Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83 results about "Micro propulsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

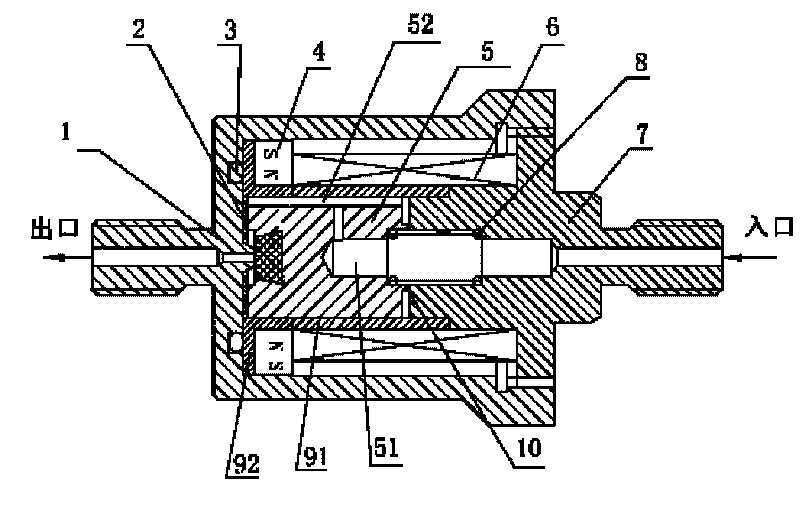

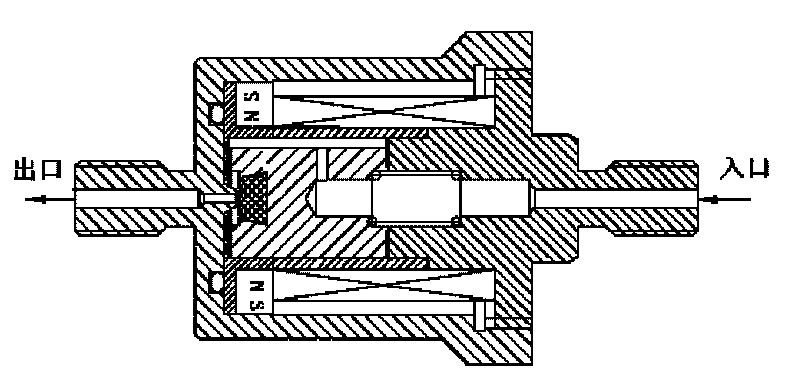

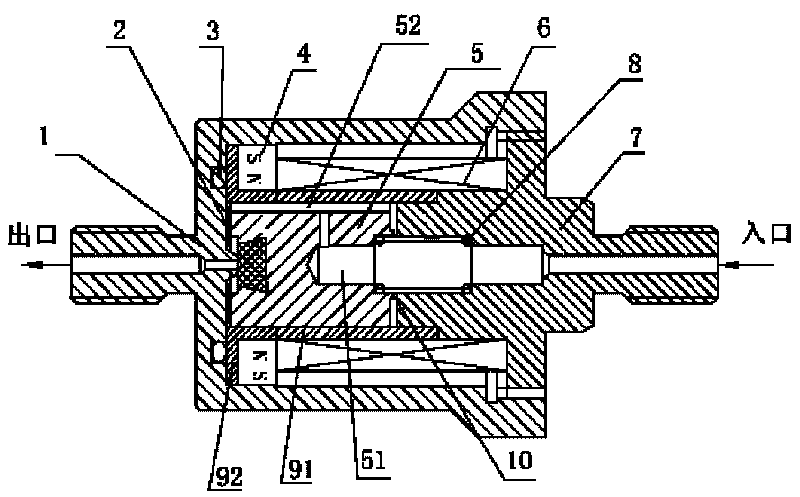

Miniature self-locking electromagnetic valve

InactiveCN101709806ASimple structureReduce volumeOperating means/releasing devices for valvesValve housingsSolenoid valveEngineering

The invention relates to a miniature self-locking electromagnetic valve. The electromagnetic valve comprises a permanent magnet, an electromagnetic coil, a flange flux sleeve, a cylindrical magnetic shield, a magnetic insulation limit pad and a boss, wherein the permanent magnet is arranged between a valve seat and the lateral surface of a valve plug, and is close to the end surface of the valve seat; the electromagnetic coil is a single-coil electromagnetic coil capable of normal and reverse electrification; the flange flux sleeve is arranged among the permanent magnet, the valve seat and the valve plug; the cylindrical flux insulation sleeve is arranged between the electromagnetic coil and the valve plug; the inner end surface of the valve seat is provided with the magnetic insulation limit pad; and the boss is arranged on the end surface contacted with the valve body on the valve plug. The electromagnetic valve solves the technical problems that the conventional electromagnetic valve cannot meet the requirement of a micro-propulsion system on the power consumption and quality of the electromagnetic valve, and is the miniature self-locking electromagnetic valve with small mass, simple and reliable structure, low power consumption and quick response time.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

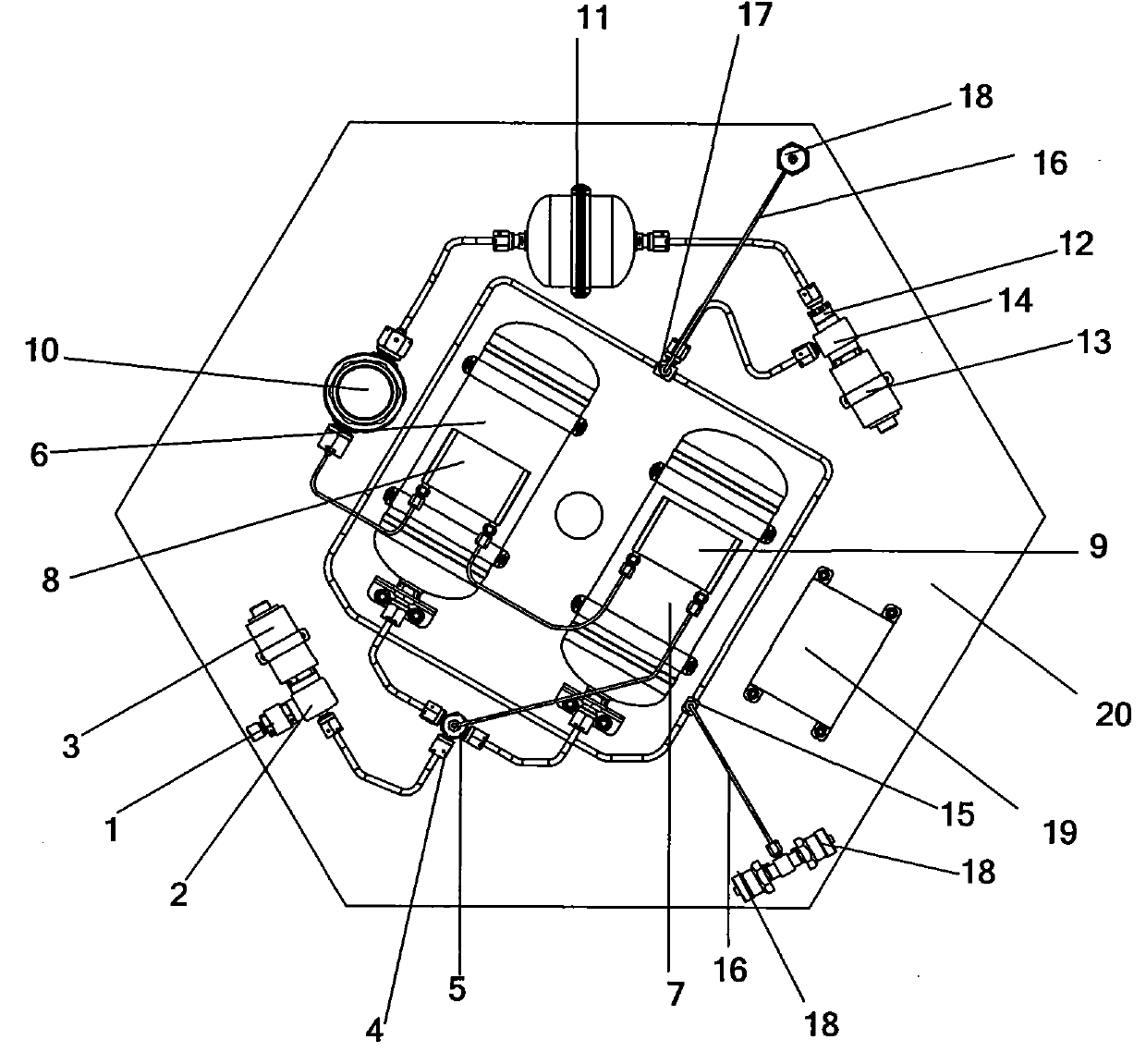

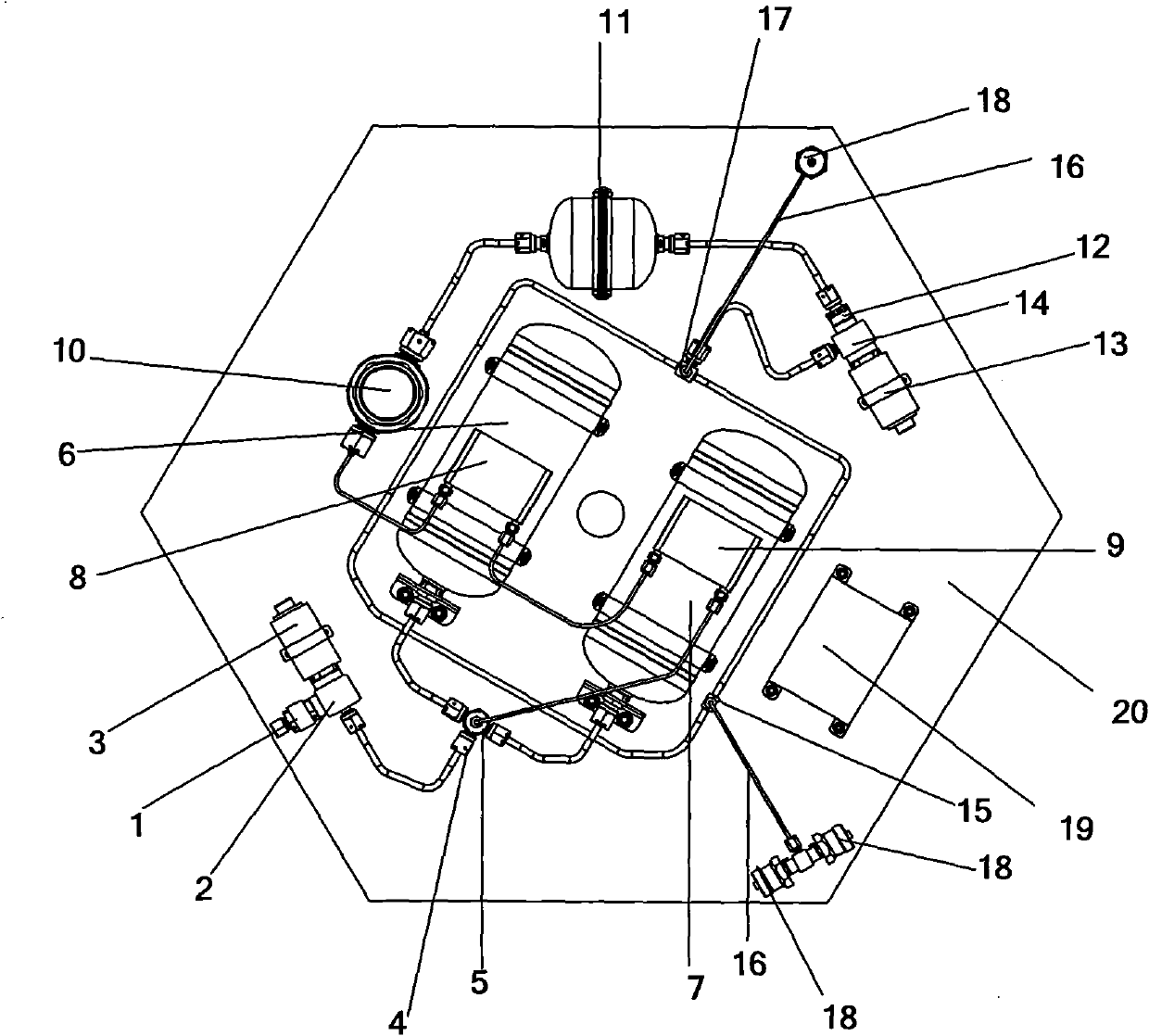

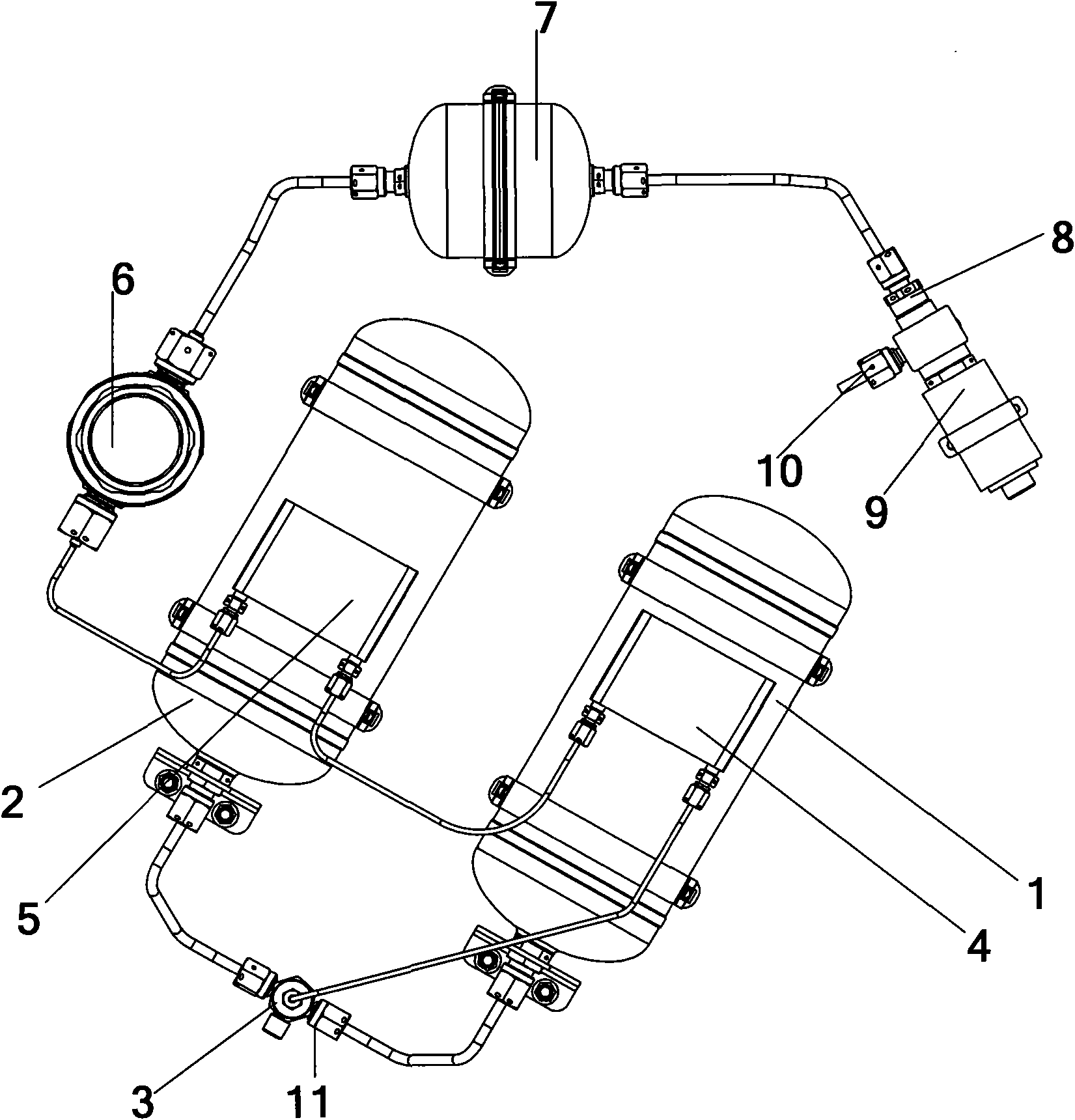

Propane liquid gas micro propulsion device suitable for micro-nano satellite

InactiveCN101907041ASimple structureLight in massCosmonautic propulsion system apparatusRocket engine plantsMicro nanoExhaust valve

The invention aims to provide a propane liquid gas micro propulsion device suitable for a micro-nano satellite. The device comprises an exhaust valve, a first propellant storage box, a second propellant storage box, a first heat-conducting module, a second heat-conducting module, a pressure reducer, a buffer tank, a safety valve, a thruster, a pressure sensor A, a pressure sensor B, a filter and a control circuit box. Propane serves as a propellant in the micro propulsion device, so the micro propulsion device is non-toxic and pollution-free; the micro propulsion device has the advantages of simple structure, low quality, low power consumption and high reliability; mounted on a mounting partition board, the micro propulsion device is convenient to be mounted and replaced; and because of no excessive relation and interference with other parts of the satellite, the micro propulsion device is convenient to be replaced and maintained.

Owner:BEIHANG UNIV +1

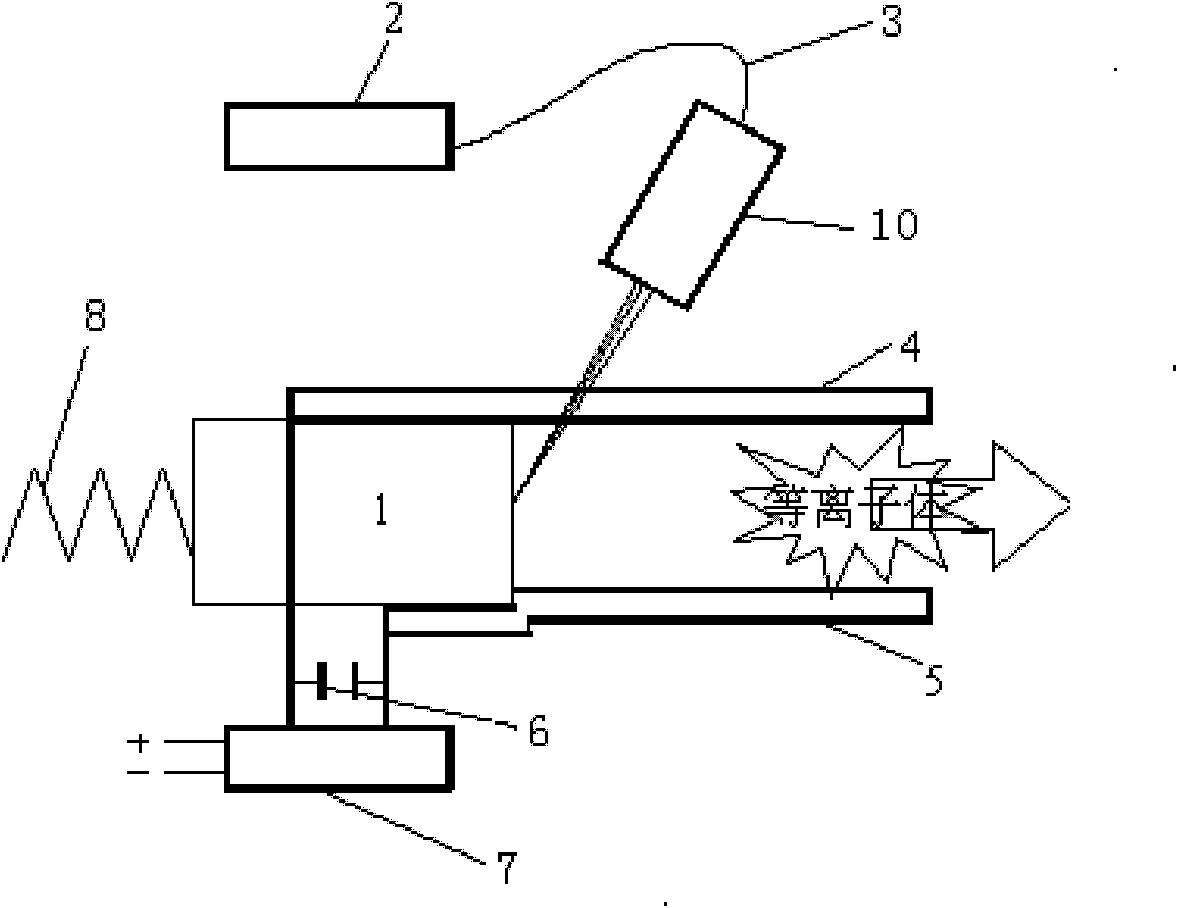

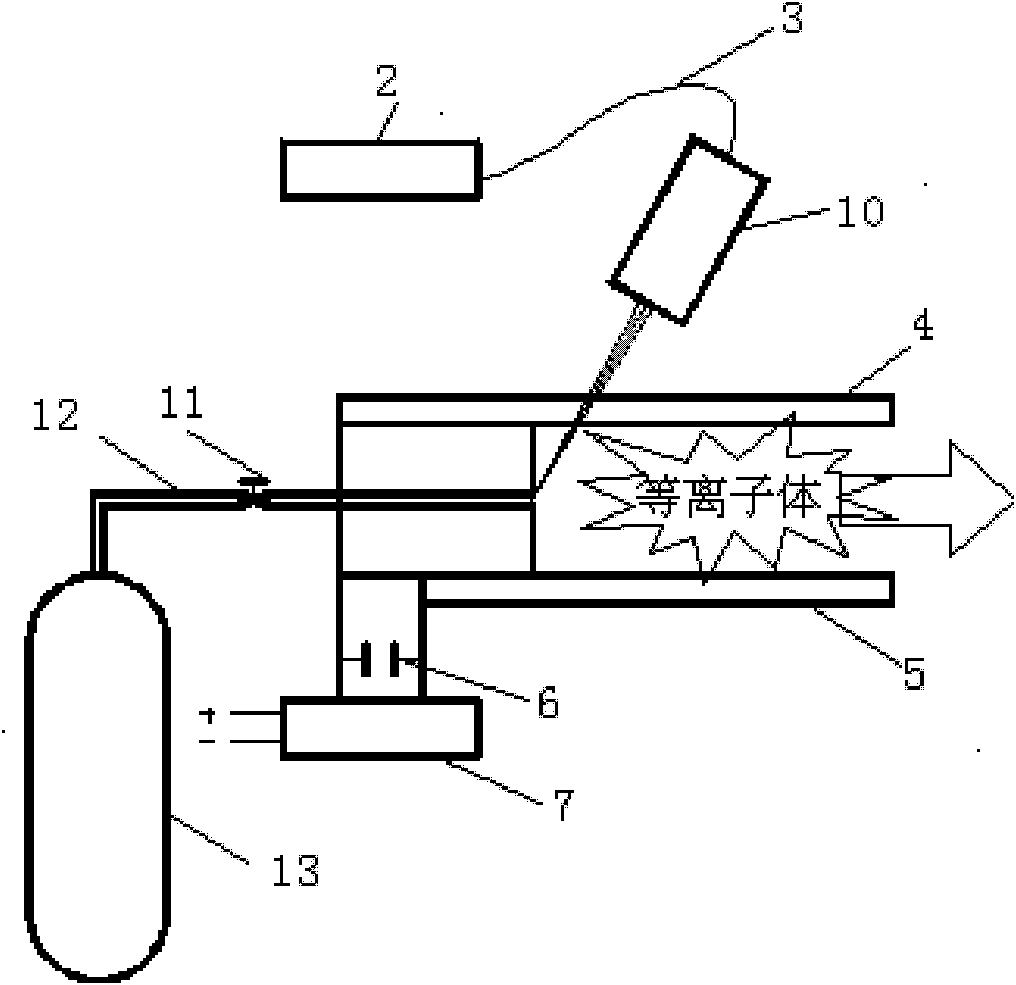

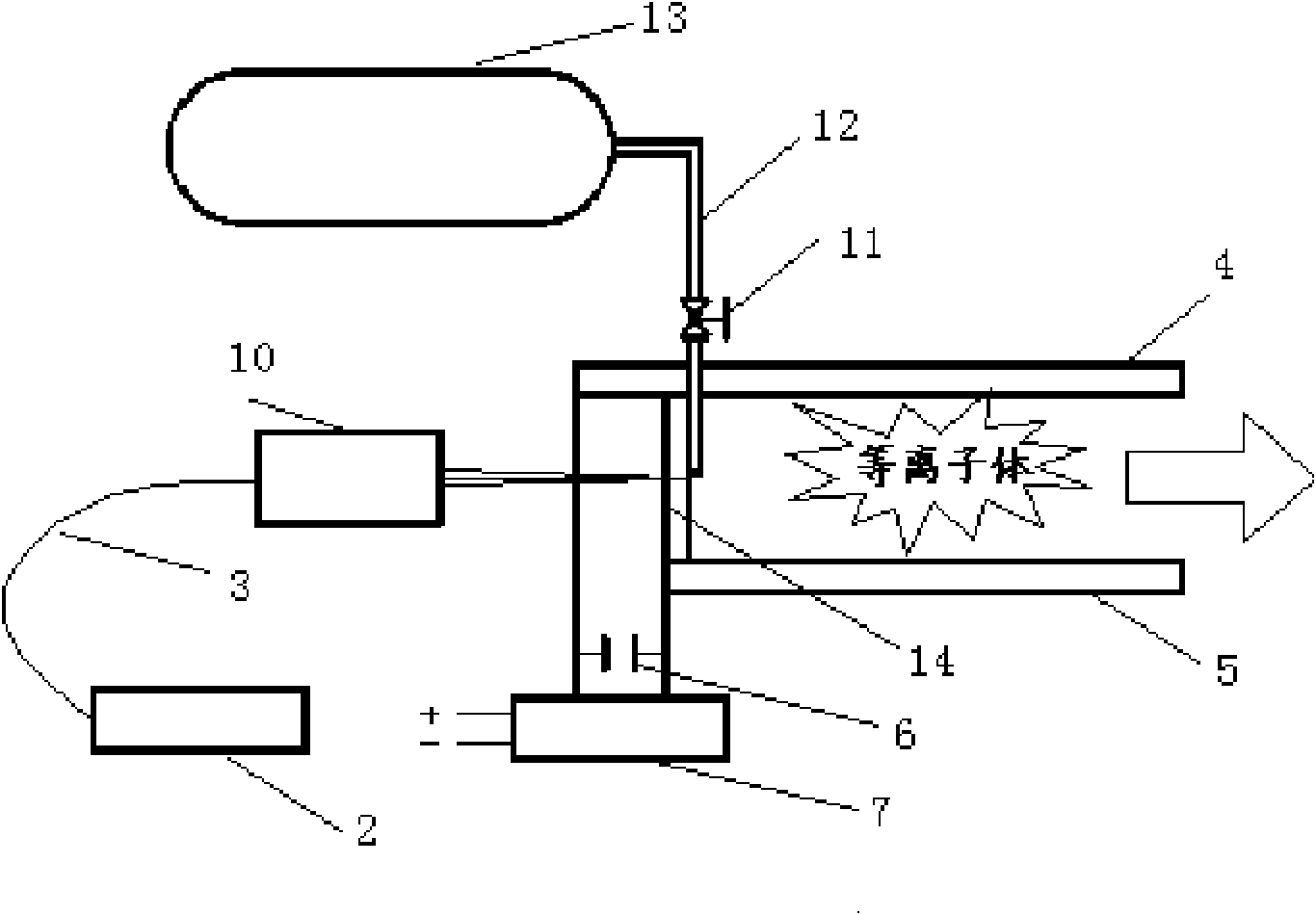

Pulse laser plasma electricity hybrid micro-propulsion unit and method

ActiveCN102374146AImprove specific impulseHigh thrust power ratioMachines/enginesUsing plasmaElectric fieldPulsed laser

The invention discloses a plasma laser plasma electricity hybrid micro-propulsion unit which comprises a pulse laser ablation device, a propellant supply device and a plasma accelerating device, wherein the pulse laser ablation device irradiates a propellant supplied by the propellant supply device to generate high-speed plasma; and the plasma accelerating device is used for accelerating the high-speed plasma again. The invention also provides a pulse laser plasma electricity hybrid micro-propulsion method which comprises the following steps of: generating high-temperature and high-speed plasma through the high-frequency pulse laser ablation propellant; and accelerating the high-temperature and high-speed plasma through an electric field or magnetic field. According to the invention, a pushing force with high specific impulse and high thrust-to-power ratio can be provided for a mini satellite.

Owner:苏州纳飞卫星动力科技有限公司

Solid chemical micro-thruster

InactiveCN102705107AReduce the difficulty of bondingIncrease thrustJet propulsion plantsGroove widthElectrical resistance and conductance

The invention discloses a solid chemical micro-thruster and belongs to the field of micro-propulsion technology and MEMS (micro-electro mechanical systems). The micro-thruster is formed by bonding of a silicon wafer and heat resistant glass, surfaces 2 of an upper silicon wafer 1 concave inward to form a combustion chamber 4 and a nozzle 3, a throat at a communication position of the combustion chamber 4 and the nozzle 3 is an arc with the curvature radius R, and a lower glass sheet 7 is formed by the heat resistant glass 8 and an ignition circuit structure on the heat resistant glass 8. The solid chemical micro-thruster has the advantages that ignition grooves are in the form of straight lines, and accordingly difficulty of silicon glass bonding is lowered by the aid of the straight line type ignition grooves under the conditions of the same ignition groove width and bonding area; the throat is the arc with certain curvature radius and is tangent to a boundary of a gas inlet and a gas outlet, so that a gas boundary layer is reduced while thrust of a device is enhanced; and the contact area of an igniter designed by a plurality of resistors in parallel connection and a propellant is increased, a heating area is enlarged, function failure of the whole device caused by fusing of one igniter is avoided, and reliability of the igniter is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

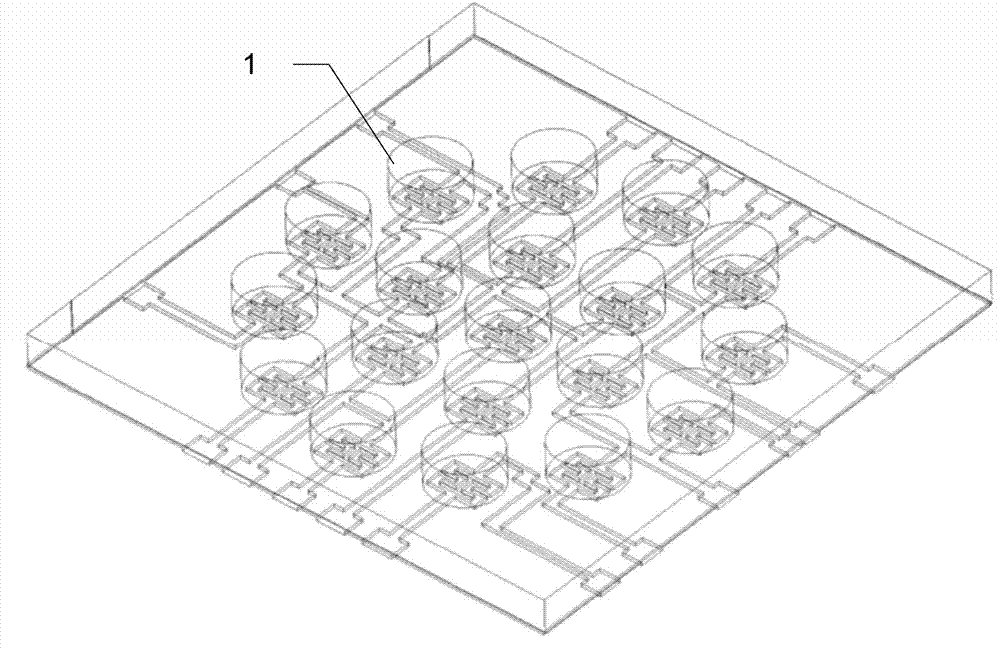

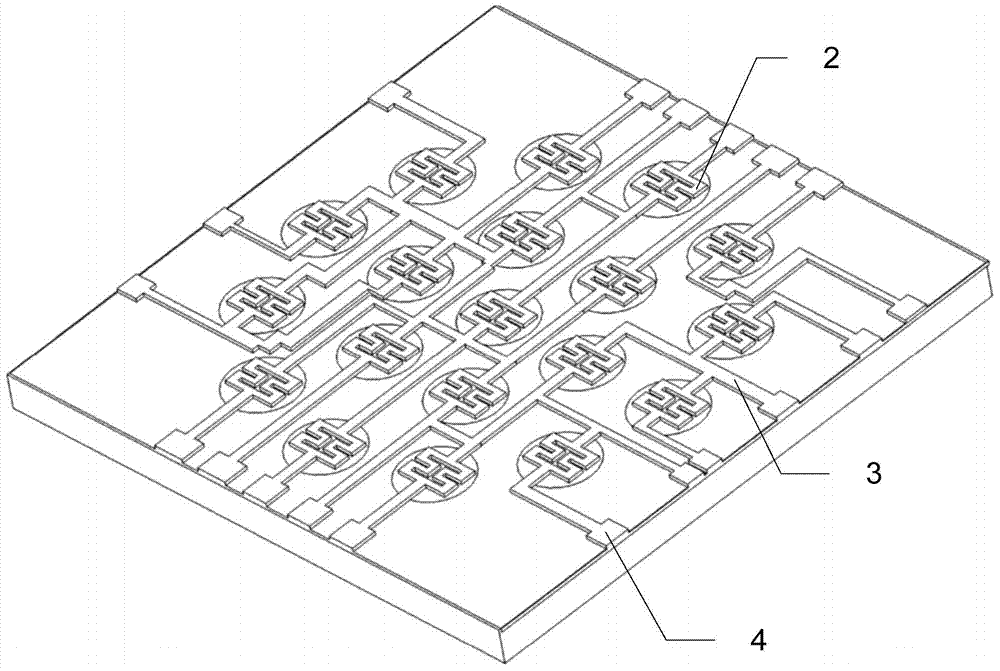

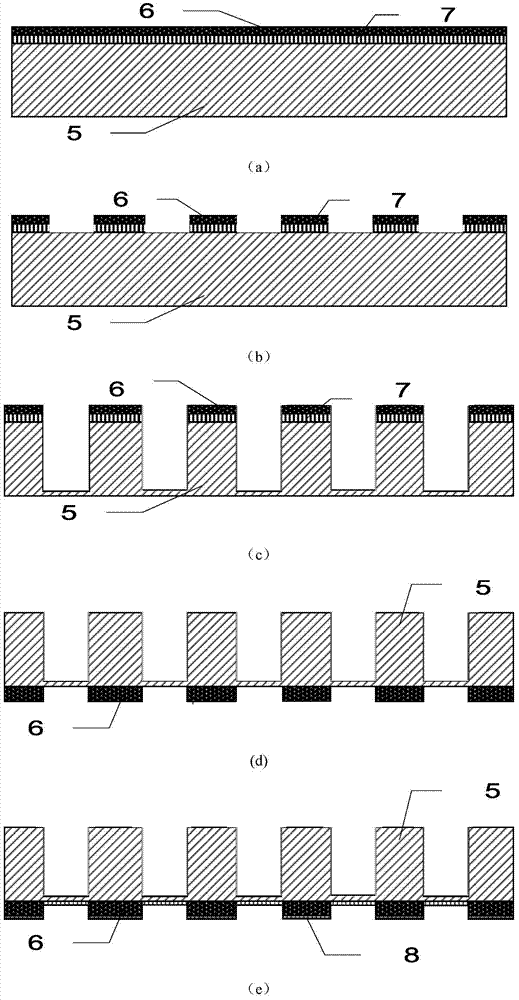

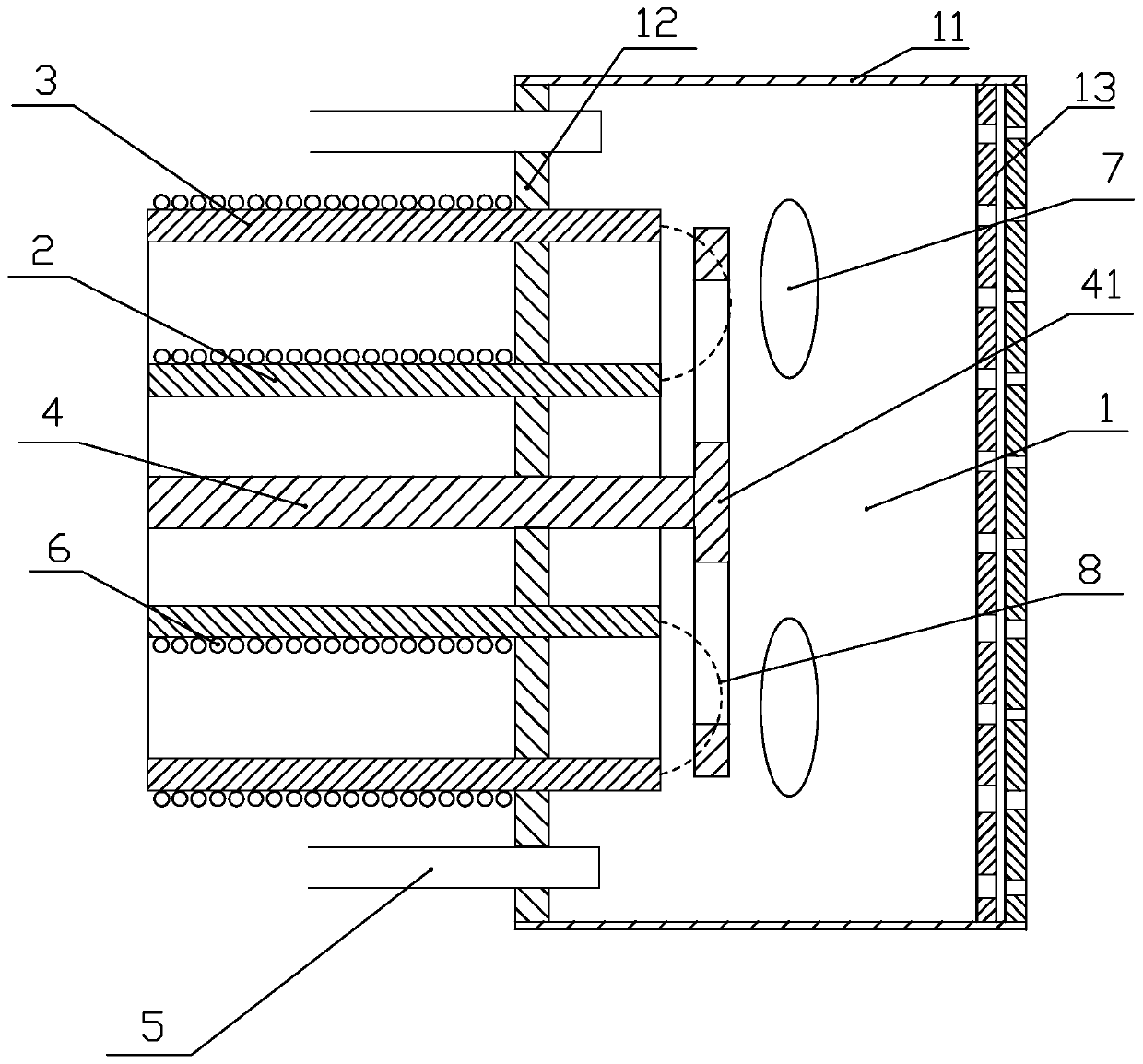

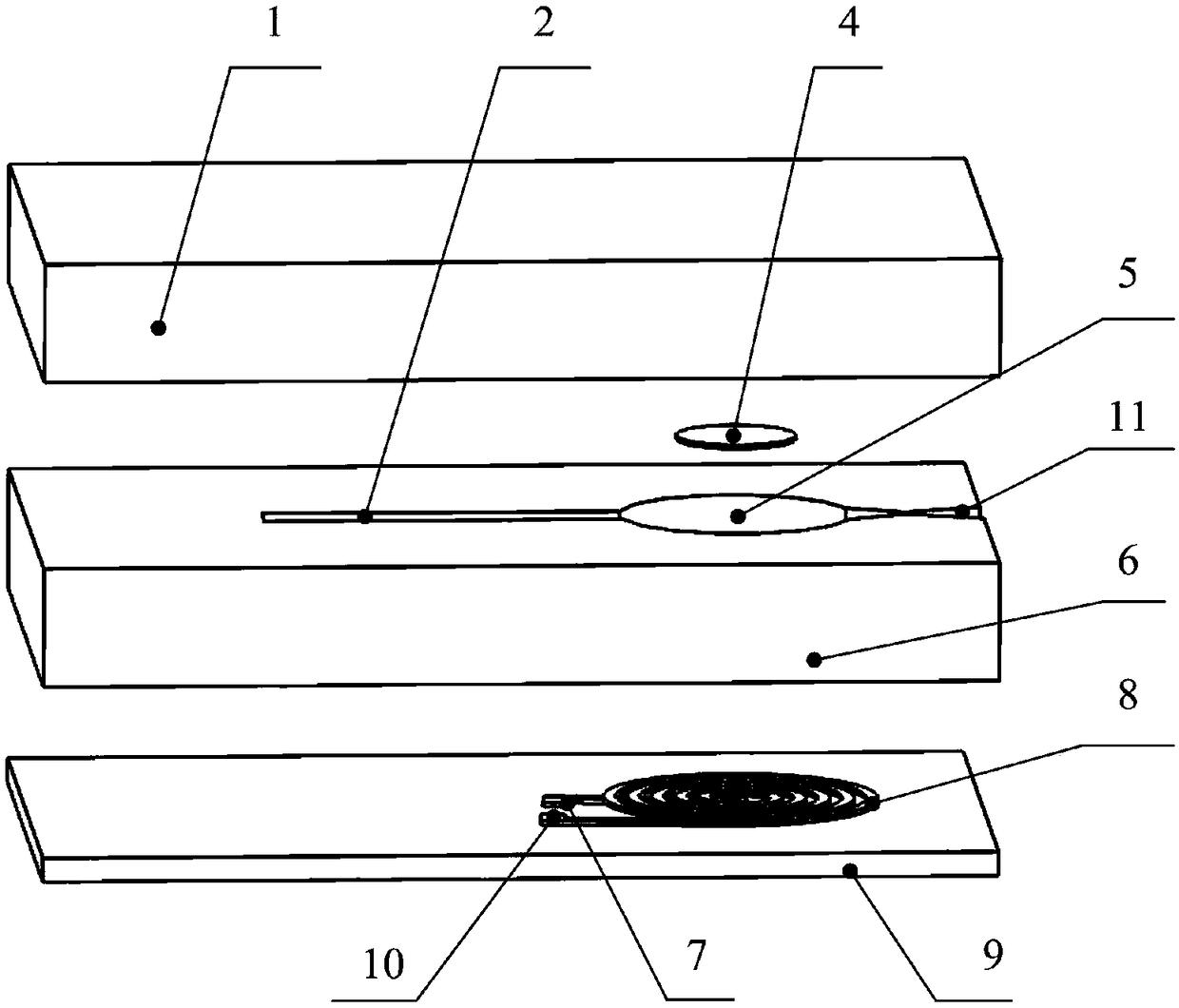

Silicon-based MEMS array propeller and preparation method thereof

InactiveCN104196650AAvoid bondingAvoid processes such as assemblyRocket engine plantsElectrical resistance and conductancePropeller

The invention discloses a silicon-based MEMS array propeller and a preparation method thereof, and belongs to the technical field of micro propulsion. The propeller mainly comprises a nozzle array part and a circuit part respectively positioned on the upper and lower surfaces of a silicon slice, wherein the nozzle array consists of cavity arrays inwards recessed in the upper surface of the silicon slice; all the nozzles are filled with oil fuel; the circuit part consists of ignition resistor 2 arrays formed on the lower surface of the silicon slice through sputtering, ignition leads 3 and welding pads 4; and all ignition resistors 2 are corresponding to all the nozzles 1 in position. The invention further discloses a non-bonding process for preparing the silicon-based MEMS array propeller. The silicon-based MEMS array propeller has the following benefits: the nozzles and the ignition resistors are integrated on the upper and lower surfaces of a silicon material so that such procedures as bonding and assembly for a conventional MEMS propeller are not needed and the production efficiency of the propeller is largely improved; meanwhile, the problems of break and failure of an igniter due to the difference of thermal expansion coefficients of a glass layer and an ignition circuit in the prior art are solved; and the yield is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

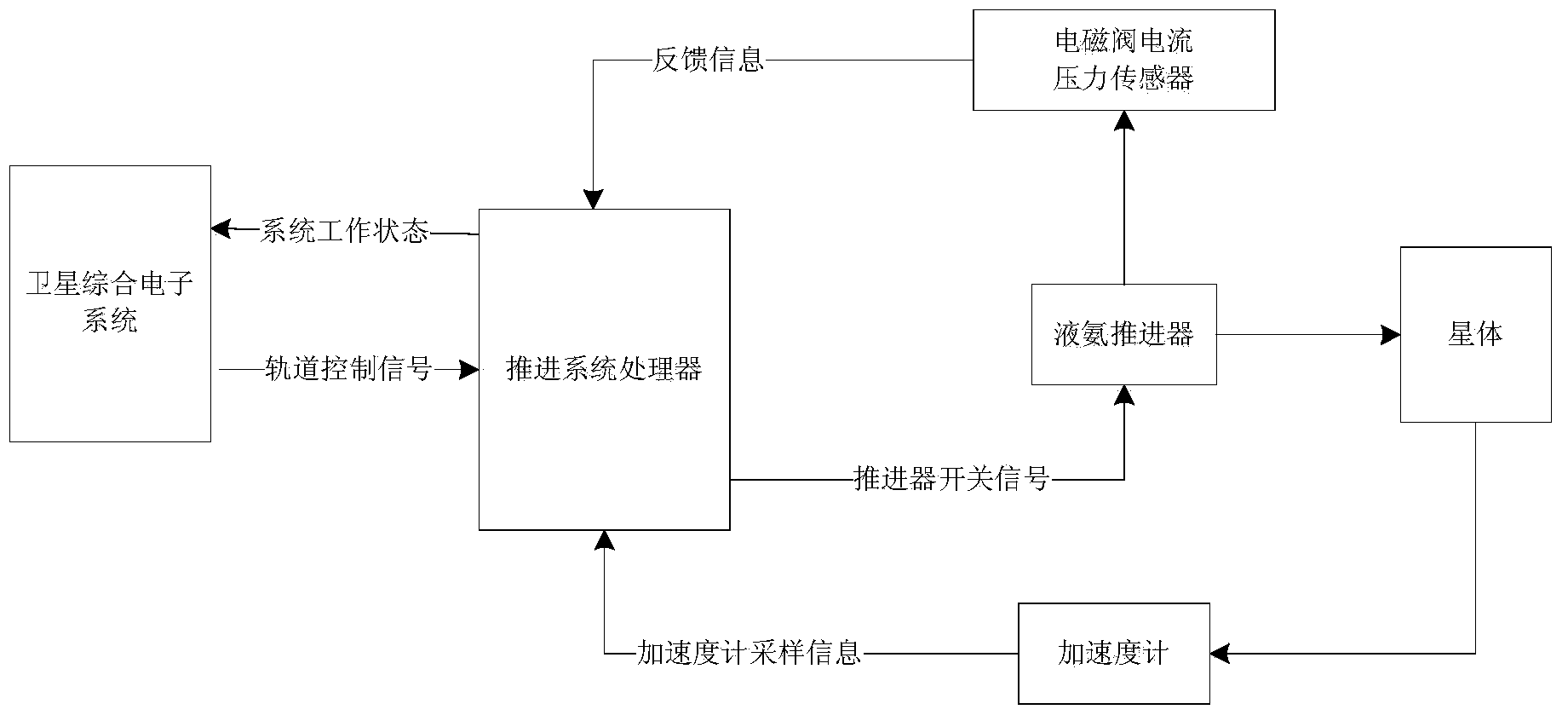

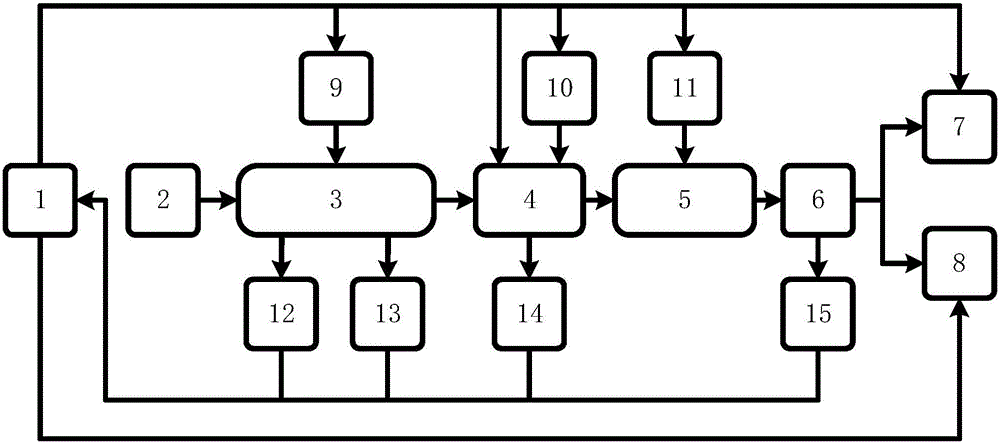

Liquid ammonia propulsion system for pico-satellite or nano-satellite

ActiveCN104358663AUniversal applicabilityReduce volumeCosmonautic power supply systemsContainer filling methodsDigital signal processingSolenoid valve

The invention discloses a liquid ammonia propulsion system for a pico-satellite or a nano-satellite. The liquid ammonia propulsion system comprises a digital signal processing circuit and a micro-propulsion device, wherein the micro-propulsion device comprises a propulsion system storage tank used for storing liquid ammonia, a thruster communicated with the propulsion system storage tank, and a solenoid valve mounted between the propulsion system storage tank and the thruster; the digital signal processor comprises an information monitoring module, a control switch module and an interface communication module; the information monitoring module is used for monitoring the current operation state of the propulsion system; the control switch module is used for controlling the solenoid valve so as to turn on or turn off the thruster; the interface communication module is used for feeding back information on the current operation state of the propulsion system to the satellite and receiving remote control commands sent by the satellite. The liquid ammonia propulsion system has the characteristics of small size, light weight, low power consumption, high specific impulse, simple structure, short development period, high safety performance, multi-functional integration, space plug and play function, universal applicability to 10 kg-magnitude pico-satellites and nano-satellites, and the like.

Owner:ZHEJIANG UNIV

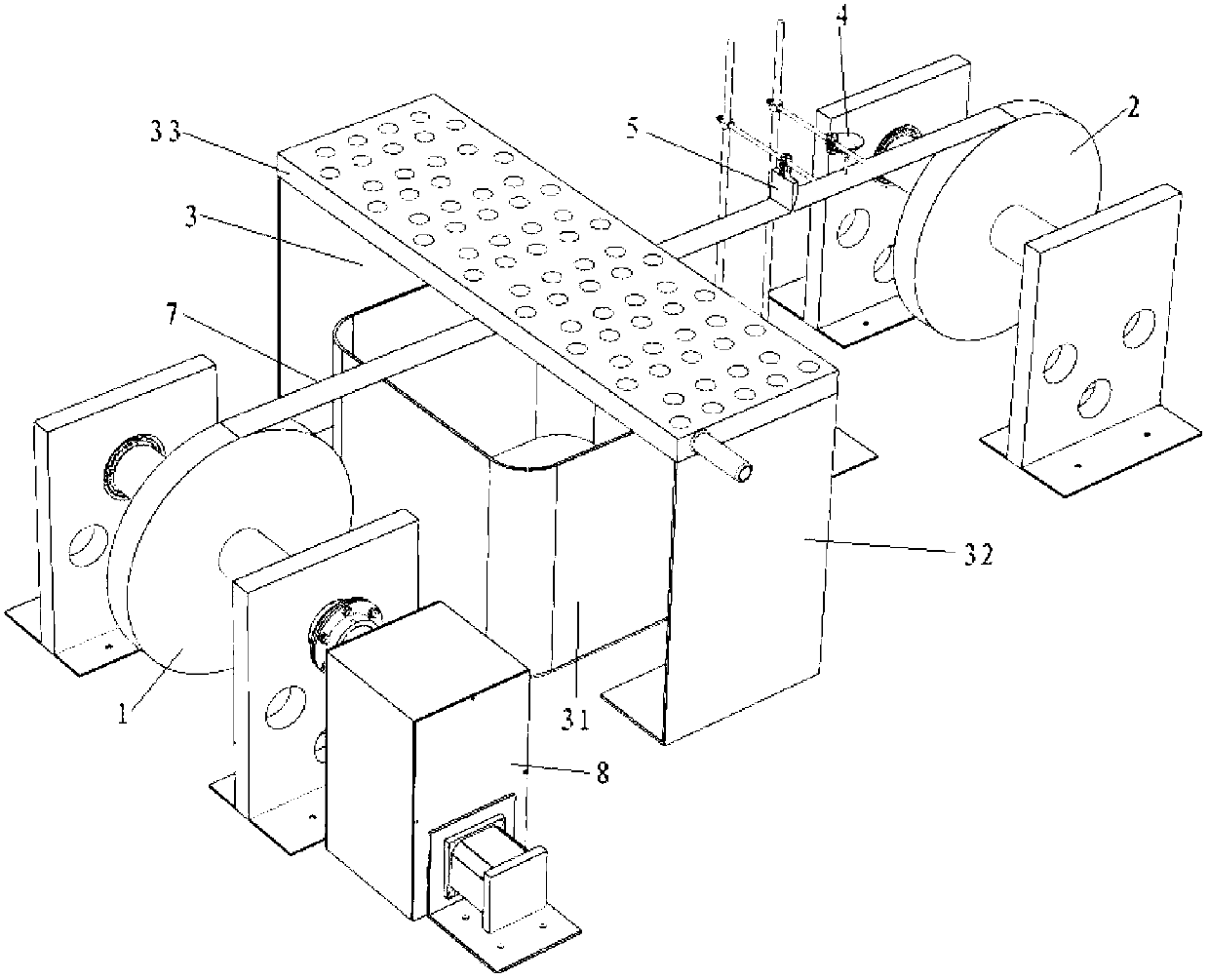

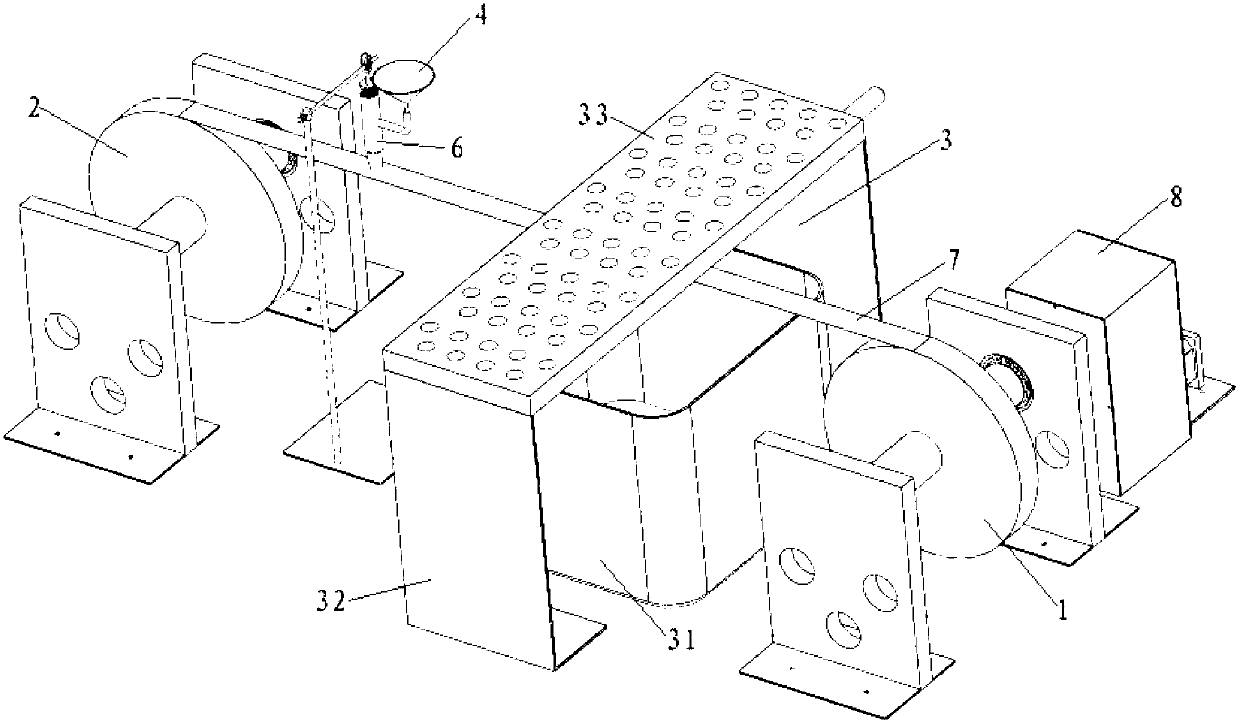

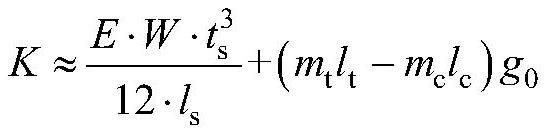

Electrode wire reciprocating progressive type wire winding method and device for WEDM (wire cut electrical discharge machining)

ActiveCN105195843AGuaranteed lossGuaranteed machining accuracyElectrical-based machining electrodesElectrical-based auxillary apparatusReciprocating motionEngineering

The invention provides an electrode wire reciprocating progressive type wire winding method and device for WEDM (wire cut electrical discharge machining). The method and the device are characterized in that an electrode wire is controlled to perform continuous reciprocating motion, the advancing length is slightly larger than the retreating length each time, and by means of unequivalence of reciprocating wire winding, electrode wire loss is offset through whole micro propulsion of the electrode wire. The device is realized by adopting a double-wire-cylinder structure. A certain number (such as 1 mm) of new wires are always supplemented in each loop, so that the electrode wire loss is offset by the newly supplemented electrode wires (such as 1 mm) each time, the electrode wire loss in a machining process can be reduced, particularly, the effect is more obvious when a workpiece with high thickness and large cutting area is cut, and accordingly, the machining precision is improved; when a wire breaking phenomenon happens, the electrode wire can be subjected to void-cut to a wire breaking point along cutting joints with consistent width or performs in-situ wire penetration at the wire breaking point, and the machining efficiency is greatly improved.

Owner:TAIZHOU CHEN HONG NC EQUIP MFG CO LTD

Heating gasification device for liquefied gas micro-propulsion system

InactiveCN101943082ASimple structureLight in massCosmonautic propulsion system apparatusRocket engine plantsPassive heatingHeat conducting

The invention discloses a heating gasification device for a liquefied gas micro-propulsion system. The device comprises a first propellant storage box, a second propellant storage box, a first heat conducting module, a second heat conducting module, a pressure reducer, a pressure stabilizing tank, a safety valve, a pressure sensor and a filter. In the device, a passive heating mode is adopted, and a satellite internal heat dissipation unit is used as a heat source, so that extra power consumption is not needed; and the gasification device has the advantages of reducing the production cost, fully gasifying the propellant and ensuring that the propellant completes work in the form of gas state, along with simple structure, a few elements and devices and high reliability and safety.

Owner:BEIHANG UNIV +1

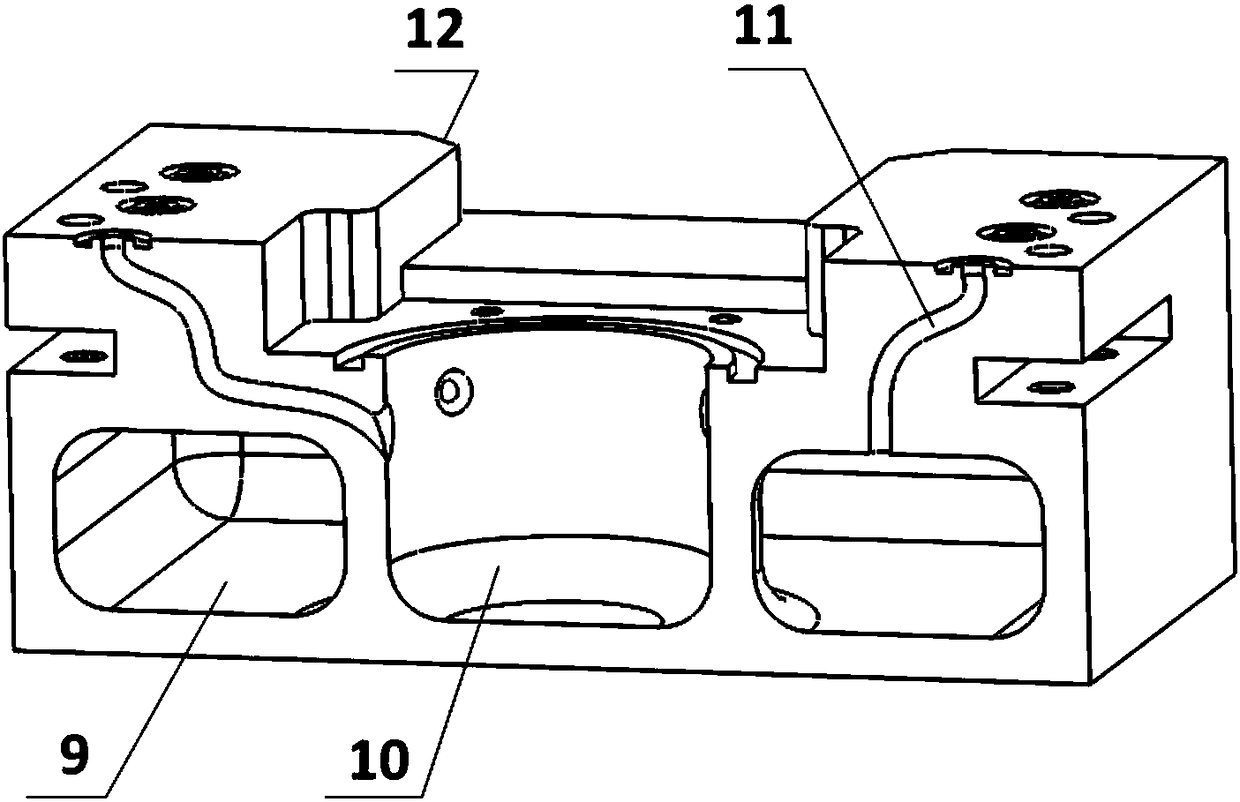

Bipropellant micro chemical propulsion array device

InactiveCN102434316ASimple designSimple structureRocket engine plantsAviationManufacturing technology

The invention belongs to the technical field of micro propulsion in aerospace and relates to the MEMS (Micro Electro Mechanical System) technique and the general rocket bipropellant device. A novel liquid bipropellant micro chemical propulsion array is provided by combining the advantages of the current solid and liquid micro chemical propulsion device structures in order to overcome the defects in the prior art. The bipropellant micro chemical propulsion array not only solves the problems on complicated working principle, high requirement of processing and manufacturing technology and low working reliability and the like in the current liquid micro chemical propulsion device, but can simply realize reignition and real-time adjustment of thrusting force and maintain the advantages that the traditional solid micro propulsion system can be distributed in arrays and has high integration level and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

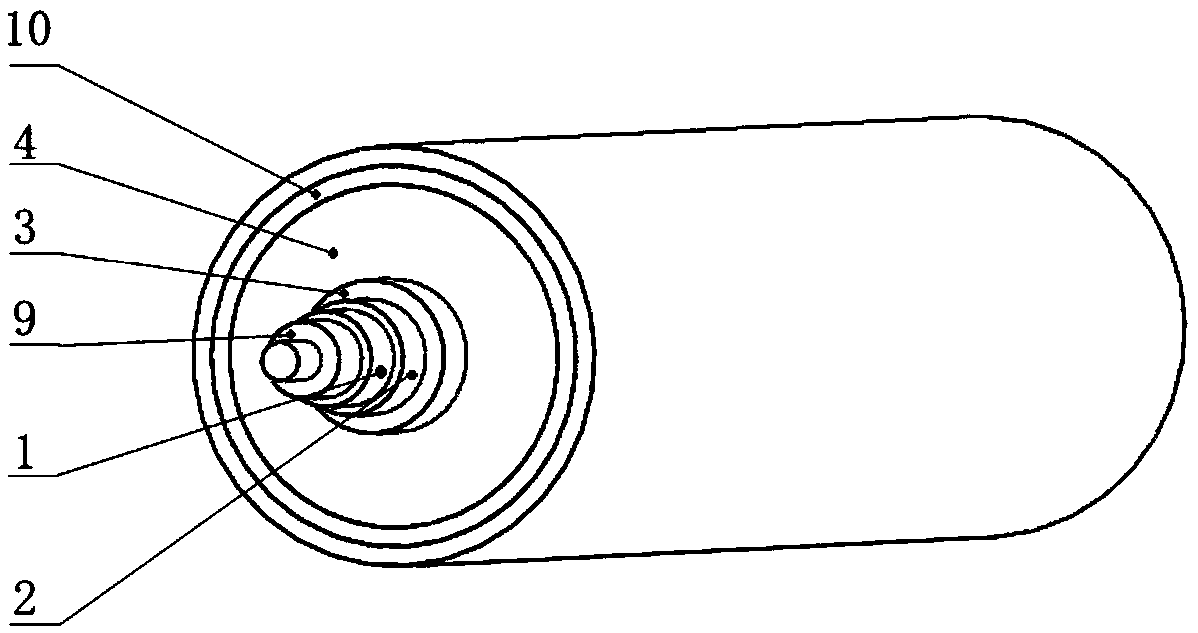

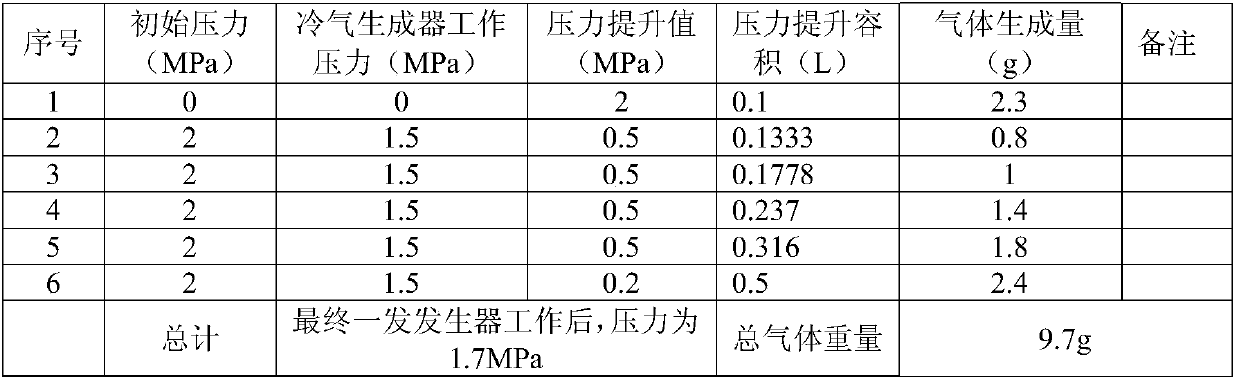

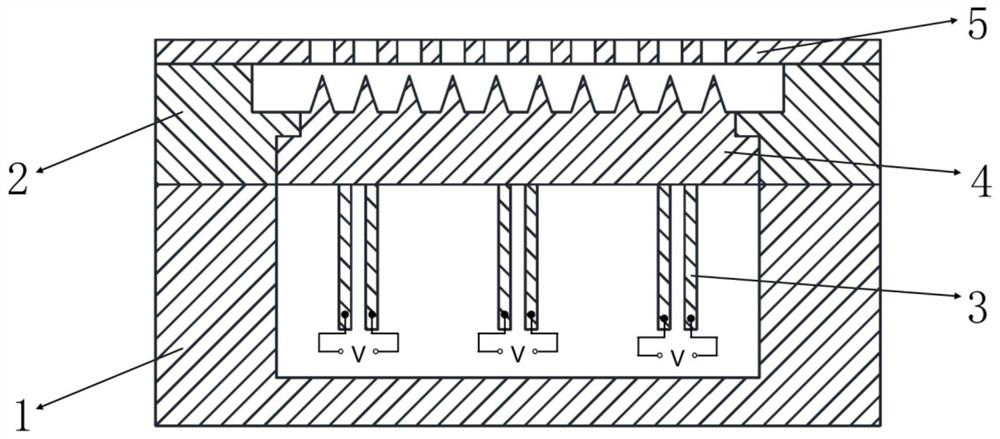

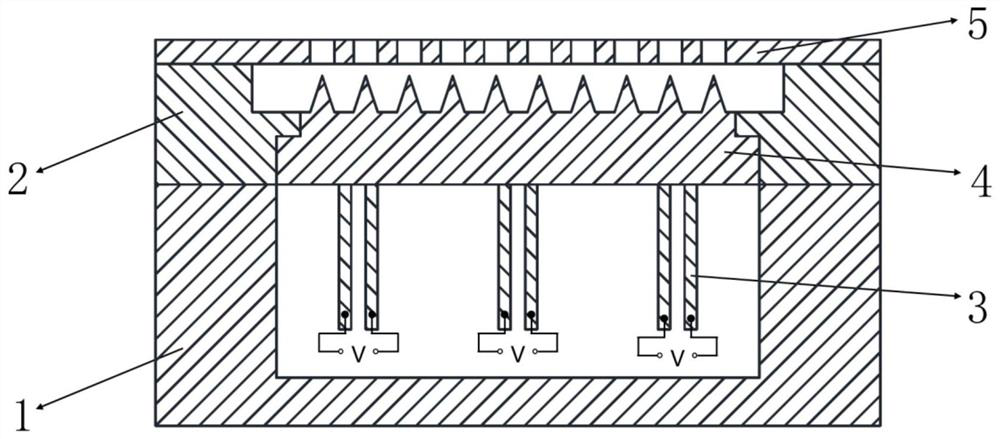

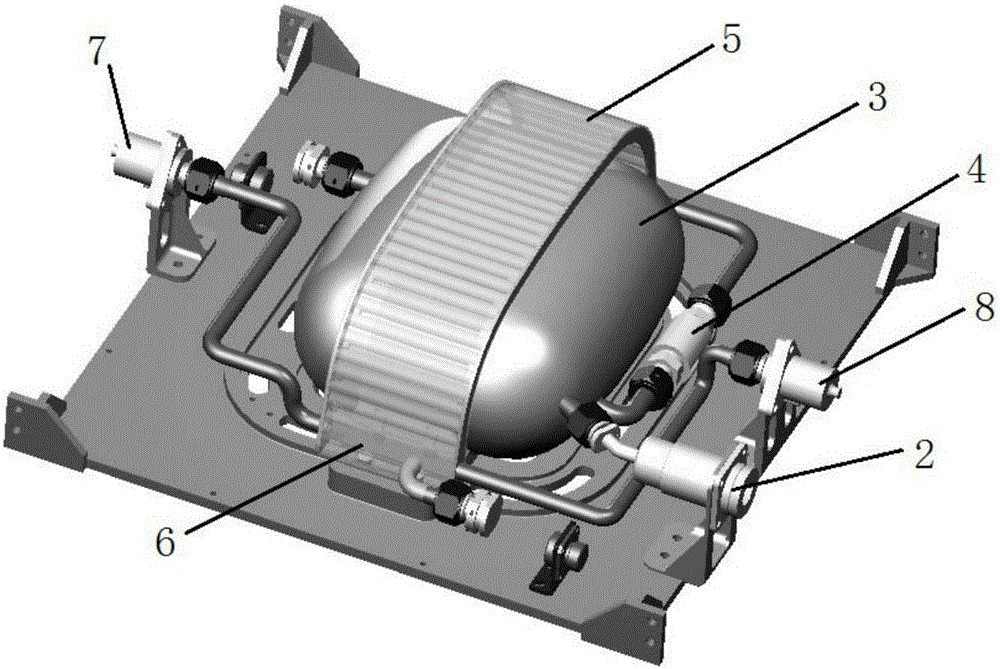

High total impulse solid cool gas micro propulsion unit

ActiveCN106246411AImprove sealingImprove air tightnessCosmonautic propulsion system apparatusRocket engine plantsMulti degree of freedomGas chamber

A high total impulse solid cool gas micro propulsion unit includes a gas chamber (1); the gas chamber (1) is a cylindrical housing with an opening at one end of the cylindrical housing; nozzles of all the micro cool gas propulsion devices (10) are arranged on the center of an end surface of the gas chamber (1) and side walls of the gas chamber (1) respectively; a gas chamber end cover (2) seals the opening end of the gas chamber (1); a temperature sensor (5), a pressure sensor (6) and a cool gas generator (7) are fixed in the gas chamber (1); the pressure sensor (6) and the temperature sensor (5) can acquire pressure parameters and temperature parameters in real time and send the parameter values to a control drive module (3); the control drive module (3) drives the cool gas generator (7) to generate gas to be injected into the gas chamber (1) according to the received pressure parameter values and the received temperature parameter values; and the control drive module (3) drives and controls the work pulse width of the micro cool gas propulsion devices (10). The high total impulse solid cool gas micro propulsion unit can improve the total impulse of the propulsion module, can improve the whole sealing performance, and can achieve multi-degree of freedom control.

Owner:BEIJING INST OF CONTROL ENG

Multi-section type high-efficiency pulse plasma thruster

InactiveCN109185090AImprove acceleration efficiencyLower breakdown voltageMachines/enginesUsing plasmaMicro nanoCapacitance

The invention discloses a multi-section type high-efficiency pulse plasma thruster, and belongs to the field of micro-nano satellite micro-propulsion. The thruster is mainly composed of a one-sectionanode, a one-section cathode, a two-section anode, a two-section cathode, an insulation section, a trigger electrode, a trigger working medium, an energy storage capacitor set, a propellant, a coatinglayer and an outer shell body; the electrodes of the thruster are divided into two sections, each section of electrodes is provided with a voltage through a respective energy storage capacitor, so that the total energy distributed to different capacitors discharging at different positions are realized, so that a propellant ablation ionization process and a plasma acceleration process are separated, more energy is enabled to be used for the plasma acceleration process, and the whole acceleration efficiency of the thruster can be improved. A small amount of plasma is generated by triggering theworking medium which is triggered through a trigger electrode, the breakdown voltage between one-section electrode is greatly reduced to facilitate the triggering of initial discharge, and then the reliability of the operation of the thruster is further improved; and the thruster is suitable for application occasions of low-power wiener satellites, and meets corresponding task thrust requirements.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Single component micro-propulsion module device based on additive manufacturing technology and supercharging method thereof

ActiveCN107891999AHigh module integrationHigh work pressureCosmonautic vehiclesCosmonautic propulsion system apparatusManufacturing technologyWork performance

The invention relates to a single component micro-propulsion module device based on additive manufacturing technology. The device is characterized by comprising a micro-thruster assembly, a gas addingand discharging valve, a liquid adding and discharging valve, a solid nitrogen generator, a temperature sensor, a pressure sensor, a bursting disc safety device, a tank assembly and a control drive circuit; the gas adding and discharging valve, the solid nitrogen generator, the temperature sensor, the pressure sensor, the tank assembly, the liquid adding and discharging valve, the bursting disc safety device and the micro-thruster assembly are installed in series in a module gas room. The invention provides a novel device and method for safety isolation of a propulsion system, the high integration is facilitated, the system complexity is reduced, the reliable operation of an entire system is guaranteed, and the work performance of the entire system is improved.

Owner:BEIJING INST OF CONTROL ENG

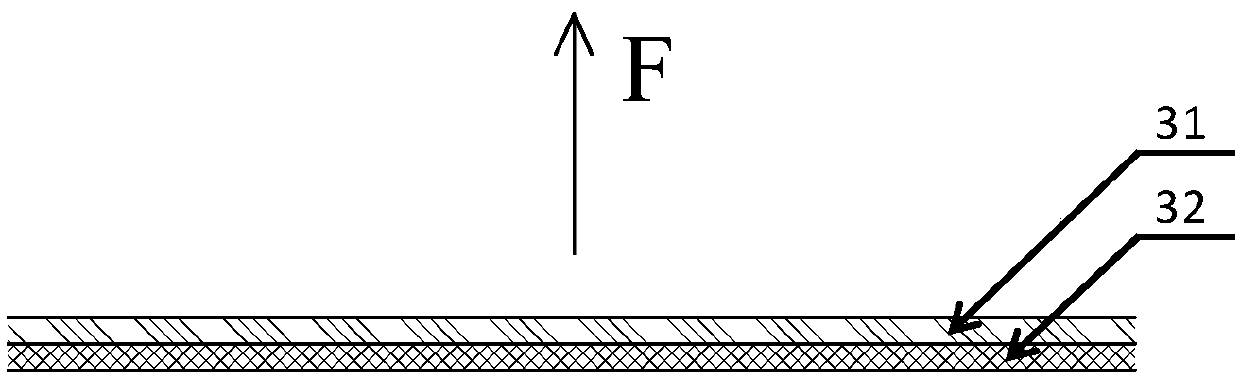

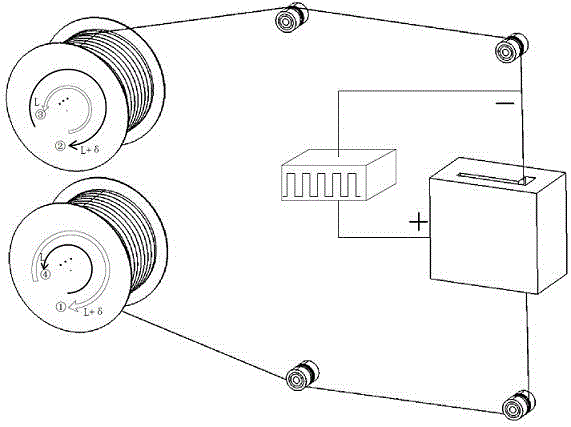

Transmission-type laser micro propulsion thin film target belt manufacturing method and manufacturing equipment thereof

ActiveCN103100516AImprove uniformityIncrease productivityLiquid surface applicatorsCoatingsTemperature differenceEngineering

The invention provides a transmission-type laser micro propulsion thin film target belt manufacturing method and manufacturing equipment of the transmission-type laser micro propulsion thin film target belt manufacturing method. A target belt which can meet test and use requirements of a transmission-type laser micro thruster can be machined. With transmission-type laser micro propulsion thin film target belt manufacturing method, a transmission-type target belt which can meet test and use requirements can be machined. The target belt is good in uniformity and the problem that orange peel, needle holes and the like are likely to occur in a conventional method is solved. The manufacturing equipment are more likely to manufacture even long target belts and can improve efficiency of producing transmission-type target belts. A manufactured ablation layer is even and manufacture of the long target belts is easy and feasible. The manufacturing equipment is easy to build up and uses existing industrial raw materials for assembly, cost is low, use is convenient, machining efficiency is high and usage can be repeated. A heating system can keep a temperature difference to be stable by simultaneous heating of upper and lower portions. The manufactured target belt is even, smoothness of the surface of the manufactured target belt is high and action stability of the micro thruster can be effectively ensured.

Owner:UNIV OF SCI & TECH OF CHINA

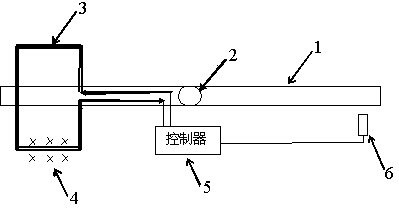

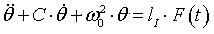

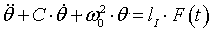

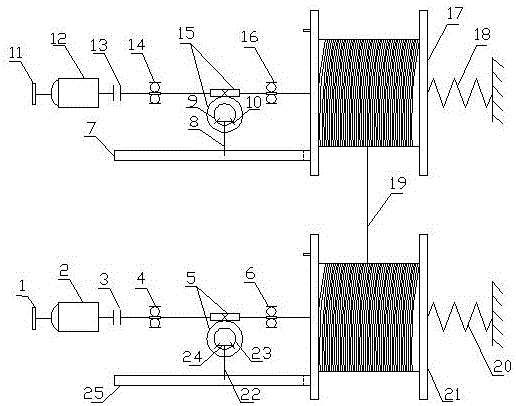

Non-contact active control method for vibration of micro thrust measurement system

The invention relates to a non-contact active control method for vibration of a micro thrust measurement system and relates to vibration control over a swing arm or a beam of a single-pendulum or torsional-pendulum type thrust measurement system of a space propulsion system of electric propulsion, laser micro propulsion and the like. According to the method, the ampere force between a local magnetic field and a current-carrying coil serves as the control force, a sensor is used for measuring angular displacement of the swing arm or the beam, and a closed loop feedback control method is used for controlling vibration of the swing arm or the beam so that the swing arm or the beam can be stabilized in a balance position. The method makes up the defect of an existing vibration damping method and has the outstanding advantages of being high in stabilization speed and control precision, free from additional error and the like.

Owner:湖南鸿星科技有限公司

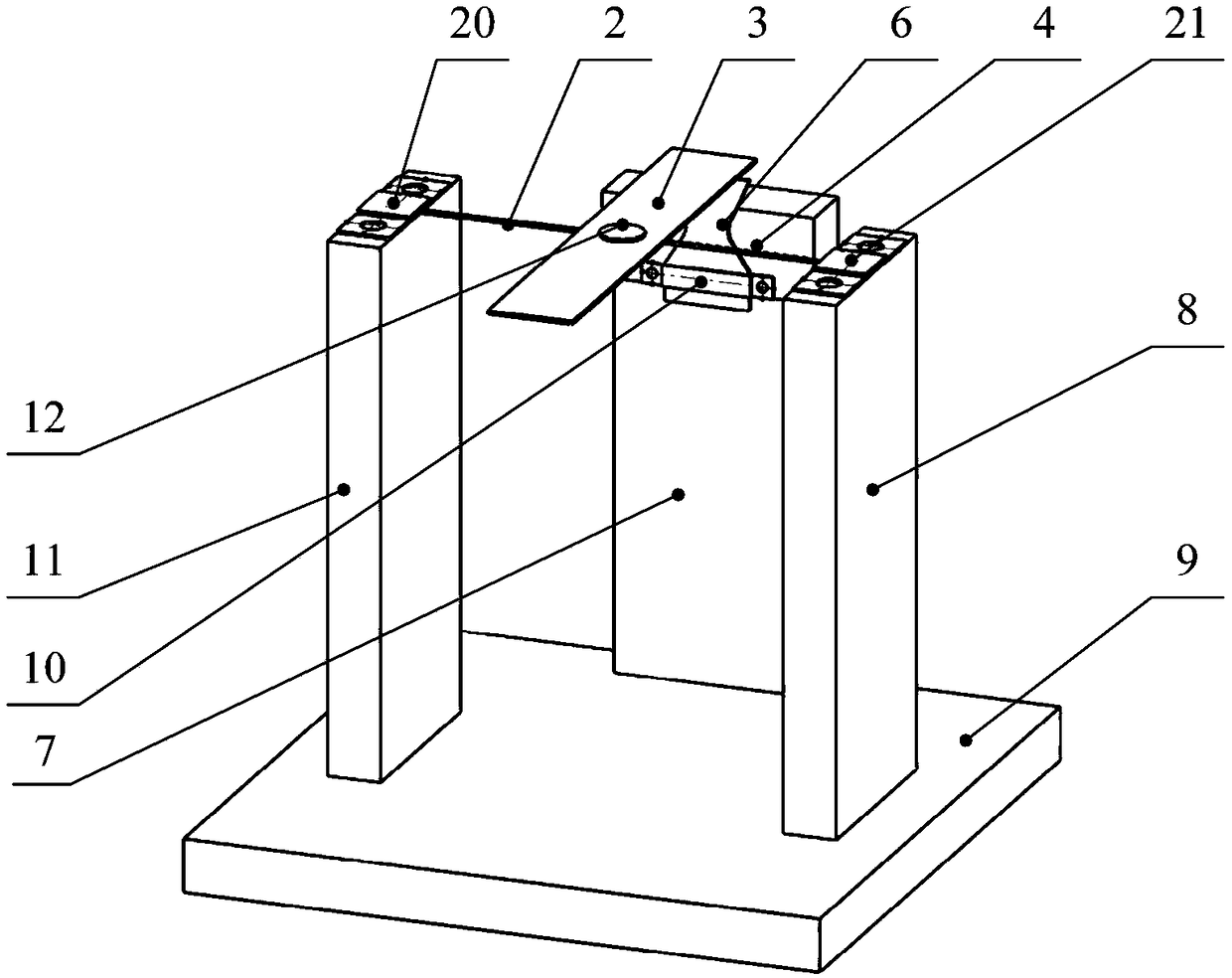

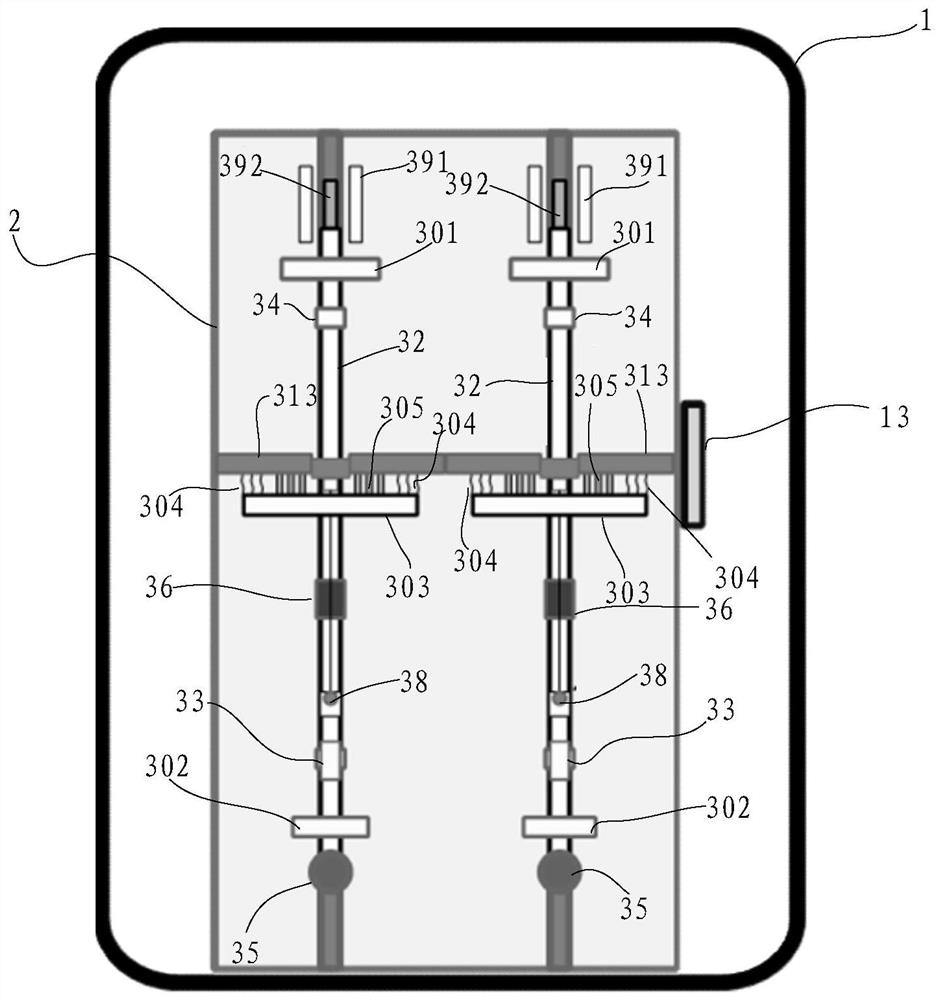

Micro-thrust measuring device that employs silicon torsion spring

ActiveCN108827512AAvoid influenceReduce the impactForce measurement by measuring optical property variationApparatus for force/torque/work measurementAviationMeasurement device

The invention relates to a micro-thrust measuring device that employs a silicon torsion spring, and specifically relates to a silicon torsion spring formed by a silicon micromachining technology; thesilicon torsion spring and an optical path can amplify the micro thrust displacement of a micro propeller, thus measuring micro thrust with high sensitivity; the micro-thrust measuring device can directly measure and evaluate the thrust performance of the micro propeller, thus providing important effects in micro propeller research and development and assessment. In addition, in some emerging fields, such as space satellite control technology, biomechanics, microrobot and bionics, have higher and higher requirements on the thrust measuring technology in a micro N level, Nano N level and even smaller level. The micro-thrust measuring device belongs to the aviation, spaceflight, micro force measurement, micro propulsion technology and micro mechanical fields.

Owner:BEIJING UNIV OF TECH

Pulse electro-magnetic micro-newton propulsion device

ActiveCN110145446AReduce air pressureMeet the needs of fast responseMachines/enginesUsing plasmaMicrowaveEngineering

The invention discloses a pulse electro-magnetic micro-newton propulsion device, and belongs to the technical field of plasma micro-propulsion. According to the pulse electro-magnetic micro-newton propulsion device, the problems that an existing thruster is single in ionization adjusting means so as not to meet high-efficiency and stable operation of wide-range adjustment and the requirement for rapid response in satellite towless control are solved. A discharge chamber main body is of a cylindrical structure; a through hole, a first annular channel and a second annular channel are coaxially formed in a base; an inner sleeve is inserted into the first annular channel and fixedly connected with the base; an outer sleeve is inserted into the second annular channel and fixedly connected withthe base; coils wind an outer wall, outside the discharge chamber, of each sleeve correspondingly; a microwave input unit is inserted into the through hole and fixedly connected with the base; an annular microwave antenna is coaxially and fixedly arranged on one end, in the discharge chamber, of the microwave input unit; a plurality of air supply holes sharing the same quantity as a plurality of air supply units are further formed in the base; and the plurality of air supply units correspondingly communicate with a discharge chamber through the plurality of air supply holes.

Owner:HARBIN INST OF TECH

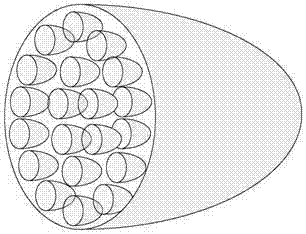

Radioactive material with alpha particle cascade decay, propelling plant adopting same and lotus seed propeller

ActiveCN104843198AReduce volumeReduce weightCosmonautic propulsion system apparatusNuclear engineeringHalf-life

The invention discloses a radioactive material with alpha particle cascade decay, a propelling plant adopting the same and a lotus seed propeller. The propelling plant generates propelling force in the mode that the adopted radioactive material radiates high-energy particles through an alpha particle cascade decay reaction. One gram of 242 Cm radioactive element with the half-life period being 163 days can provide propelling force of 3-5 muN, and One gram of 238 Pu radioactive element with the half-life period being 87 years can provide propelling force of 0.02 muN. The propelling plant which adopts the radioactive material and has a specific surface shape can provide propelling force in a specific direction which is perpendicular to the focus plane of the propelling plant. The radioactive material can provide stable propelling force for hundreds years, and is particularly suitable for micro propellers and high-power propellers.

Owner:XIANGTAN UNIV

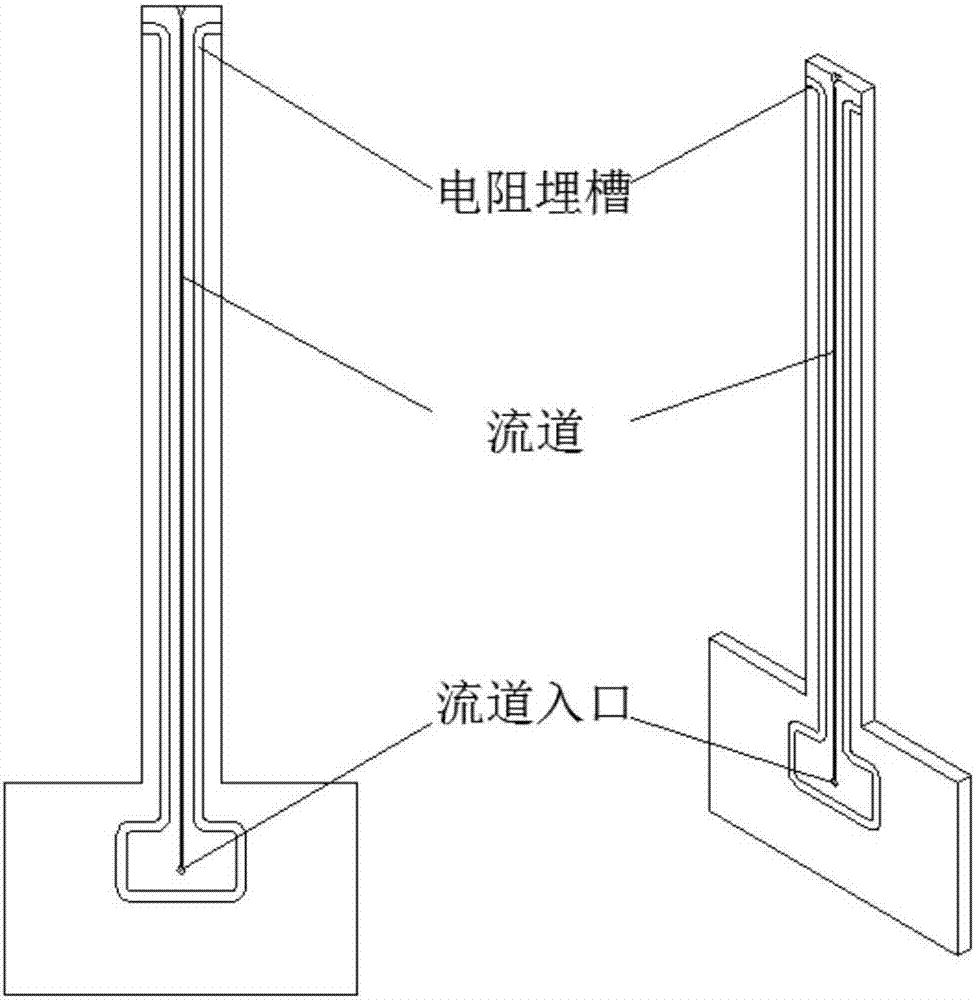

Electrothermal micro-thruster

ActiveCN107975462AStable resistanceIncrease temperatureMachines/enginesUsing plasmaMicro nanoElectrical resistance and conductance

The invention discloses an electrothermal micro-thruster based on a nickel film resistor. The electrothermal micro-thruster comprises a Pyrex glass substrate, the nickel film resistor, a welding discand a silicon wafer. Joule heat produced by the nickel resistor is used to heat the silicon wafer, then a propellant fluid in a runner is heated, and then a high-temperature fluid generates a thrust through a nozzle; for a gas propellant, the electrothermal micro-thruster can effectively heat the gas in the runner so as to improve specific impulse of the electrothermal micro-thruster, and the total thrust of a propulsion system is improved accordingly; for propellants in liquid form such as water and butane, the liquids can be vaporized, and steam generates thrust through a Laval nozzle; and the electro-electric micro-thruster is applied to a micro-propulsion system of a micro-nano satellite, adjusting on single freedom degree of the micro-nano satellite can be completed, and attitude control and orbital elevation of the micro-nano satellite can also be achieved.

Owner:NANJING UNIV OF SCI & TECH

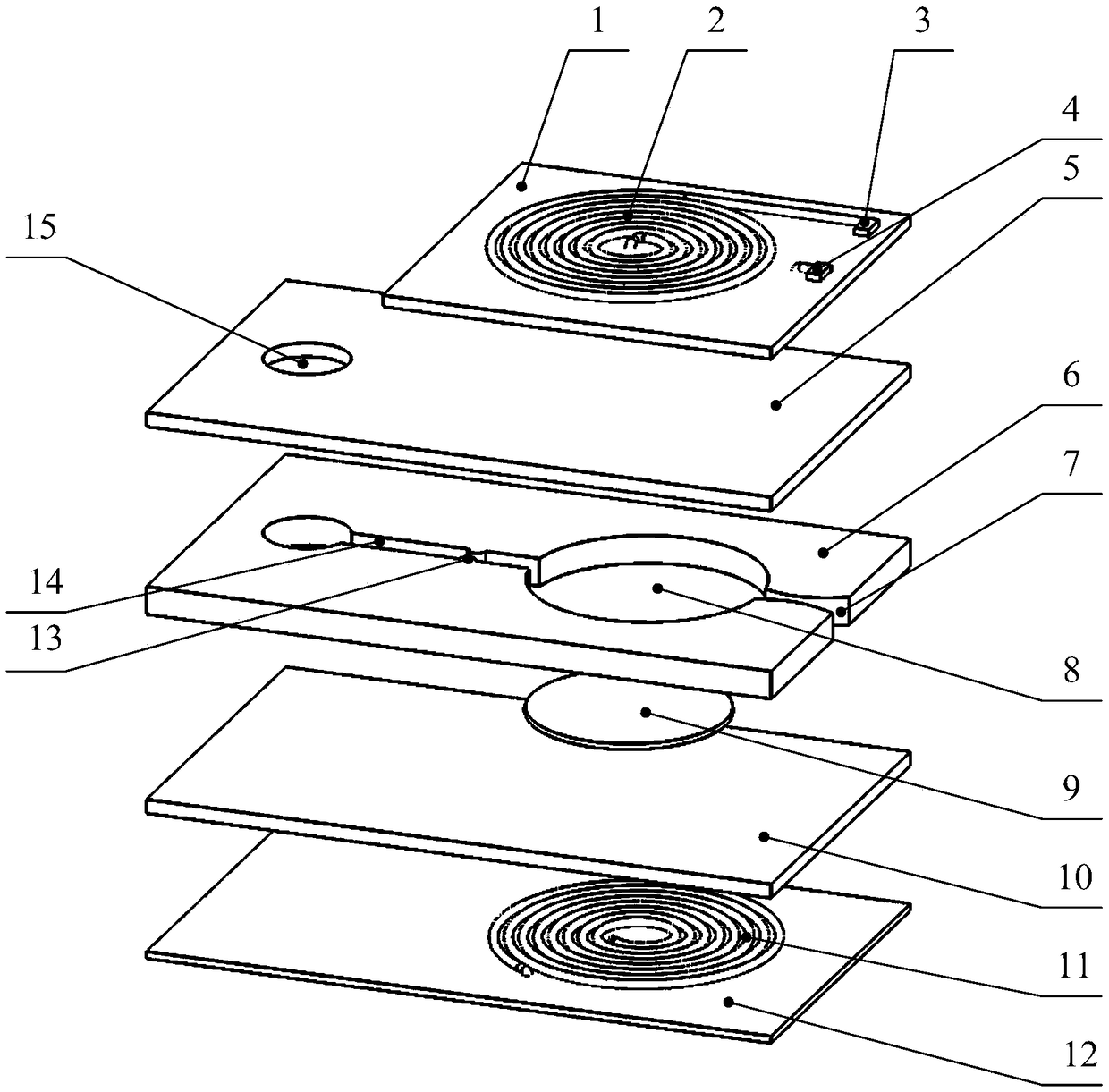

Micro-modularized butane propulsion system structure and propulsion method

ActiveCN108190048AReduce volumeReduce weightCosmonautic propulsion system apparatusMicro nanoSolenoid valve

The invention discloses a micro-modularized butane propulsion system structure and a propulsion method. The micro-modularized butane propulsion system structure comprises a module main body structure,an adding-discharging valve, a heating system and solenoid valves; the heating system is located in the center position of module main body structure and used for conducting state determining and heating on a propellant; the solenoid valves are arrayed on the upper portion of the module main body structure side by side and used for conducting on-off management on circulation of the propellant; and the adding-discharging valve is located in a groove in one side of the module main body structure and is structurally connected with the module main body structure through screws, and adding and discharging of the propellant are achieved through the adding-discharging valve. The micro-modularized butane propulsion system structure adopts the modularized design idea to highly integrate all singlemachines in a traditional propulsion system, different from the split-type distribution structures of the single machines in the traditional propulsion system, the micro-modularized butane propulsionsystem structure has the characteristics of high integration, small size, low weight, convenient installation, achieving rapid mass production, low cost and the like, and the requirement of a micro-nano satellite for the micro propulsion system can be met.

Owner:BEIJING INST OF CONTROL ENG

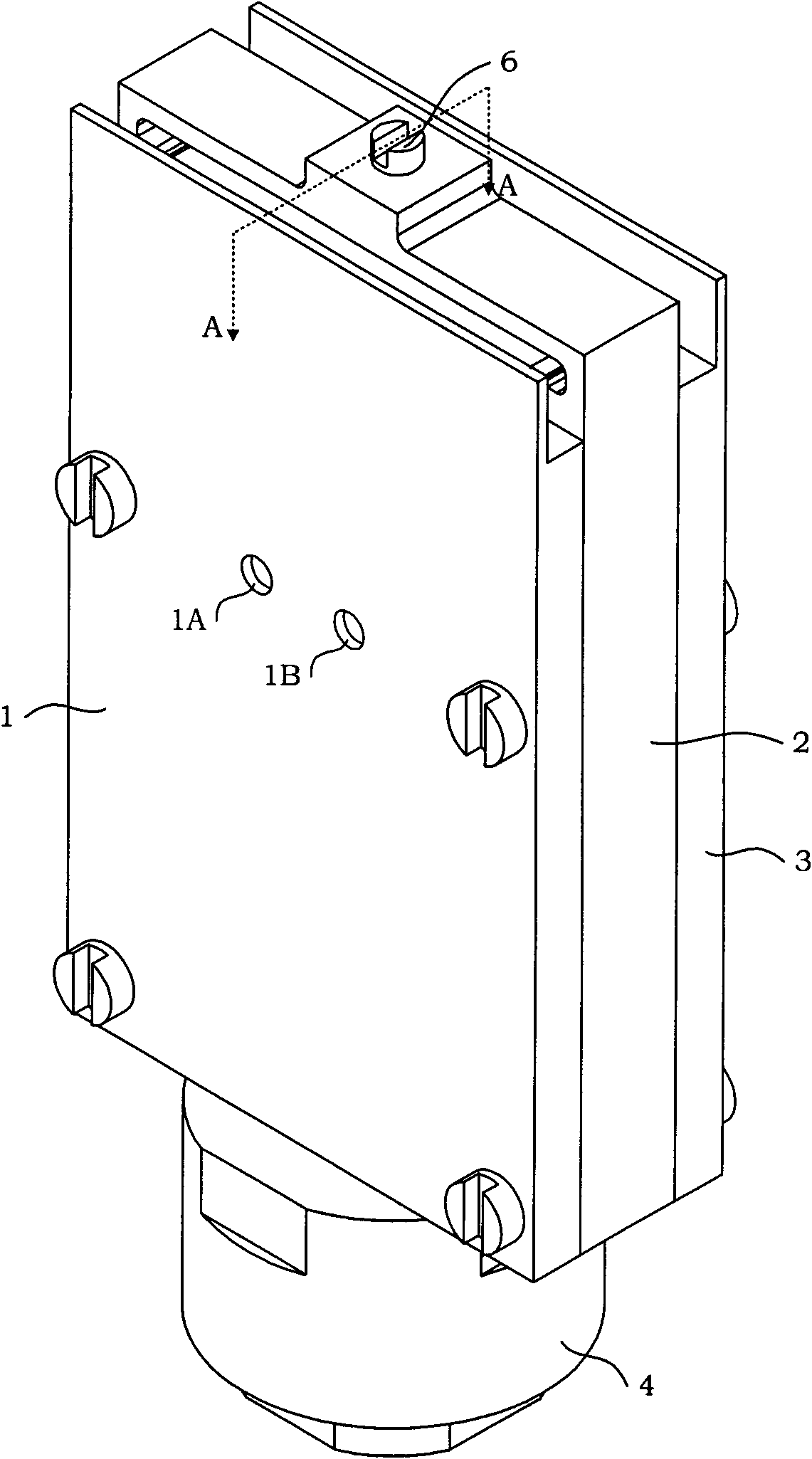

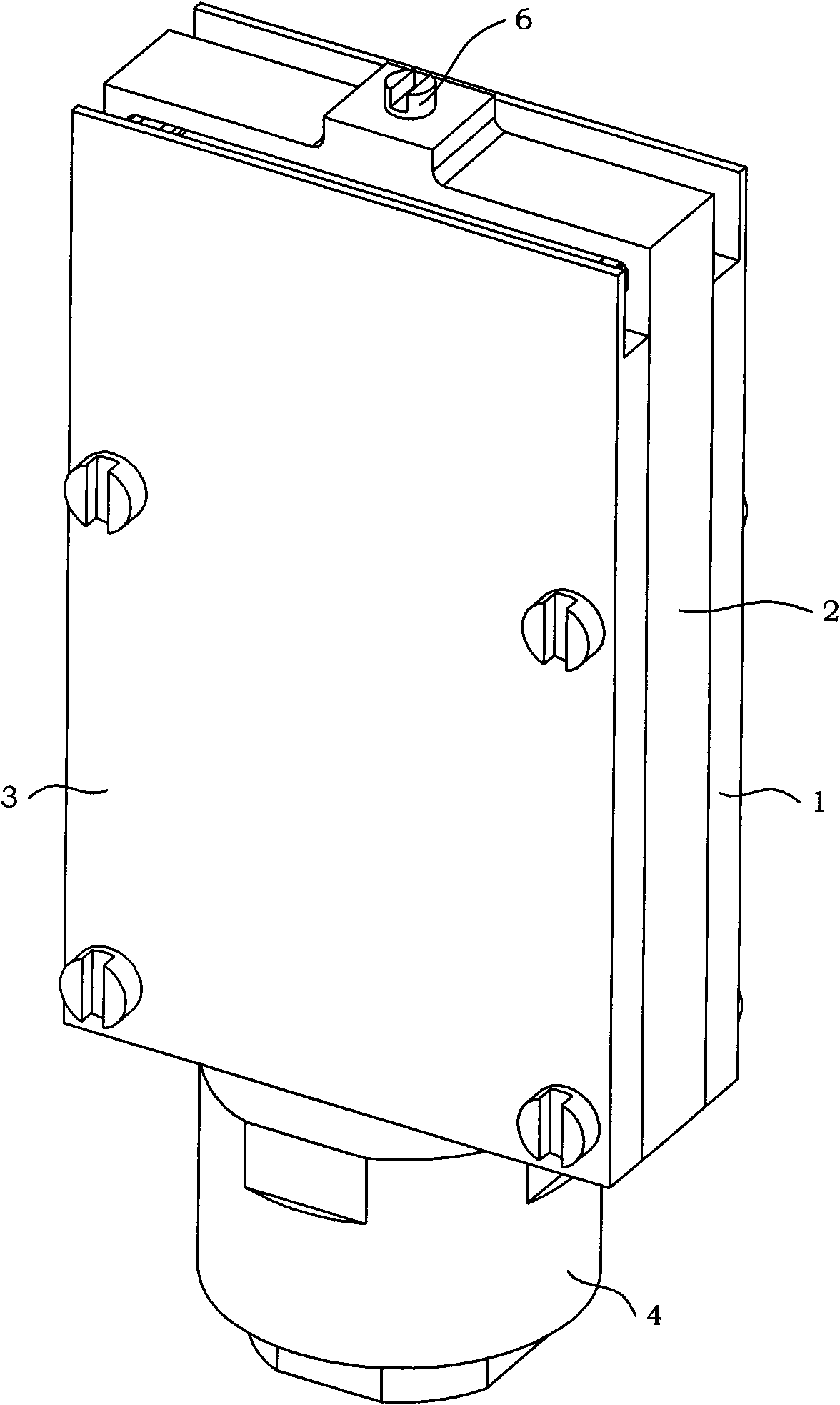

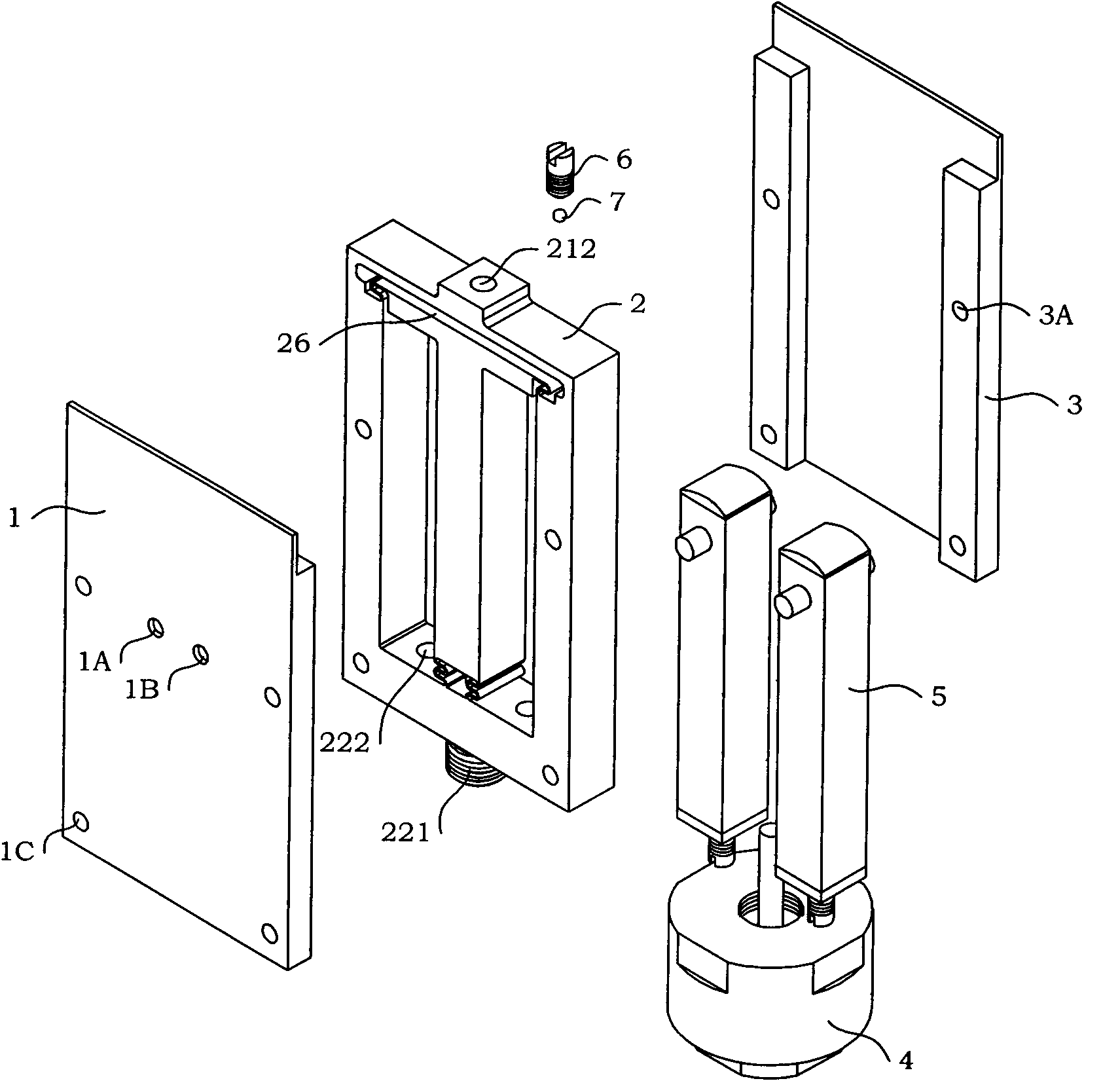

Piezoelectric valve

InactiveCN102072352AOvercome the difficulty of small displacementHigh control precisionOperating means/releasing devices for valvesLiquid mediumEngineering

The invention discloses a piezoelectric valve comprising a front baffle plate, a flexible bracket, a rear baffle plate, a valve body assembly, a piezoelectric driver, a force applying screw and a sliding steel ball; the front baffle plate and the rear baffle plate are the same in structure; the flexible bracket is arranged between the front baffle plate and the rear baffle plate; the piezoelectric driver is arranged in the flexible bracket; the valve body assembly is arranged below the flexible bracket; the force applying screw and the sliding steel ball are arranged above the flexible bracket; and one end of the force applying screw tightly is abutted against the sliding steel ball. The piezoelectric driver is manufactured by combining the traditional manufacturing process and the micro manufacturing process. The flexible bracket has a hinge structure. The piezoelectric valve can satisfy the application of the micro-propulsion system of the aircraft, and can also be suitable for gas and liquid medium with good sealing performance.

Owner:BEIHANG UNIV

Ignition circuit for solid micro-propeller and manufacturing method of ignition circuit

ActiveCN105422316ALow ignition voltageMeet needsRocket engine plantsHemt circuitsMechanical engineering

The invention discloses an ignition circuit for a solid micro-propeller and a manufacturing method of the ignition circuit. The ignition circuit is arranged on a substrate and is an array composed of a*b ignition units in a lines and b columns. Each ignition unit comprises an ignition resistor and a diode. The ignition resistors are thin film resistors and are arranged on the front face of the substrate, the diodes are arranged on the back face of the substrate, and the ignition resistors and the diodes are connected in series through metalized via holes formed in the substrate. The manufacturing method includes the steps that a, the substrate is punched and the via holes are metalized; b, the ignition resistors, leads and electrode regions are manufactured on the front face of the substrate; and c, leads and electrode regions are manufactured on the back face of the substrate and the diodes are attached to the back face of the substrate. By the adoption of the ignition circuit and the manufacturing method of the ignition circuit, ignition can be performed reliably at the low ignition voltage, power consumption is low, the logic addressing function is achieved, and the requirement for independent ignition or combined ignition can be met.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

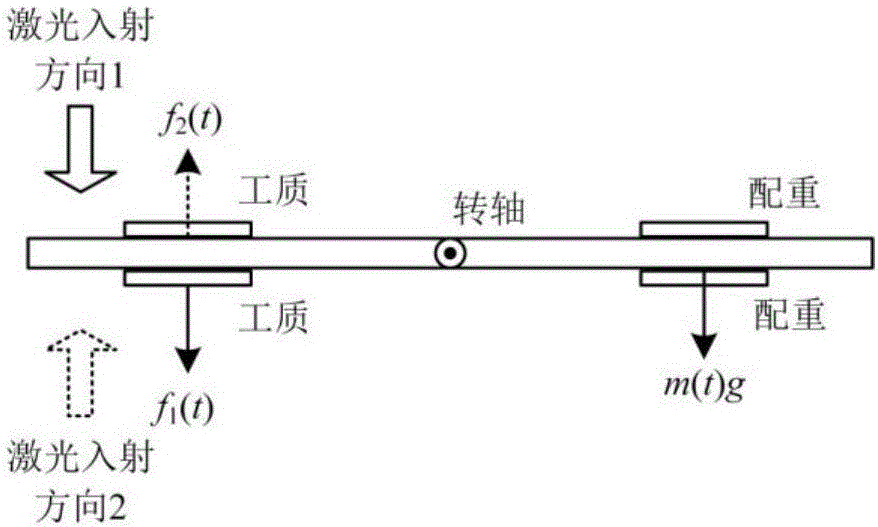

Method for directly measuring specific impulse of laser ablation micro-propulsion

ActiveCN106644395AImprove versatilityAvoid frequent disassemblyOptical apparatus testingPeak valueMeasurement precision

The invention discloses a method for measuring the impulse generated by a single-pulse laser ablation working medium and the corresponding ablation weight, and achieves the purpose of directly measuring the specific impulse. The method comprises the steps: obtaining the corresponding impulse and ablation weight in a mode that the weight isotropic and anisotropic effects aroused by the pulse generated by the single-pulse laser ablation working medium and the ablation weight are respectively carried out once based on a vertical motion torsional pendulum model; obtaining the impulse according to the maximum peak value of each torsional pendulum rotation angle and a rotation angle measurement value before the maximum peak value, and obtaining the ablation weight of the working medium according to a stable rotation angle mean value of the torsional pendulum rotation angles. The method can shorten the test cycle, avoids the frequent disassembly and assembly of the working medium, protects the working medium from being polluted, guarantees the measurement authenticity, and improves the specific impulse measurement precision.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

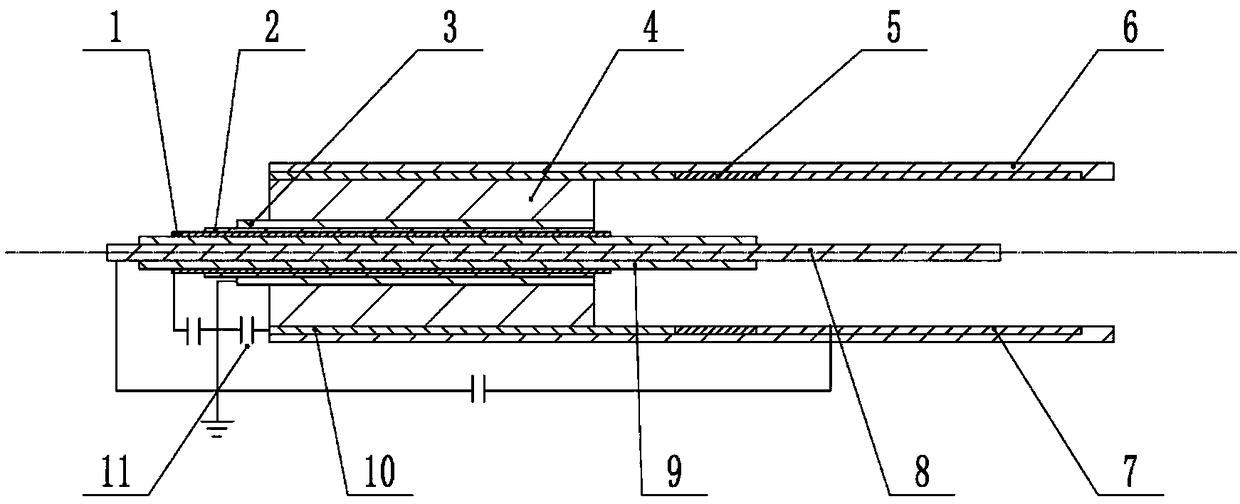

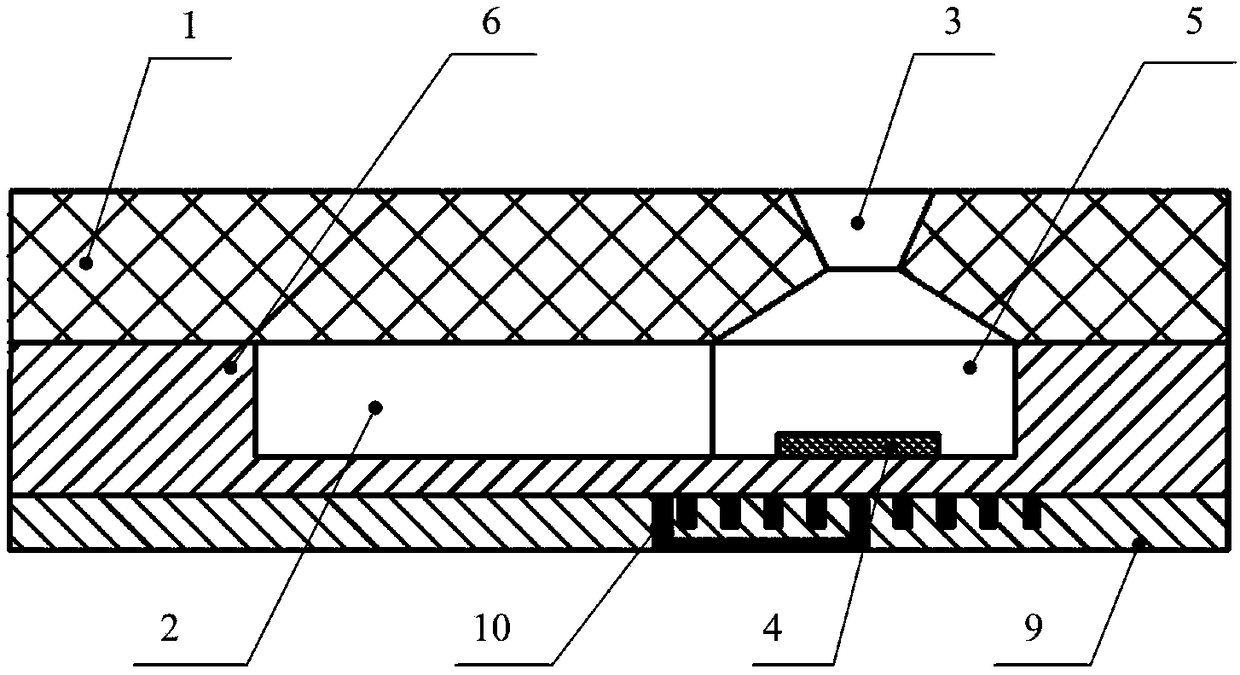

Sensitively heated liquid evaporation type micro-thruster and preparation method thereof

ActiveCN108725846AImprove power supply capacityIncrease the heating areaSteam generation heating methodsCosmonautic vehiclesAviationAttitude control

The invention provides a sensitively heated liquid evaporation type micro-thruster and a preparation method thereof and belongs to the field of aviation, spaceflight, micro-propulsion technologies andmicromechanics. The micro-thruster comprises a cavity layer, an upper cover piece, a substrate, a metal heating plate, an upper PCB, a lower PCB, a magnet exciting coil I and a magnet exciting coil II, wherein the structures manufactured on the cavity layer include a micro-channel, a shrinkage opening, a heating evaporation cavity and a laval spray port. Specifically, electromagnetic induction heating liquid is utilized and is vaporized in a heating cavity, the pressure in the cavity is increased, high-pressure gas is sprayed out of a micro-spraying orifice to produce a thrust, and thus the micro-thruster obtains a driving force in the opposite direction. The micro-thruster plays the very important effect on position keeping, gesture control, gravitation compensation, track adjustment andthe like of a microsatellite.

Owner:BEIJING UNIV OF TECH

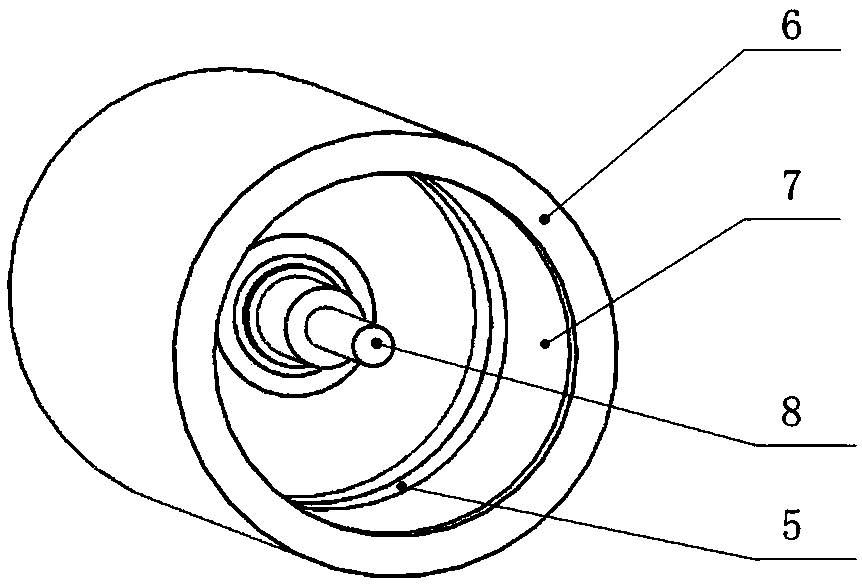

Ionic liquid electronic injection thruster for controlling liquid supply through electric field

ActiveCN112780514ARealize active supplyImprove stabilityMachines/enginesUsing plasmaPorous mediumLiquid storage tank

The invention relates to an ionic liquid electronic injection thruster for controlling liquid supply through an electric field, and belongs to the technical field of micro-propulsion of micro-nano satellites. The ionic liquid electronic injection thruster comprises a liquid storage tank, a copper sheet covered with a hydrophobic dielectric layer, an insulating spacer used for controlling the distance of the copper sheet, an upper shell, an emitting electrode and an extraction electrode. According to the thruster, the wettability between the ionic liquid and the porous medium type emitting electrode is improved through the electric field, meanwhile, the flowing characteristic of the ionic liquid in a capillary pipeline is controlled through the electric field, active supply of a propellant can be achieved, the emission stability of the ionic liquid electronic injection thruster is improved, the service life of the ionic liquid electronic injection thruster is prolonged, the thruster is suitable for resistance compensation of low-power micro-nano satellites, and task requirements of position keeping, attitude control and the like are met.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

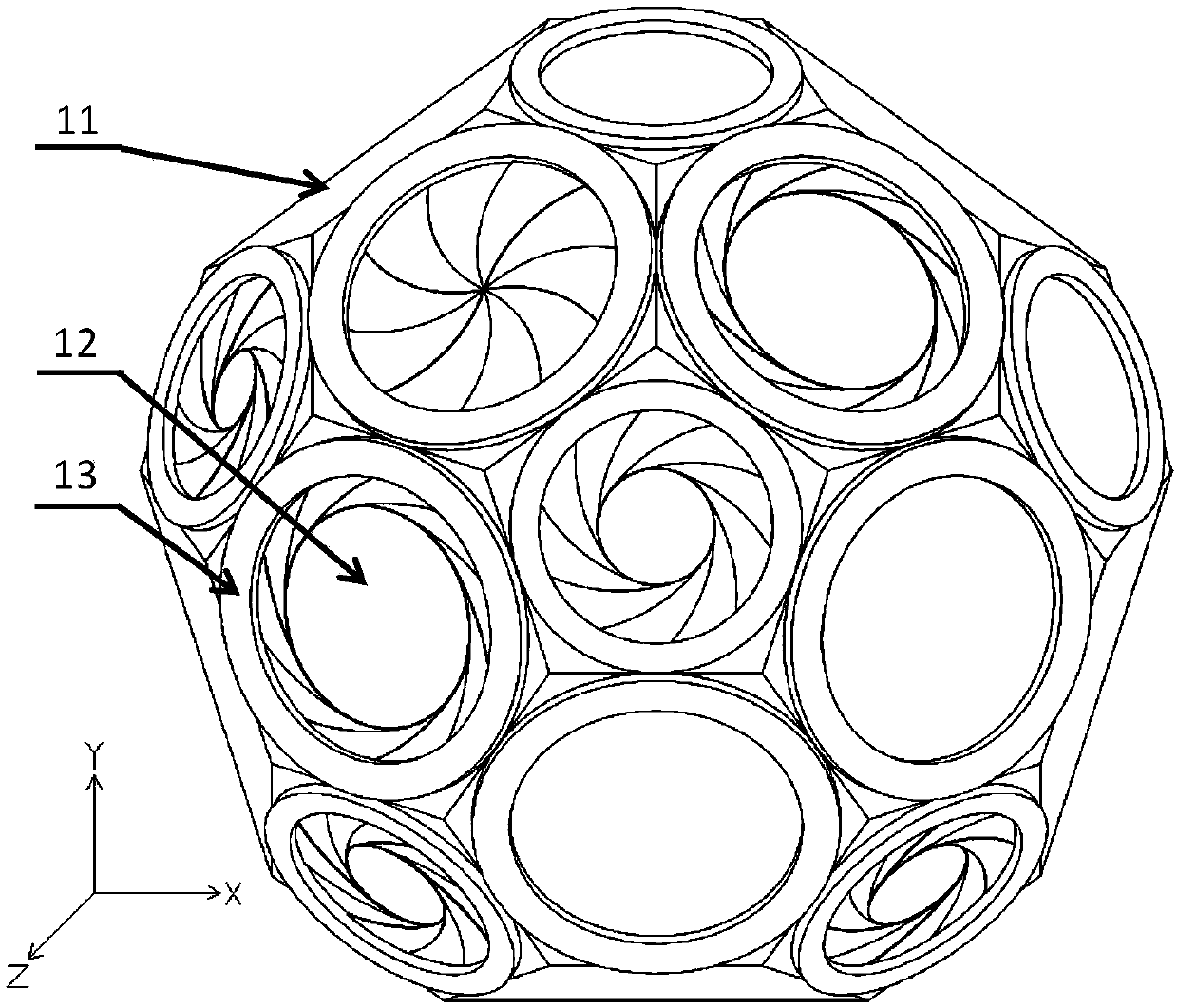

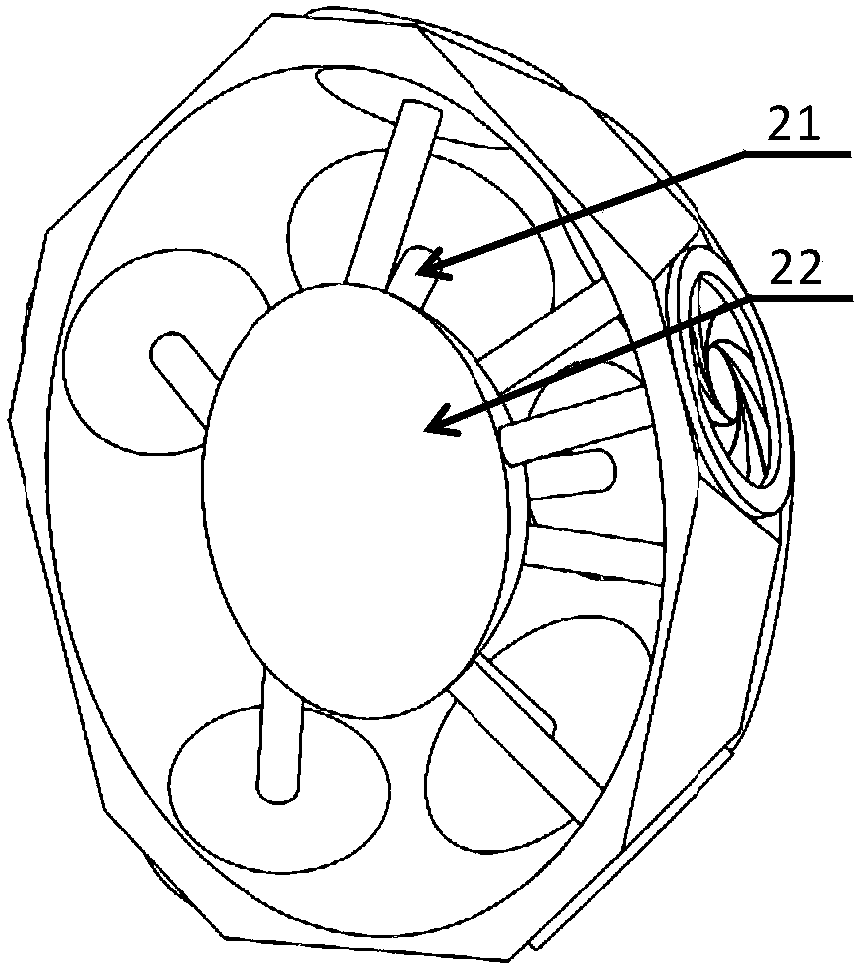

Spheroidic structure high precision vector synthesis nuclear energy micro propulsion system

ActiveCN108648848AAperture size adjustableThe size of the power can be adjusted arbitrarilyCosmonautic propulsion system apparatusRadiation electrical energyThermal energyNuclear power

The invention discloses a spheroidic structure high precision vector synthesis nuclear energy micro propulsion system. The spheroidic structure high precision vector synthesis nuclear energy micro propulsion system includes five substructures: a spheroidic vector synthesis support, a nuclear power surface element, a surface element control switch, a surface element heat transfer unit, and a thermoelectric conversion center. The spheroidic structure high precision vector synthesis nuclear energy micro propulsion system uses the particle kinetic energy formed by spontaneous decay of the nucleusto form the recoil power, uses the spheroidic structure to arrange thrust units with different thrust directions, independently and continuously controls each thrust unit through a laminated counter-rotating structure to form a micro propeller in which the magnitude and the direction of the total thrust can be adjusted with high precision, can further convert associated thermal energy of decay into power sources and heat sources to use, and is specifically suitable for precise control and application of a high precision platform with high stability.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

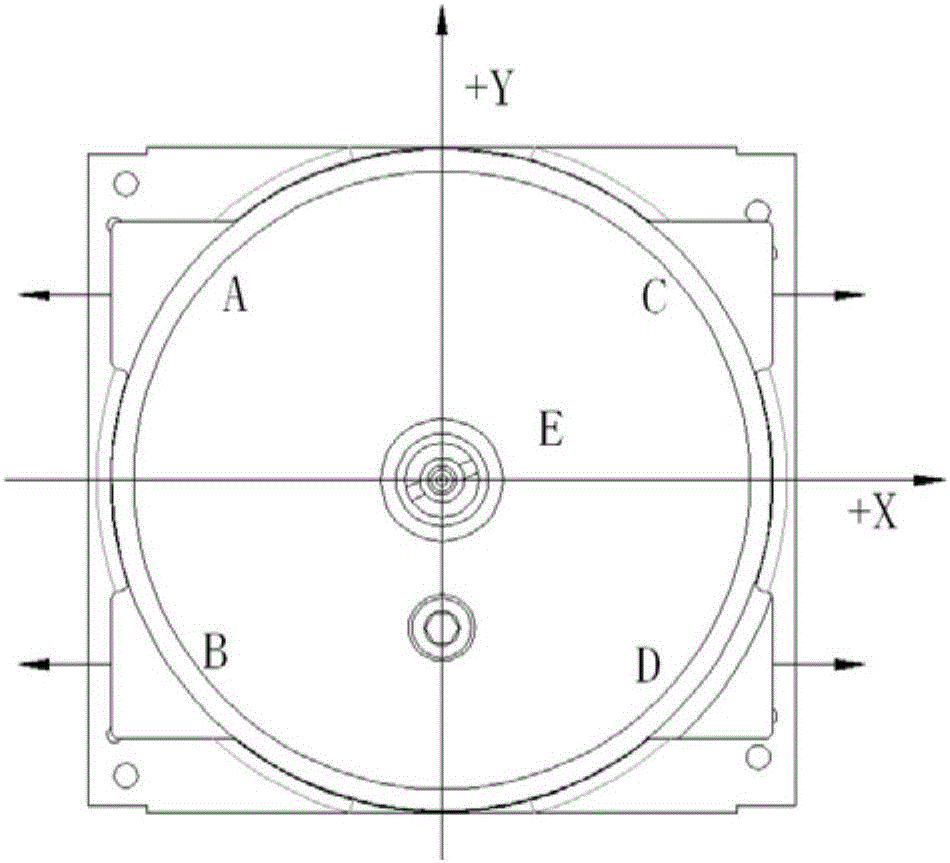

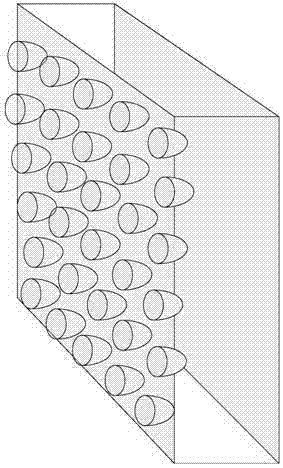

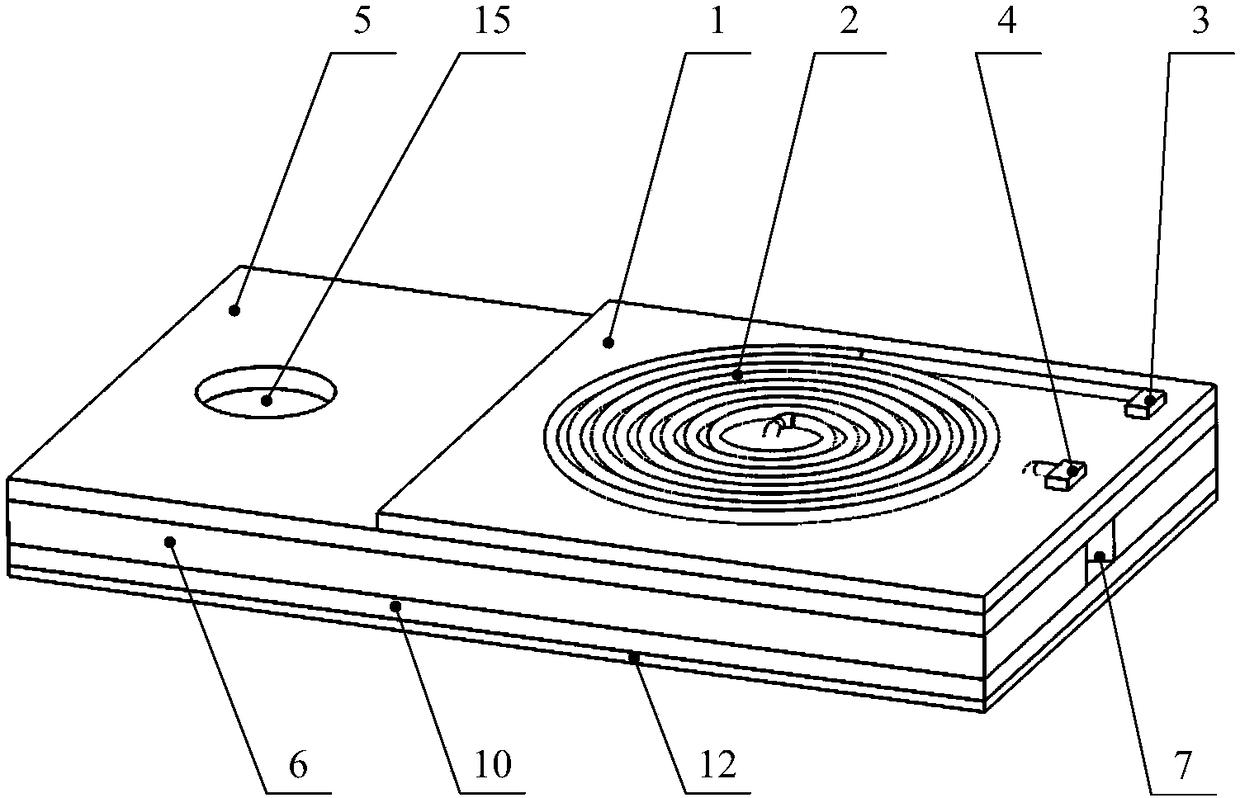

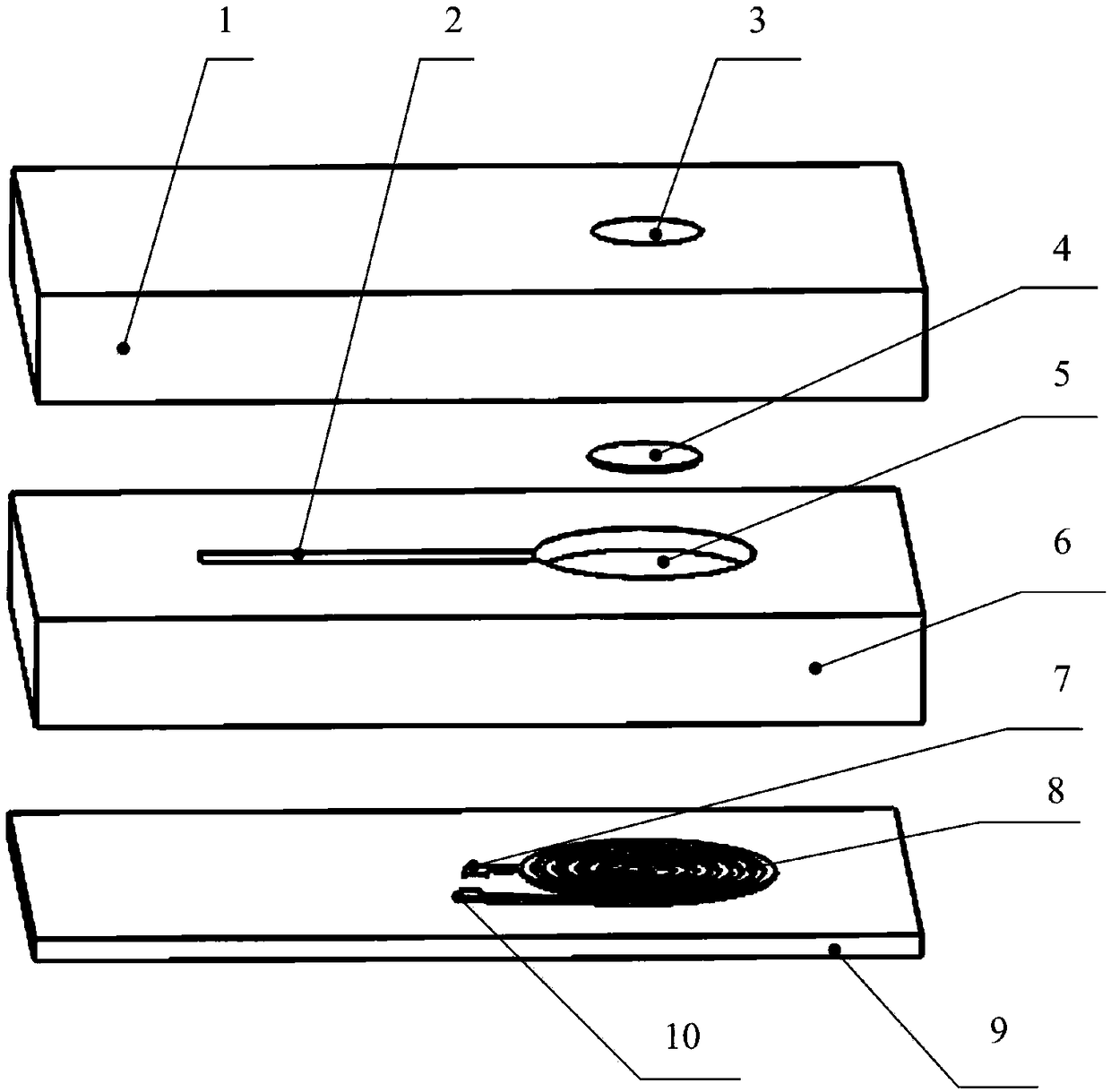

Multipolar output array type thin micro-electromechanical system (MEMS) micro-propeller

ActiveCN108757361ASimple structure and processSimple preparation processDecorative surface effectsMachines/enginesAttitude controlMicrosatellite

The invention discloses a multipolar output array type thin micro-electromechanical system (MEMS) micro-propeller, and belongs to the field of micro-propulsion technologies and MEMSs. The micro-propeller adopts a mode that a front-face-type micro-propeller body and a side-face-type micro-propeller are combined. After an upper cover piece and a base of the multipolar output array type thin MEMS micro-propeller are manufactured, the upper cover piece and the base are assembled together through a bonding method and finally are bonded with a PCB with an excitation coil. Specifically, the multipolar output array type thin MEMS micro-propeller is manufactured through an MEMS micromachining technology, through high-frequency pulse induction heating, liquid around a heating disc is vaporized intogas rapidly, the high pressure is formed in a micro-cavity, the gas is ejected at a high speed through a nozzle under the effect of the high pressure, and the micro-propeller obtains driving force inthe opposite direction. The micro-propeller can be used for position holding, attitude control, orbital adjustment and the like of a microsatellite.

Owner:BEIJING UNIV OF TECH

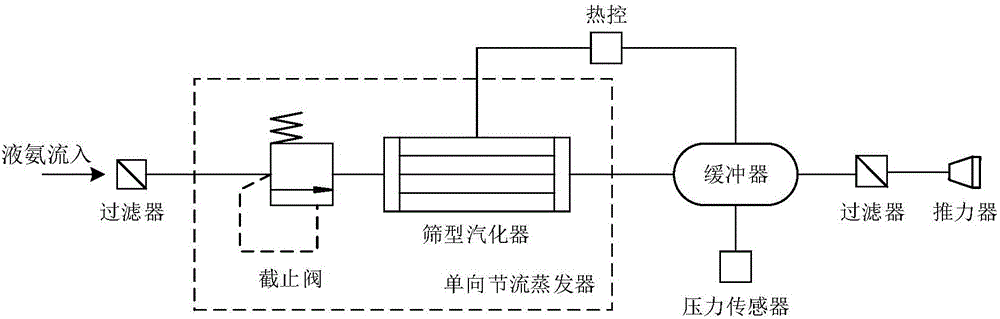

Autonomous vaporization management method and liquid ammonia micro-propulsion system

ActiveCN106184823AMake up for the defect of pressure lossGuaranteed to be fully vaporizedCosmonautic propulsion system apparatusArtificial satellitesMicro nanoVaporization

The invention discloses an autonomous vaporization management method and a liquid ammonia micro-propulsion system. The method is implemented in a way that a storage tank, a cut-off valve and a vaporizer are sequentially connected to form a vaporization device, the vaporizer is heated to completely vaporize a liquid ammonia propellant in the vaporizer, and thus constant pressure vaporization or pressurized vaporization is realized. The system applies the method to a propulsion system, the vaporizer which completely vaporizes the liquid ammonia propellant is arranged in the system, and thus the propellant is finally completely output at a relatively high specific impulse through a thruster in the gaseous form; heating is performed to adjust the pre-thrust pressure, and thus the output thrust is controlled. According to the micro-propulsion system, the thrust can be accurately and stably controlled, and furthermore, the problem of difficulty in precisely measuring the remaining propellant of the liquid ammonia propulsion system is solved by using the specific heat characteristic of liquid, and reusing heating of the storage tank, and a temperature-collecting pressure-collecting device. The system can improve the in-orbit maneuver capability of micro / nano-satellites and has great significances on expanding the space application of micro-nano satellites.

Owner:ZHEJIANG UNIV

Vertical pendulum type micro-small thrust test board device, calibration method and weak force testing method

PendingCN112504534AGuaranteed test accuracySimple structureForce measurement using counterbalancing forcesApparatus for force/torque/work measurementMeasuring instrumentClassical mechanics

The invention relates to the technical field of weak force testing, and concretely relates to a vertical pendulum type micro-small thrust test board device, a calibration method and a weak force testing method. The vertical pendulum type micro-small thrust test board device comprises a vacuum container, a test board frame, a vertical pendulum body, a feedback voice coil motor, a calibration voicecoil motor and a micro-displacement measuring instrument, and a propeller is arranged at the lower end of the vertical pendulum body. By means of the mode, when the vertical pendulum body is in a balanced state, the micro-propelling force and the feedback weak force which are applied to the vertical pendulum body by the propeller and the feedback voice coil motor respectively have a linear relation, and the structure and the operation method are simplified under the condition that the testing precision is guaranteed; and when the vertical pendulum body is in the balanced state, the calibrationvoice coil motor and the feedback voice coil motor respectively apply a linear relationship to the directions of the standard weak force and the feedback weak force applied to the vertical pendulum body, and the calibration voice coil motor can calibrate the feedback weak force of the feedback voice coil motor, so that the measurement precision of the device is ensured.

Owner:INNOVATION ACAD FOR PRECISION MEASUREMENT SCI & TECH CAS

Wire EDM electrode wire reciprocating progressive wire-moving method and device

ActiveCN105195843BGuaranteed lossGuaranteed machining accuracyElectrical-based machining electrodesElectrical-based auxillary apparatusReciprocating motionMachining process

Owner:TAIZHOU CHEN HONG NC EQUIP MFG CO LTD

Handheld electrostatic spinning gun

The invention discloses a handheld electrostatic spinning gun. The handheld electrostatic spinning gun comprises a handheld portion and a power supply portion, wherein the handheld portion comprises ahandheld insulating shell, a propeller is arranged inside the handheld insulating shell, a micro propulsion pump is arranged at one end of the propeller, a spinning nozzle is arranged at the other end of the propeller, and the micro propulsion pump is connected with a propulsion pump controller and a switch through wires; the power supply portion comprises a high-voltage power supply, a propulsion pump controller power supply and a grounding plate, the positive pole of the high-voltage power supply is connected with the spinning nozzle through a wire, the negative pole of the high-voltage power supply is connected with the grounding plate through a wire, and the propulsion pump controller power supply is connected with the propulsion pump controller through a wire. By the equipment, the problems that existing equipment is large in size, the size and the shape of a fiber membrane are limited by the equipment and the like are solved, and the handheld electrostatic spinning gun has a good application prospect.

Owner:QINGDAO XINZHIYUAN HEALTH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com