Multi-section type high-efficiency pulse plasma thruster

A pulsed plasma and plasma technology, applied in the field of plasma thrusters, can solve the problems of insufficiency, low energy conversion efficiency, easy failure reliability of ignition starting devices, etc., and achieve the effects of improving acceleration efficiency and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

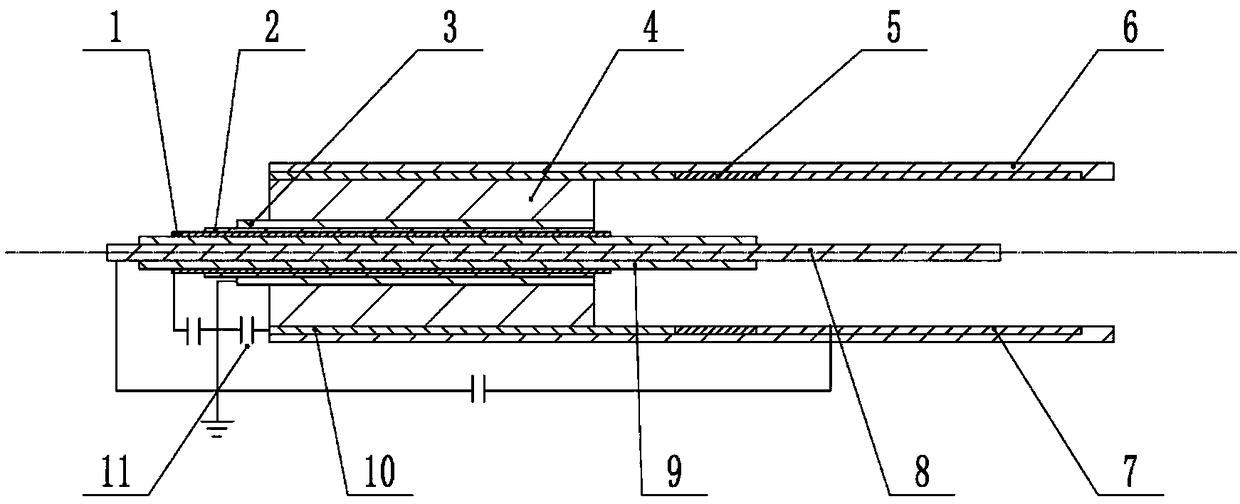

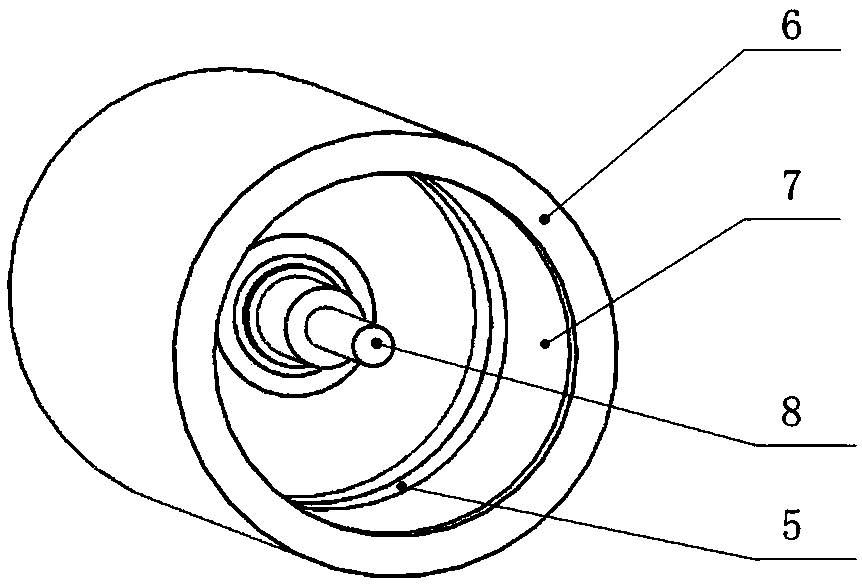

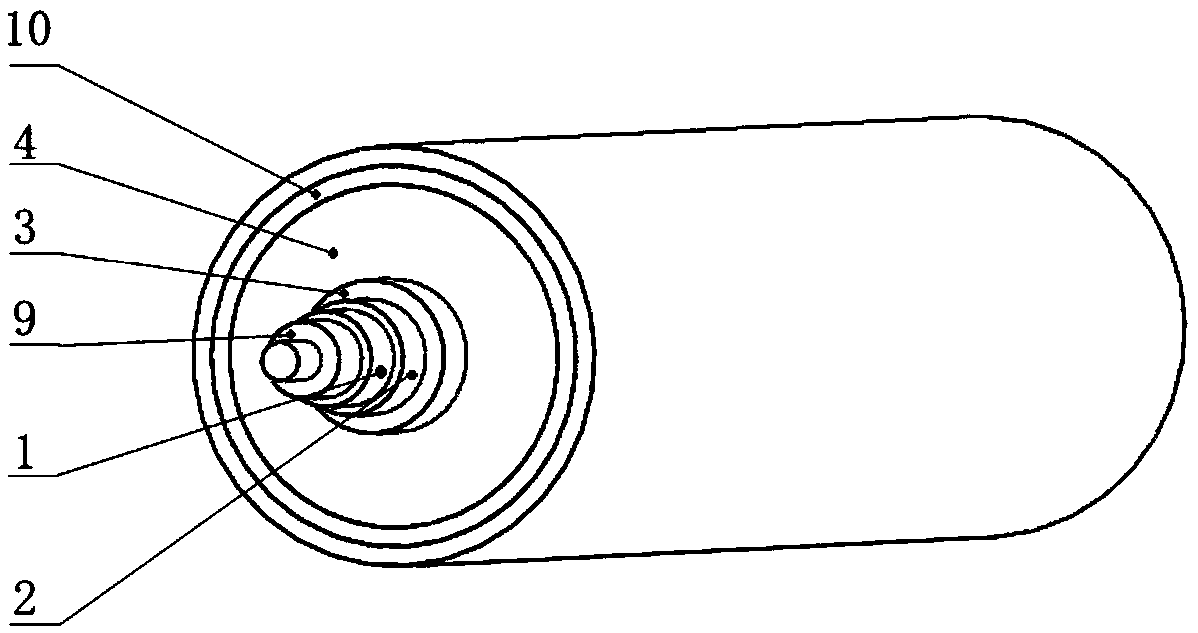

[0020] This embodiment discloses a multi-stage high-efficiency pulse plasma thruster. The structure of the thruster is mainly composed of one section of anode 10, one section of cathode 3, two sections of anode 7, two sections of cathode 8, insulating section 5, trigger pole 1, trigger work Composition of mass 2, energy storage capacitor group 11, propellant 4, cladding layer 9 and outer casing 6.

[0021] The thruster has a coaxial structure as a whole, and the electrodes are divided into two sections. The first section of electrodes is mainly used for the process of ablating and ionizing the propellant, and the second section of electrodes is mainly used for the process of plasma acceleration. The first section of electrode consists of a section of anode 10 and a section of cathode 3, both of which are coaxial rings made of brass, wherein the section of anode 10 has an inner diameter of 9 mm, an outer diameter of 10 mm, and a length of 25 mm. A section of cathode 3 has an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com