Sensitively heated liquid evaporation type micro-thruster and preparation method thereof

A liquid evaporation and induction heating technology, applied in steam generation methods, lighting and heating equipment, steam generation and other directions, can solve the problems of small thrust and slow response speed, and achieve the improvement of heating capacity, heating area and reduction of manufacturing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

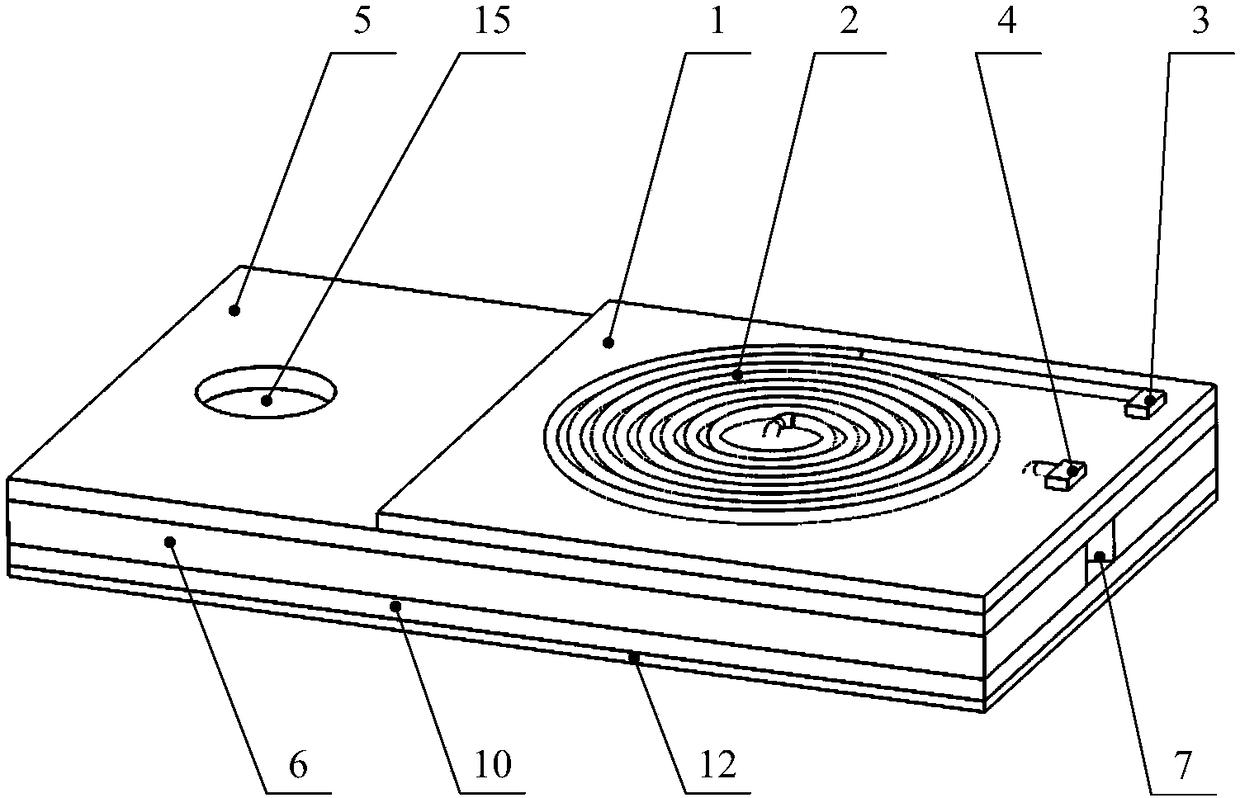

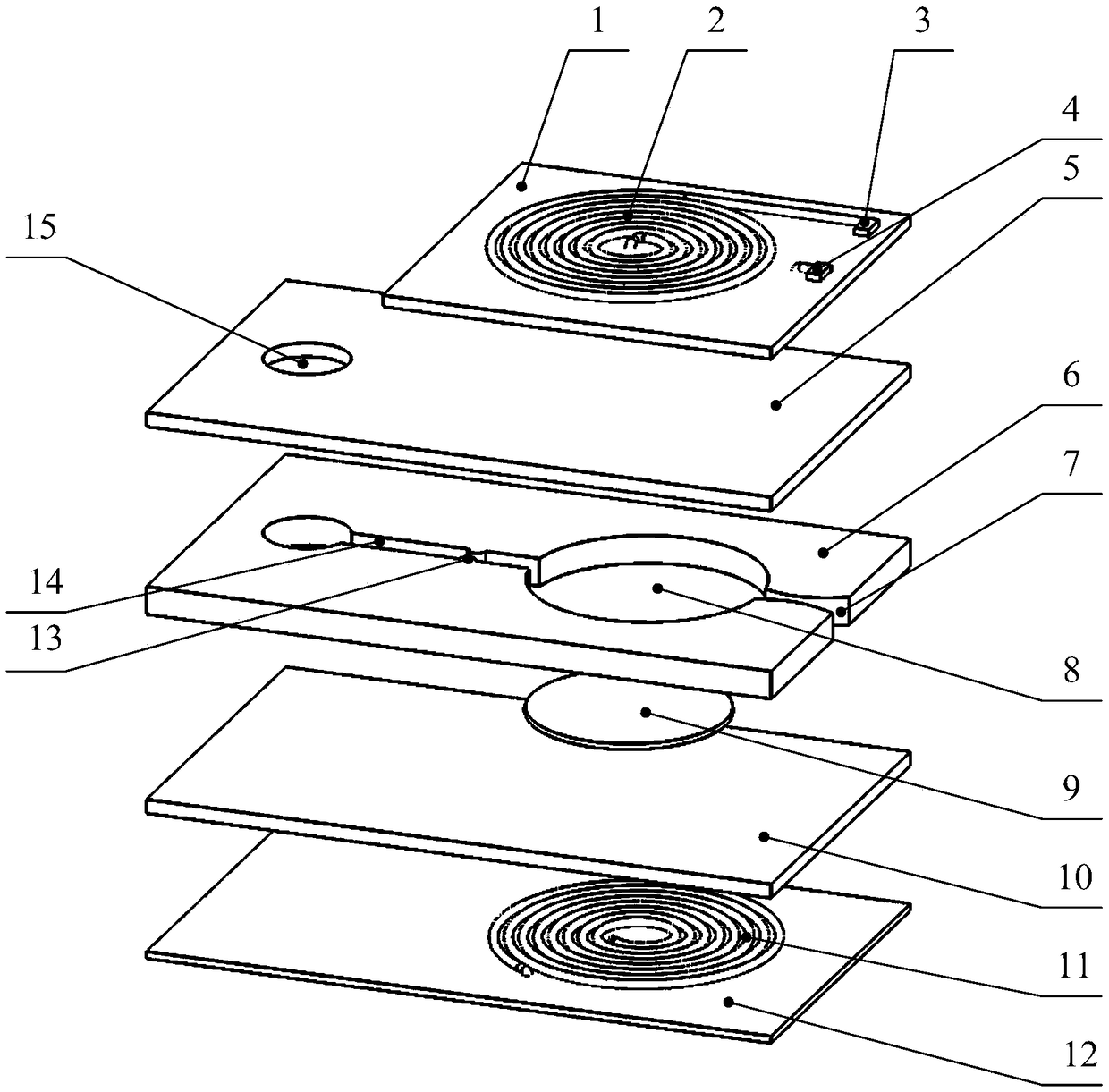

[0042] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0043] The present invention adopts following technical scheme:

[0044] Induction heating liquid evaporation micro-propeller, including cavity layer 6, upper cover sheet 5, base 10, metal heating plate 9, upper PCB board 1, lower PCB board 12, excitation coil I2 and excitation coil II11; The structure fabricated on the bulk layer 6 includes a micro-channel 14 , a constriction port 13 , a heating evaporation chamber 8 and a Laval nozzle 7 .

[0045] The micro-channel 14 has the same depth as the Laval nozzle 7, which is 150 μm-300 μm, and the width is 80 μm-300 μm;

[0046] The upper cover sheet 5, cavity layer 6 and substrate 10 are zirconia ceramic blocks;

[0047]The circular liquid inlet 15 is processed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com