Silicon-based MEMS array propeller and preparation method thereof

An array type thruster technology, applied in the field of micro-propulsion technology and micro-electromechanical systems, can solve problems such as igniter fracture and failure, achieve the effects of improving yield, avoiding igniter fracture, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

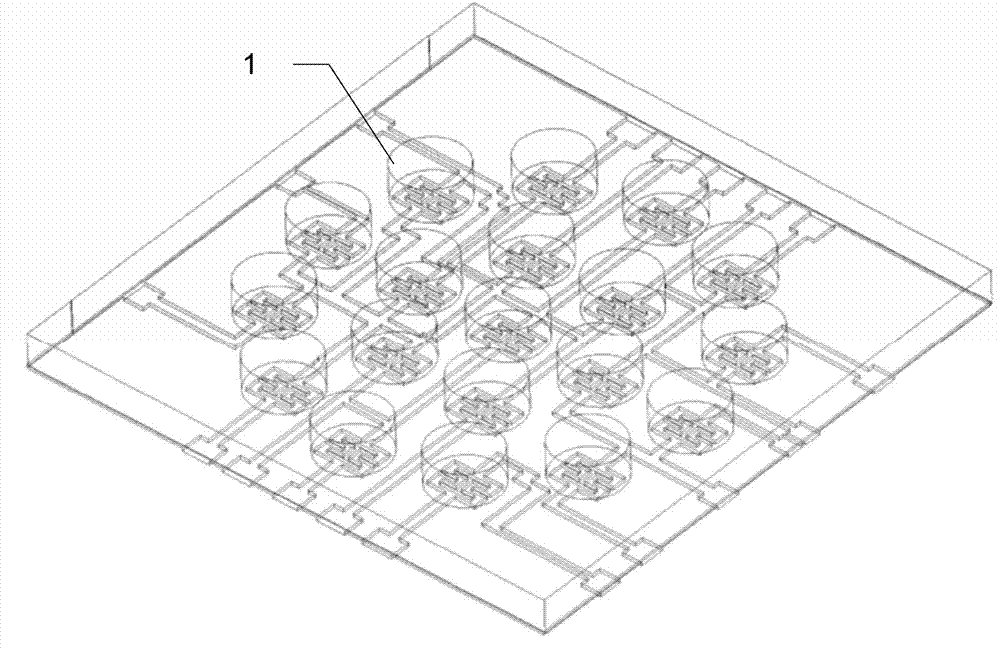

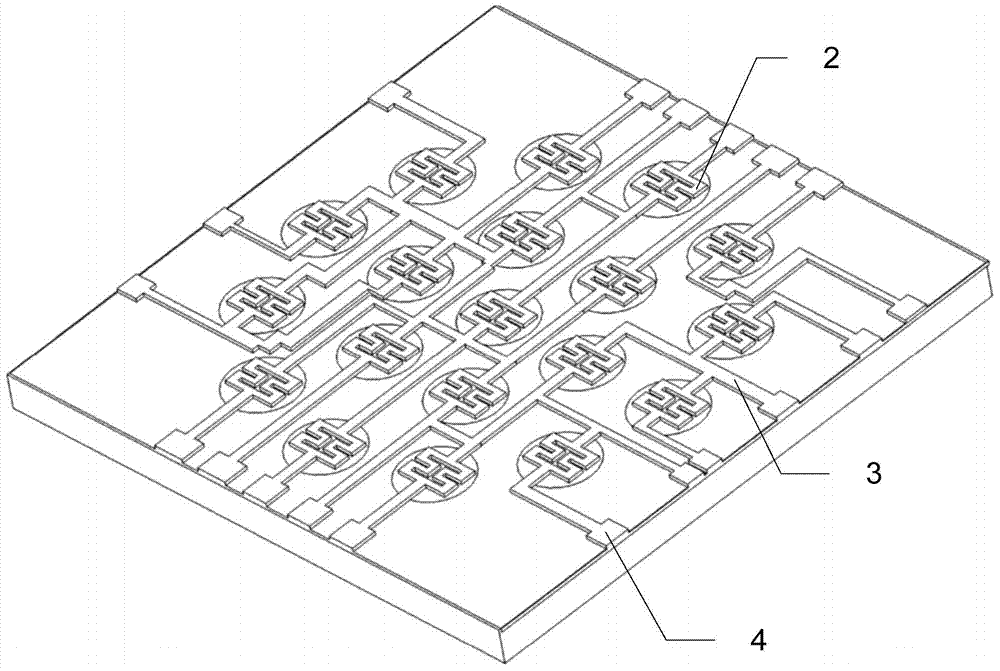

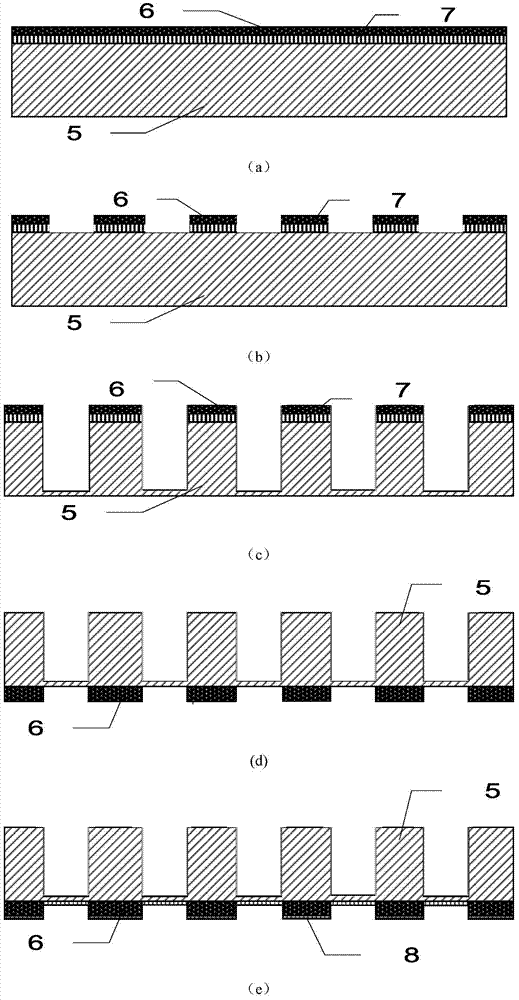

[0023] refer to Figure 1-2 , the silicon-based MEMS array propeller in this embodiment includes a nozzle 1, an ignition resistor 2, an ignition wire 3 and a pad 4; the thickness of the silicon-based material is 500 μm; the upper surface of the propeller is concaved to form a nozzle 2 The nozzle 2 is a circle with a diameter of 1000 μm; the lower surface of the propeller is sputtered with an ignition resistor 2, an ignition wire 3 and a welding pad 4; the ignition resistor 2 is composed of two parallel serpentine folded metal gold film resistors; The width and thickness are 50 μm and 300 nm respectively; each ignition resistor 2 corresponds to the position of each nozzle 1; the ignition resistor 2 is connected to the ignition wire 3; the width and thickness of the ignition wire 3 are 100 μm and 300 nm respectively; the ignition wire 3 and the pad 4 connections; the area and thickness of pad 4 are 0.5mm 2 , 300nm.

[0024] When working, the ignition resistor 2 is energized th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com