimeAnalysing fluids using sonic/ultrasonic/infrasonic wavesUsing mechanical meansProcess engineeringGas concentration

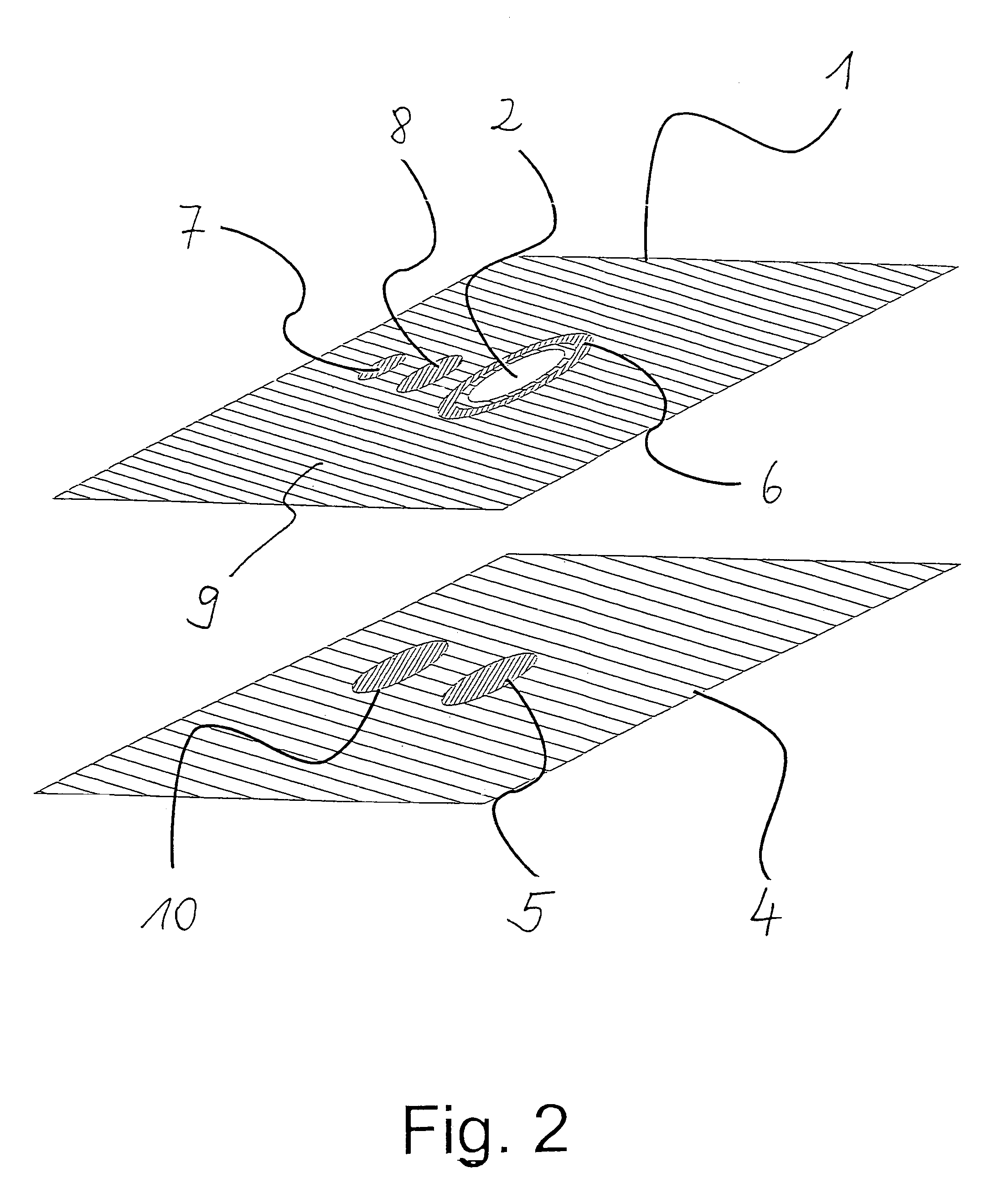

A gas-measuring system contains at least one gas sensor (1) and at least one gas generator (4). The gas sensor (1) has at least one measuring surface (3), at which a target gas concentration can be measured. The gas generator (4) has at least one discharge surface (5), from which a current-proportional quantity of test gas can be discharged. The measuring surface (3) and the discharge surface (5) are designed and the gas sensor (1) and the gas generator (4) can be arranged such that the measuring surface (3) and the discharge surface (5) are in direct contact with the ambient atmosphere and the distance between the two surfaces is shorter than the extension of the smaller of the two surfaces.

Owner:DRAGER SAFETY

Coupling utilization system and method of anaerobic fermentation of fruit and vegetable wastes and afterheat of bio-gas generator

ActiveCN104651218ATotal Solids Concentration ReductionImprove separation efficiencyBioreactor/fermenter combinationsInternal combustion piston enginesResource utilizationEngineering

The invention discloses a coupling utilization system and method of anaerobic fermentation of fruit and vegetable wastes and afterheat of a bio-gas generator. The system comprises a pretreatment device, a tempering preheating tank, a first extrusion solid-liquid separator, a hydrothermal reactor, a high-temperature dry fermentation bin, a second extrusion solid-liquid separator and a drying machine which are sequentially communicated, and also comprises a medium-temperature high-efficiency anaerobic digestion tank, a bio-gas purifier, a bio-gas generator unit and a first heat exchange device, wherein liquid outlets of the first extrusion solid-liquid separator and the second extrusion solid-liquid separator are communicated with an inlet of the medium-temperature high-efficiency anaerobic digestion tank. According to the coupling utilization system of the anaerobic fermentation of fruit and vegetable wastes and the afterheat of a bio-gas generator, the bio-gas generation afterheat is combined with temperature-rising and heat preservation of anaerobic fermentation, intensified hydrolysis of solid residues, high-temperature dry fermentation of solid residues and drying of fermentation residues like solid organic fertilizers, so that the comprehensive energy sources and resource utilization efficiency of fruit and vegetable wastes are improved.

Owner:深圳市海吉星环保有限责任公司

Fluid sprayer and spraying method

InactiveCN1506612AImprove versatilityLimit temperatureLiquid fuel feeder/distributionTurbine/propulsion fuel supply systemsCombustion chamberSprayer

There are provided an injector and an associated method for injecting and mixing gases, comprising a carbonaceous fuel and oxygen, in a combustion chamber of a combustion device. The injector has jets, which can be used to separately inject different combustion fuels. The injector is compatible with combustion devices that inject only gases, for example, a reheater that provides initial combustion in a power generation cycle or a reheater that recombusts a discharged gas from a gas generator and turbine. Further, the injector defines an annular space through which a recycle gas can be injected into the combustion chamber to lower the combustion temperature.

Owner:UNITED TECH CORP

Solid gas generator and preparation method thereof

The invention provides a solid gas generator and a preparation method thereof. The solid gas generator comprises 12 to 23% of a polyether adhesive, 1.2 to 3.6% of a curing agent, 50 to 80% of an oxidizing agent, 0 to 5% of a plasticizer, 0 to 30% of a cooling agent, 0 to 5% of a combustion conditioning agent and 0 to 2% of other additives, wherein the polyether adhesive is one or a composition of more than one selected from the group consisting of ethylene oxide tetrahydrofuran copolyether and propylene oxide tetrahydrofuran copolyether, the curing agent is one or a composition of more than one selected from the group consisting of toluene diisocyanate, isophorone diisocyanate and multifunctional aliphatic diisocyanate, and the plasticizer is one or a composition of more than one selected from the group consisting of dioctyl sebacate, acetyl triethyl citrate and triethyl glycerin tricarbonate. The solid gas generator provided by the invention has a negative pressure exponent of 0 to - 0.30 and provides a power source for attitude control and orbit control power systems of light-weight kinetic kill vehicles (KKV).

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

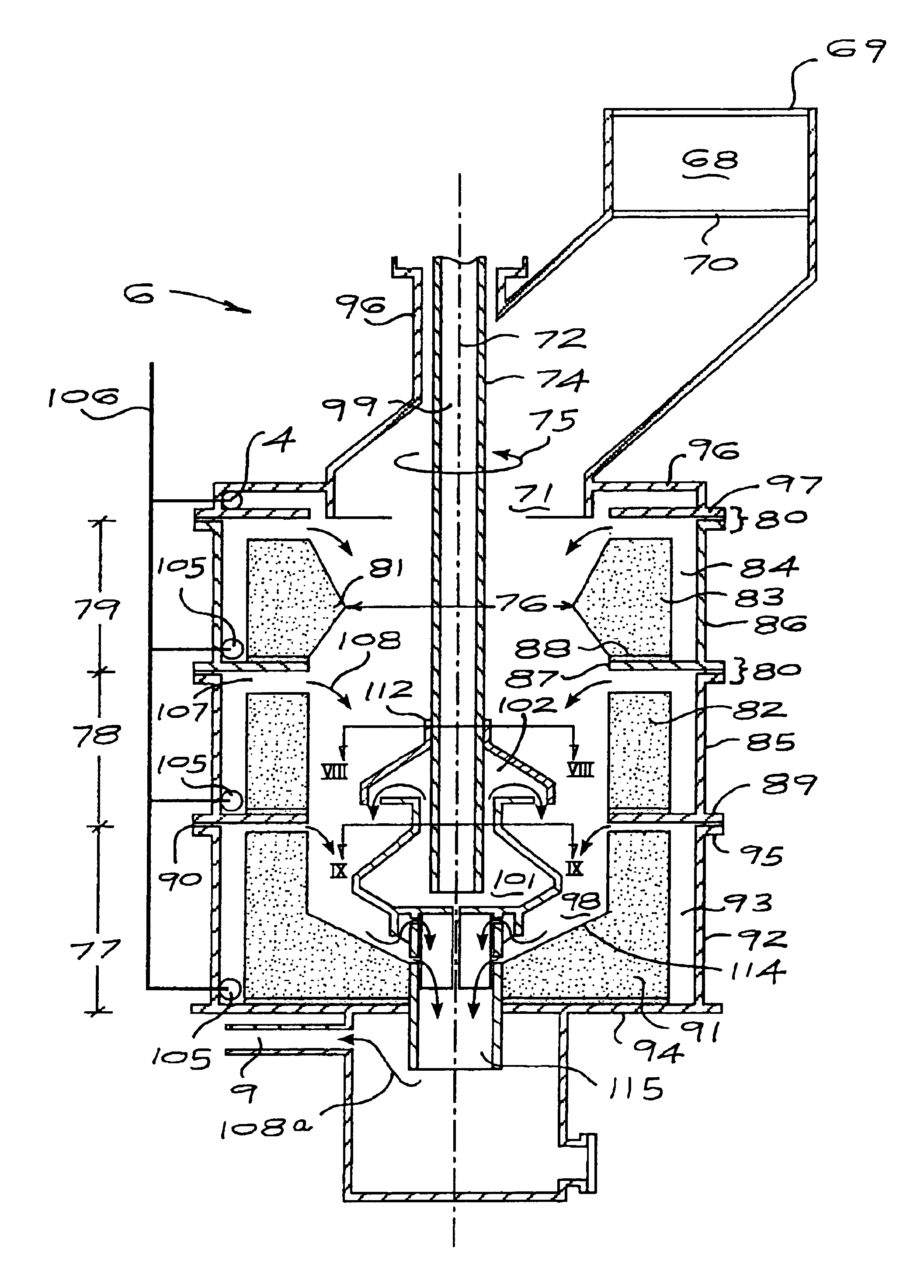

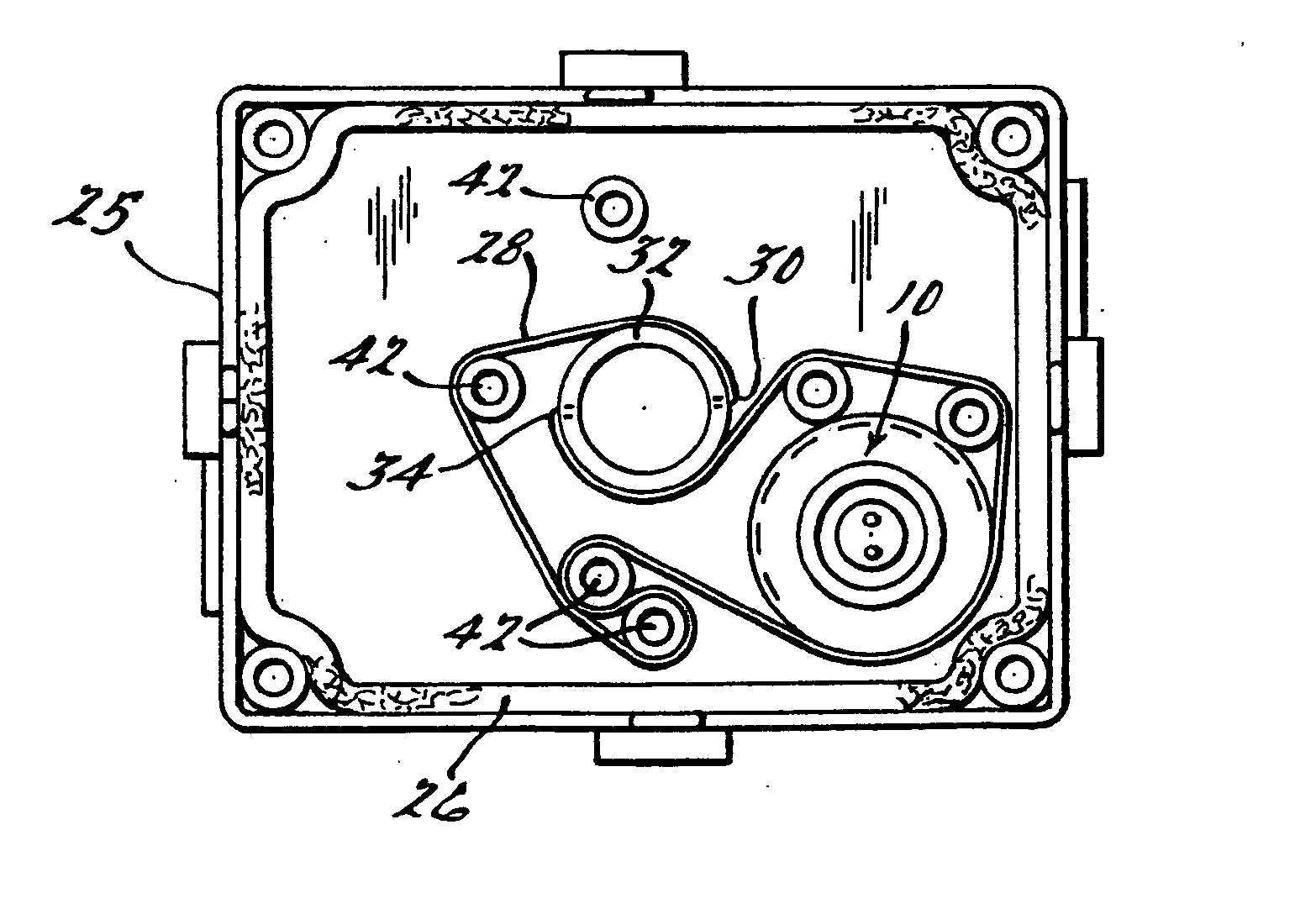

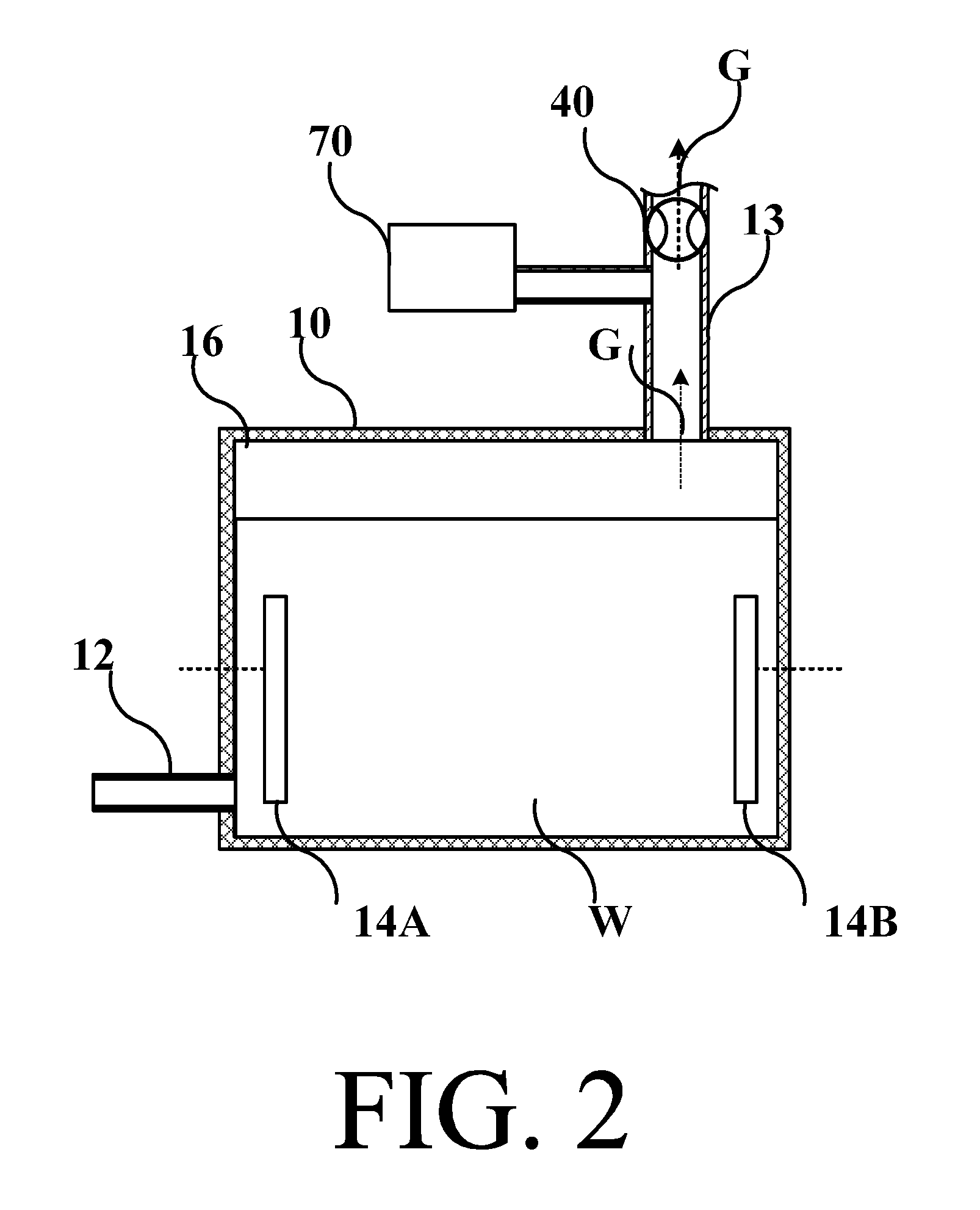

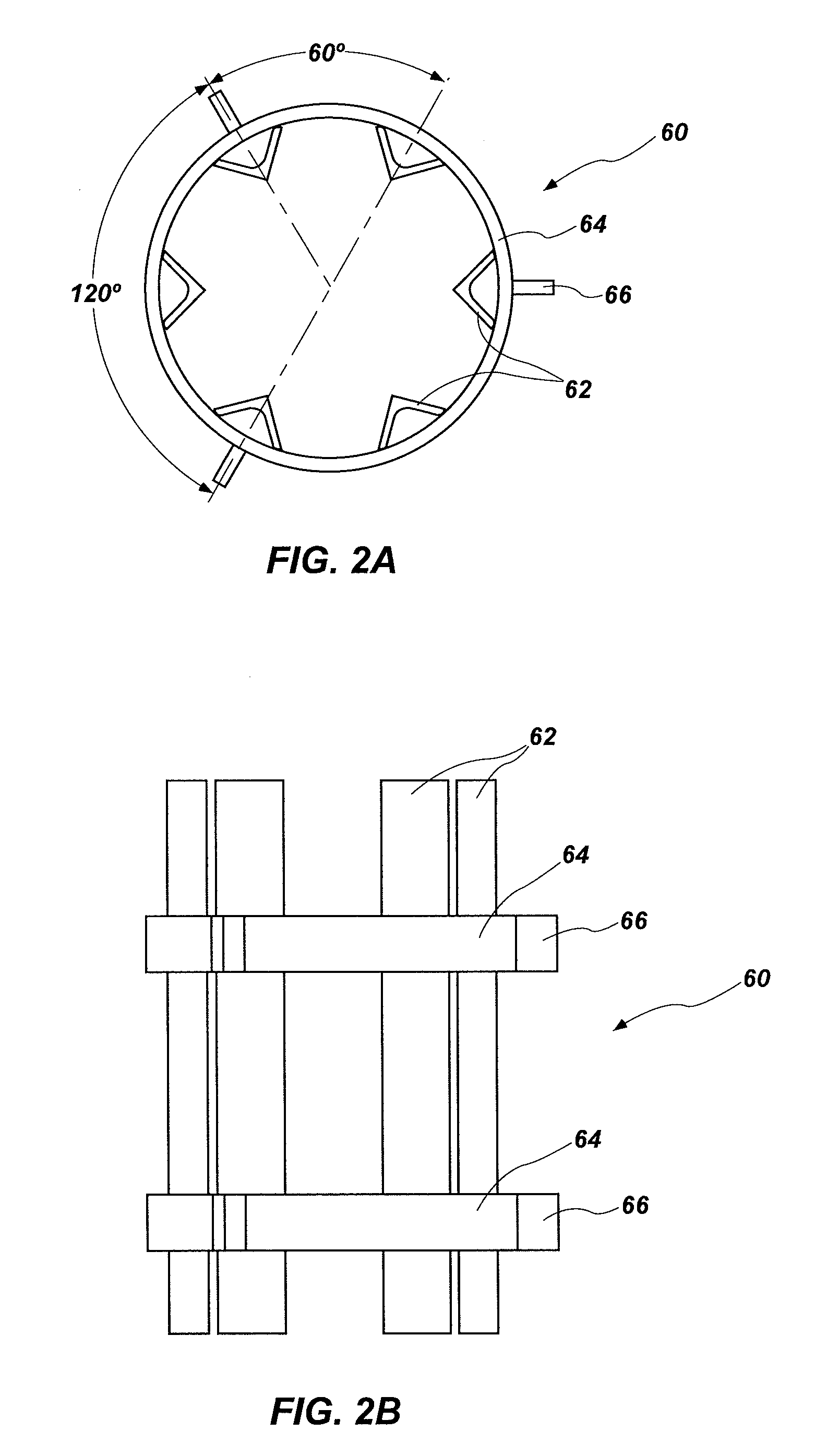

Process and gas generator for generating fuel gas

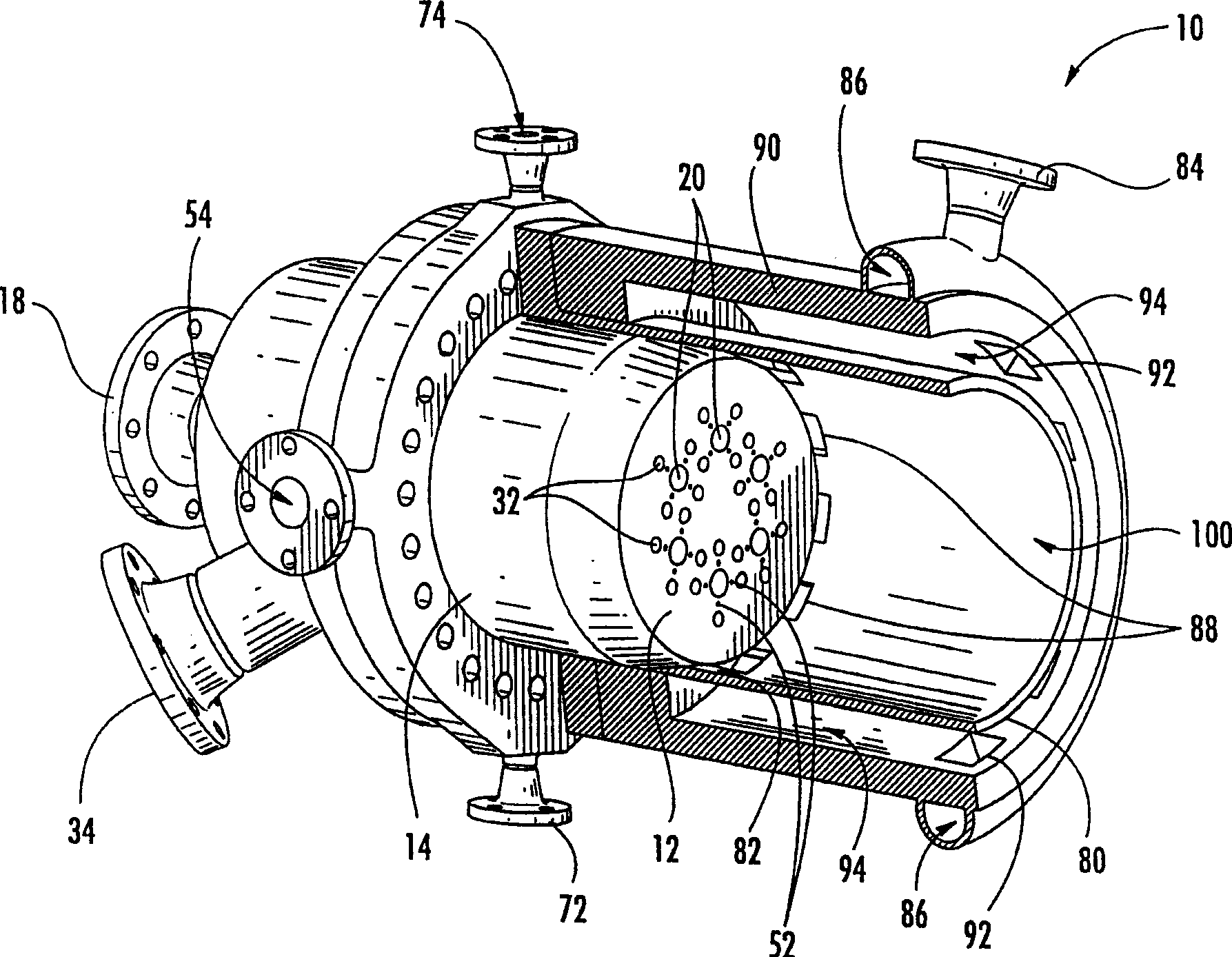

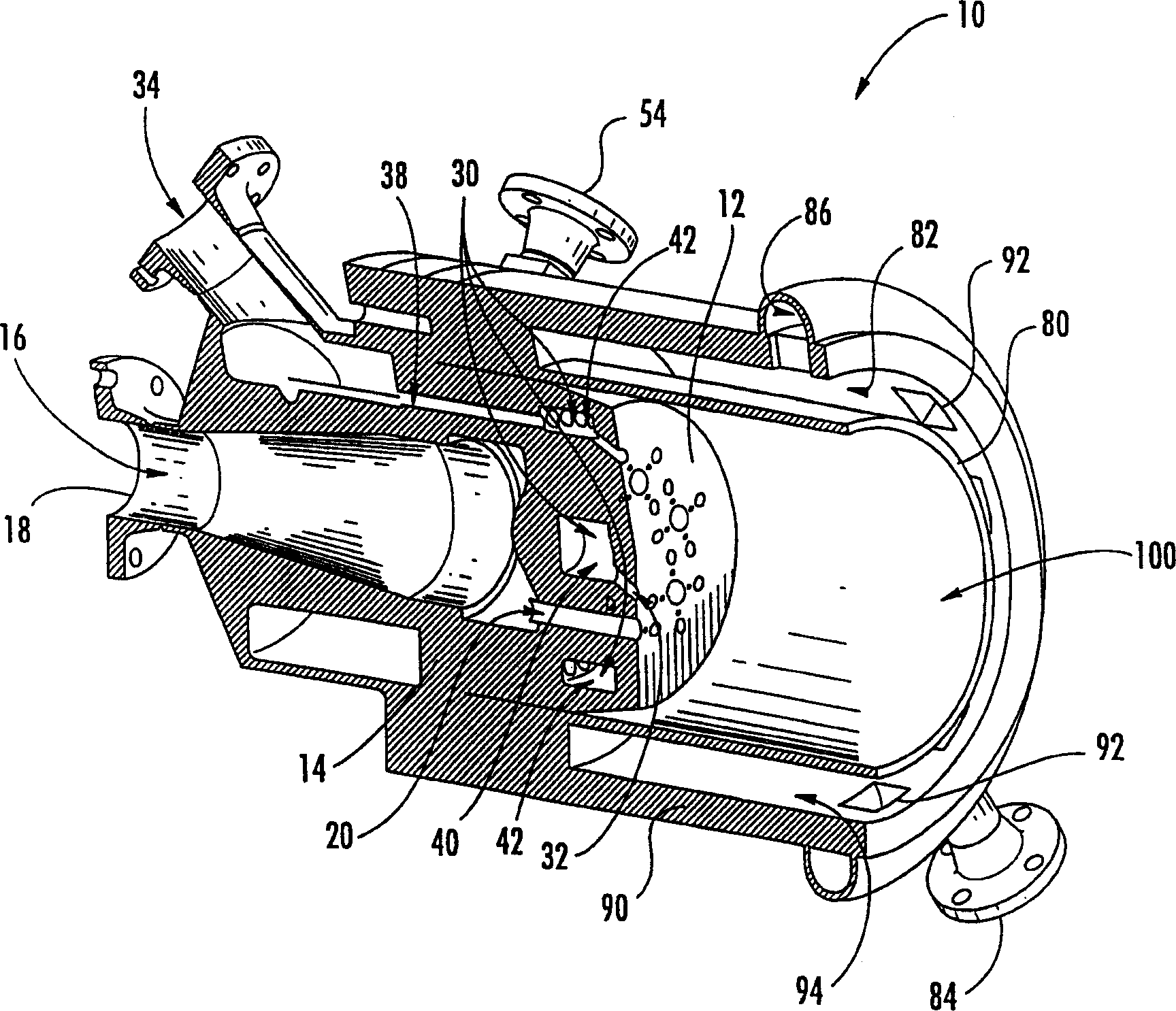

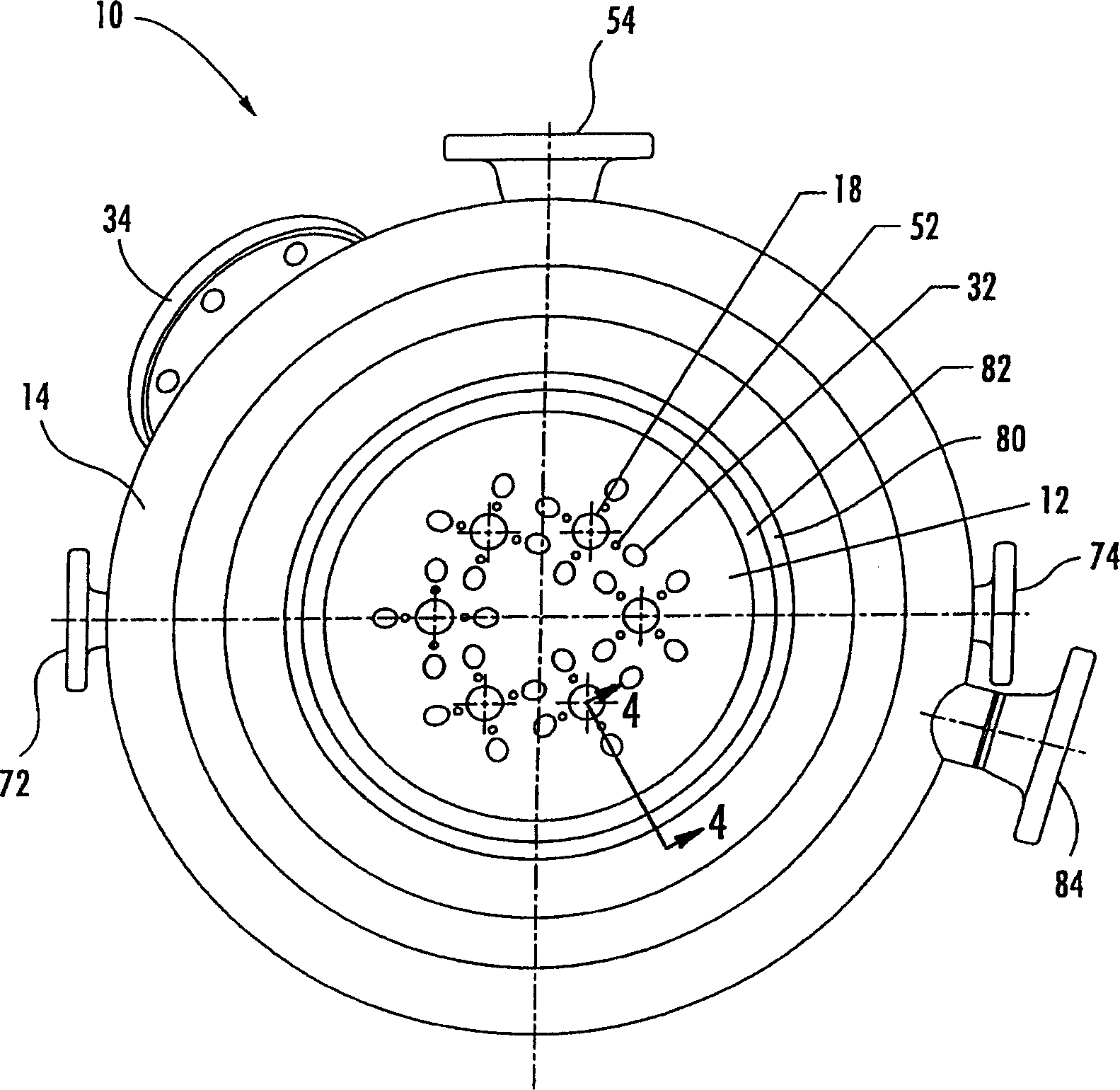

InactiveUS6941879B2Prevent channelingImprove gas qualityDirect heating destructive distillationCombustible gas catalytic treatmentEmberVolatiles

A process and gas generator is disclosed for generating by dry distillation of solids and gasification of solids, a fuel gas substantially free of condensable dry distillation volatiles which would interfere with the intended use of the gas, e.g. for powering an internal combustion engine.To achieve this, solids beds in distinct dry distillation and gasification zones are maintained under conditions favouring thermal cracking of condensable (tar) volatiles in the hot regions of both zones. For optimal control of these conditions these zones are physically separated by internals within a single reactor vessel and optionally by performing part of the dry distillation (pyrolysis) in a separate reactor vessel, in which case pyrolysis volatiles are fed in counter-current to the dry distillation bed, withdrawn from the top thereof and fed into and through the embers bed of the gasification zone. Thermal cracking of pyrolysis volatiles is prolonged and intensified by the manner in which these volatiles are conducted in intimate contact through the embers bed of the gasification zone in co-current therewith. The embers bed is guided along a progressively constricting pathway, which controls the rate of travel of and the period of residence of the solids bed in the process and generator.

Owner:FORETOP CORP

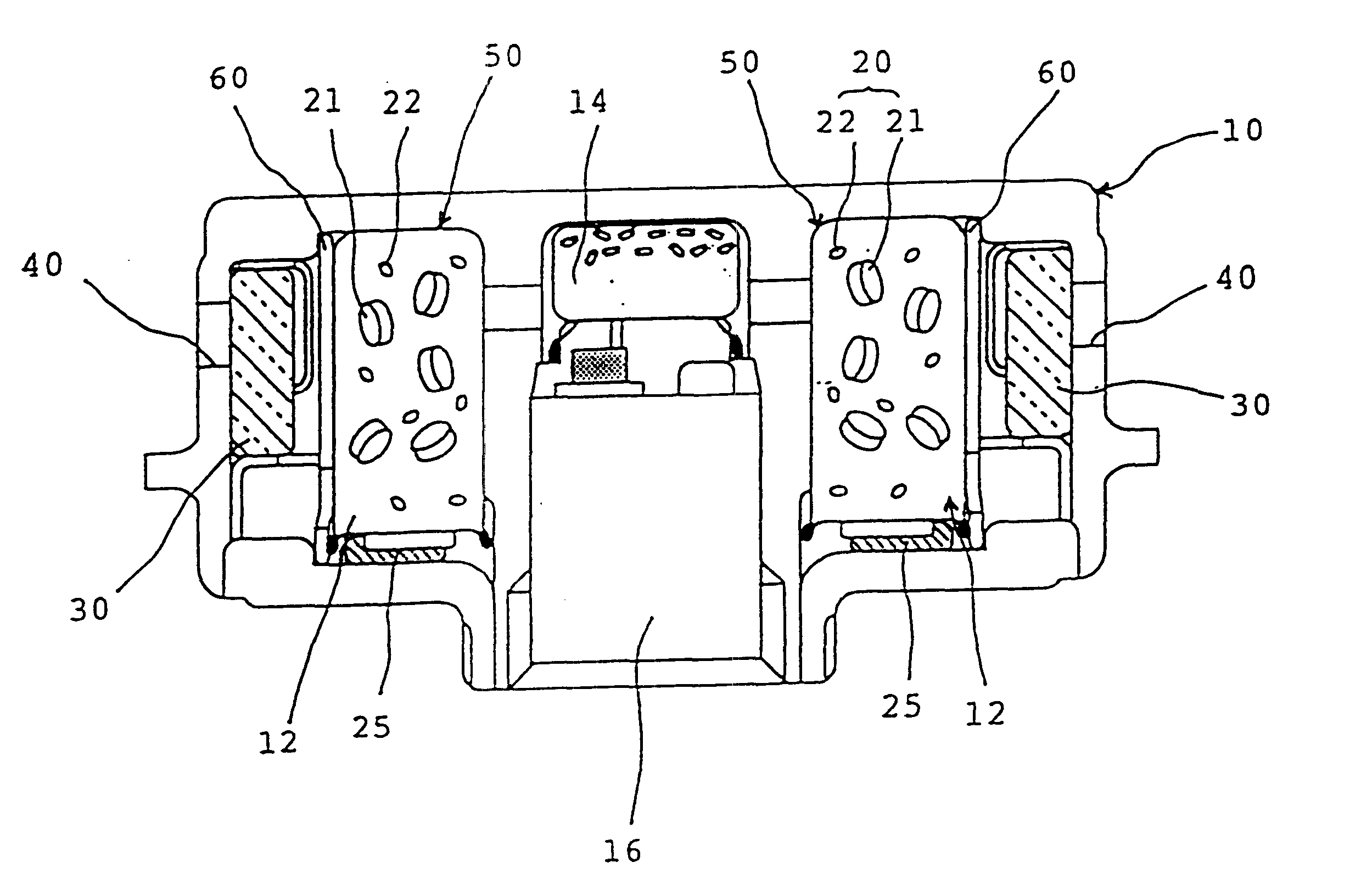

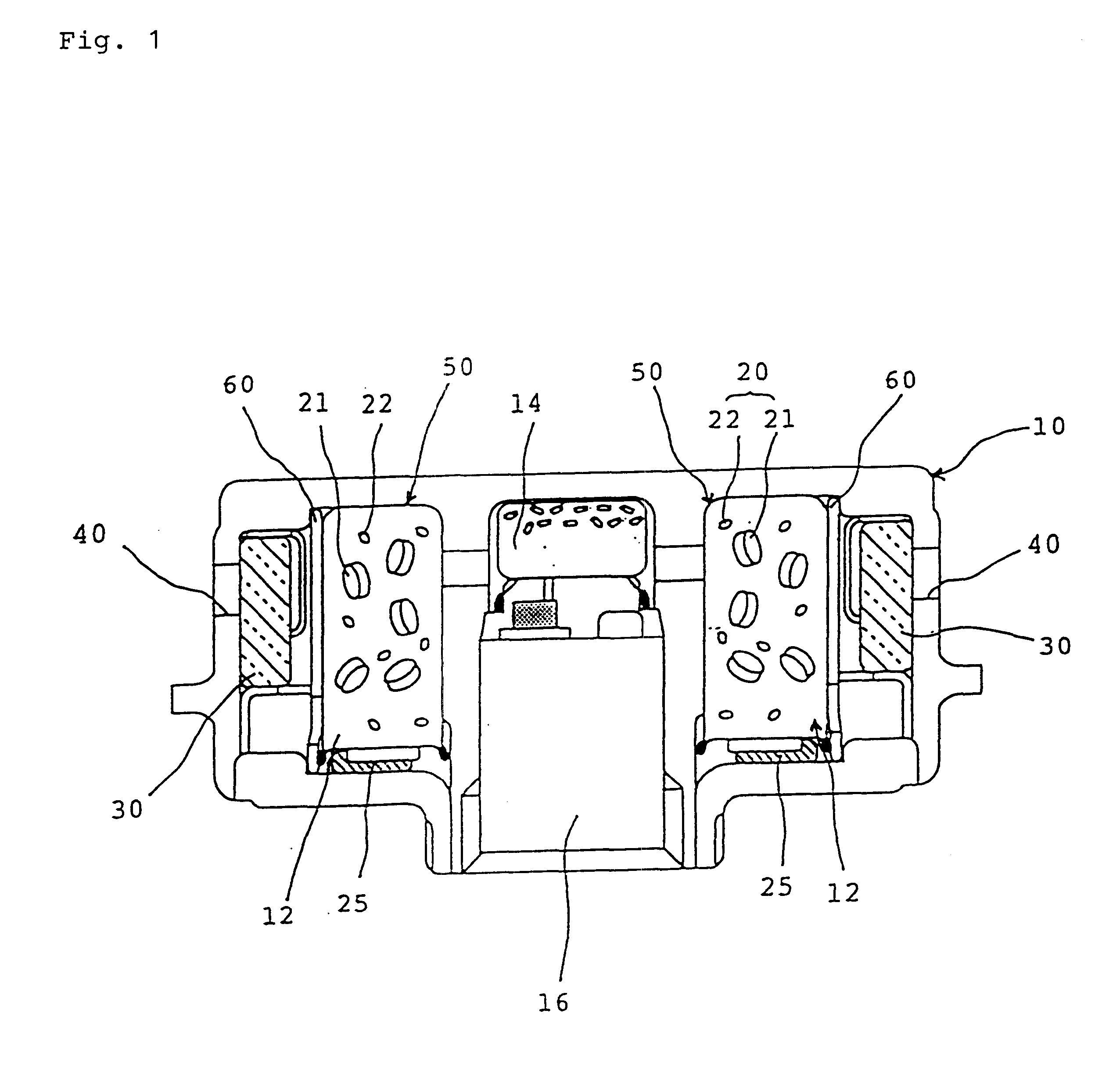

Reducing gas generator and solid reductant SCR system having the generator

ActiveUS8088336B2Simple configurationMeet high volumeCombination devicesPressurized chemical processEngineeringAmmonia

A reducing gas generator generates reducing gas including ammonia. The generator includes a solid reductant and a heat-generating portion. The solid reductant is formed in a columnar shape. A cross-sectional surface of the solid reductant has a constant shape and is perpendicular to a central axis of the solid reductant. The heat-generating portion includes a heat-generating surface opposed to a lower surface of the solid reductant in a vertical direction thereof and in contact with an entire region of the lower surface, and a heating element that heats the heat-generating surface when energized, so that the solid reductant is heated and decomposed to generate the reducing gas.

Owner:DENSO CORP

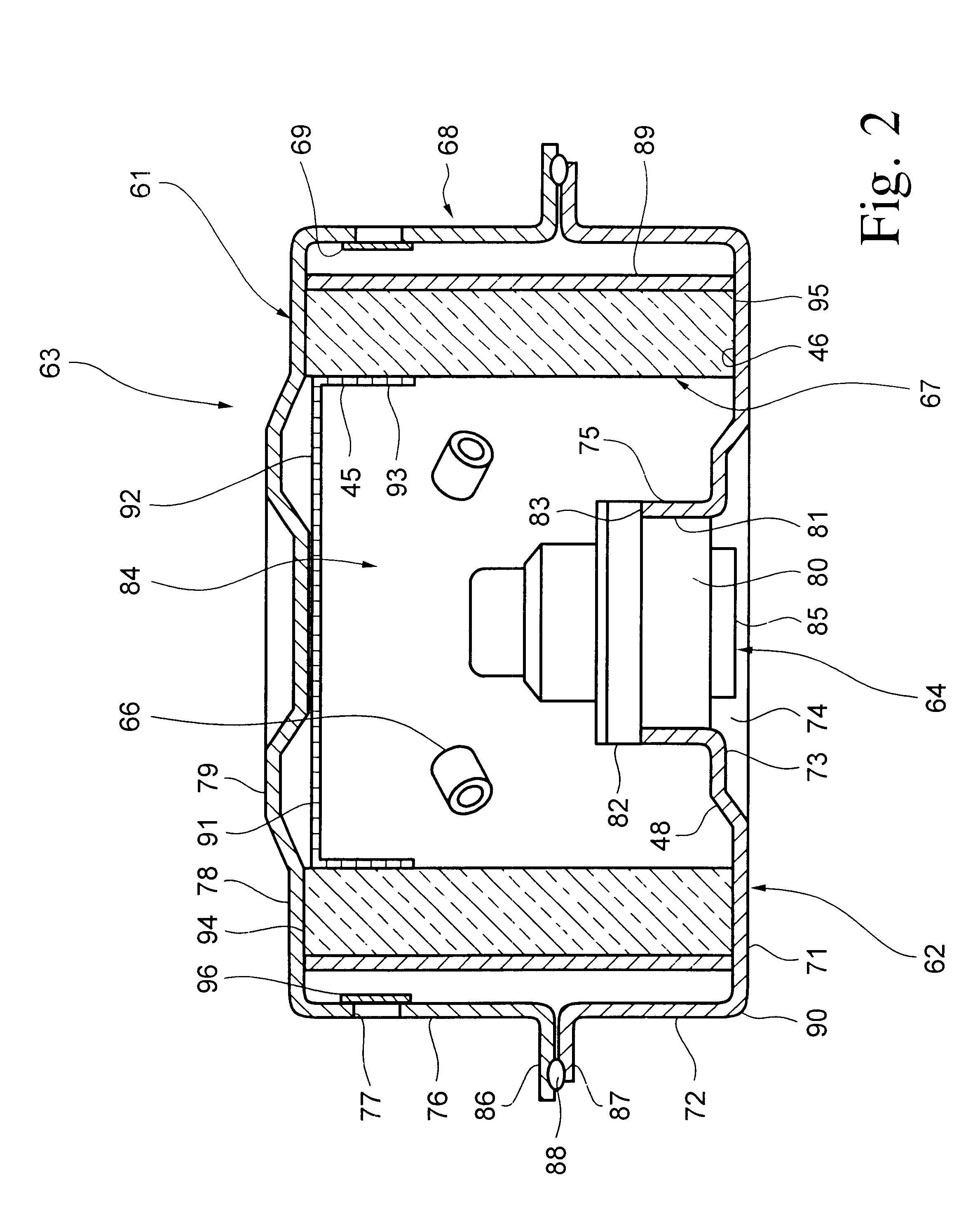

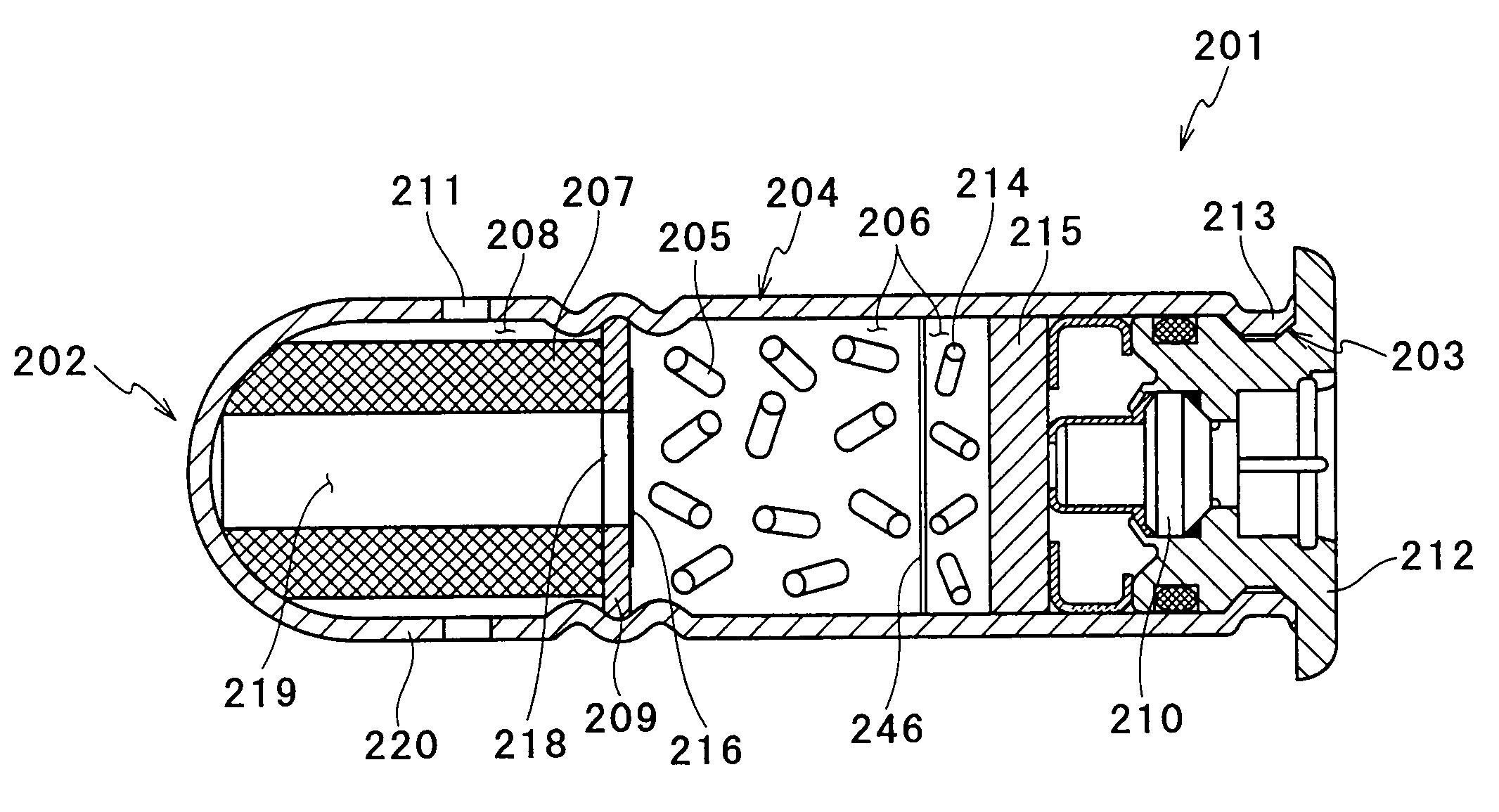

Gas generator for airbag and airbag system

InactiveUS6406060B1Low costImprove stabilityPedestrian/occupant safety arrangementPressure gas generationCombustionNuclear engineering

A gas generator for an air bag which enables a gas generating agent to be completely burned in a desired period of time, and shows sufficient operating characteristics is provided. In a gas generator for an air bag, wherein igniting unit to be actuated when an impact sensor detects an impact, solid bodies of gas generating agent ignited by the igniting unit and burned to generate a combustion gas, and filter unit for cooling the combustion gas and scavenging combustion residues are accommodated in a housing having gas discharge ports. The ratio (A / At) of the total surface area A of the solid bodies of gas generating agent to the total opening area At of the gas discharge ports is controlled to be larger than 300.

Owner:DAICEL CHEM IND LTD

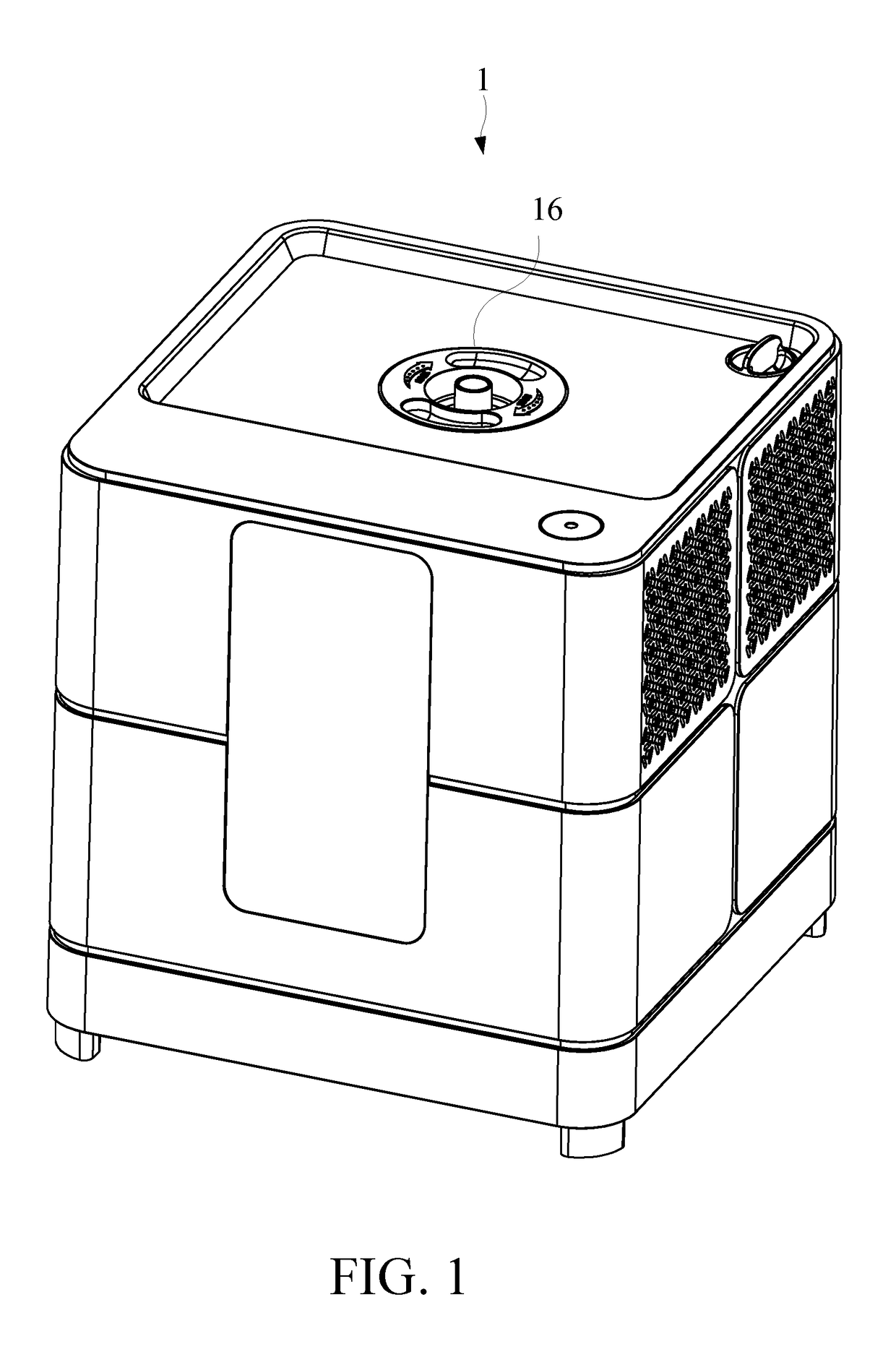

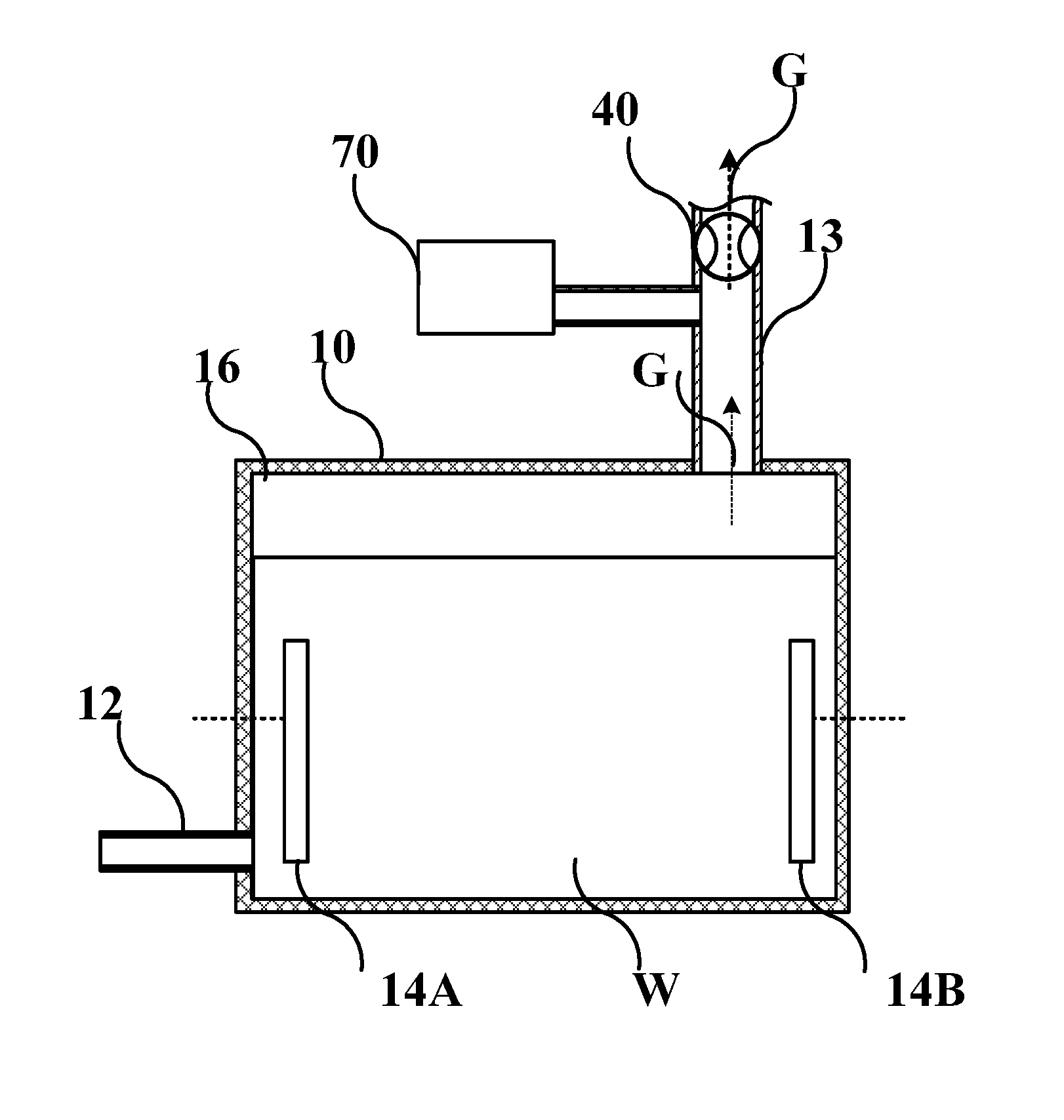

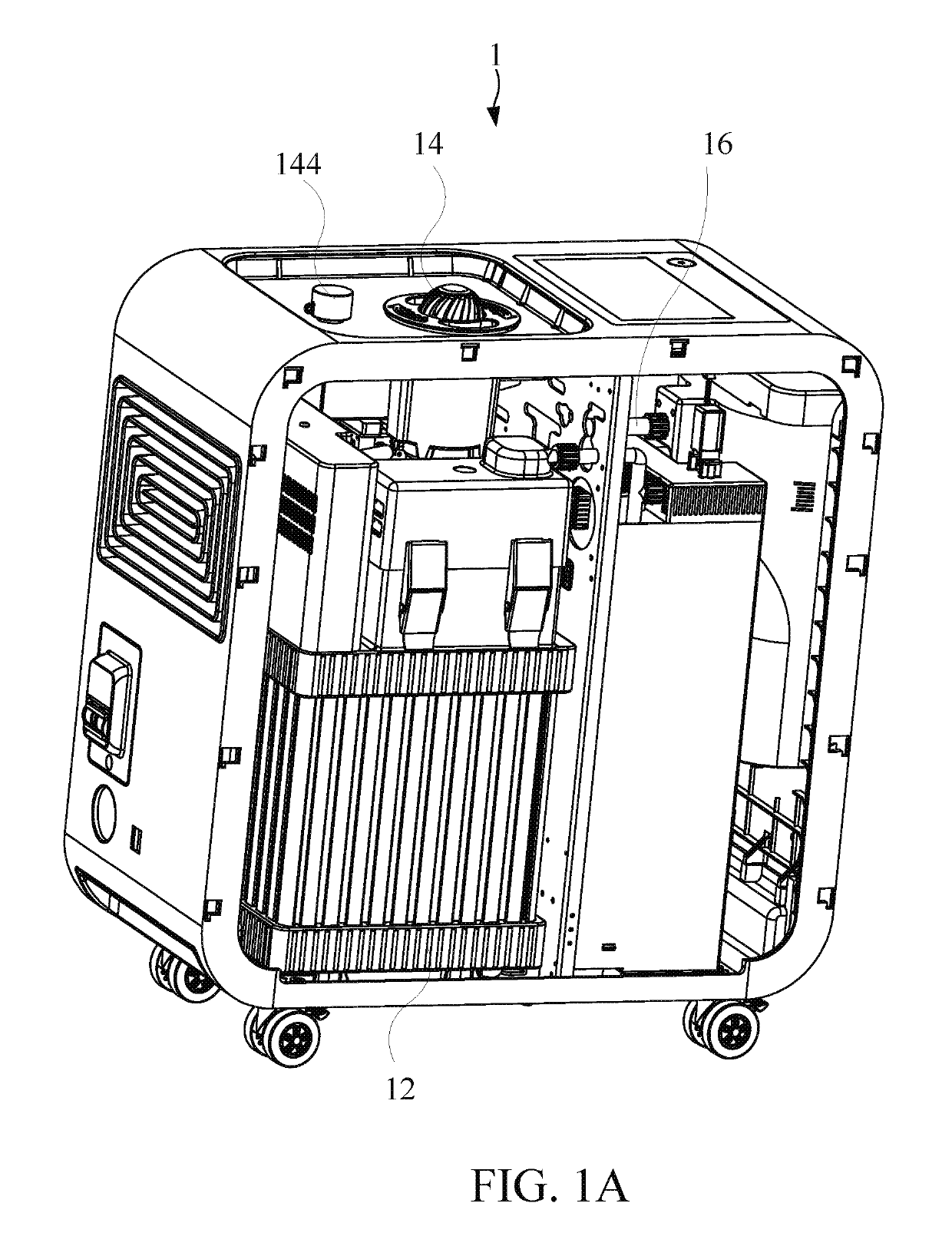

Gas generator

The present invention provides a gas generator and comprises an electrolytic cell and a water-blocking device. The electrolytic cell is used for electrolyzing electrolyzed water to generate a gas with hydrogen. The electrolytic cell has an outlet for outputting the gas with hydrogen. The water-blocking device is set on the outlet for preventing the electrolyzed water from flowing out when the electrolytic cell is tilted by a tilt angle. The gas pathway of the invention will be closed by the water-blocking device when the gas generator is toppled, thereby preventing the electrolyte-rich electrolyzed water from flowing out.

Owner:LIN HSIN YUNG

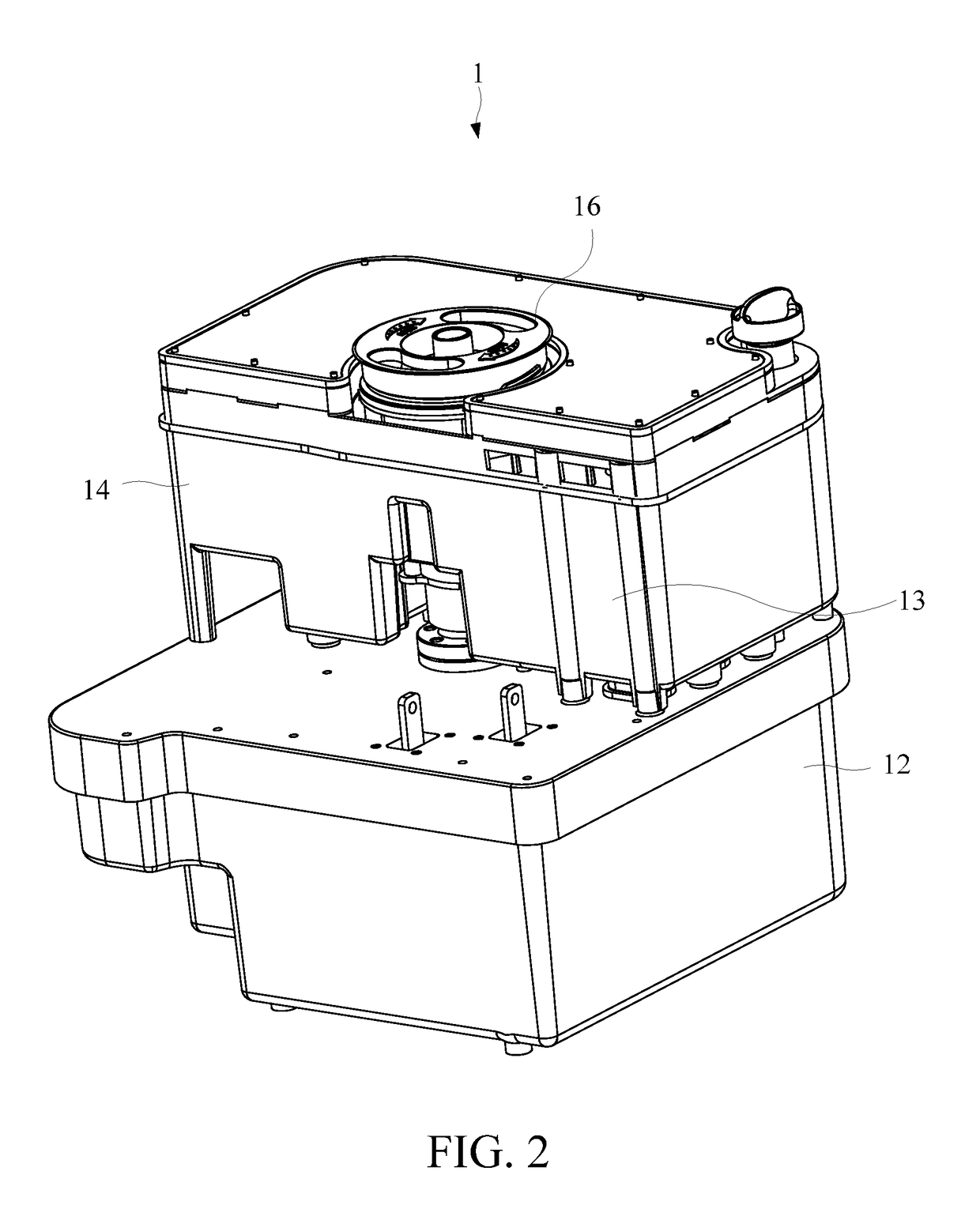

Gas generator

The present invention provides a gas generator comprising an electrolysis device and a condensation filer. The electrolysis device is used for electrolyzing electrolyzed water to generate a hydrogen-oxygen mixed gas. The condensation filer is used for condensing the hydrogen-oxygen mixed gas and filtering impurities in the hydrogen-oxygen mixed gas, and is equipped with a gas inlet and a gas outlet. The gas outlet of the condensation filer is used for inputting make-up water to the electrolysis device. The gas generator may provide the hydrogen-oxygen mixed gas suitable for the inhalation of humans, reduces the consumption of electrolyte, and prevents the electrolyte from blocking the condensation filer.

Owner:SHANGHAI ASCLEPIUS MEDITEC CO LTD

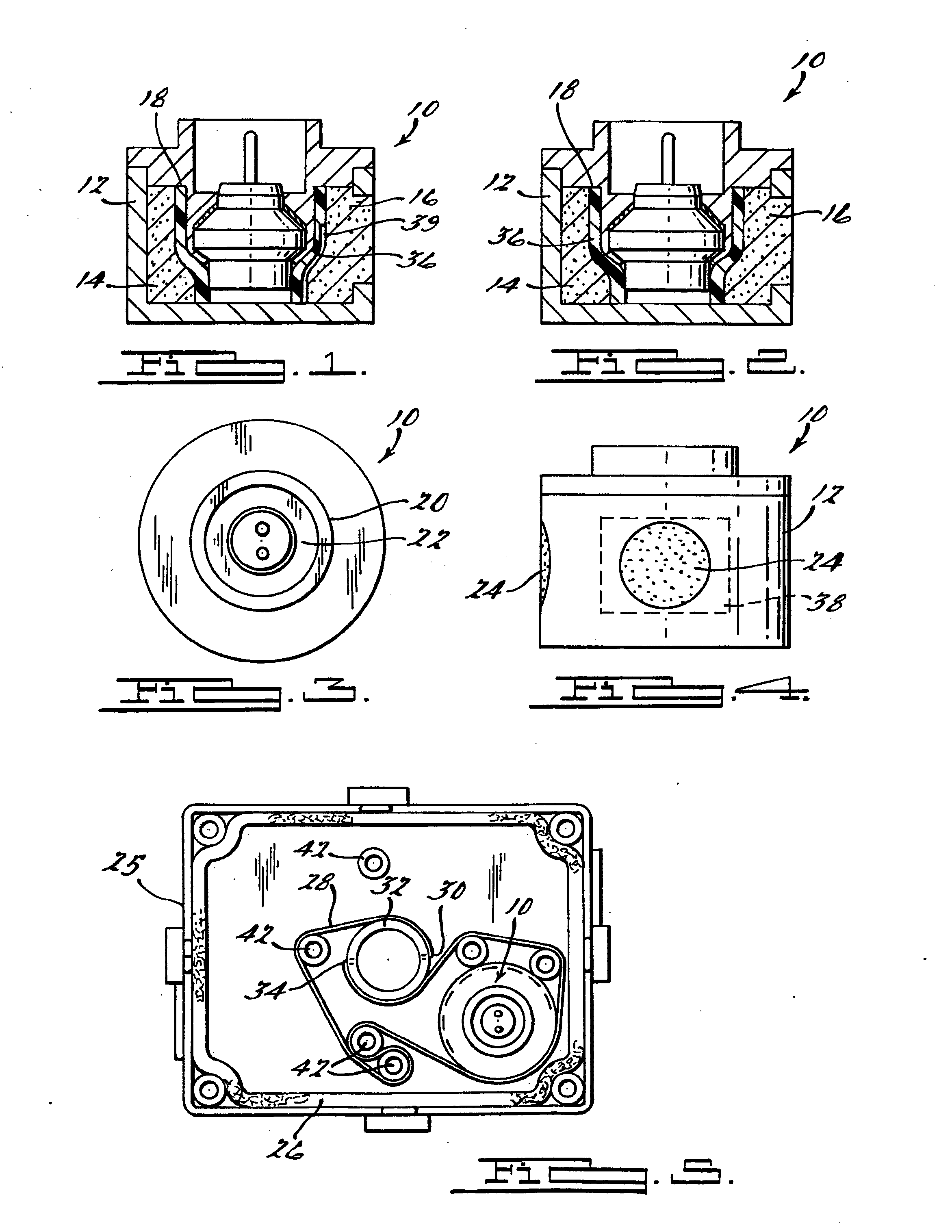

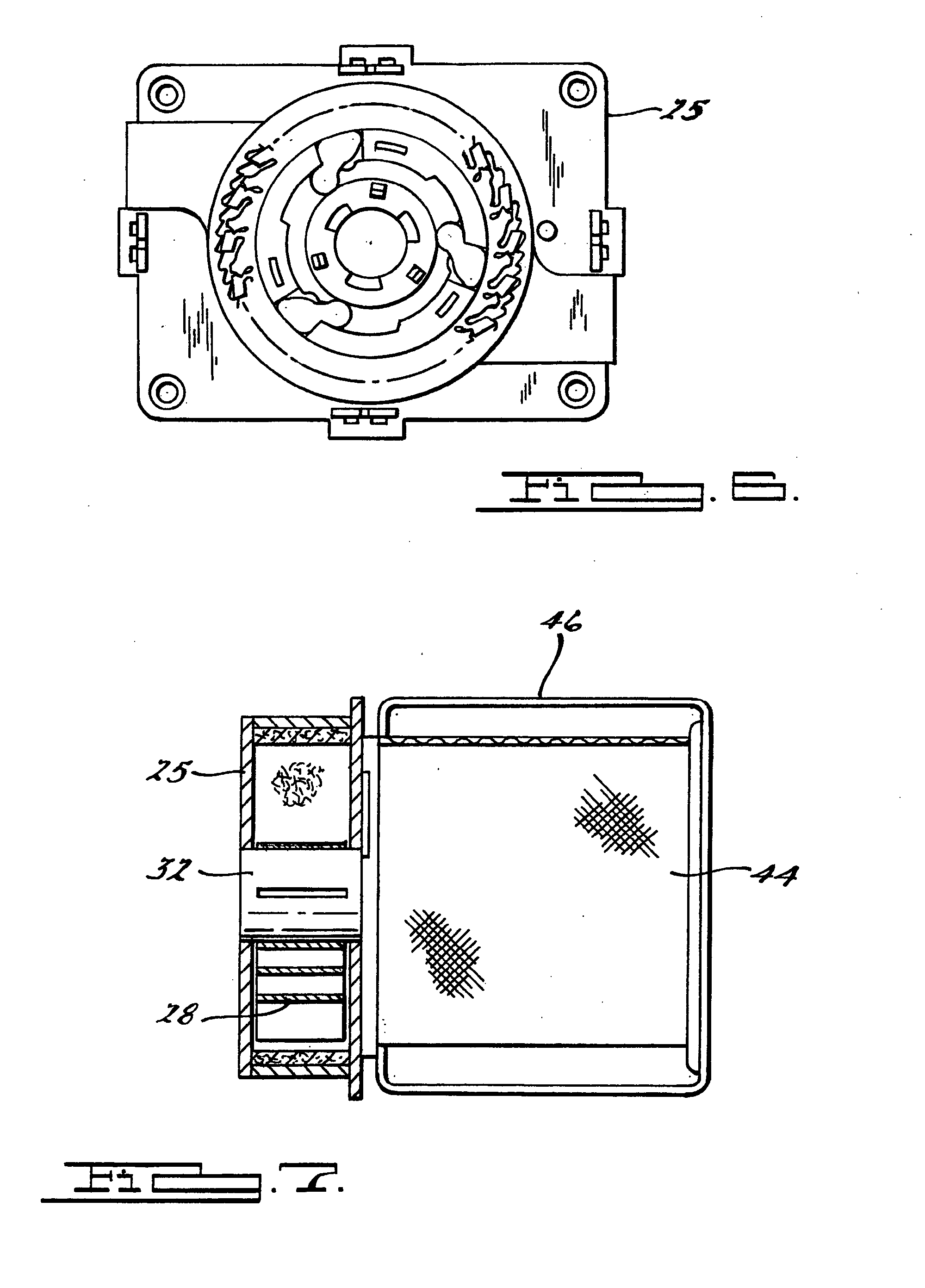

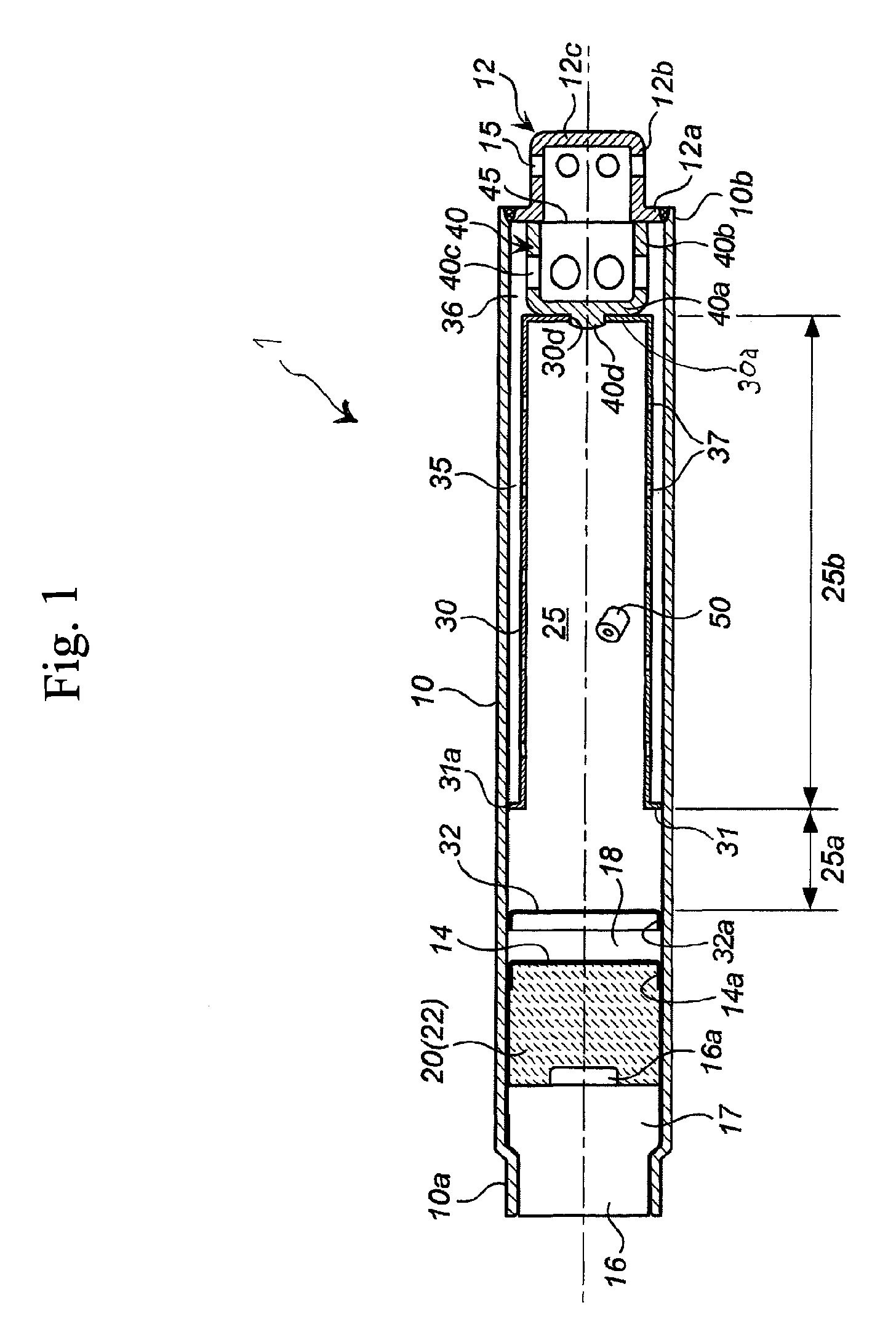

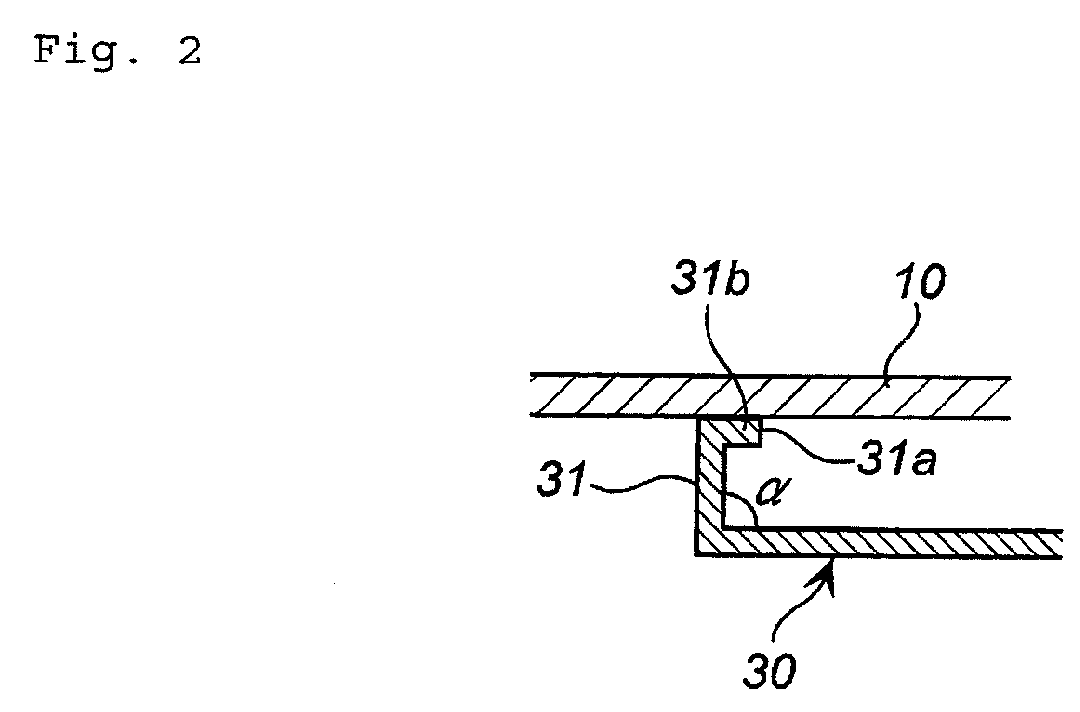

Micro gas generator including an initiator blast shield

InactiveUS20050017496A1Gradual and controlled combustionReduce burning rateBelt retractorsPedestrian/occupant safety arrangementCombustionNuclear engineering

A micro gas generator 10 is provided primarily for supplying and directing gas from the combustion of pyrotechnic materials into a seatbelt pretensioner 26, for example. A perforated housing 12 of gas generator 10 provides a body for containment of the other gas generant constituents, and forms a propellant chamber 14. A propellant or gas generant 16 is contained within chamber 14 and provides combustion thereof. An annular bore 20 is centrally oriented within the bore seal 18 thereby providing a seat for an associated initiator 22. An initiator blast shield 36 is encased about the initiator 22 thereby attenuating or mitigating the force and progression of the combustion of an ignition compound (not shown) within the initiator 22.

Owner:AUTOMOTIVE SYST LAB

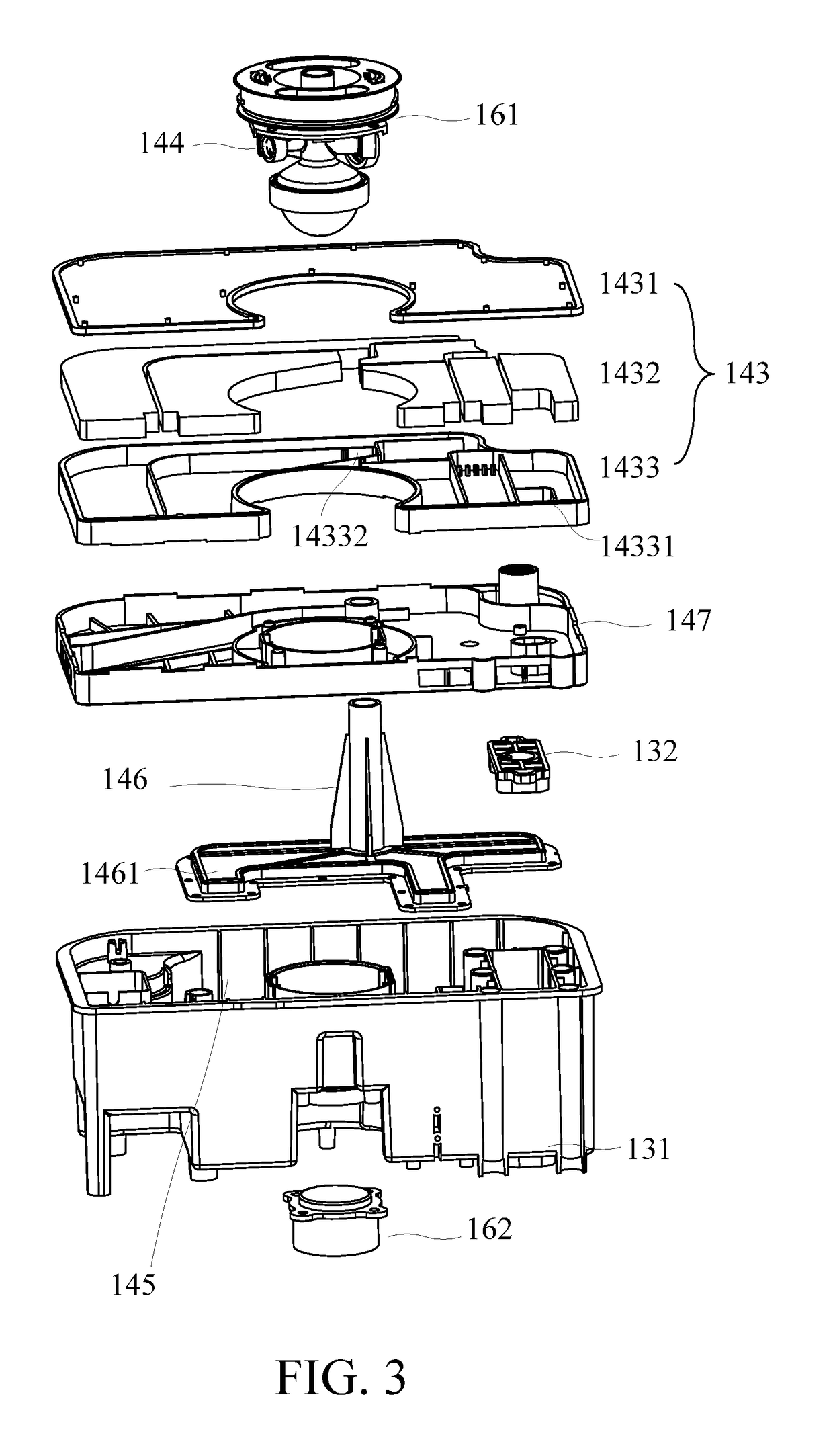

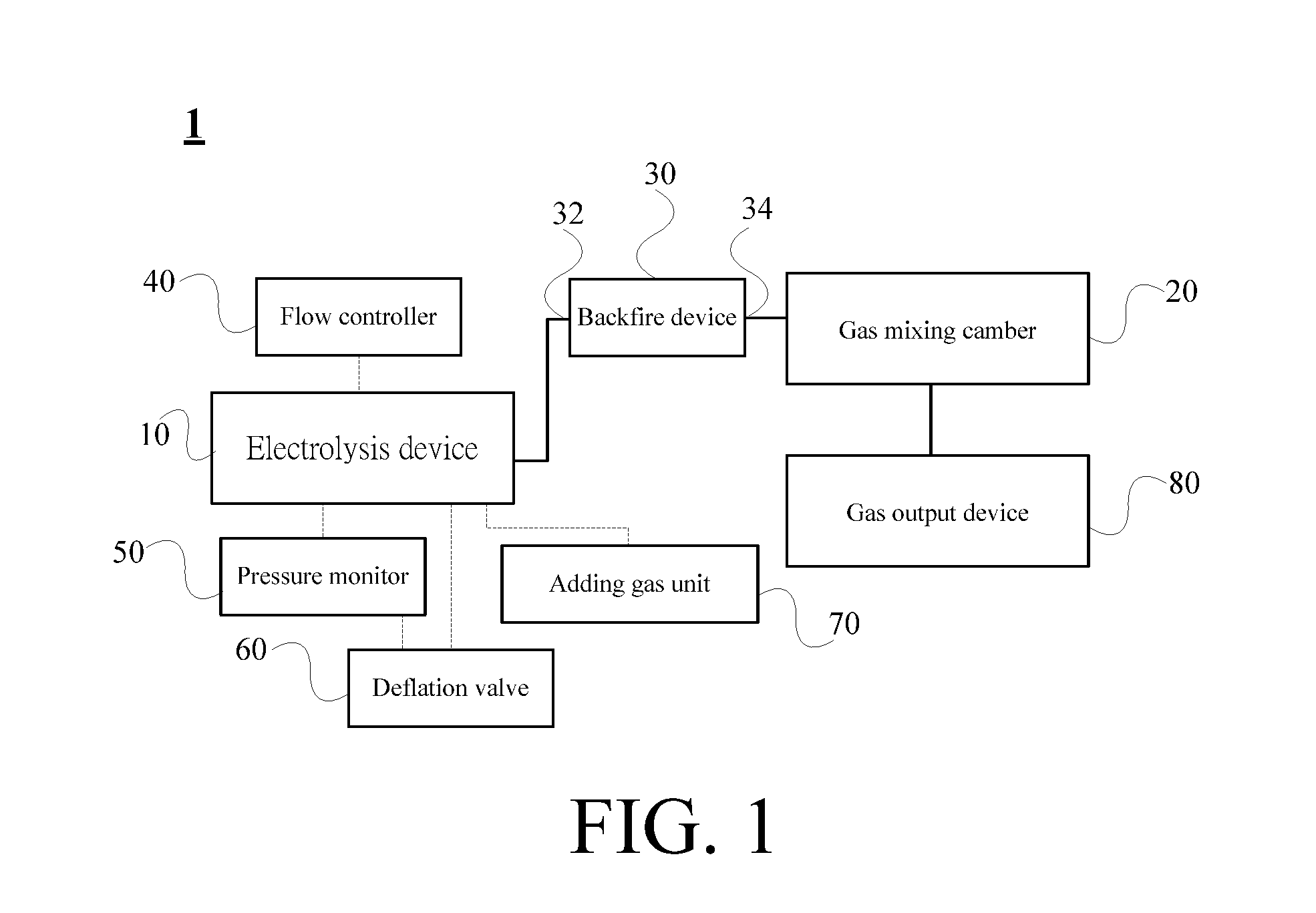

Gas generator

A gas generator for health is provided. The gas generator for health includes an electrolysis device, a gas mixing chamber and a gas output device. The electrolysis device is for electrolyzing water to produce a combination gas including hydrogen and oxygen. The gas mixing chamber includes a shell and a cover. The shell has an anti-explosion hole. The cover is separatably disposed on the anti-explosion hole, and the diameter of the anti-explosion hole is larger than 0.5 cm. The gas mixing chamber is connected to the electrolysis device for receiving the combination gas. A vaporized gas is generated by the gas mixing chamber and mixed with the combination gas to produce a healthy gas. The gas output device is connected to the gas mixing chamber for outputting the healthy gas to a user to breath.

Owner:LIN HSIN YUNG

Gas generator

ActiveUS10385463B2Reducing and eliminating static electricityReduce the possibilityRespiratorsCellsHydrogenEngineering

The present invention provides a gas generator and comprises an electrolytic cell, a gas pathway, and an anti-static device. The electrolytic cell is for electrolyzing electrolyzed water to generate a gas with hydrogen. The gas generated from the electrolytic cell is transferred by the gas pathway. The anti-static device is set in the gas generator for reducing or eliminating the static electricity. The present invention uses the anti-static device to prevent the gas with hydrogen in the gas pathway from exploding by the static electricity, thereby providing a safe gas generator.

Owner:LIN HSIN YUNG

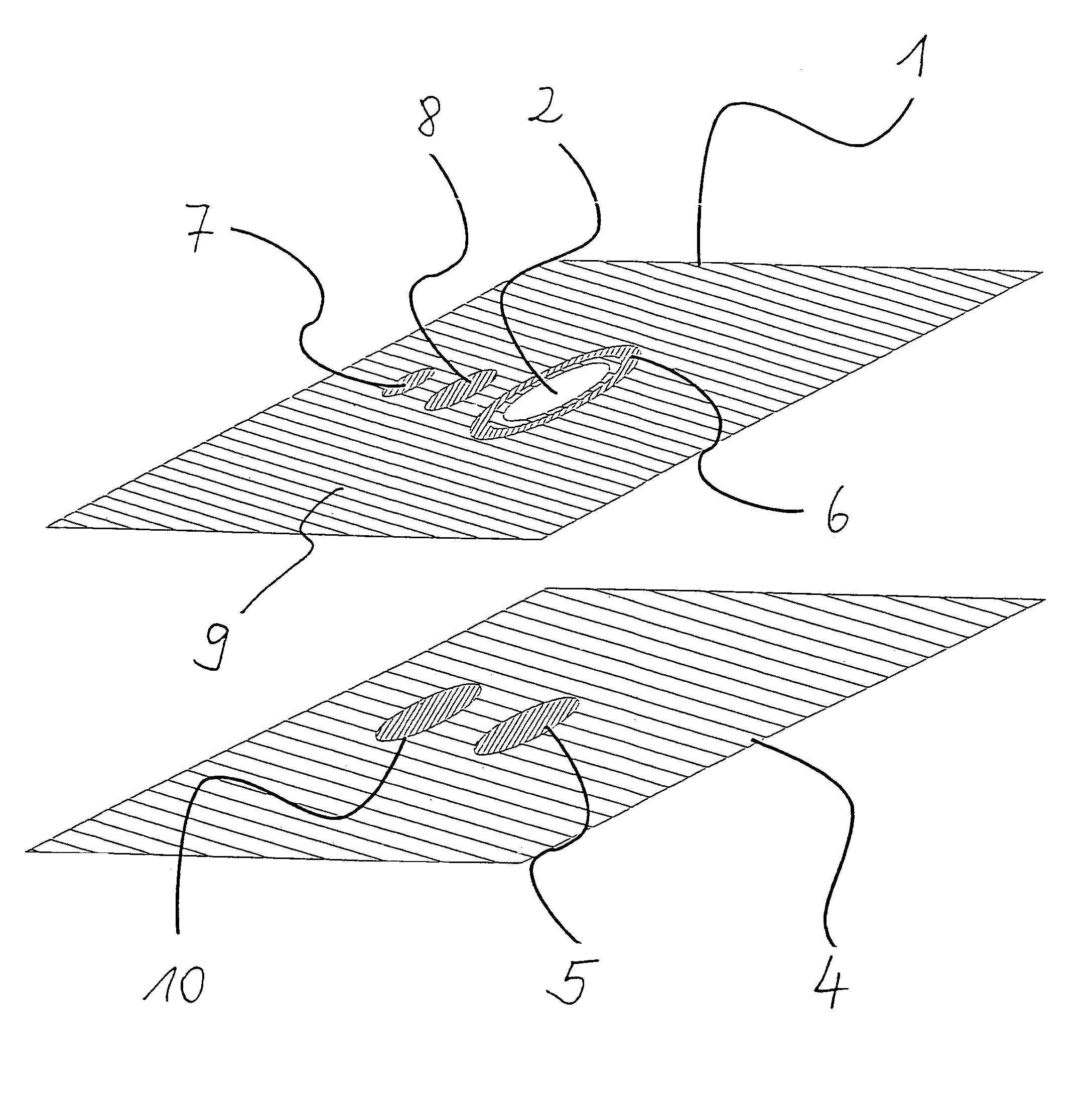

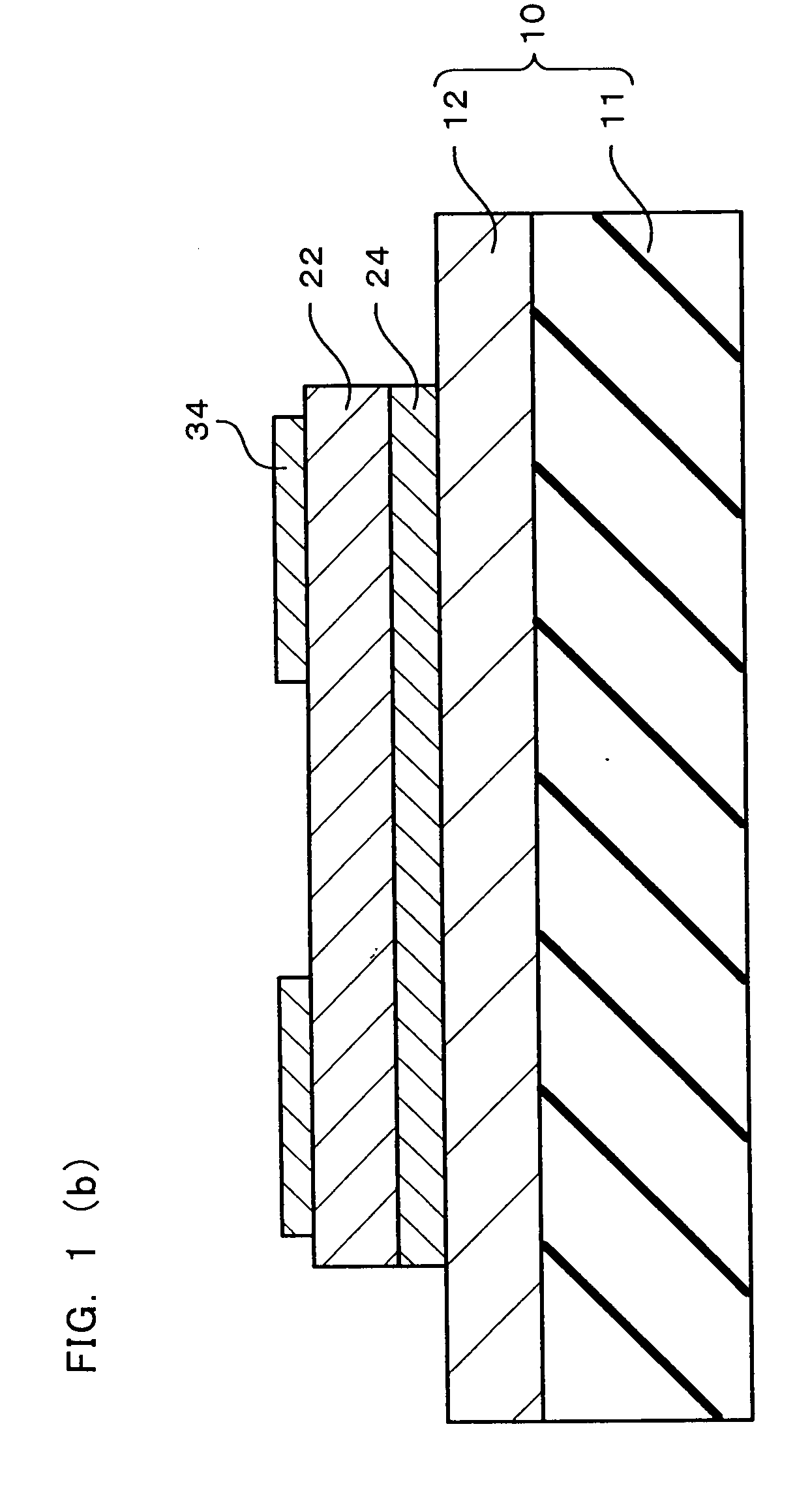

Semiconductor bridge, igniter, and gas generator

ActiveUS20090126592A1Shorten ignition timeEnergizing time can be shortenedBlasting cartridgesPedestrian/occupant safety arrangementPower flowEngineering

The invention provides a semiconductor bridge, an igniter, and a gas generator each of which satisfies a high-speed responsiveness required of, for example, an automotive side inflator. The semiconductor bridge includes a bridge part heated by being supplied with a current. The bridge part is disposed on a substrate. The bridge part includes a first layer and an ignition bridge layer. The first layer is formed on the substrate and has insulating properties. The ignition bridge layer serves as a second layer disposed on the first layer. The width of the bridge part at the first layer and the width of the bridge part at the second layer are substantially equal to each other. A space is provided around the bridge part. With this structure, the diffusion of current and heat into the substrate can be restricted to the minimum level, and the ignition time can be quickened as an ignition characteristic. Each of the igniter and the gas generator includes the semiconductor bridge.

Owner:NIPPON KAYAKU CO LTD

Method of operation of a downhole gas generator with multiple combustion chambers

ActiveUS20140034302A1Control outputKeep the pressureSurveyTurbine/propulsion engine coolingCombustion chamberPetroleum product

A method for generating gasses in a borehole for use in the recovery of petroleum products. The method utilizes a multiple chamber gas generator system that includes a plurality of gas generators each having an elongate combustion chamber. The multiple chamber gas generator system is positioned in the borehole, and the operation of each of the plurality of gas generators is controlled to selectively turn each of the gas generators on or off, to regulate the volume of gasses being generated in response to changes in conditions within the borehole.

Owner:KREIS SYNGAS

Preparation method of sulfide mineral collector

The invention relates to a preparation method of sulfide mineral collector. The method comprises the following steps: sodium sulfide and phosphoric acid are weighed according to the mol ratio of 2 to 3:3 to 6 and added into a gas generator; generated gas is collected and charged into a high-pressure reactor charged with 10 to 13 C of fatty alcohol, thorium oxide catalyst or strongly acid cation resin; the mol ratio of the alcohol to gas is kept to be 1 to 2:1.2 to 2.5; the reaction is performed for 6 to 8 h under the condition that the pressure is 12 to 15 MPa and the temperature is 300 to 450 DEG C to obtain liquid mixture; distillate is collected by distillation under normal pressure at 180 to 300 DEG C according to different carbon numbers, and after the refracting index is detected to be qualified, transparent, colorless and adhesive liquid substance with peculiar odor is obtained, which is the sulfide mineral collector. By adopting the sulfide mineral collector, sulphide ore can be efficiently recovered without active agent, the overall recovery of the sulphide ore reaches larger than 89 percent, and the production cost is reduced.

Owner:广西华锡集团股份有限公司 +1

Gas generator and processes for the conversion of a fuel into an oxygen-depleted gas and/or hydrogen-enriched gas

A gas generator and process for converting a fuel into an oxygen-depleted gas and / or hydrogen-enriched gas. The gas generator, which may be used in any process requiring oxygen-depleted gas and / or hydrogen-enriched gas, is preferably used for generating protection gas or reducing gas for start up, shut down or emergency shut down of a SOFC or SOEC.

Owner:TOPSOE FUEL CELL

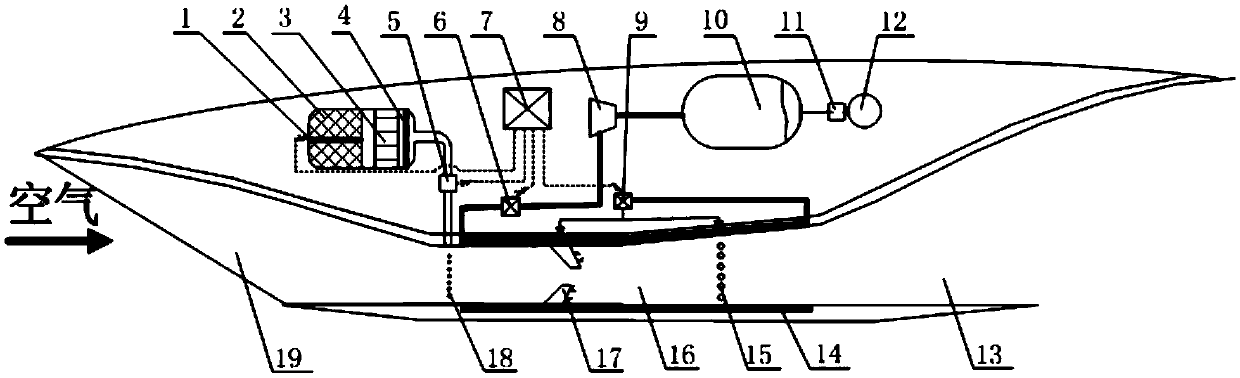

Gas suction type engine cold start system and cold start method

ActiveCN109630314AEliminate potential safety hazardsEasy to use and maintainRam jet enginesComposite engine plantsCombustion chamberSolid fuel

The invention relates to a gas suction type engine cold start system. The hidden danger of use safety existing in a flammable material guiding fuel ignition combustion preheating cold start structureand a gaseous fuel combustion preheating cold start structure used in an existing engine are eliminated. The cold start system comprises a gas generator, a gas distribution valve and at least one first fuel injector opening in the inner wall of a combustion chamber and located at the front end of the combustion chamber. The gas generator comprises a gas generating device, a cooling device and a filter, wherein the gas generating device, the cooling device and the filter are connected in sequence. The gas generating device comprises a fuel cavity and a generator igniter, the fuel cavity is provided with solid fuel, and the generator igniter is used for igniting the solid fuel. An inlet of the gas distribution valve is connected with an outlet of the filter, the gas distribution valve is provided with at least one outlet corresponding to the first fuel injectors, and the outlets of the gas distribution valve are connected with the first fuel injectors correspondingly.

Owner:XIAN AEROSPACE PROPULSION INST

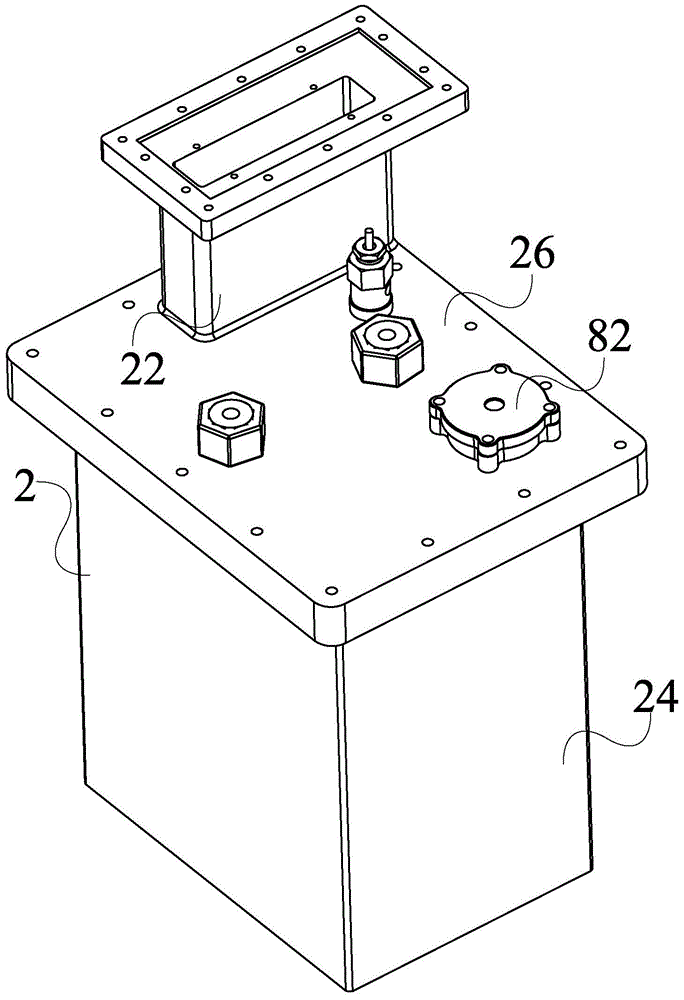

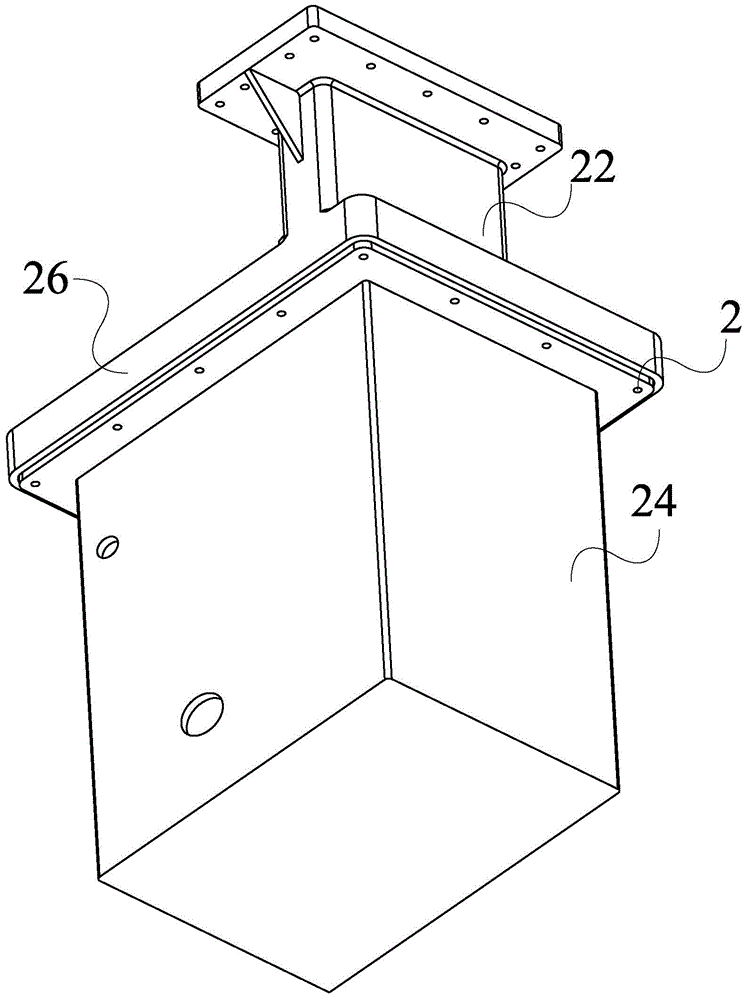

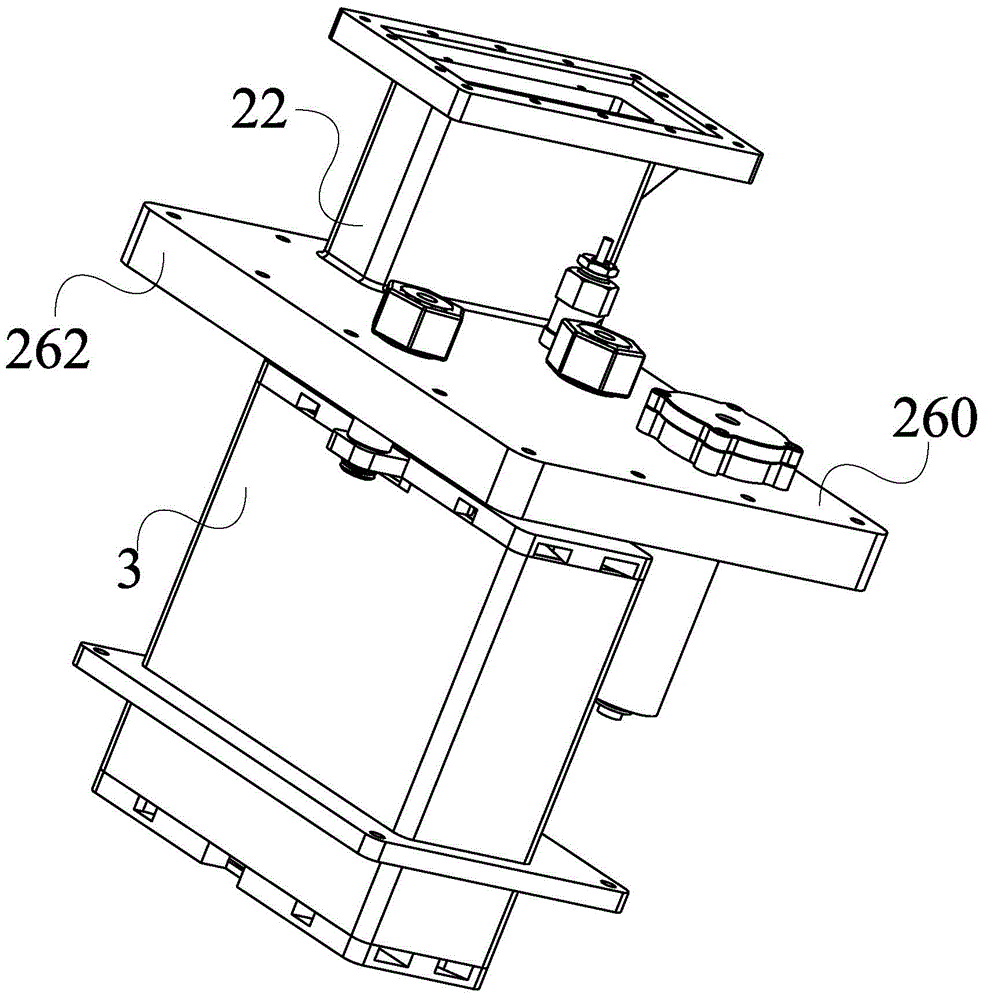

High total impulse solid cool gas micro propulsion unit

ActiveCN106246411AImprove sealingImprove air tightnessCosmonautic propulsion system apparatusRocket engine plantsMulti degree of freedomGas chamber

A high total impulse solid cool gas micro propulsion unit includes a gas chamber (1); the gas chamber (1) is a cylindrical housing with an opening at one end of the cylindrical housing; nozzles of all the micro cool gas propulsion devices (10) are arranged on the center of an end surface of the gas chamber (1) and side walls of the gas chamber (1) respectively; a gas chamber end cover (2) seals the opening end of the gas chamber (1); a temperature sensor (5), a pressure sensor (6) and a cool gas generator (7) are fixed in the gas chamber (1); the pressure sensor (6) and the temperature sensor (5) can acquire pressure parameters and temperature parameters in real time and send the parameter values to a control drive module (3); the control drive module (3) drives the cool gas generator (7) to generate gas to be injected into the gas chamber (1) according to the received pressure parameter values and the received temperature parameter values; and the control drive module (3) drives and controls the work pulse width of the micro cool gas propulsion devices (10). The high total impulse solid cool gas micro propulsion unit can improve the total impulse of the propulsion module, can improve the whole sealing performance, and can achieve multi-degree of freedom control.

Owner:BEIJING INST OF CONTROL ENG

Gas generating agent for gas generator and manufacturing method thereof

InactiveCN104418676AHigh nitrogen contentMature and stable manufacturing processPressure gas generationTetrazoleSlag

The invention discloses a gas generating agent for a gas generator and a manufacturing method thereof, wherein the gas generating agent comprises the following components by the mass percentage: 15%-30% of a bis(tetrazole) potassium salt; 50%-80% of modified ammonium nitrate; 0%-15% of a performance regulator; and 0%-15% of a bonding and slag forming agent. The gas generating agent is prepared by weighing the components according to the proportion and through dry granulation and water-soluble granulation process; the bis(tetrazole) potassium salt is adopted to cooperate with modified ammonium nitrate, the dry or spray granulation process is used, the medicament granulating requirements can be met, and the granulating efficiency is improved. The gas generating agent can be ignited to burn under heat released from igniting gunpowder, ignition is quick, combustion can be smoothly carried out, gas is produced, the use requirements of inflatable airbags are met, the gas generation amount is large, the gas generation speed is fast, ignition is easy, low-temperature ignition performance is excellent, and thermal stability and chemical stability are good. The gas generating agent cannot be liquified to flow during self combustion.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

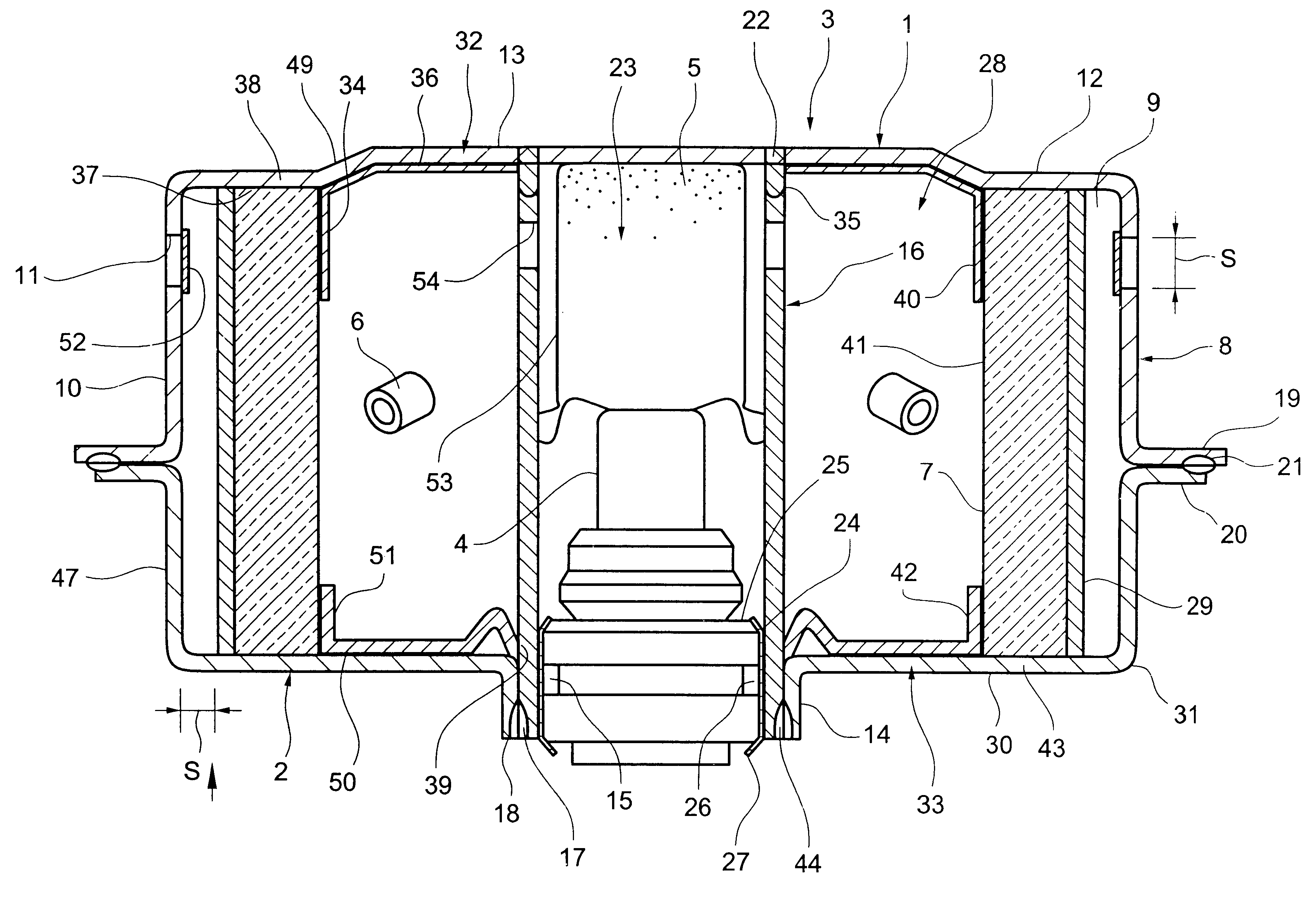

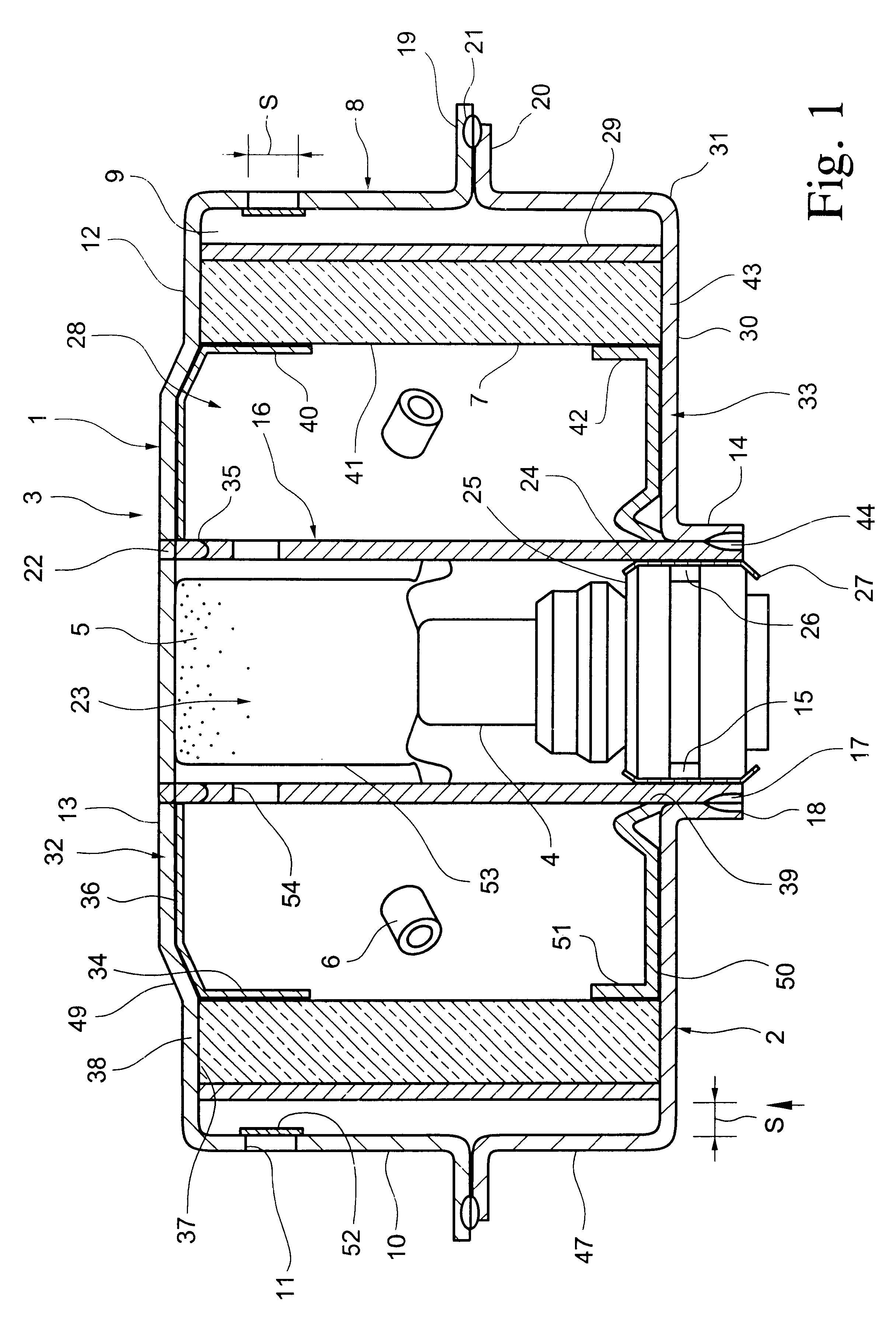

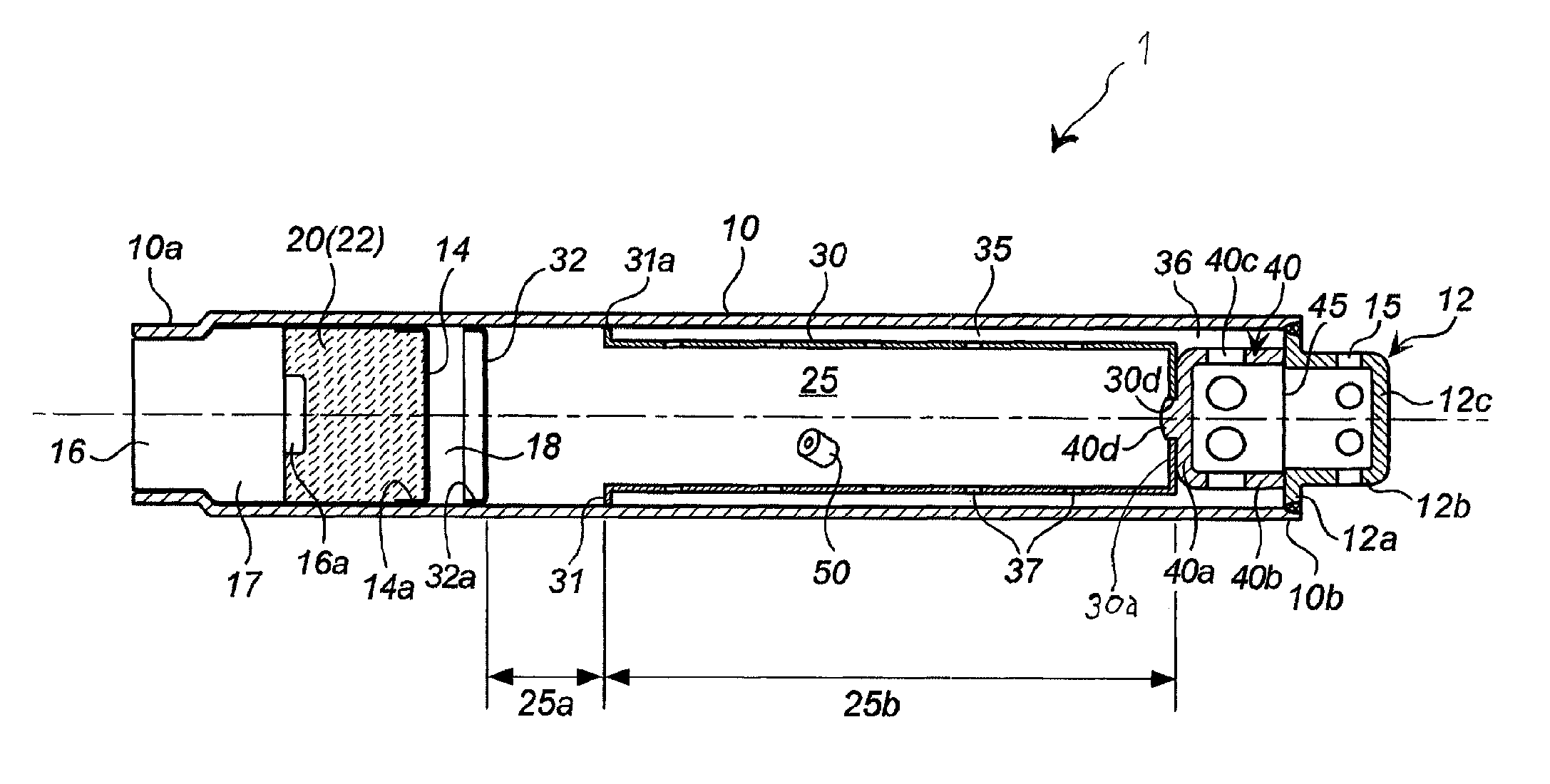

Gas generator and assembling method of the same

ActiveUS8302992B2Pedestrian/occupant safety arrangementMetal working apparatusCombustion chamberEngineering

The present invention provides a gas generator, including:a tubular housing, an ignition device attached to one end of the tubular housing, a diffuser portion having a gas discharge port and being attached to the other end of the tubular housing,in the tubular housing,a first combustion chamber defined by a first perforated-plate member on one end side in the tubular housing and filled with a first gas generating agent,a tubular member disposed in the remaining inner space of the tubular housing and having a communication hole on a peripheral wall portion thereof, a second-perforated plate member disposed between the first perforated-plate member and the tubular member, a second combustion chamber defined by the tubular member and filled with a second gas generating agent,the tubular member being disposed so that a gap is formed between the peripheral wall portion of the tubular housing and the tubular member, the tubular member having a first opening end portion abutting against the inner peripheral surface of the tubular housing in the side of the first perforated-plate member and a second end portion supported in the side of the diffuser portion.

Owner:DAICEL CHEM IND LTD

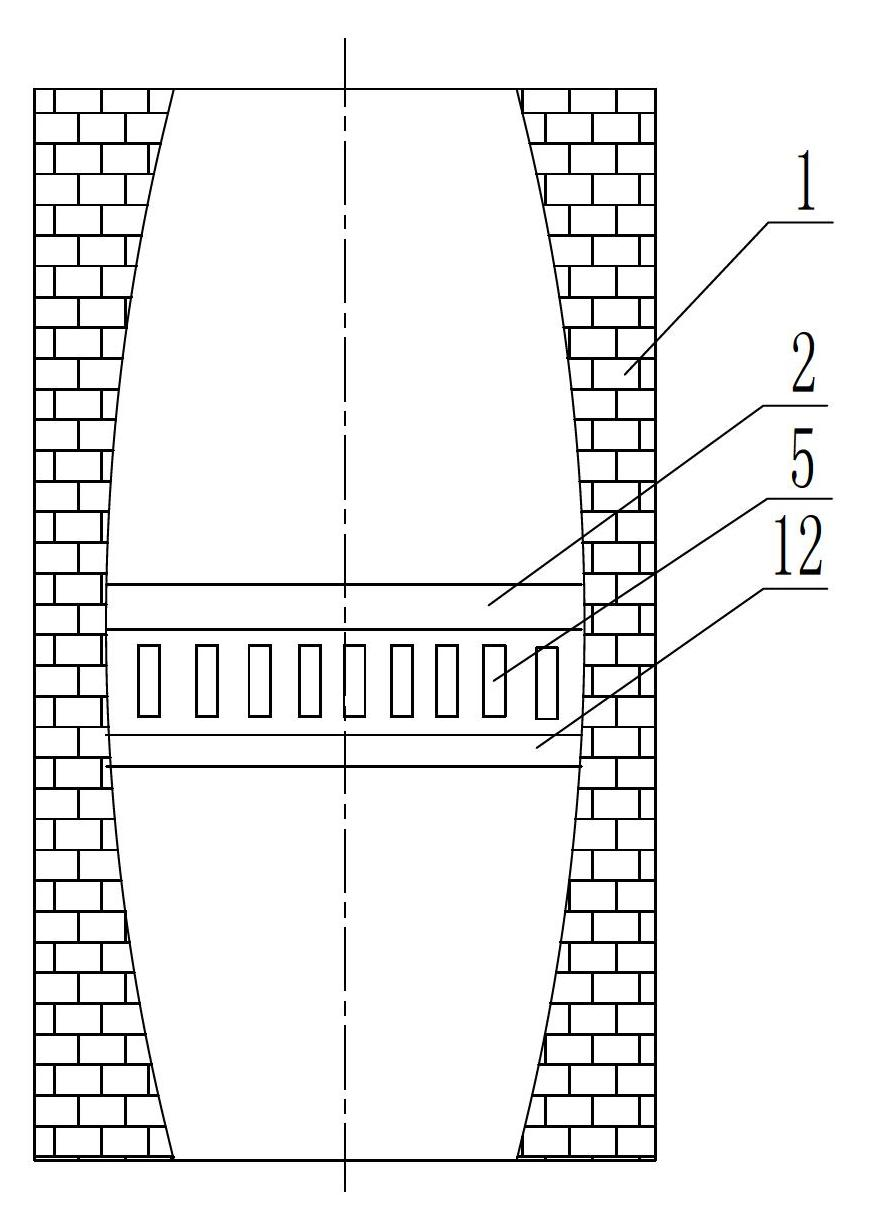

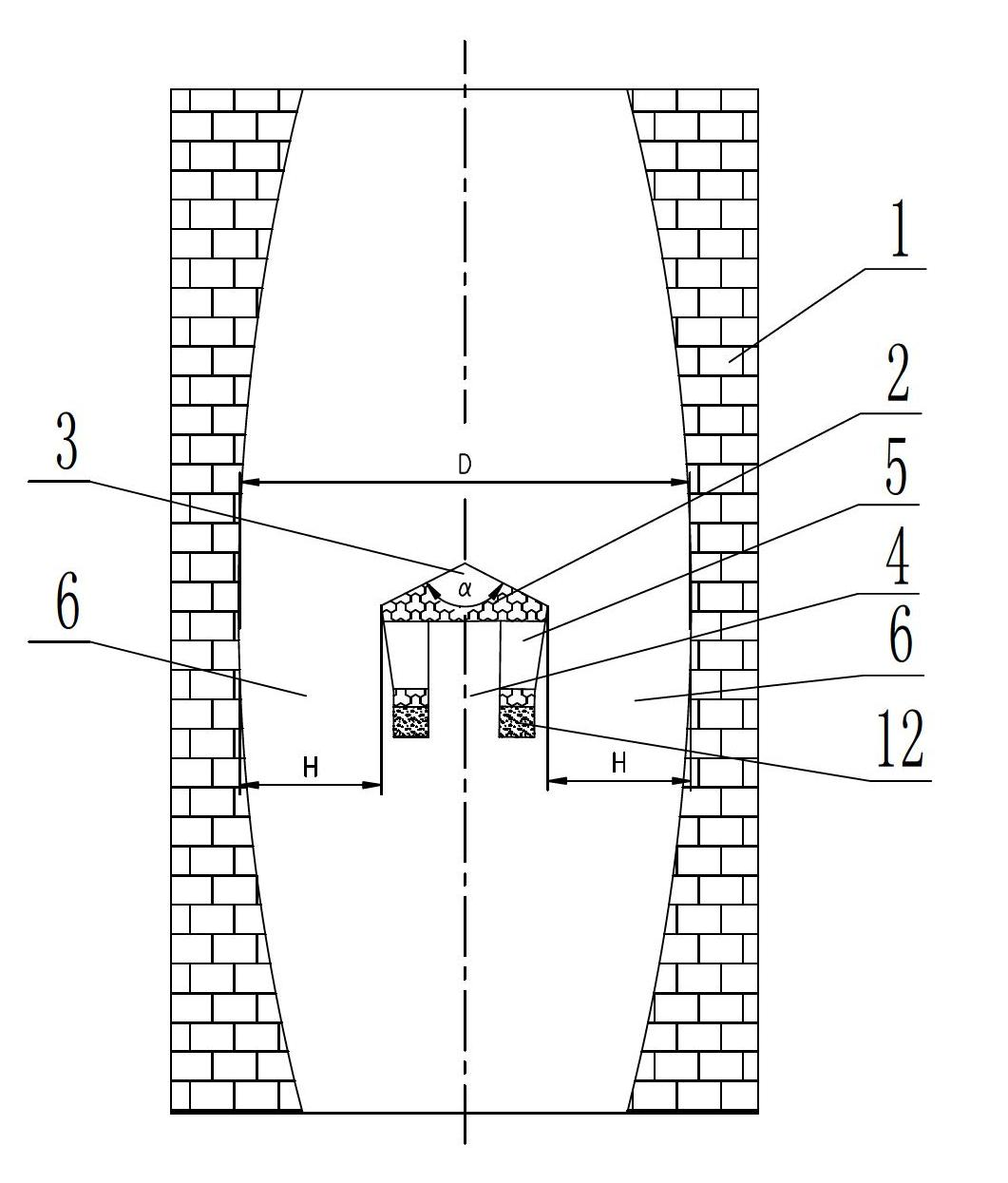

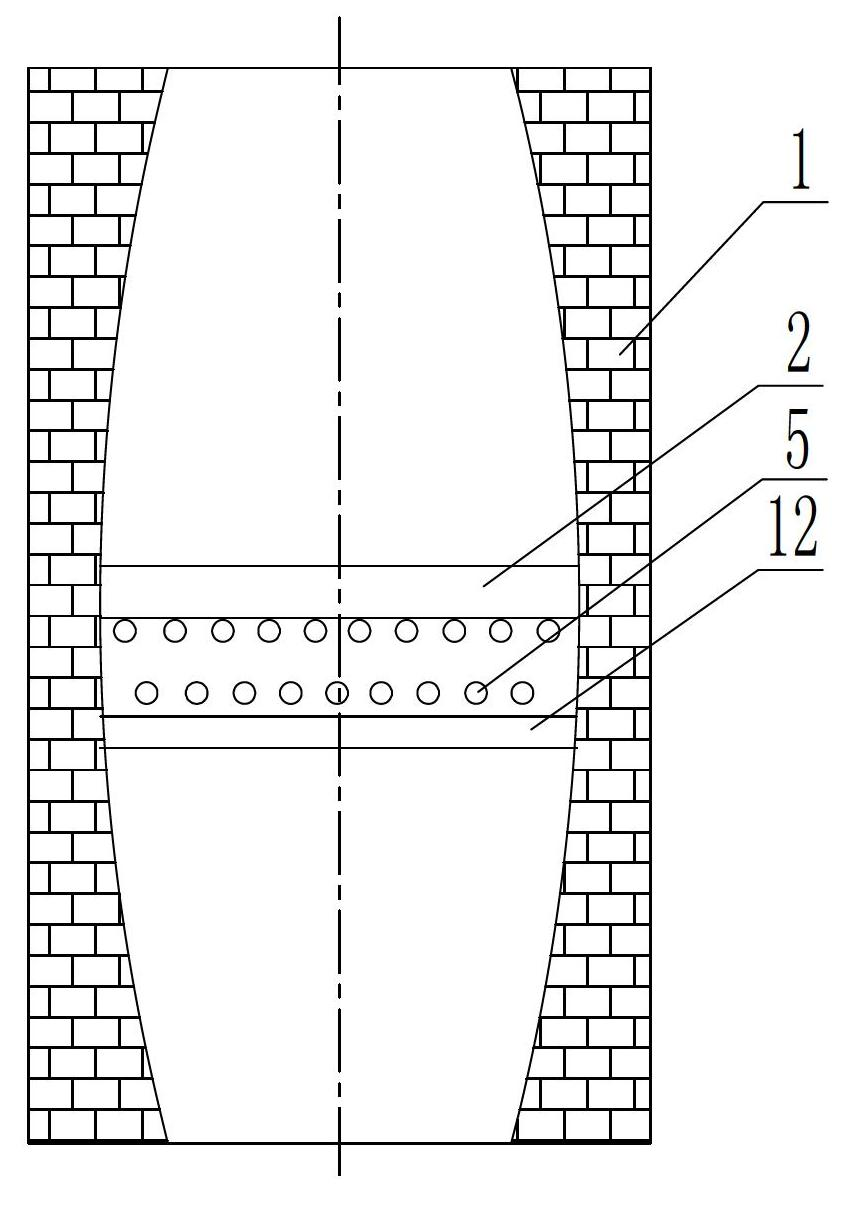

Continuous production method of undercalcined magnesia kiln

InactiveCN102674408ARealize continuous productionIncrease profitMagnesiaLime productionCombustorProcess engineering

The invention relates to the field of vertical undercalcined magnesia kiln production, in particular to a continuous production method of an undercalcined magnesia kiln. The continuous production method of the undercalcined magnesia kiln is characterized in that a coal gas storage tank is arranged between the kiln and a coal gas generator and the volume of the coal gas storage tank is required to be not less than the coal gas consumption of the kiln at the period of adding coal; and a tunnel burner is arranged in the kiln, materials are burned on the two sides of the burner, discharging passages are respectively arranged between the two sides of the burner and the inner wall of the kiln, the calcined materials automatically slide down from the discharging passages, continuous automatic discharging machines are arranged at the outlets of the discharging passages and therefore continuous production is realized. Compared with the prior art, the continuous production method of the undercalcined magnesia kiln has the beneficial effects: 1) the continuous production of the undercalcined magnesia kiln is realized, and while the product quality and the production efficiency are greatly improved, the energy utilization ratio is improved; 2) vertical heating and calcination are realized, the materials are burned more fully and the emission of gas pollutants is reduced; and 3) the labor intensity is reduced and the calcination time is stably controlled by controlling the discharging speed.

Owner:海城市华圣耐火材料有限公司

Gas generator

A gas generator assembly and method of operation. A plurality of stacks of laterally adjacent and laterally and axially supported gas generant wafers are contained within a housing. An igniter material is placed between the wafer stacks and an initiator. Upon ignition of the igniter material by the initiator, the wafer stacks are ignited and combust, generating a gas which, when reaching sufficient pressure within the housing in excess of ambient exterior pressures, opens a closed exhaust gas port and is released into a gas discharge structure where the gas passes through a heat sink material, cooling the gas before it exits the gas discharge structure for an intended use.

Owner:NORTHROP GRUMMAN SYST CORP +1

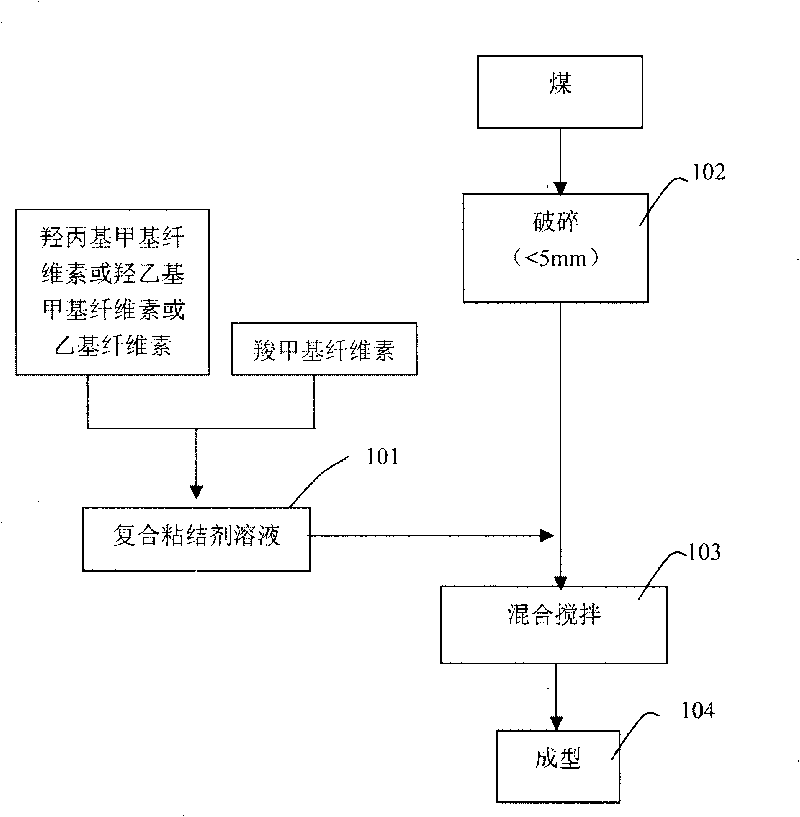

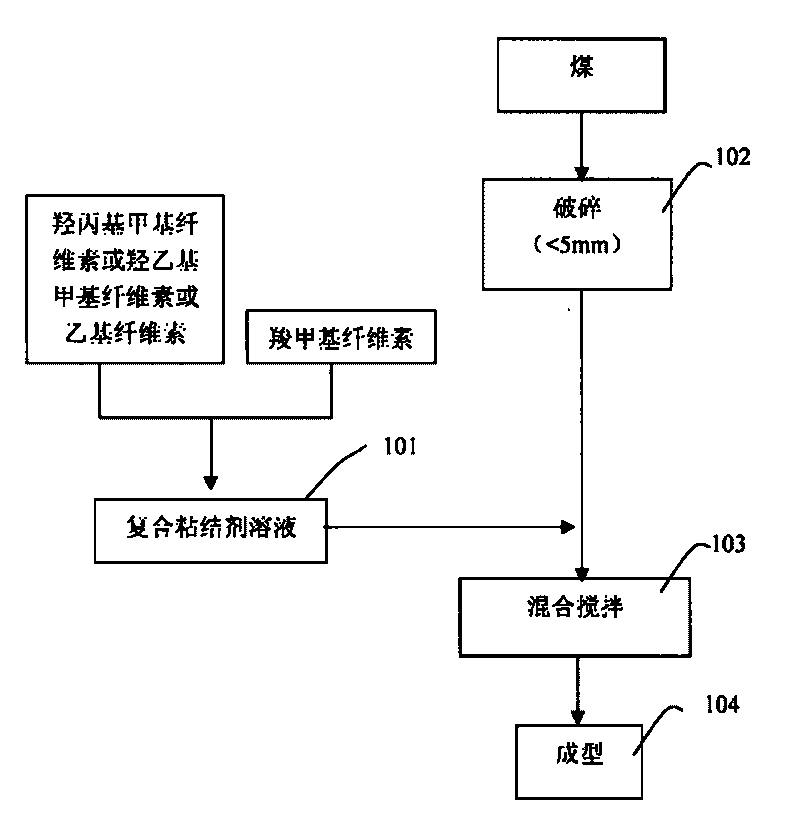

Industrial briquette for molten iron production and gas generator and preparation method thereof

The invention relates to industrial briquette for molten iron production and gas generator and a preparation method thereof. The preparation method comprises the following steps: a. preparation of composite bonding agent: preparing solution of 0.5-5.0 percent with carboxymethyl cellulose and hydroxypropyl methylcellulose or hydroxyethylmethyl cellulose or ethyl cellulose, wherein the carboxymethyl cellulose accounts for 0.3-3 percent by weight percentage, the hydroxypropyl methylcellulose or the hydroxyethylmethyl cellulose or the ethyl cellulose accounts for 0.2-2 percent by weight percentage; b. preparation of coal powder: preparing the coal powder with the particle diameter below 5mm through crushing and screening; c. mixing of the composite bonding agent and the coal powder: mixing well and pressing the mixture through a roller briquetting machine to obtain the briquette with a certain size. The briquette preparation method is simple, the briquette has high strength and good thermal stability, the production cost is reasonable, and the raw materials are available from a variety of sources.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Gas generating agent composition, method for preparing same, application of gas generation agent composition and gas generator

InactiveCN107698415AKeep shapeForm-retaining agents do not work wellPedestrian/occupant safety arrangementNon-explosive/non-thermic compositionsStrontium titanateCopper nitrate

The invention relates to a gas generating agent composition, a method for preparing the same and a gas generator with the gas generation agent composition. The gas generating agent composition comprises, by weight, 40%-60% of guanidine nitrate, 25%-40% of alkali copper nitrate, 1%-20% of strontium nitrate, 1%-10% of ammonium perchlorate, 5.5%-10% of strontium titanate and 0.6%-10% of talc powder.The gas generating agent composition, the method and the gas generator have the advantages that the strontium titanate and the talc powder are jointly used as shape keeping agents, synergistic effectscan be realized by the strontium titanate and the talc powder, accordingly, pre-combustion shapes of tablets can be effectively kept after the tablets are combusted, and gas bags can be prevented from being burnt due to melting and splashing of the combusted tablets; the strontium nitrate is used as an auxiliary oxidizing agent, the usage amount of the alkali copper nitrate is reduced, and accordingly molten copper residues can be reduced; the ammonium perchlorate is used as an ignition performance regulator, accordingly, the low-temperature ignition performance of the gas generating agent composition can be obviously improved, the combustion speeds can be increased, and the gas generating agent composition mainly can be used for gas generators for supplementary restraint systems of automobiles.

Owner:HUBEI HANGPENG CHEM POWER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com