Multipolar output array type thin micro-electromechanical system (MEMS) micro-propeller

A technology for output arrays and micro-thrusters, applied in the field of micro-propulsion technology and micro-electromechanical systems, can solve the problems of small specific impulse, difficult processing and production, and inability to multi-stage output, and achieve high thrust, simple structure and manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

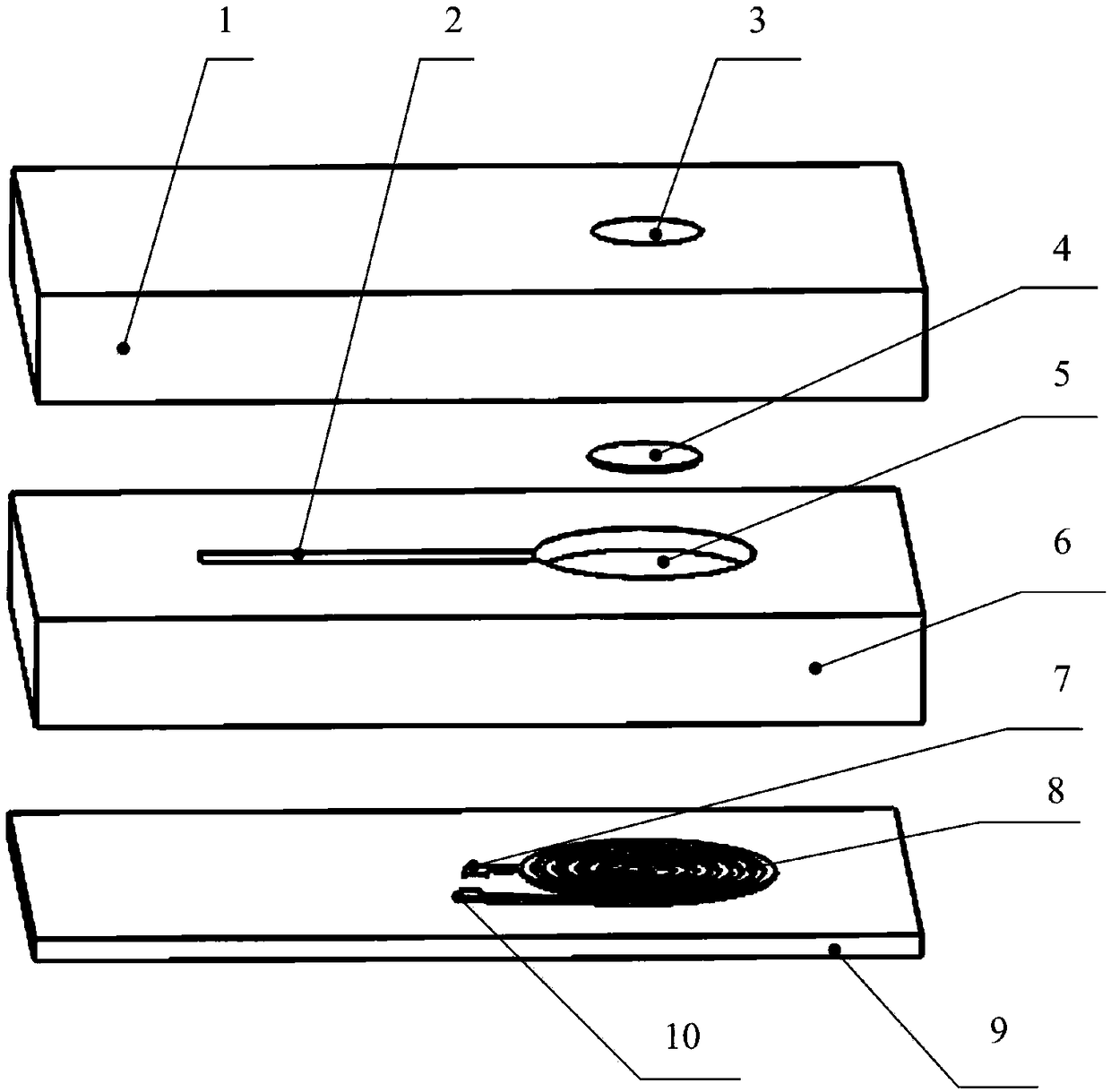

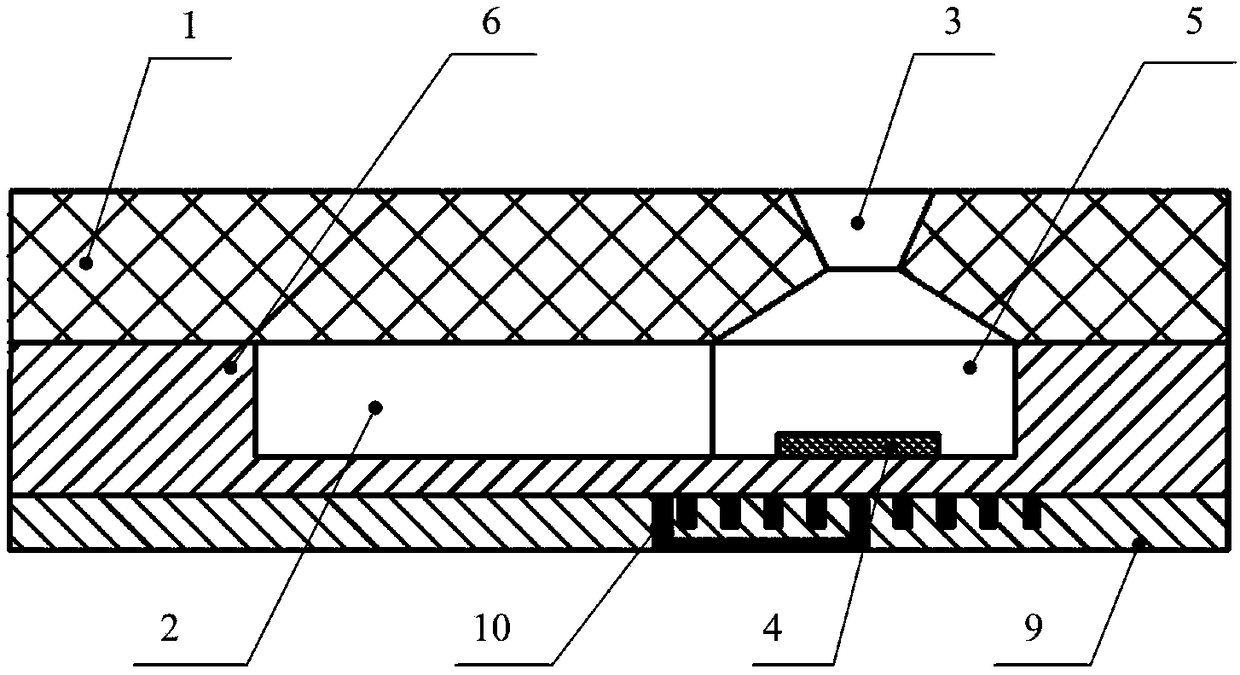

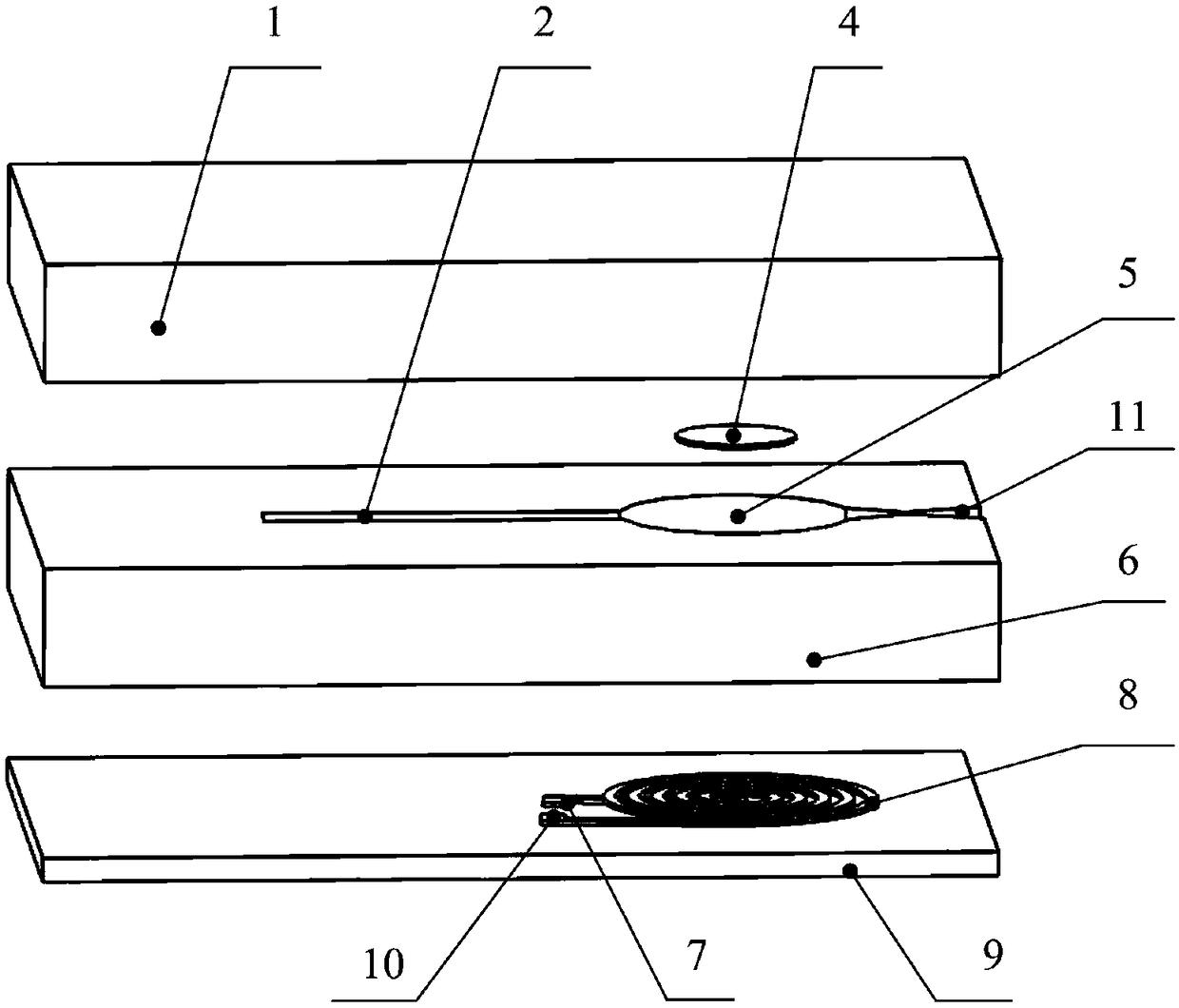

Method used

Image

Examples

Embodiment Construction

[0038] A 200 μm thick double-sided polished silicon wafer is used as the upper cover 1, and the side micro-propeller liquid inlet 13 and the front micro-propeller liquid inlet 14 are fabricated on the upper cover 1, and the isotropic wet etching process is adopted, and the specific steps as follows:

[0039] first step, Figure 10 As shown in (a), the upper substrate 1 is cleaned with a standard RCA process; both sides are thermally oxidized and grown with a thickness of 1 μm Si0 2 , and then deposited 2μm Si by PECVD 3 N 4 , as a masking layer 29, and coat photoresist I28 on the upper and lower surfaces of the masking layer 29;

[0040] second step, Figure 10 As shown in (b), the circular pattern was made by UV deep exposure lithography, and CHF 3and He mixed gas reactive ion etching (DRIE) of Si0 in circular holes 2 and Si 3 N 4 The formed masking layer 29 exposes the surface of the upper substrate 1 to form a circular window to be etched;

[0041] third step, Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com