Micro-modularized butane propulsion system structure and propulsion method

A propulsion system and modularization technology, applied in the direction of aerospace vehicle propulsion system devices, etc., can solve the problems of high system pressure, large volume and weight of storage tanks, and large volume, so as to improve reliability and life, and compact and novel space layout , volume and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

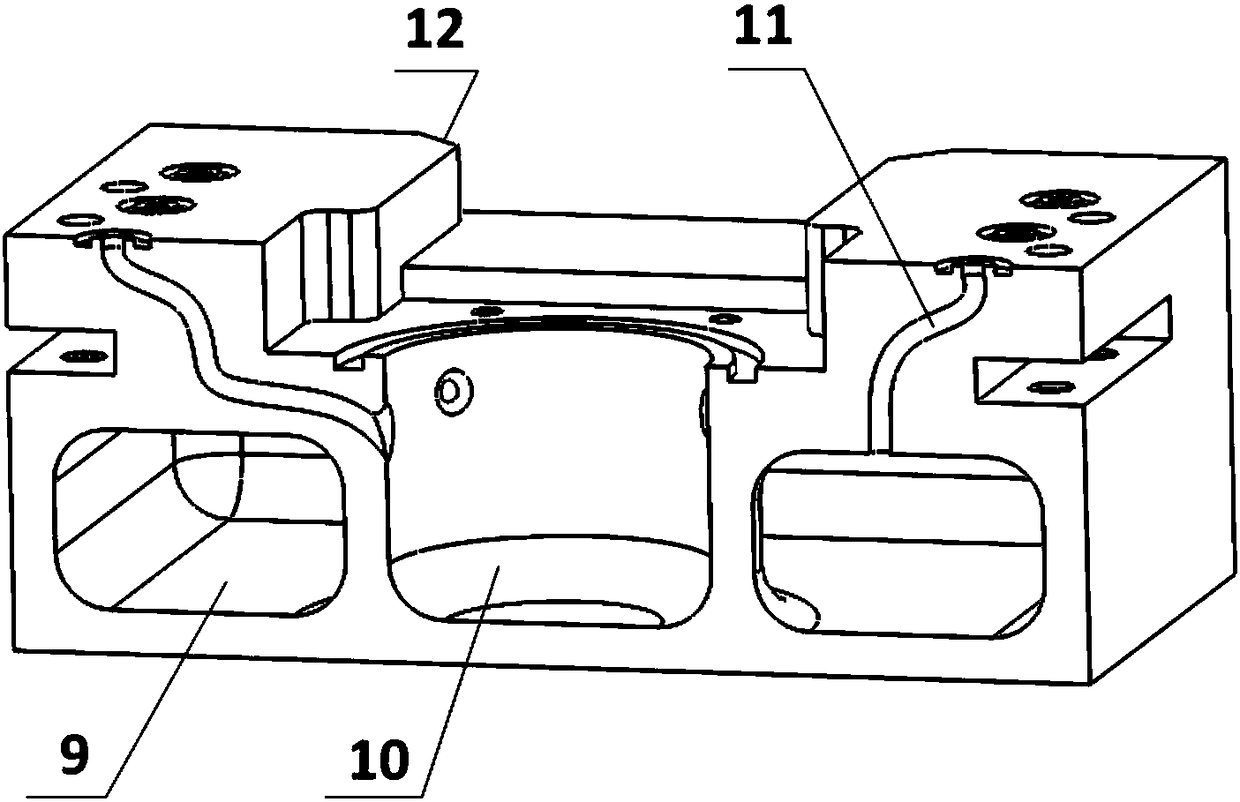

[0030] Such as figure 1 As shown, a micro-butane propulsion system structure of the present invention includes: a module main structure 1, a discharge valve 2, a heating system, and a solenoid valve 8; the heating system is located at the center of the module main structure 1, and is used to carry out State determination and heating; solenoid valves 8 are arranged side by side on the upper part of the module main structure 1 for on-off management of the flow of propellant; the addition and discharge valve 2 is located in the groove on one side of the module main structure 1, and is connected to the module through screws The main structure 1 is connected, and the filling and discharging of the propellant is realized through the filling and discharging valve 2 .

[0031] It also includes a metal auxiliary bracket 6 and a solenoid valve mounting bracket 7; the two ends of the solenoid valve 8 are fixed by the solenoid valve mounting bracket 7, and then the solenoid valve bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com