Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130results about "Reactive propulsion thrust device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

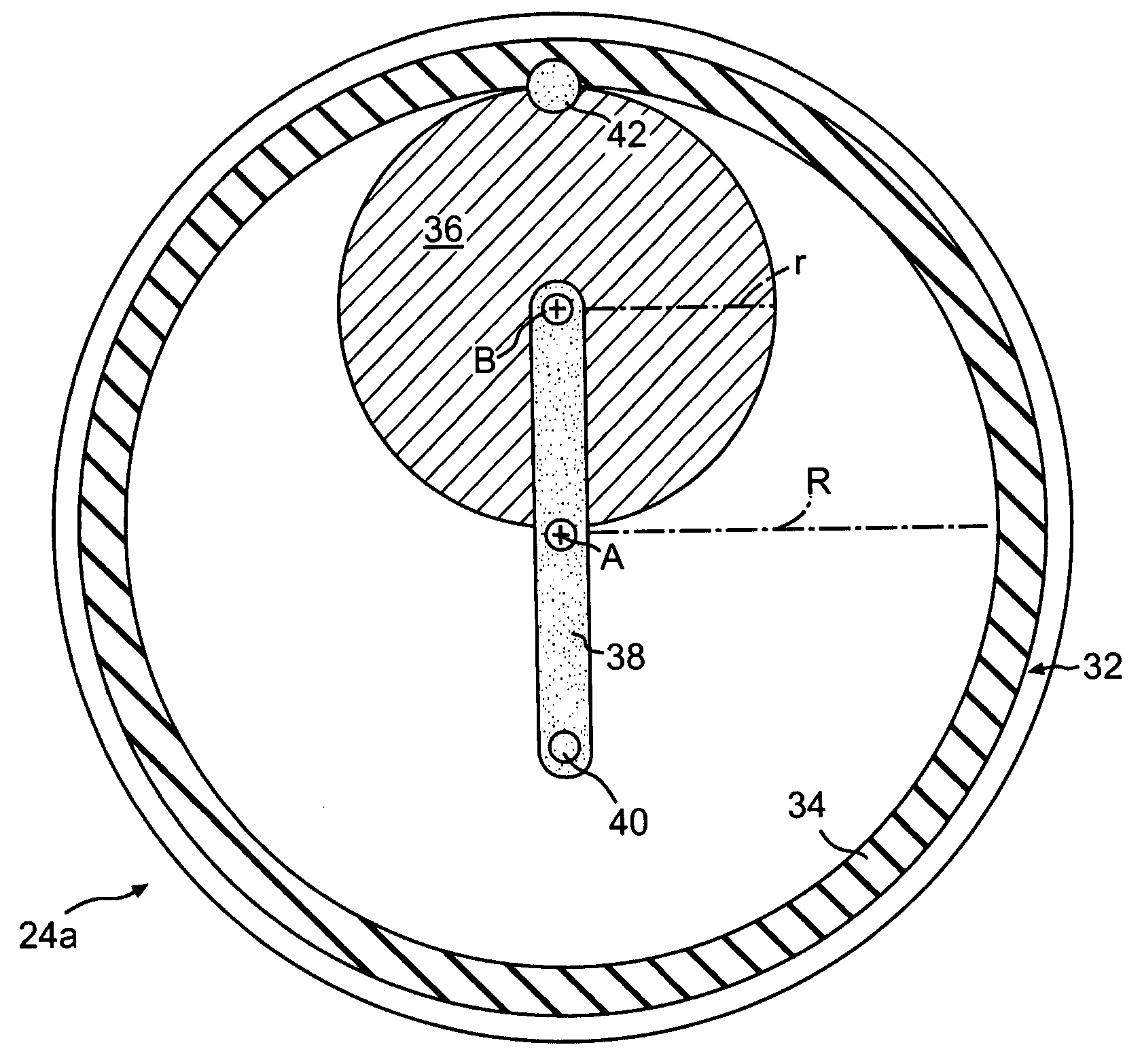

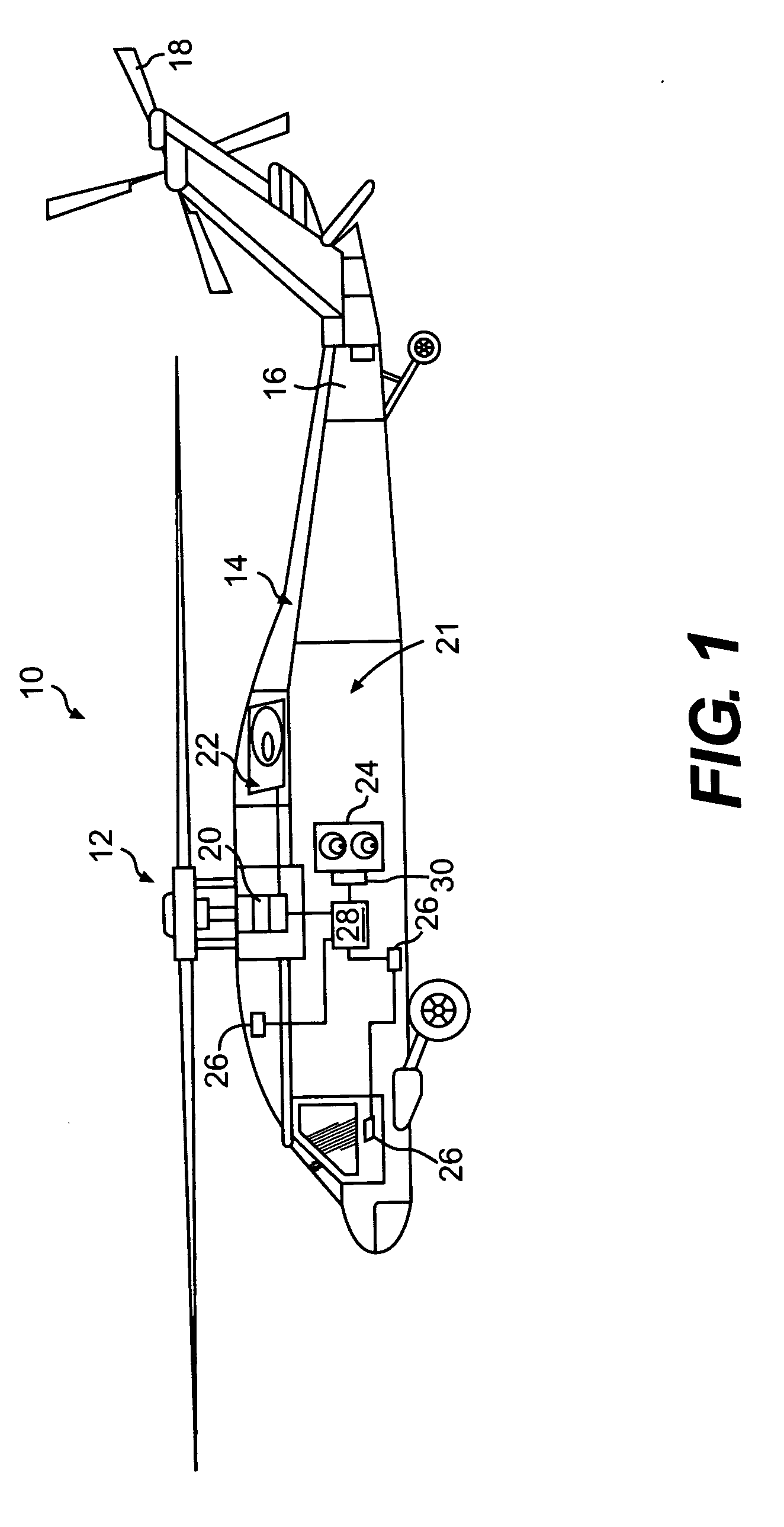

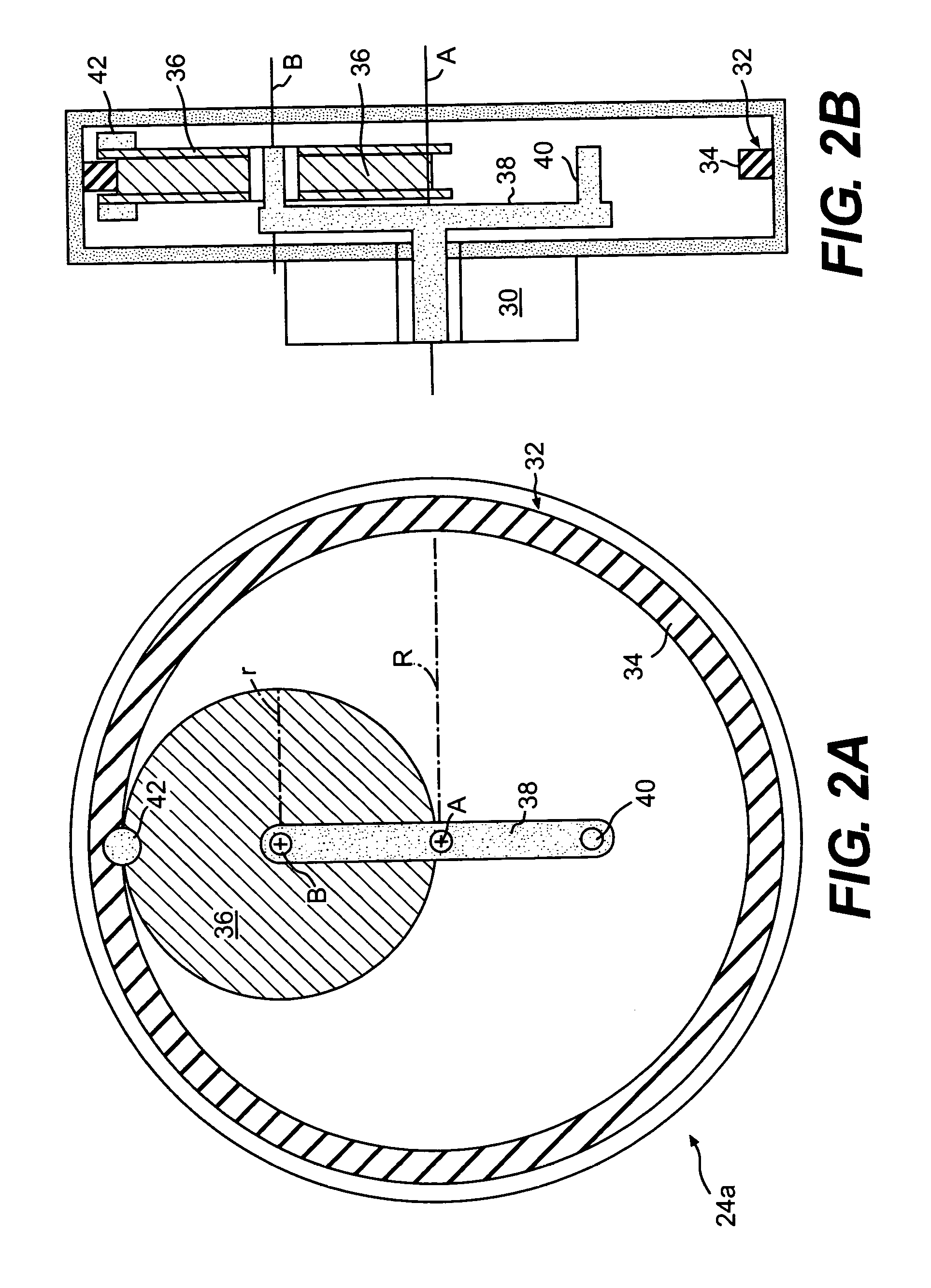

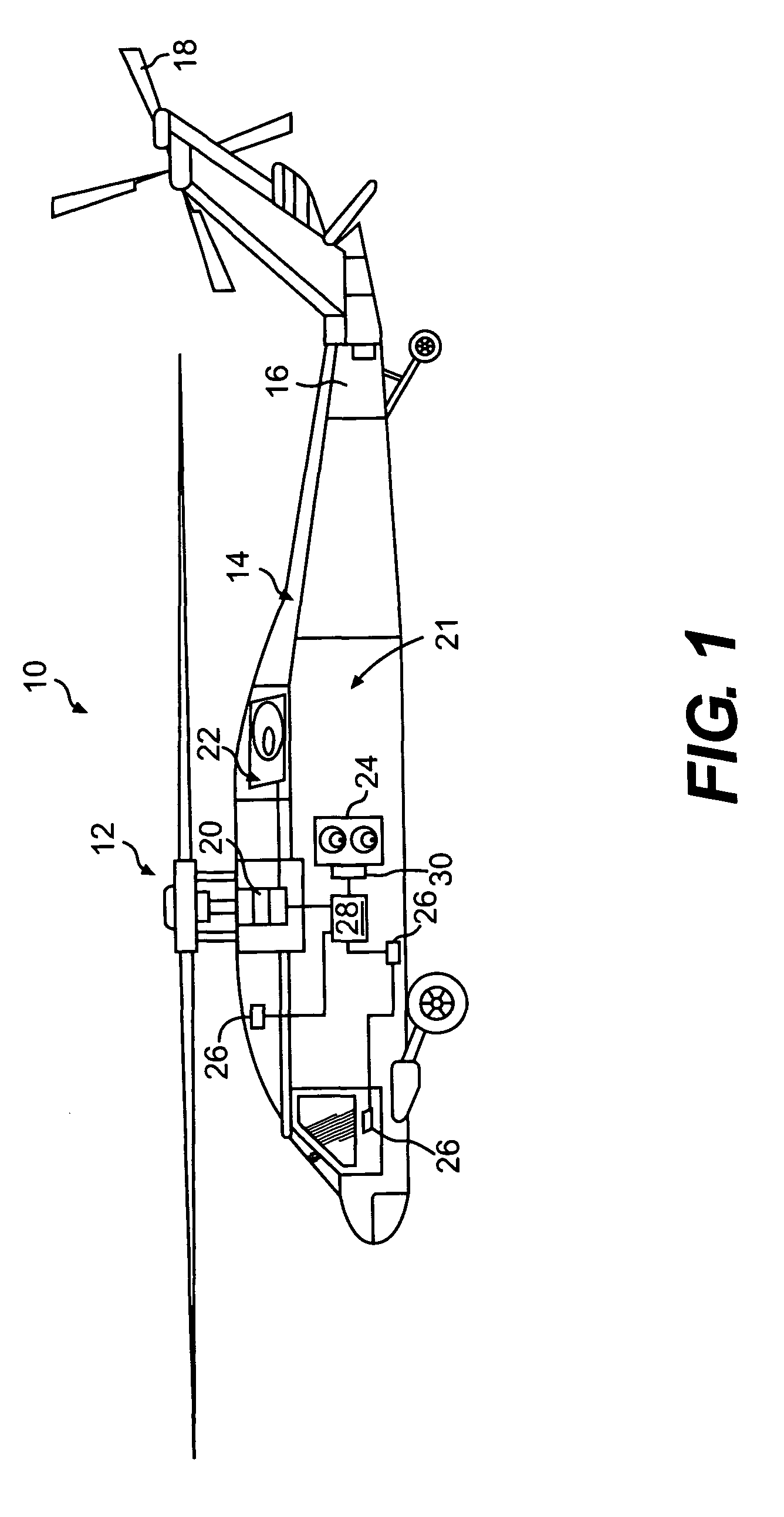

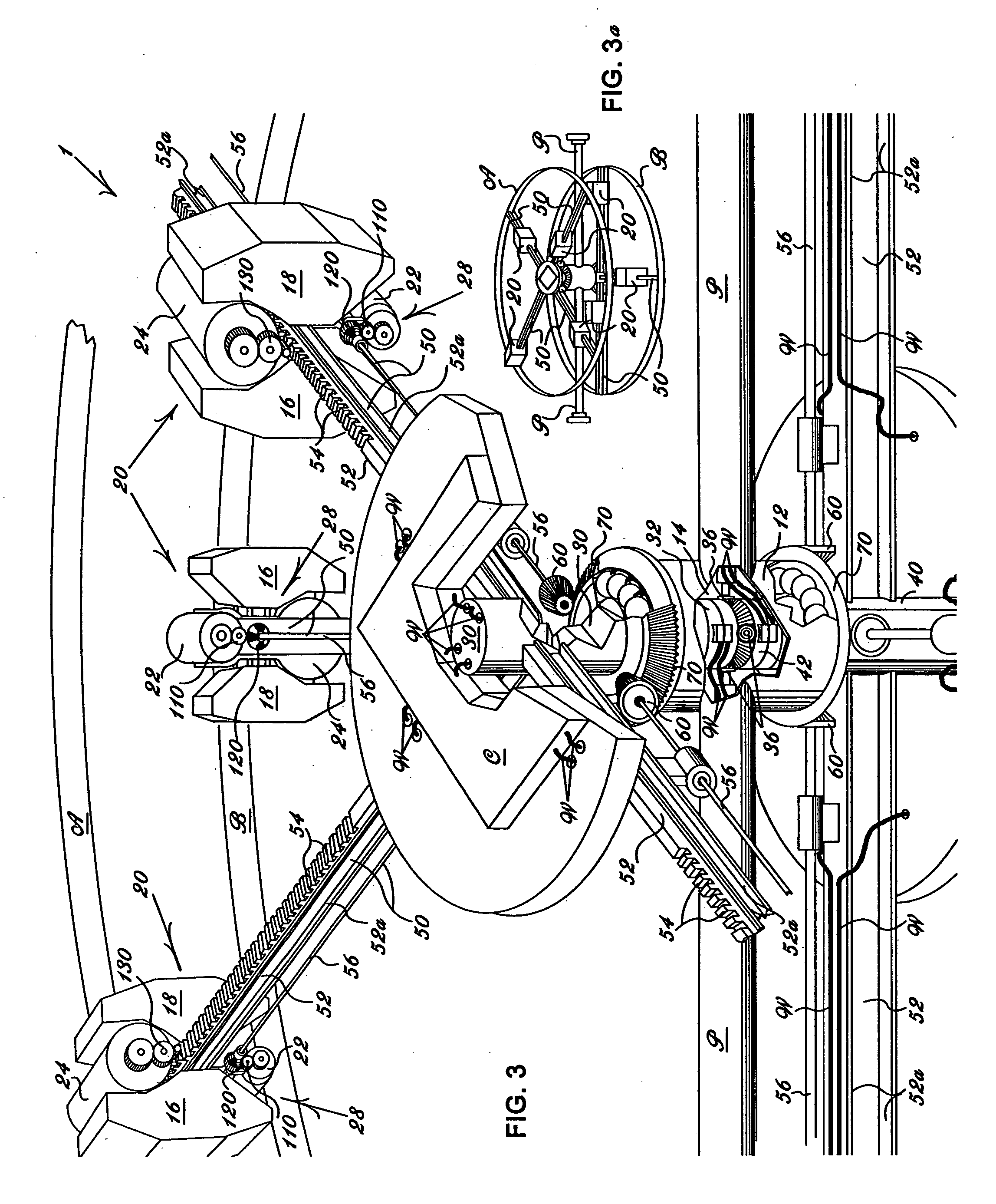

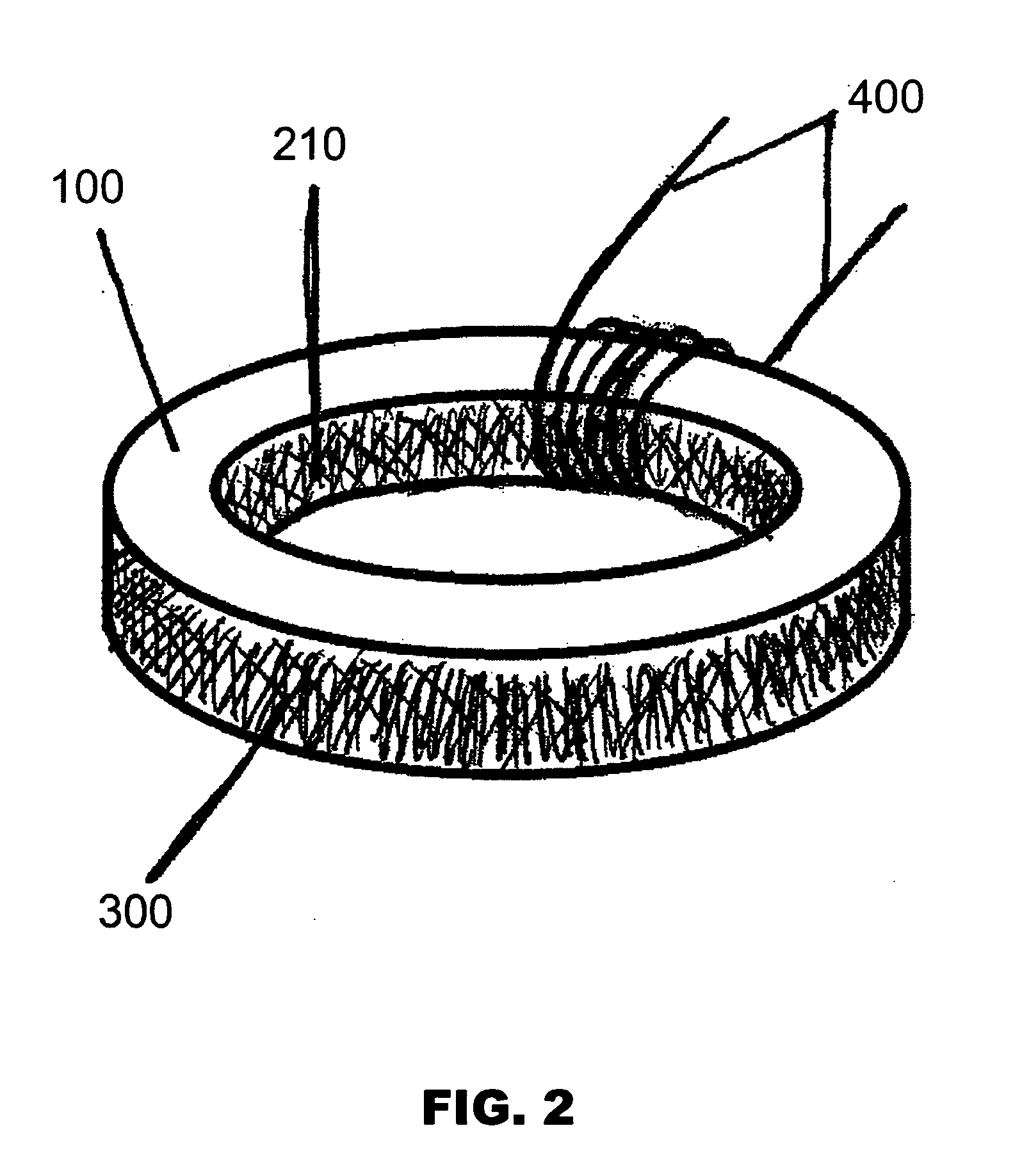

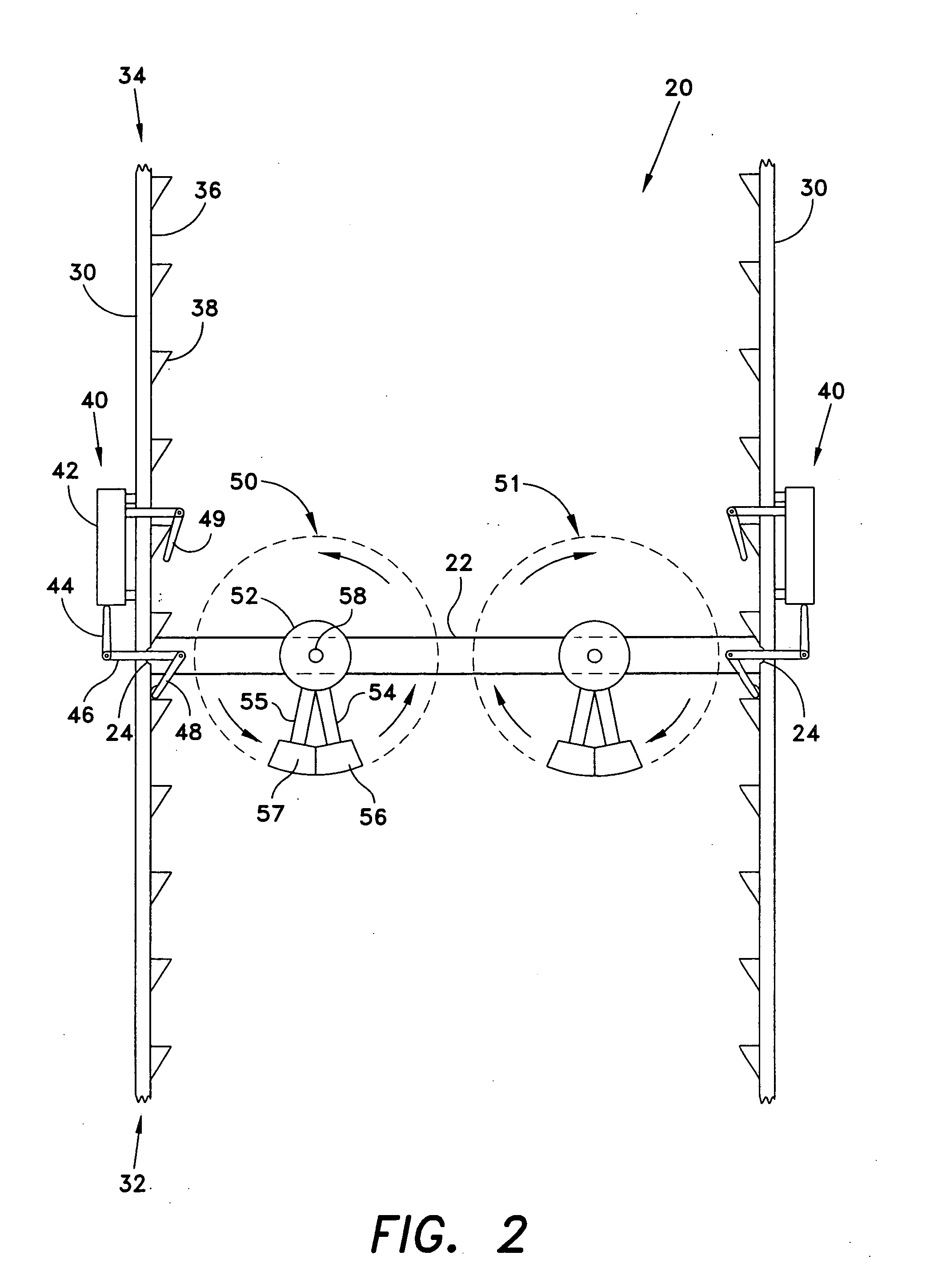

Harmonic force generator for an active vibration control system

A force generator for an active vibration control (AVC) system provides a mass located upon an inner circular member which is movable within an outer circular member to simultaneously complete one revolution about its axis as it orbits within the outer circular member to compensate for sensed vibrations. A crank mounts the inner circular member and a counterweight. The crank is rotated by a prime mover such as an electric motor. The mass will therefore generate a sinusoidal inertial force in a straight line. Multiple systems are suitably arranged to be used in conjunction with one another to provide a wide range of inertial force outputs.

Owner:SIKORSKY AIRCRAFT CORP

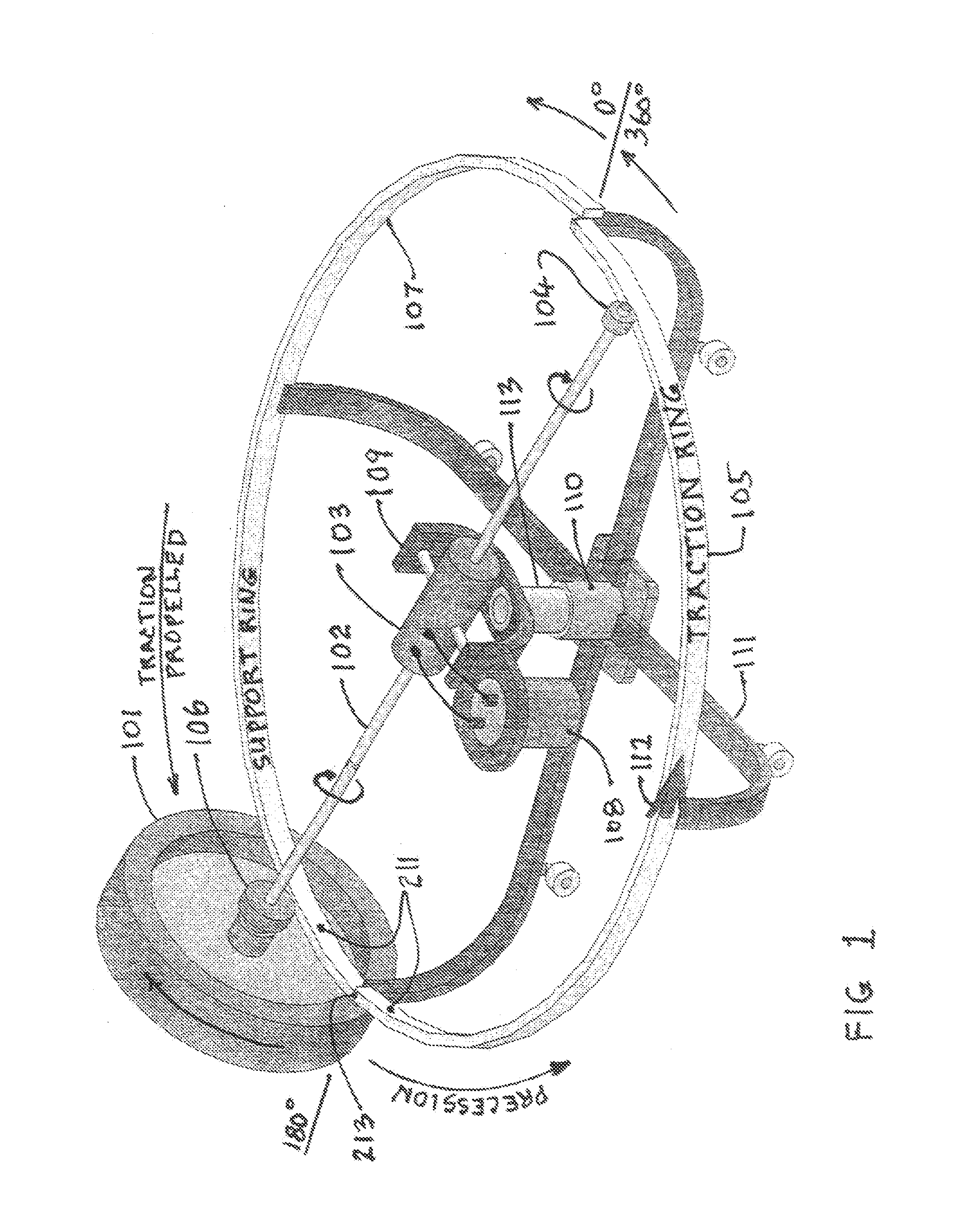

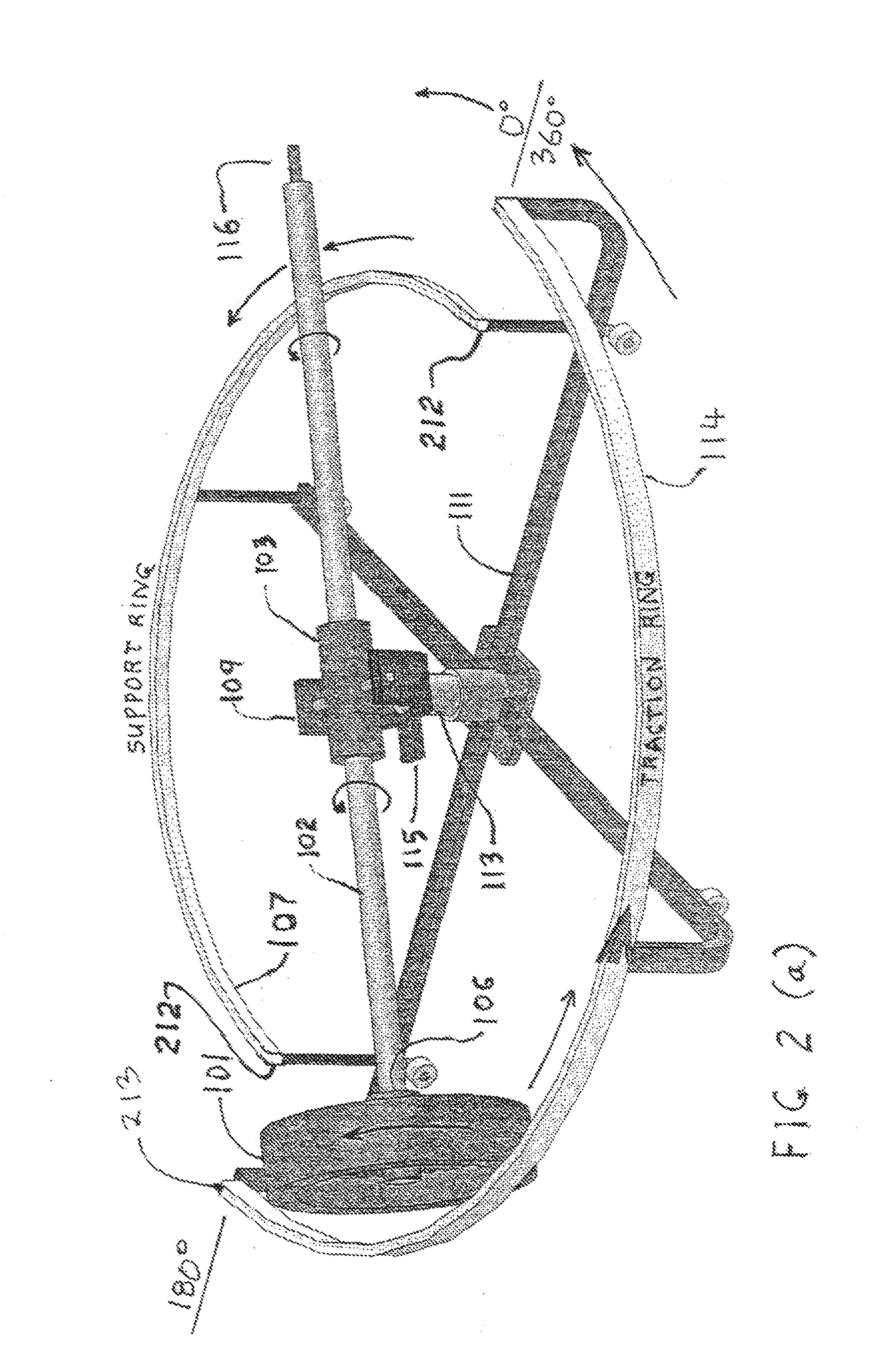

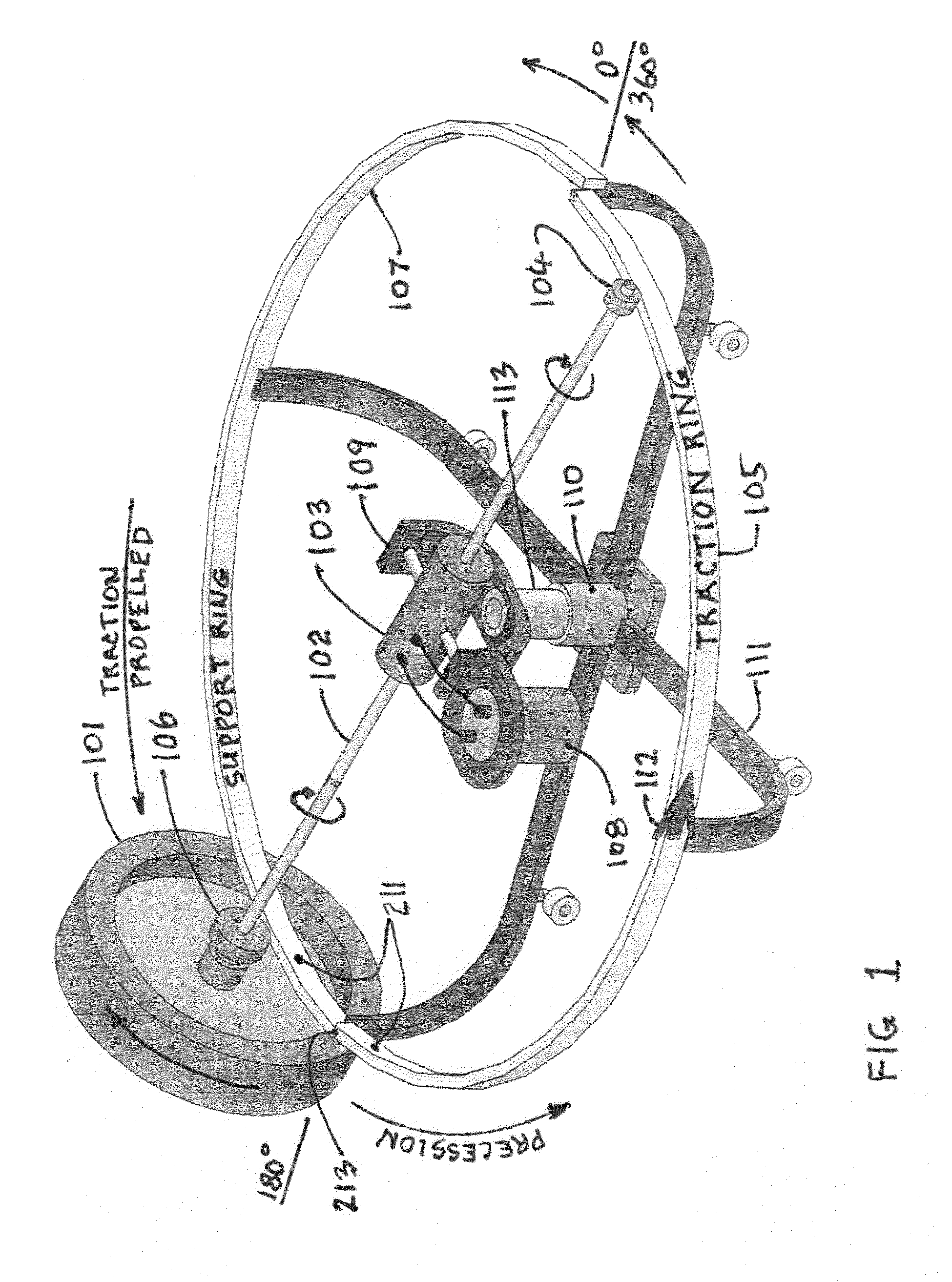

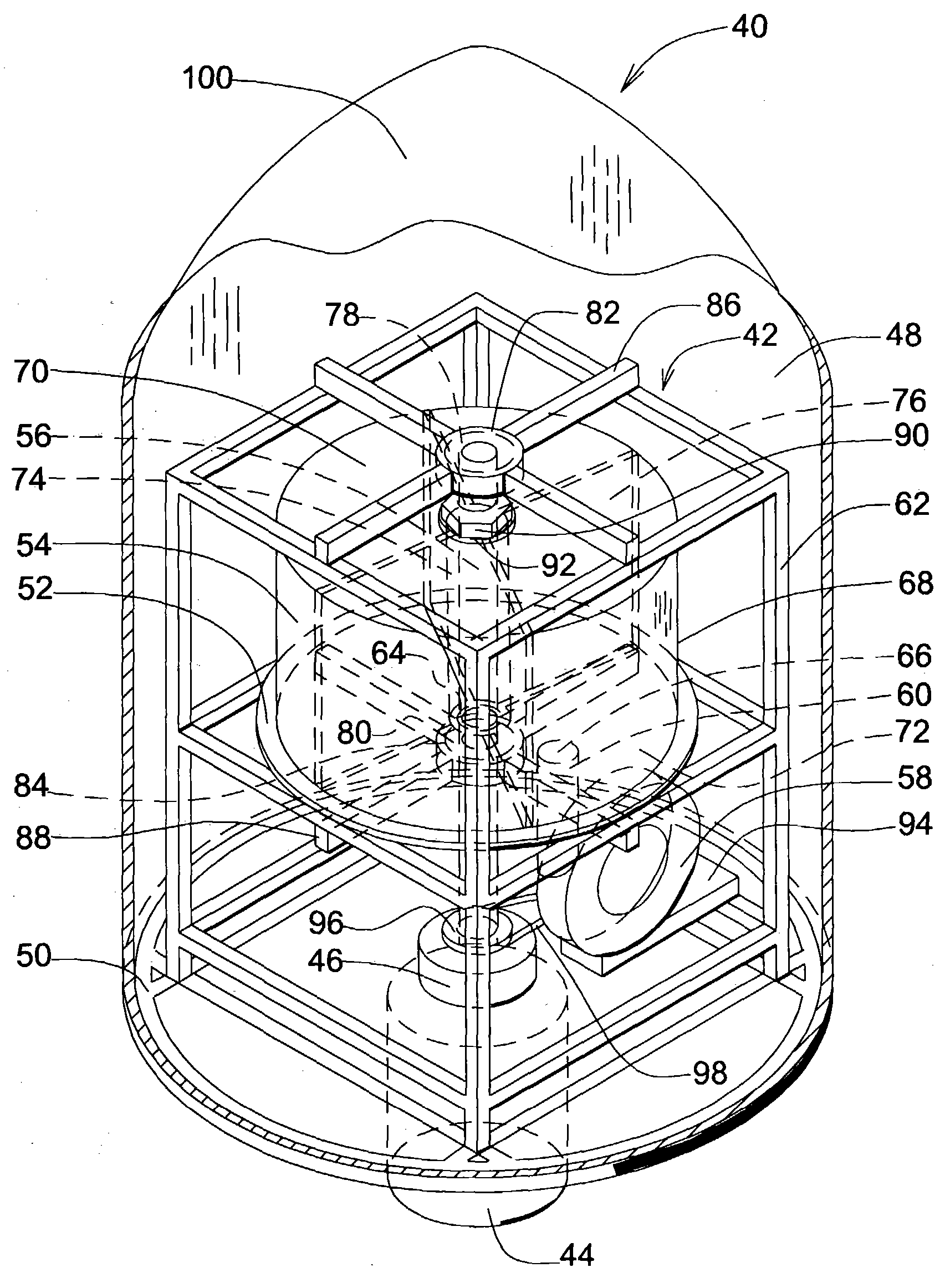

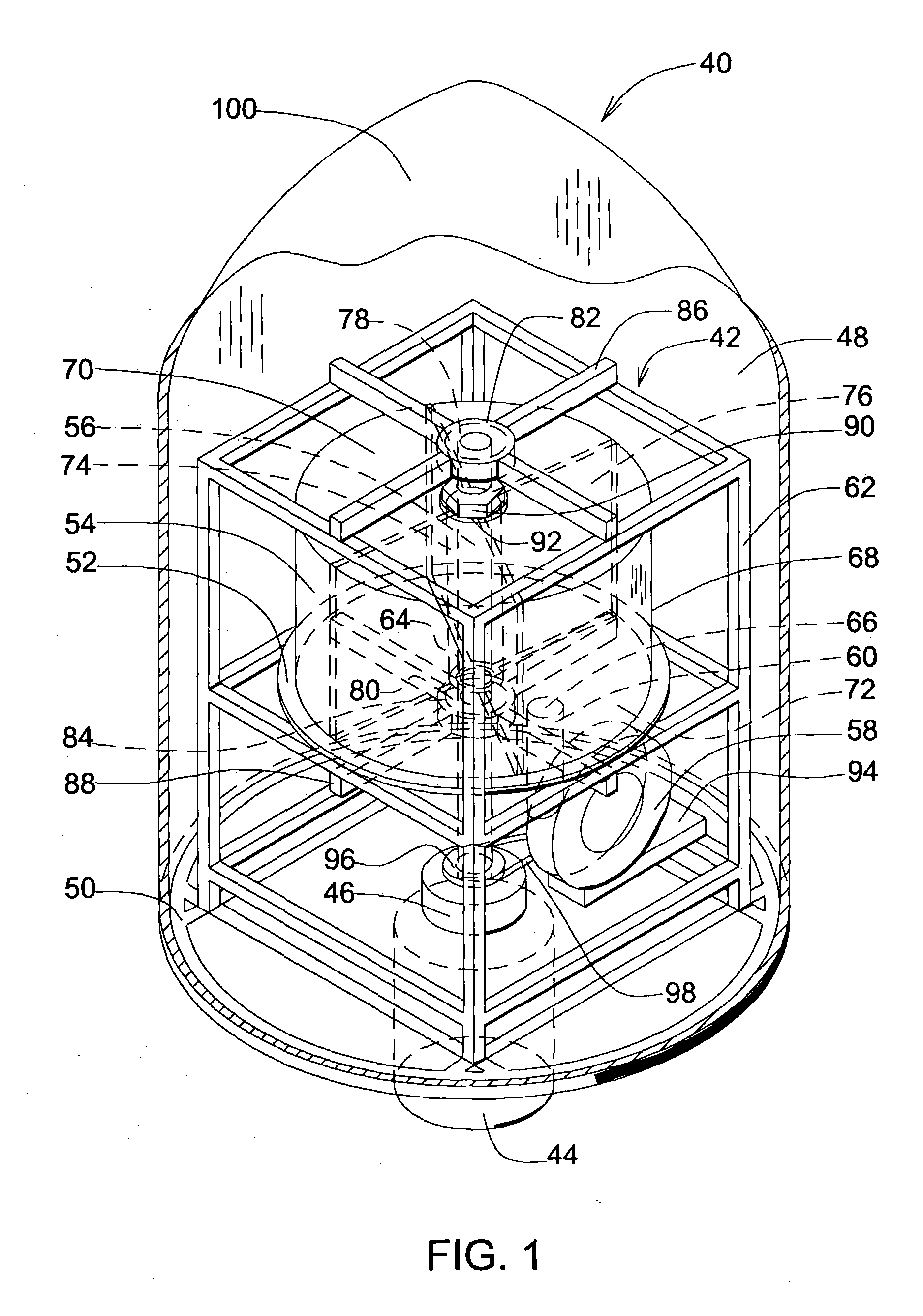

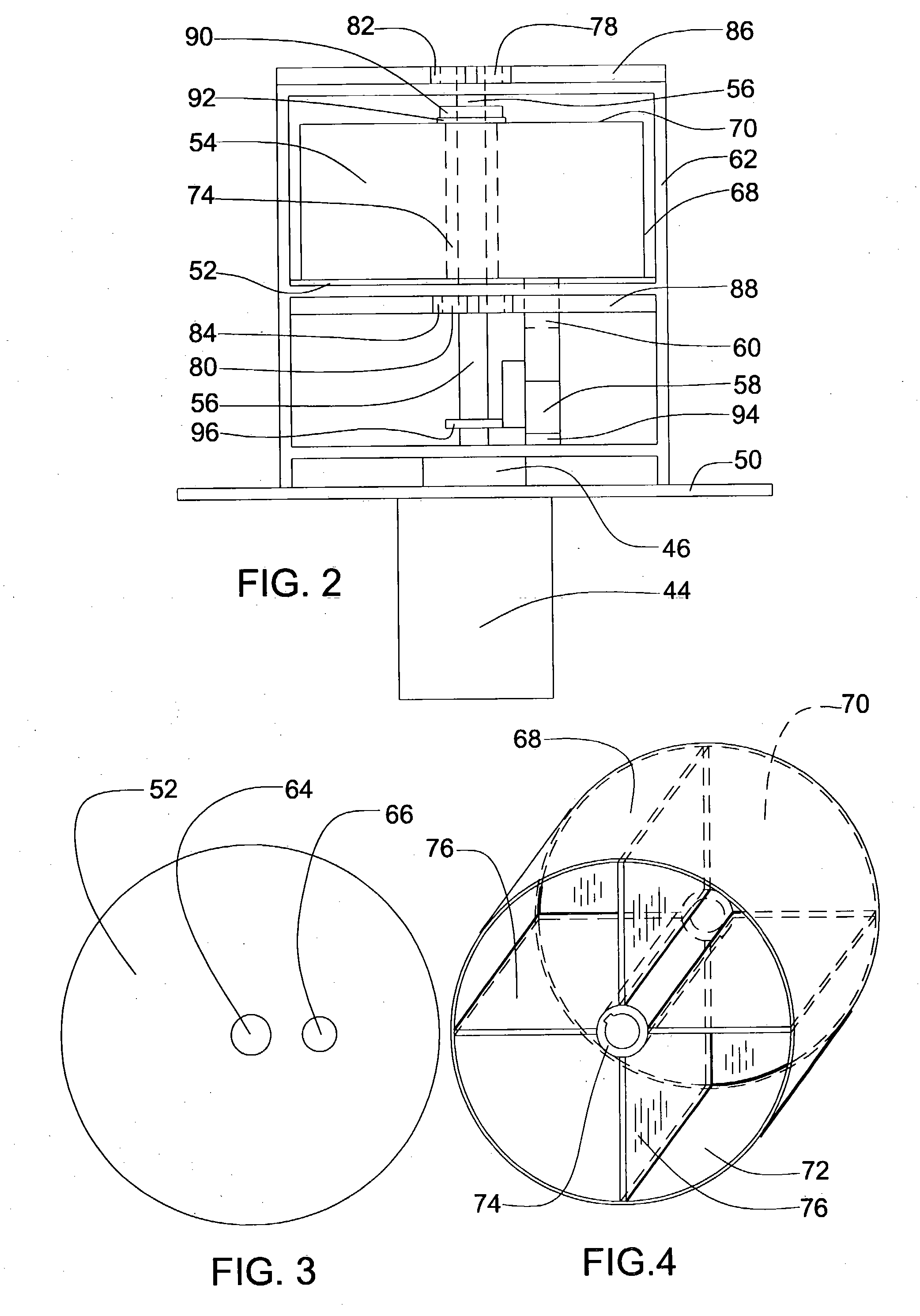

Inertial propulsion device to move an object up and down

ActiveUS20110219893A1Process controlImprove efficiencyCosmonautic vehiclesCosmonautic partsGyroscopePrecession

Disclosed herein are two separate processes that do not require a propellant and do not produce an equal and opposite reaction against any external form of matter in the Local Inertial Reference Frame and do not violate Newton's Laws in the Universal Reference Frame. The first process produces horizontal motion, relies on the earth's gravitational field as an external force, and has been successfully tested. The second process produces vertical motion and relies only on the aether. It has been successfully tested considering the effect of the earth's gravity. Due to the law of conservation of angular momentum, the first process is considered by some to not be possible, but with the proper use of an external field (for example, gravity) and the phenomenon of precession, it is clearly possible. A clear distinction is made between a simple rotor and a gyroscope which is a far more complex device.

Owner:FIALA HARVEY E +2

Harmonic force generator for an active vibration control system

A force generator for an active vibration control (AVC) system provides a mass located upon an inner circular member which is movable within an outer circular member to simultaneously complete one revolution about its axis as it orbits within the outer circular member to compensate for sensed vibrations. A crank mounts the inner circular member and a counterweight. The crank is rotated by a prime mover such as an electric motor. The mass will therefore generate a sinusoidal inertial force in a straight line. Multiple systems are suitably arranged to be used in conjunction with one another to provide a wide range of inertial force outputs.

Owner:SIKORSKY AIRCRAFT CORP

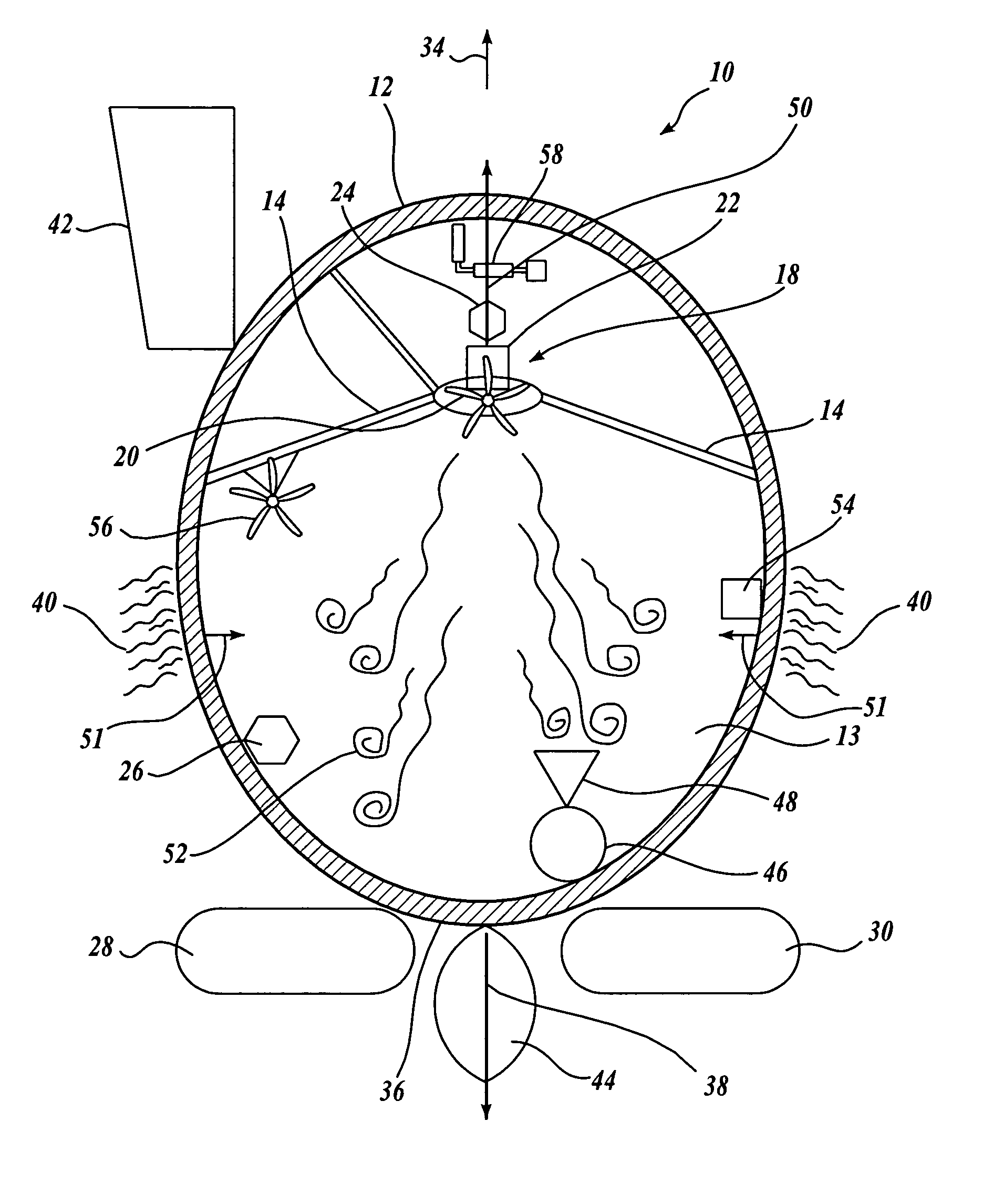

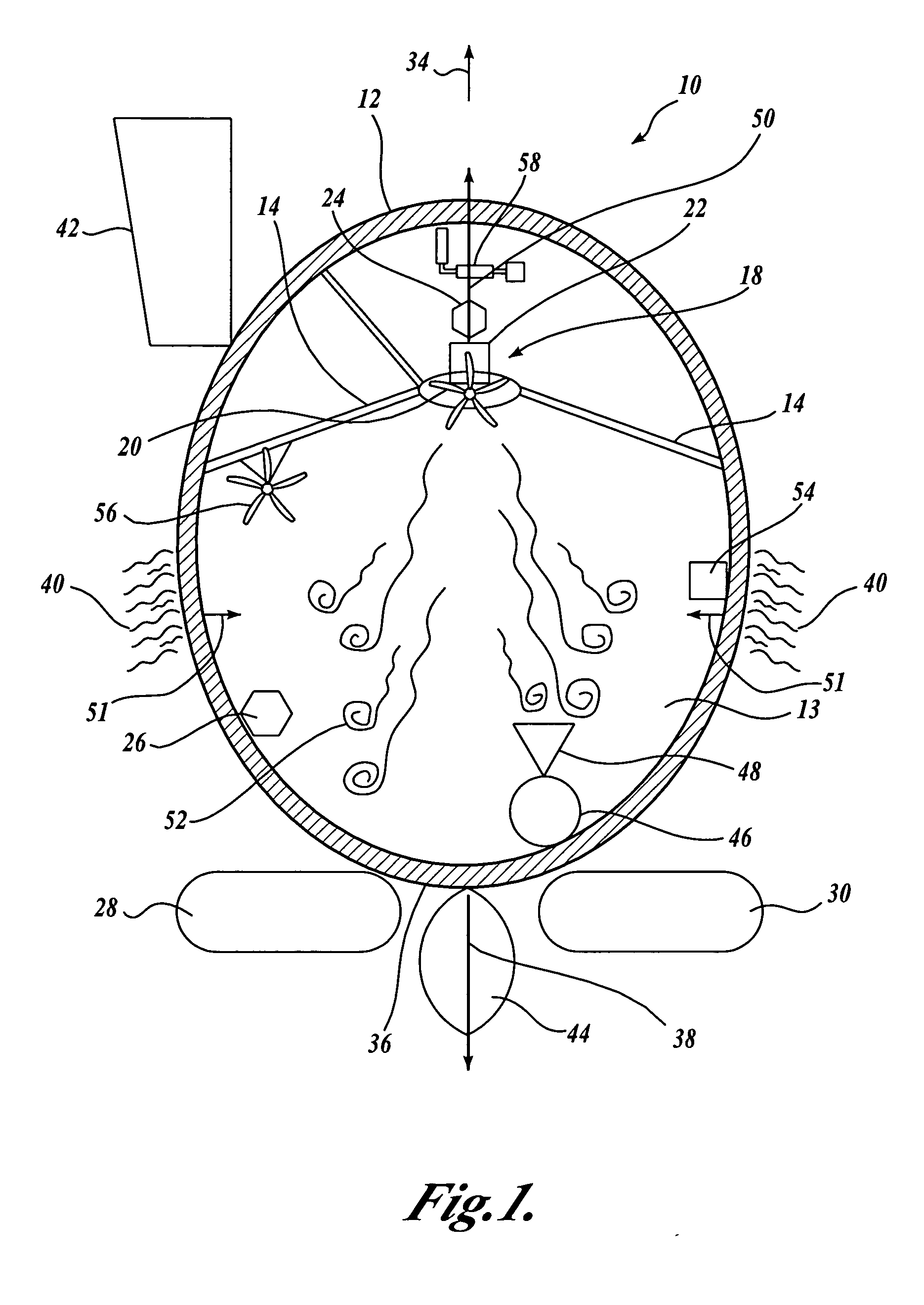

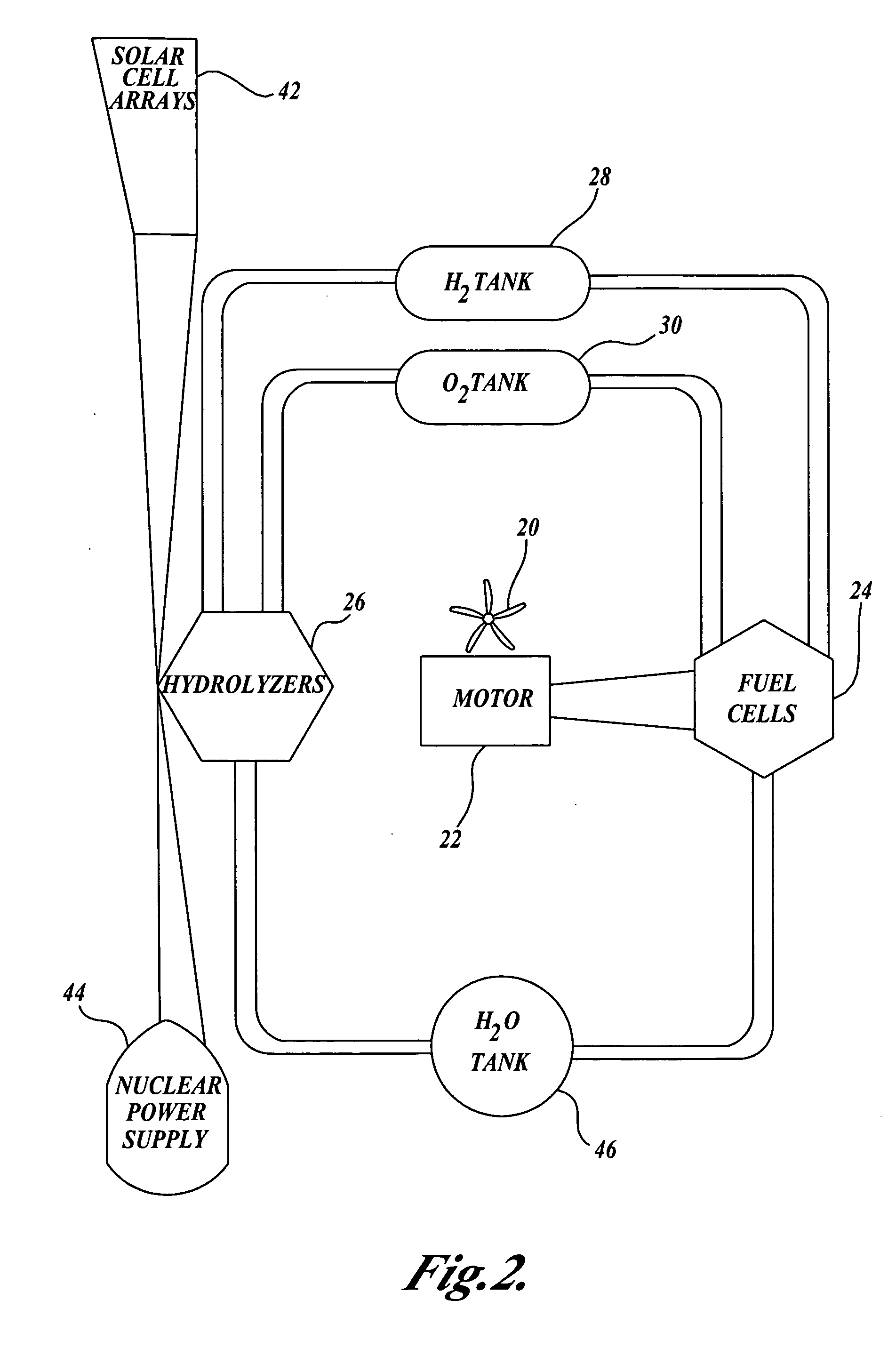

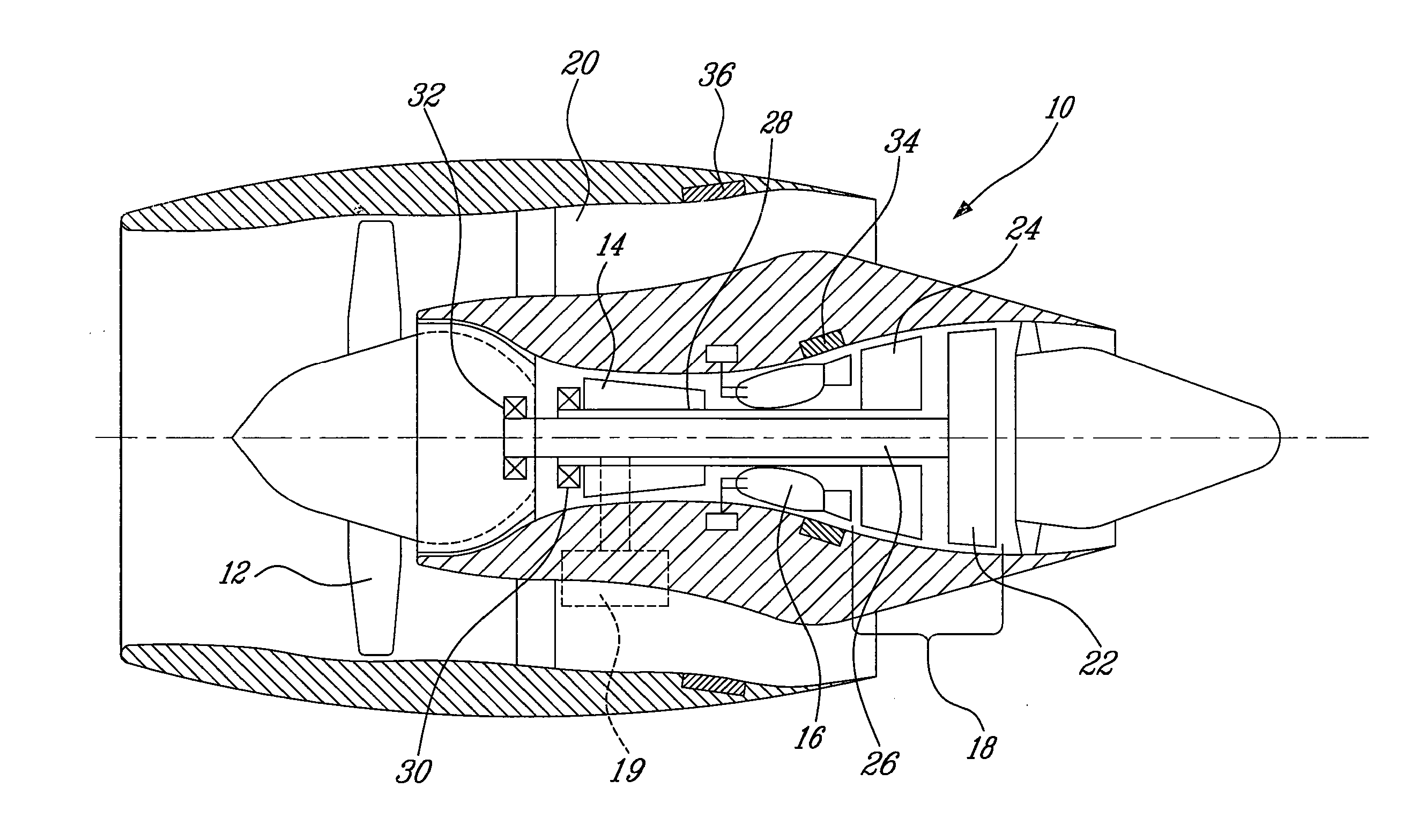

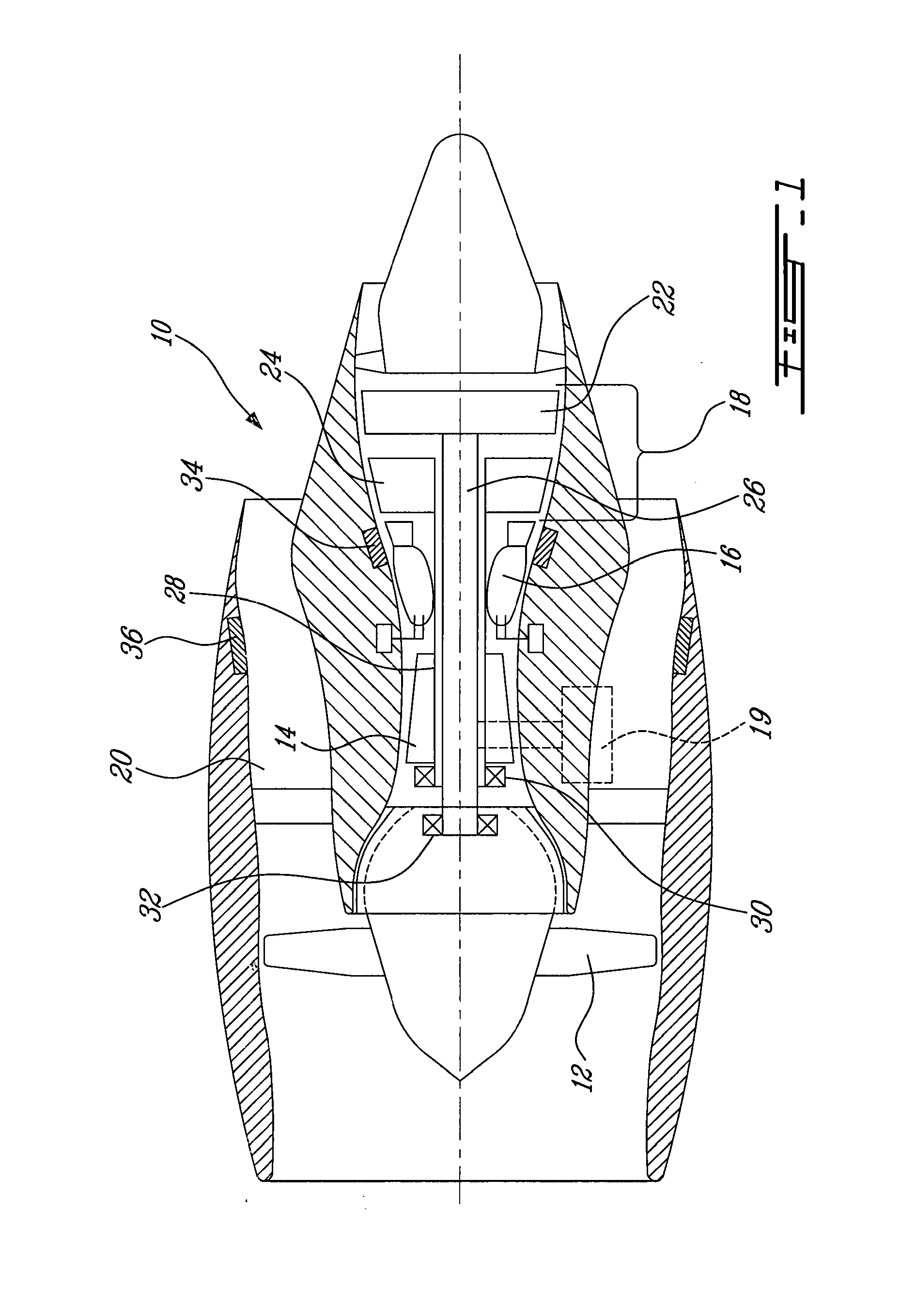

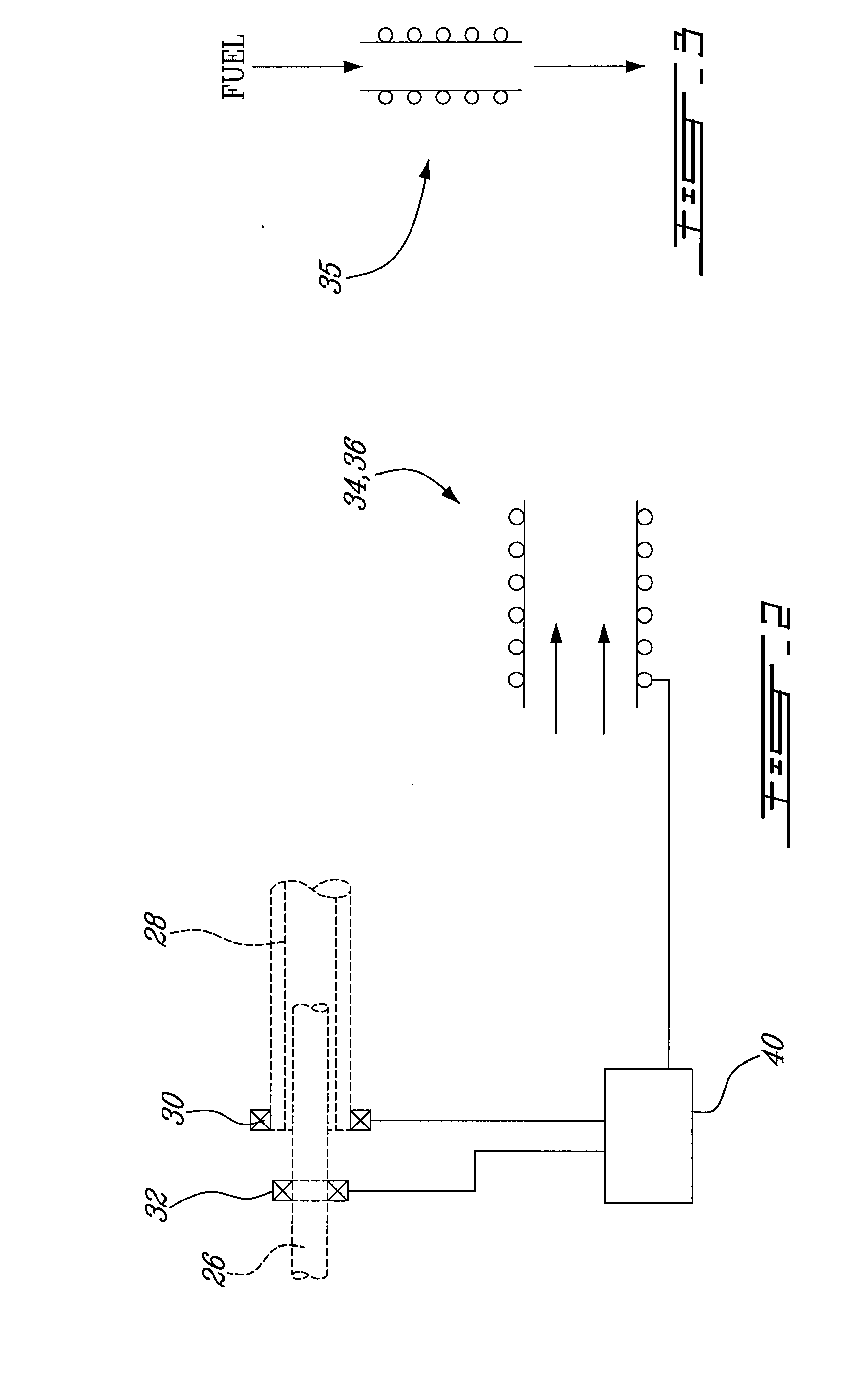

Spacecraft propulsion system

InactiveUS20050178920A1Cosmonautic vehiclesCosmonautic propulsion system apparatusSpacecraft propulsionPressure hull

A spacecraft is disclosed. The spacecraft (10) includes a pressure hull (12) for containing a gas (13). The spacecraft further includes a propulsion system (18) coupled to the pressure hull so as to be disposed within the pressure hull, the propulsion system operable to generate a propulsion force for propelling the spacecraft through space.

Owner:WILSON THOMAS R

Centrifugal propulsion engine

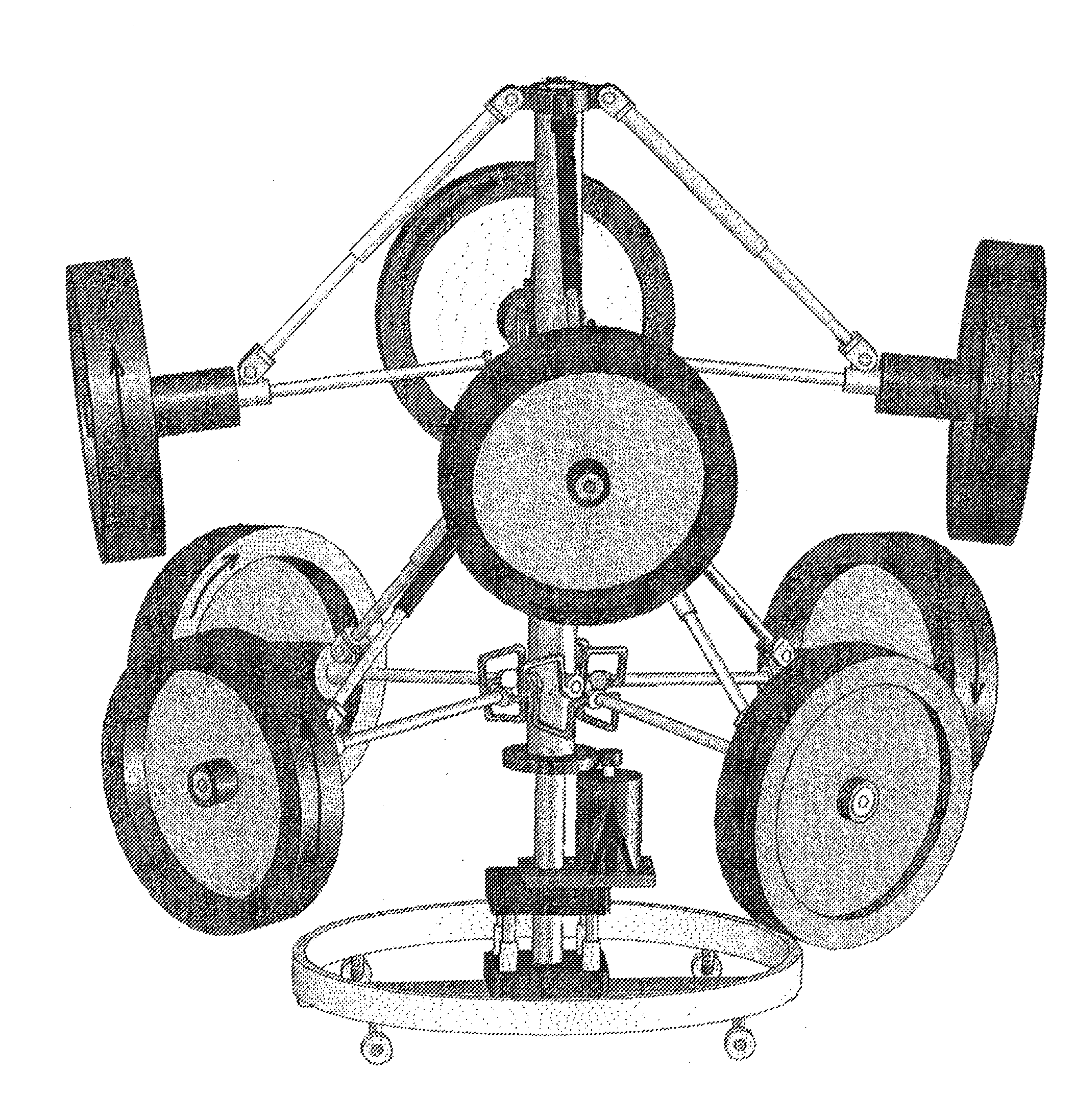

A centrifugal engine includes first and second centrifugal assemblies having independent assembly hub structures, each hub structure being rotatably mounted to a common bearing mount to rotate co-axially and in opposite directions; several spokes protruding radially from each hub structure; a mobile mass structure slidably mounted to each spoke; a rotation motor; several mass structure displacement motors, each for displacing one mobile mass structure along a corresponding spoke; a power source delivering electrical energy to the rotation motor to rotate each hub structure and attached spokes relative to the bearing mount, and also to the mass structure displacement motor to sequentially move the mobile mass structures longitudinally along the spokes and radially away from the given the hub structure and then rapidly toward the hub structure at a repeating rotational position to impart linear force to the assembly.

Owner:PEREZ DANIEL

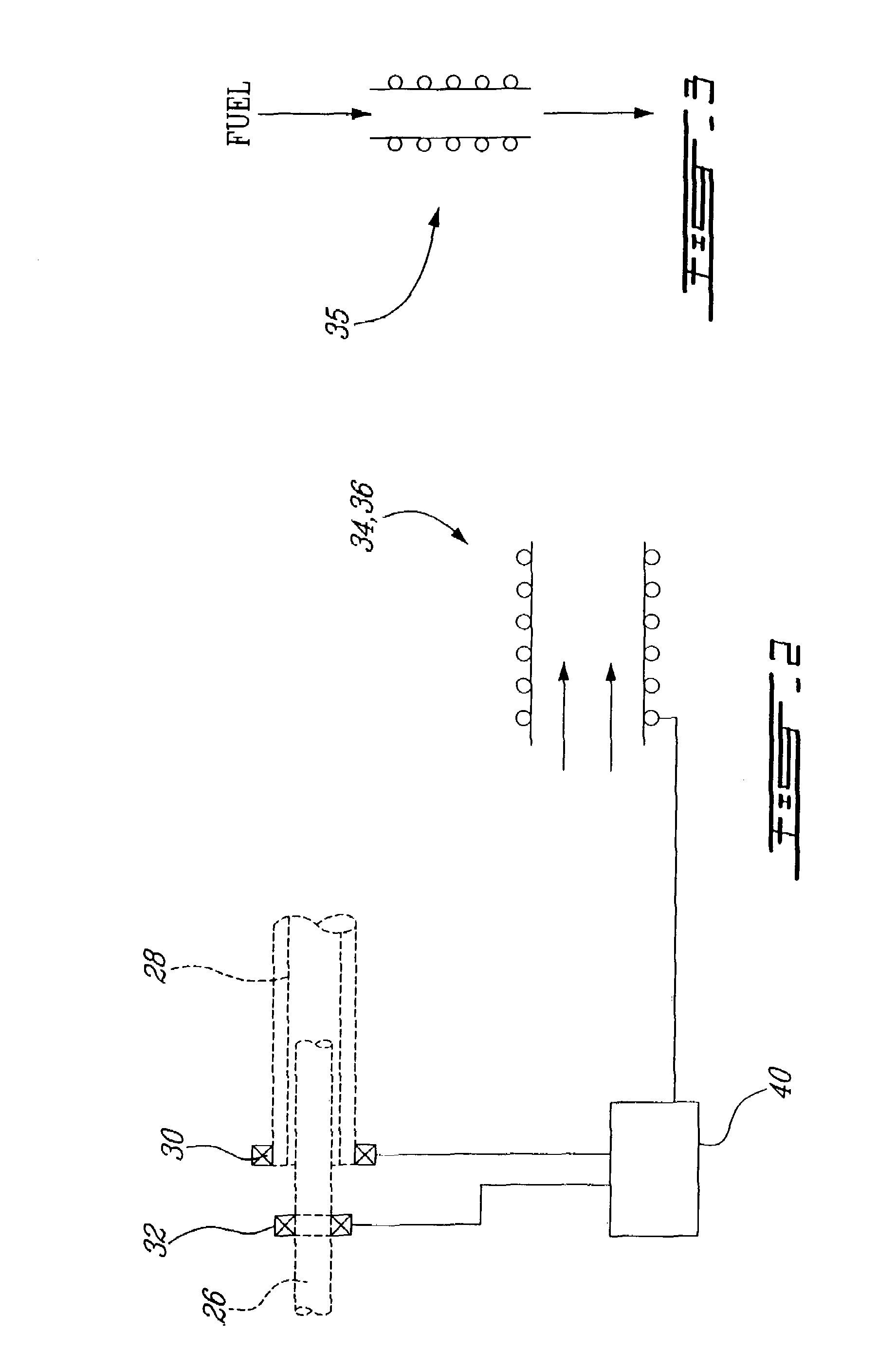

Powder propellant-based space propulsion device

InactiveUS20070044450A1High densityEasy to operateCosmonautic vehiclesCosmonautic partsHigh densityEnergy supply

Disclosed is a powder propellant-based space propulsion device using a powder propellant having high density and excellent handleability. The powder propellant-based space propulsion device comprises a powder-propellant storage container for storing a powder propellant, a powder-propellant attracting surface for attracting the powder propellant thereto through an opening of the powder-propellant storage container and attractively holding the attracted powder propellant thereon, powder-propellant transfer means for transferring the held powder propellant to a release position for releasing the powder propellant, and propulsive-energy supply means for energizing the transferred powder propellant to release the powder propellant from the powder-propellant attracting surface, toward a downstream side thereof as a propulsive jet, while accelerating the powder propellant in a direction approximately perpendicular to the powder-propellant attracting surface at said release position. The powder-propellant transfer means is designed to move the powder-propellant attracting surface in such a manner that a powder-propellant holding area of the powder-propellant attracting surface is returned to a position adjacent to the opening of the powder-propellant storage container in a repetitive manner.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

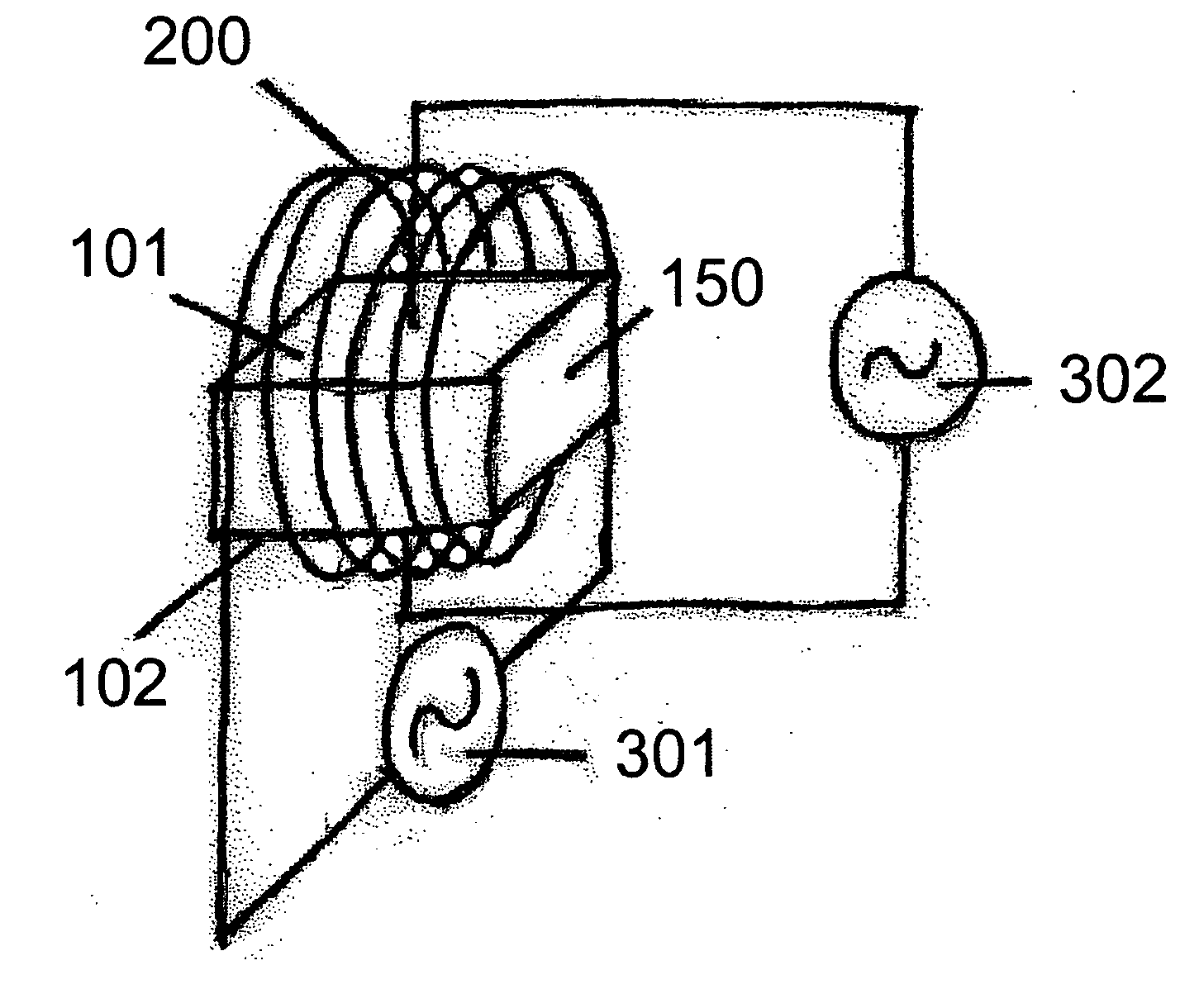

Method for producing thrusts with "Mach" effects manipulated by alternating electromagnetic fields

InactiveUS20060065789A1Cosmonautic vehiclesCosmonautic propulsion system apparatusNet forceElectromagnetic field

A method for producing thrusts in devices where a “Mach” effect mass fluctuation is driven by applying a high voltage, high frequency electrical signal to capacitive circuit elements made with high dielectric constant core material and at the same time applying a current signal of the same frequency to inductive circuit elements arranged so that the magnetic fields produced thereby thread the capacitors perpendicular to the electric fields between their plates. With appropriate relative phase established between the electric and magnetic fields in the dielectric material between the plates of the capacitor, the Lorentz force acting on the lattice ions in the dielectric yields a net force. That net force is a consequence of the fact that in each cycle when the Lorentz force acts in one direction the effective masses of the ions are different from their effective masses in the parts of each cycle where lattice forces act to restore the initial configuration. Operated at sufficiently high frequencies and powers, such devices can produce useful levels of thrust.

Owner:WOODWARD JAMES F +2

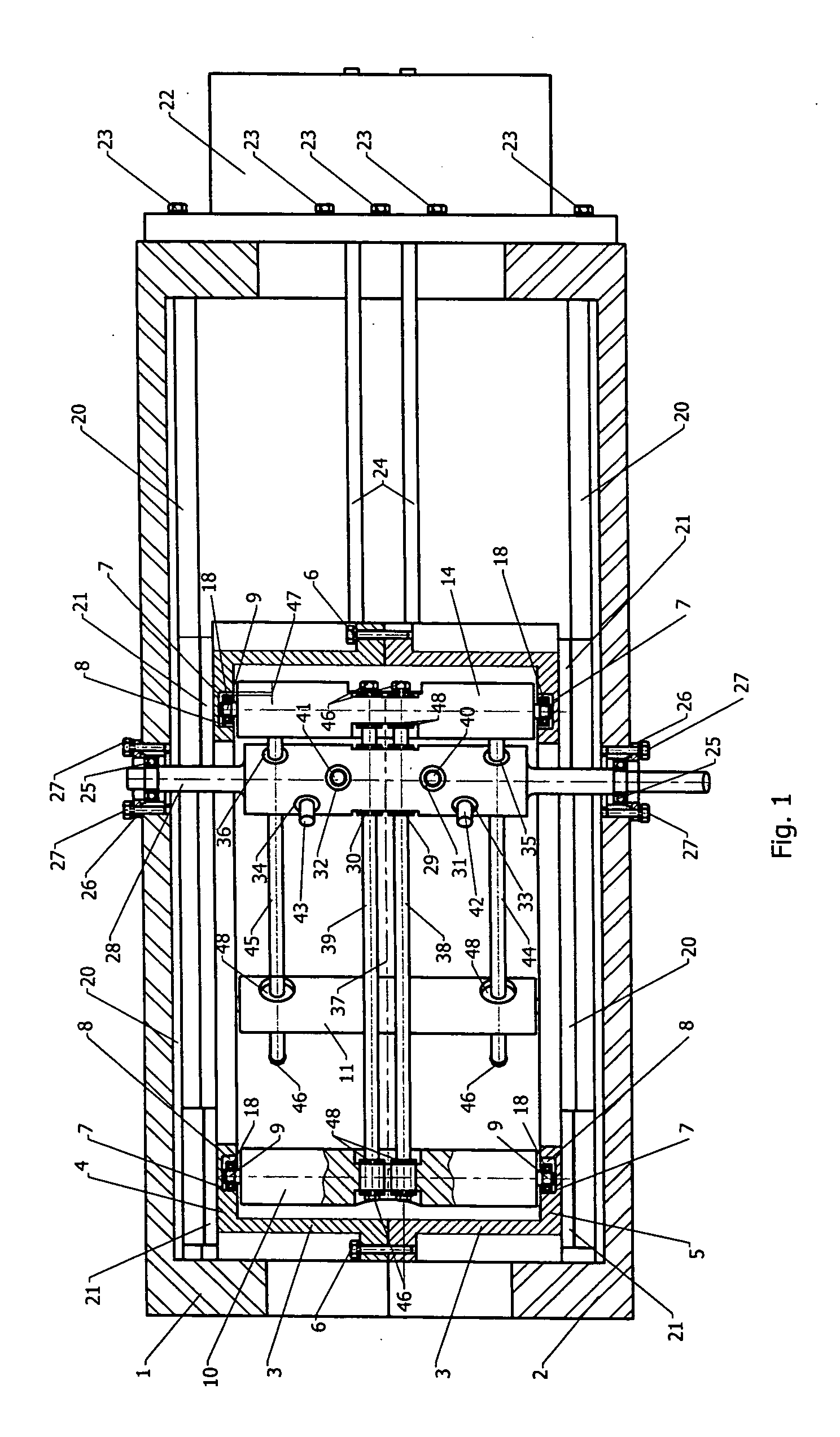

Centrifugal generator of a thrust force for aviation and space apparatuses

A centrifugal generator of a thrust force for aviation and space application has a housing, an integrating element, work masses, a drive, the integrating element being composite and arranged in the housing with a possibility of a forced reciprocating displacement along parallel guides and has an annular guide formed by two identical annular grooves which surround console parts of the work mass with a clearance, the drive being formed as a lever-type drive with floating rods, that are provided with end stops with dampers and extending through an axis of a shaft and central parts of the work masses, the rods being arranged in pairs parallel to one another and in the pairs are located at a same distance from an axis of symmetry of the drive and arranged in pairs with a uniform angle of displacement, the rods interacting with the shaft and the work masses through sliding bearings, the rods having a length which provides a clearance of the console parts of the work masses when the console parts of opposite ones of the work masses are in contact in a position of a maximum distance from one another.

Owner:TSEPENYUK MIKHAIL +2

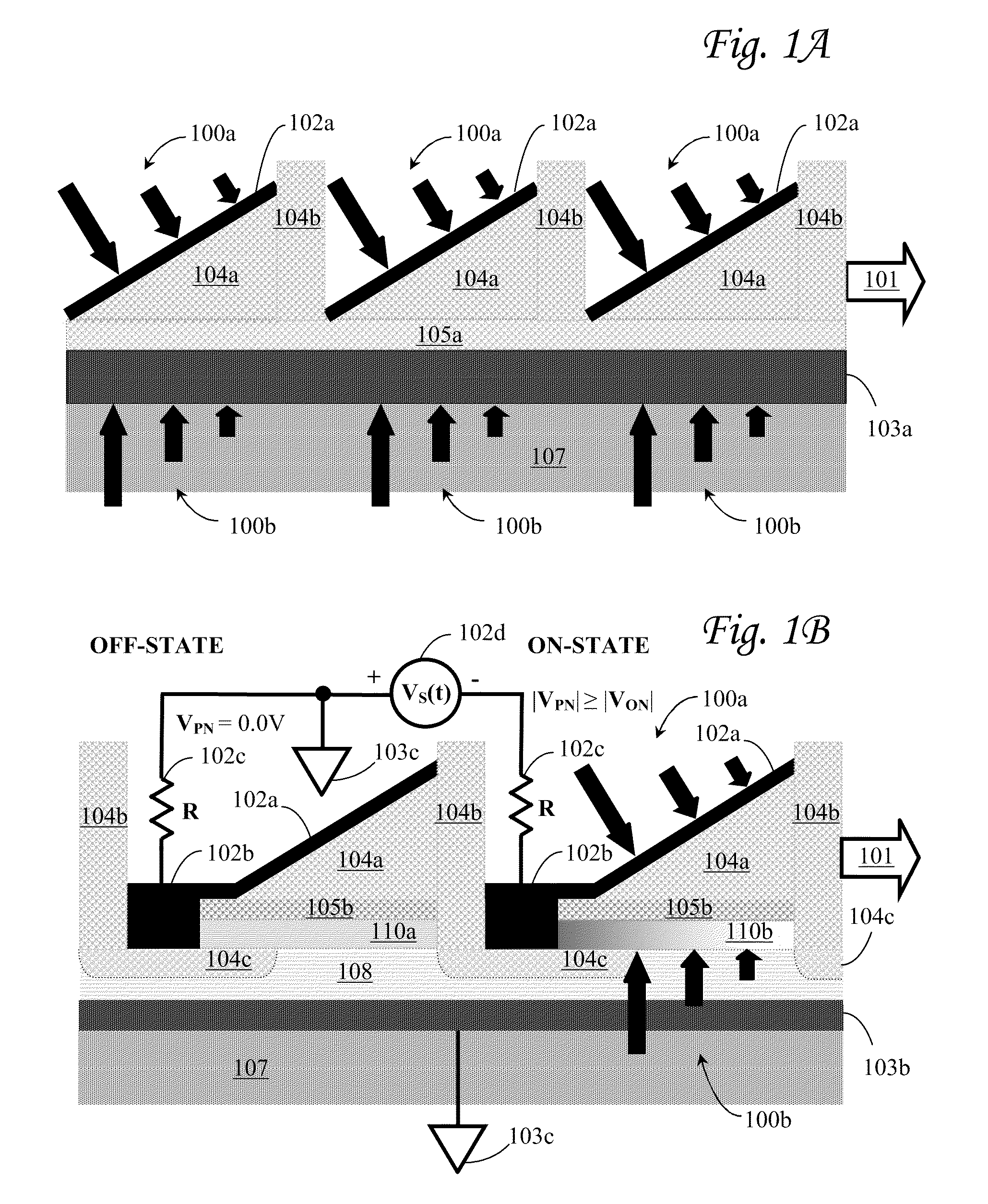

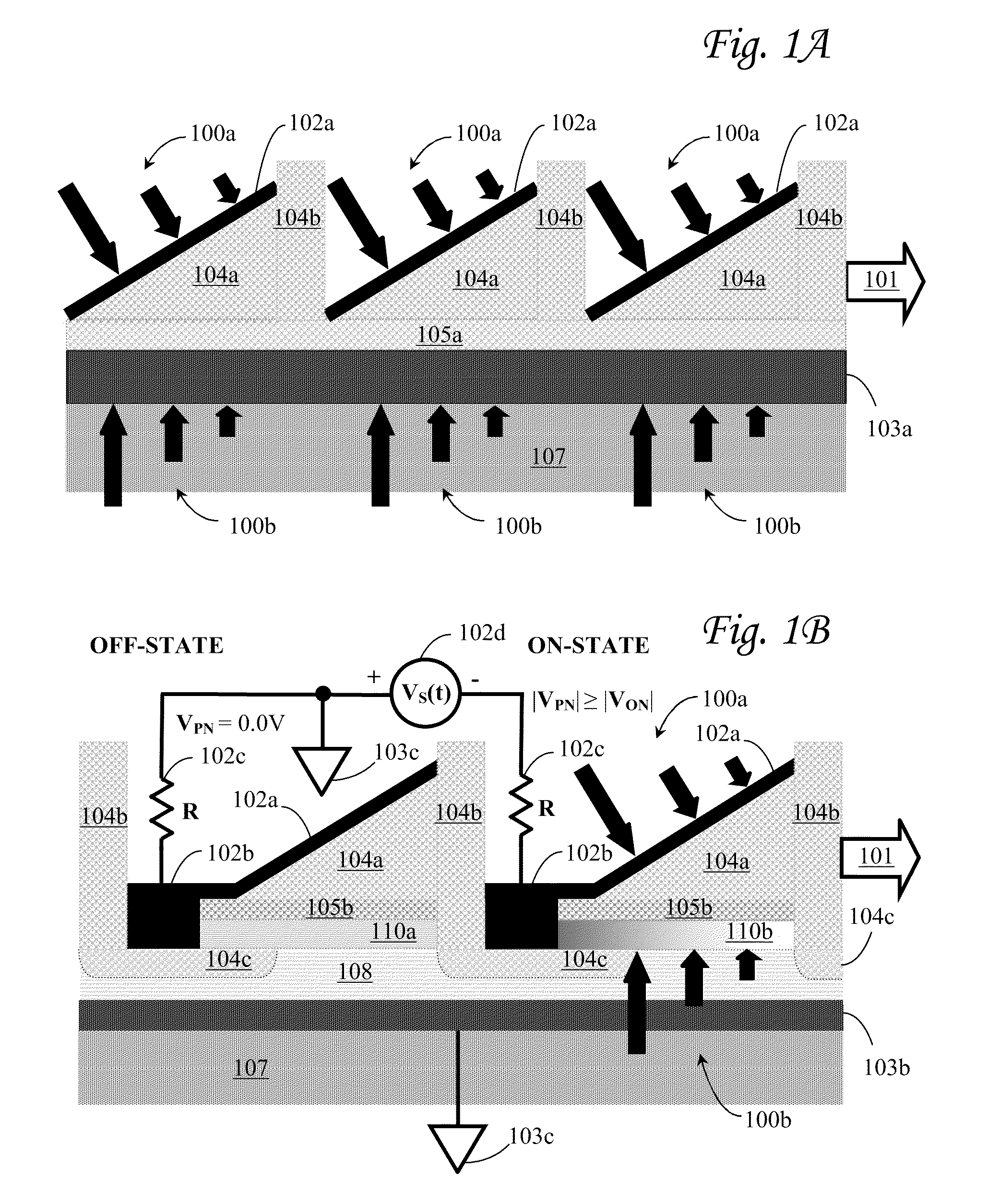

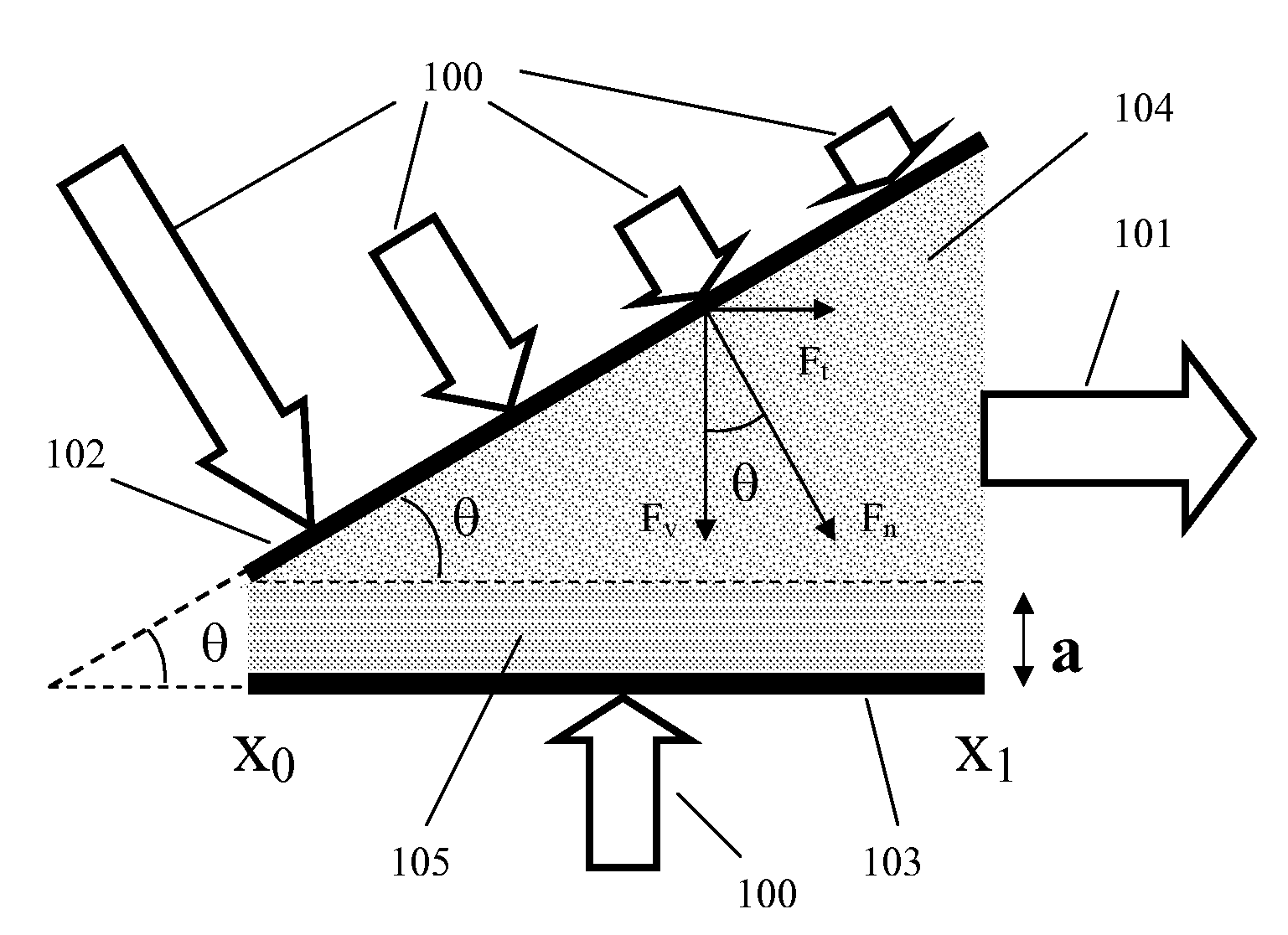

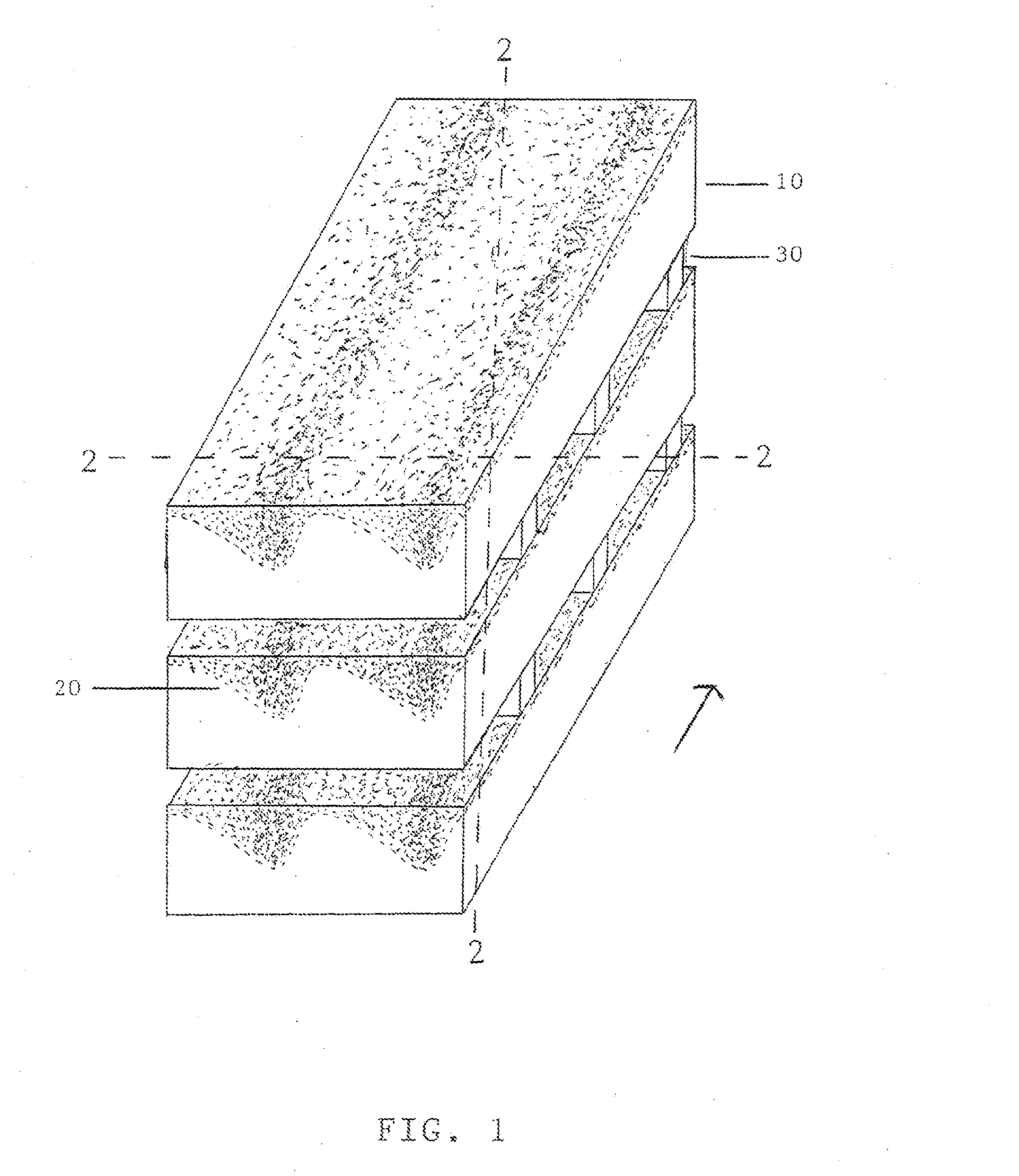

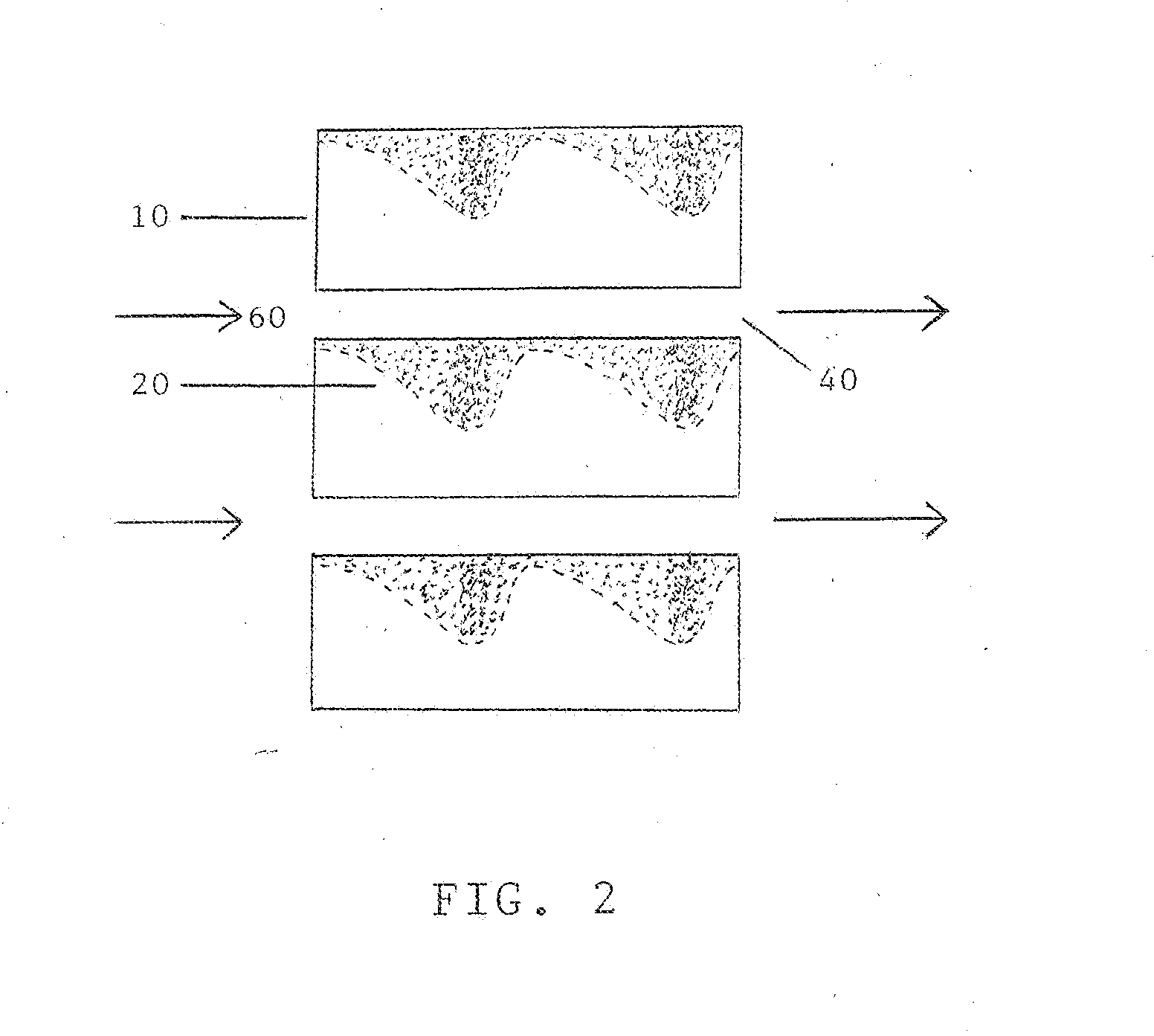

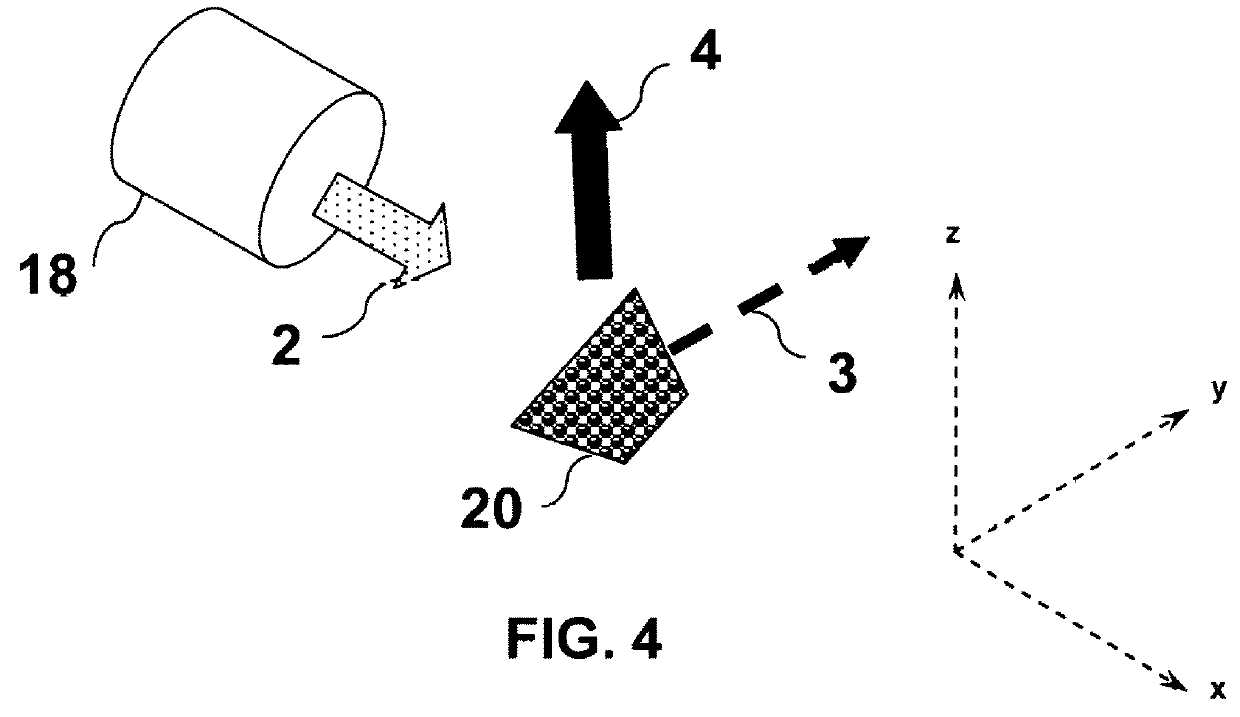

Switchable Article and Device to Generate a Lateral or Transverse Casimir Force for Propulsion, Guidance and Maneuvering of a Space Vehicle

ActiveUS20100237198A1Magnitude is alteredCosmonautic vehiclesCosmonautic propulsion system apparatusEngineeringNanostructure

An article and device are provided comprising a switchable microstructure or nanostructure array of non-parallel conducting plates, supported by a plurality of shaped prismatic oxide stages upon layered conductive and substrate-base materials, for directly generating a lateral or transverse Casimir force. Illustrative embodiments include a device for switchable generation of lateral or transverse Casimir force components that work in an orthogonal direction to normal Casimir forces which can be externally switched “on” or “off” electronically, mechanically or thermally by using a semiconductor PN-junction or superconductor to produce a thrust for guidance, maneuvering and propulsion of a manned or unmanned space vehicle, or in other novel applications requiring generation of precisely switched or continuous forces.

Owner:CORMIER DENNY CHARLES

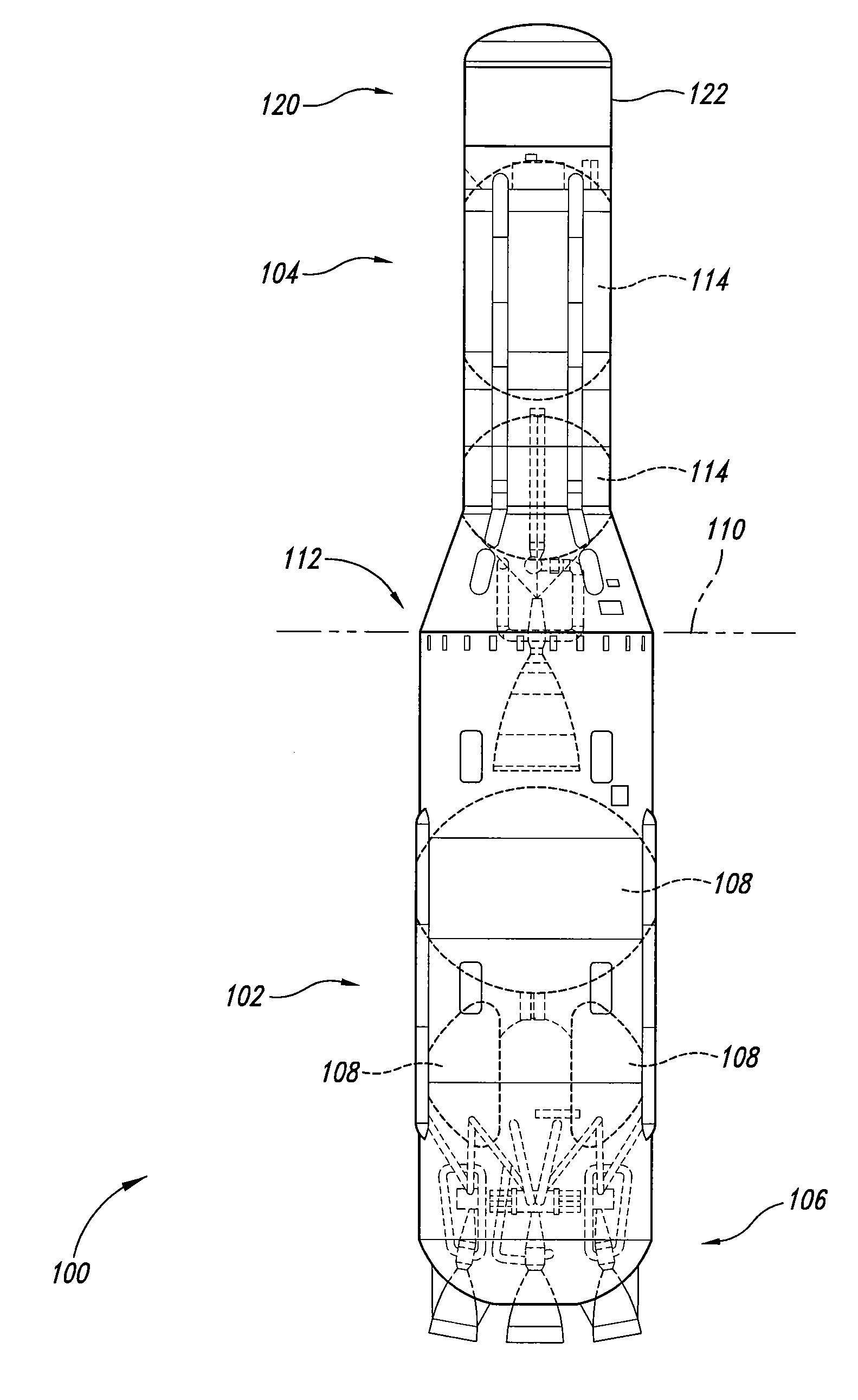

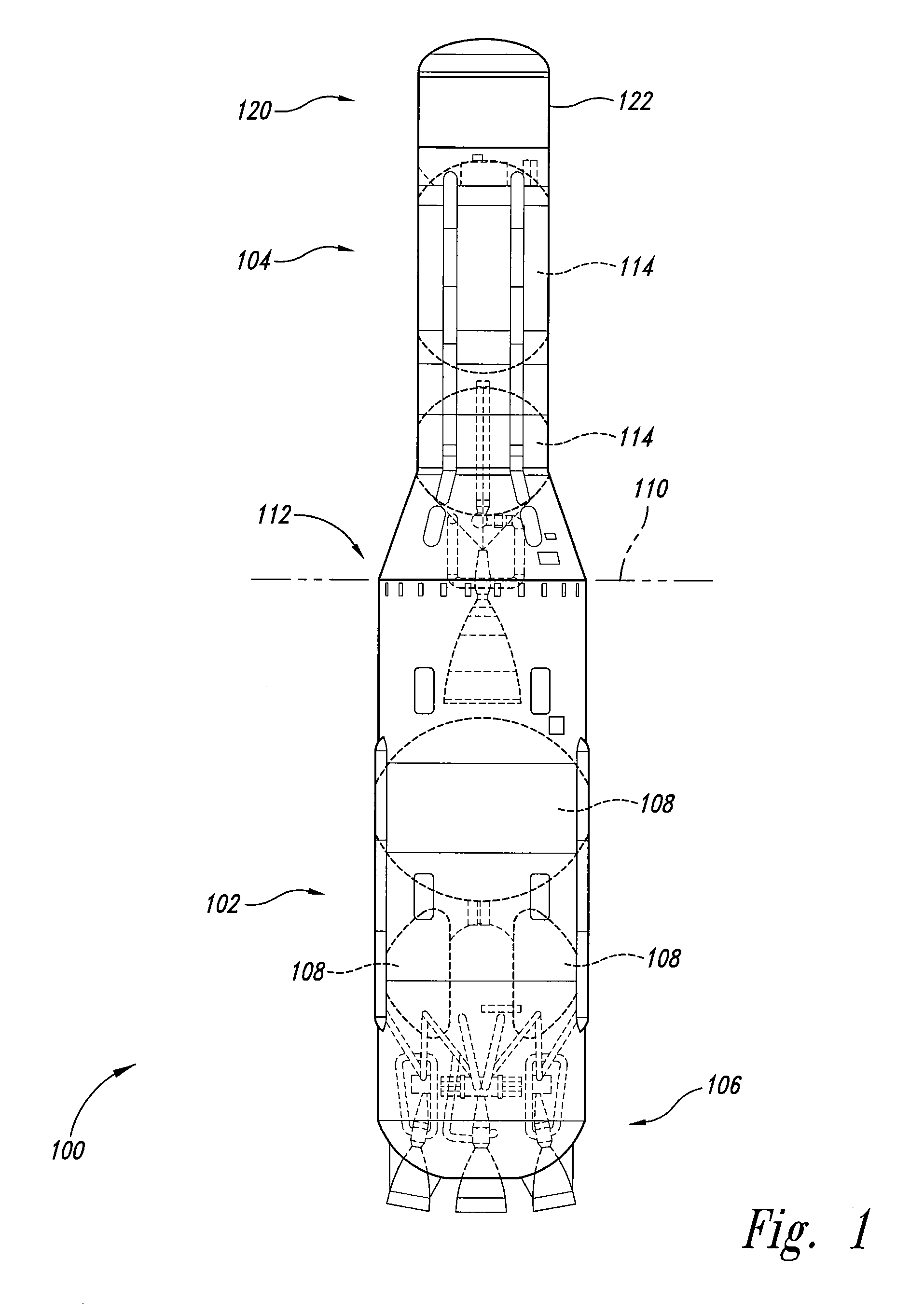

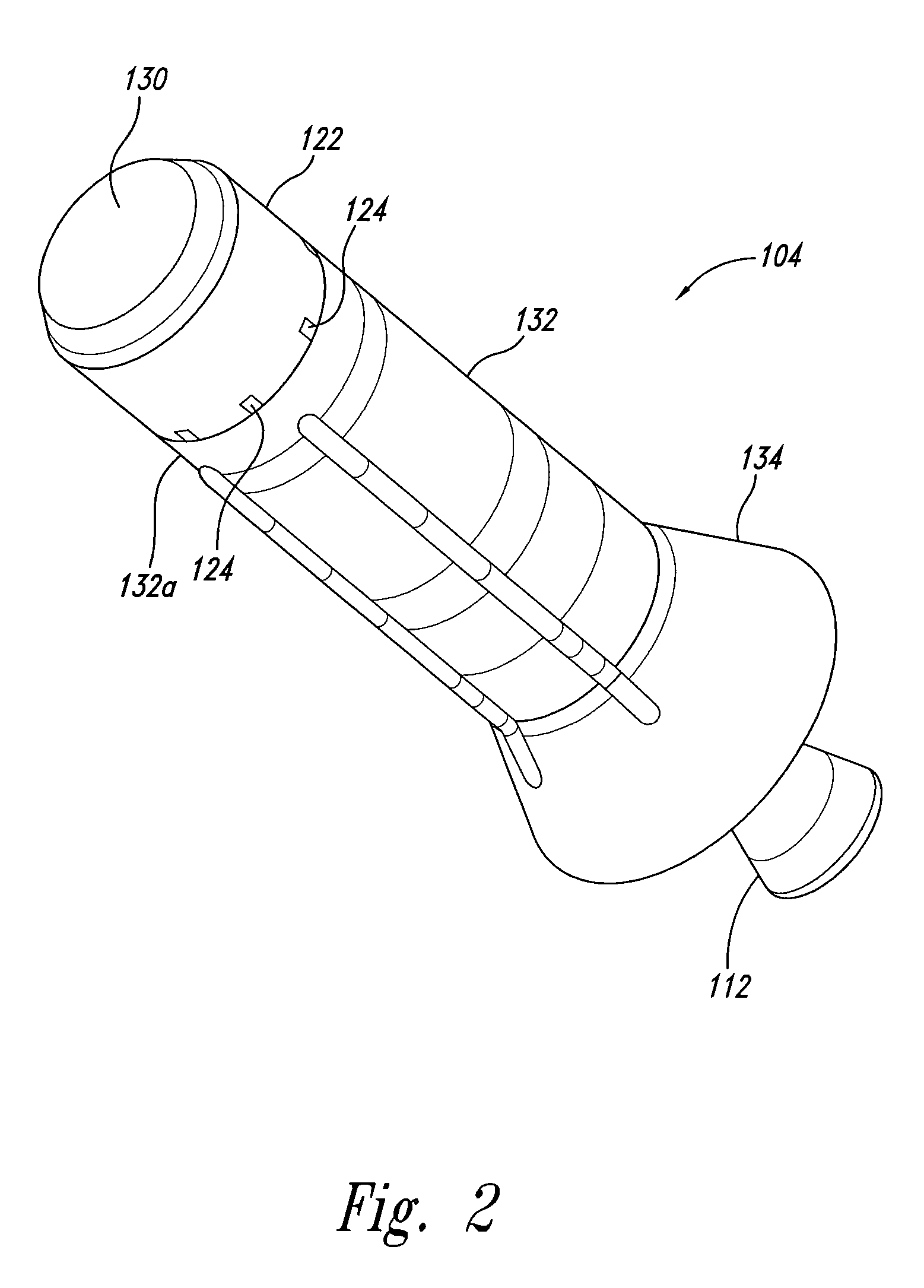

Reusable orbital vehicle with interchangeable cargo modules

A reusable module is affixed atop a reusable orbital vehicle (OV). Various configurations of the reusable module have identical external dimensions in the region of attachment to the OV to permit interchangeability. Different configurations can accommodate a variety of missions of different type and duration. A variety of cargo modules of different configurations allow cargo to be uplifted into orbit. In one embodiment, the cargo module is an unpressurized cargo module in which the cargo is exposed to the environment of space during the unloading process. The cargo module may also be a pressurized cargo module. In an alternative embodiment, the cargo module may include both a pressurized cargo module and unpressurized cargo module.

Owner:KISTLER AEROSPACE CORP

Inertial propulsion device to move an object up and down

ActiveUS8066226B2Save on fuel costsIncrease flight speedCosmonautic vehiclesCosmonautic propulsion system apparatusGyroscopePrecession

Disclosed herein are two separate processes that do not require a propellant and do not produce an equal and opposite reaction against any external form of matter in the Local Inertial Reference Frame and do not violate Newton's Laws in the Universal Reference Frame. The first process produces horizontal motion, relies on the earth's gravitational field as an external force, and has been successfully tested. The second process produces vertical motion and relies only on the aether. It has been successfully tested considering the effect of the earth's gravity. Due to the law of conservation of angular momentum, the first process is considered by some to not be possible, but with the proper use of an external field (for example, gravity) and the phenomenon of precession, it is clearly possible. A clear distinction is made between a simple rotor and a gyroscope which is a far more complex device.

Owner:FIALA HARVEY E +2

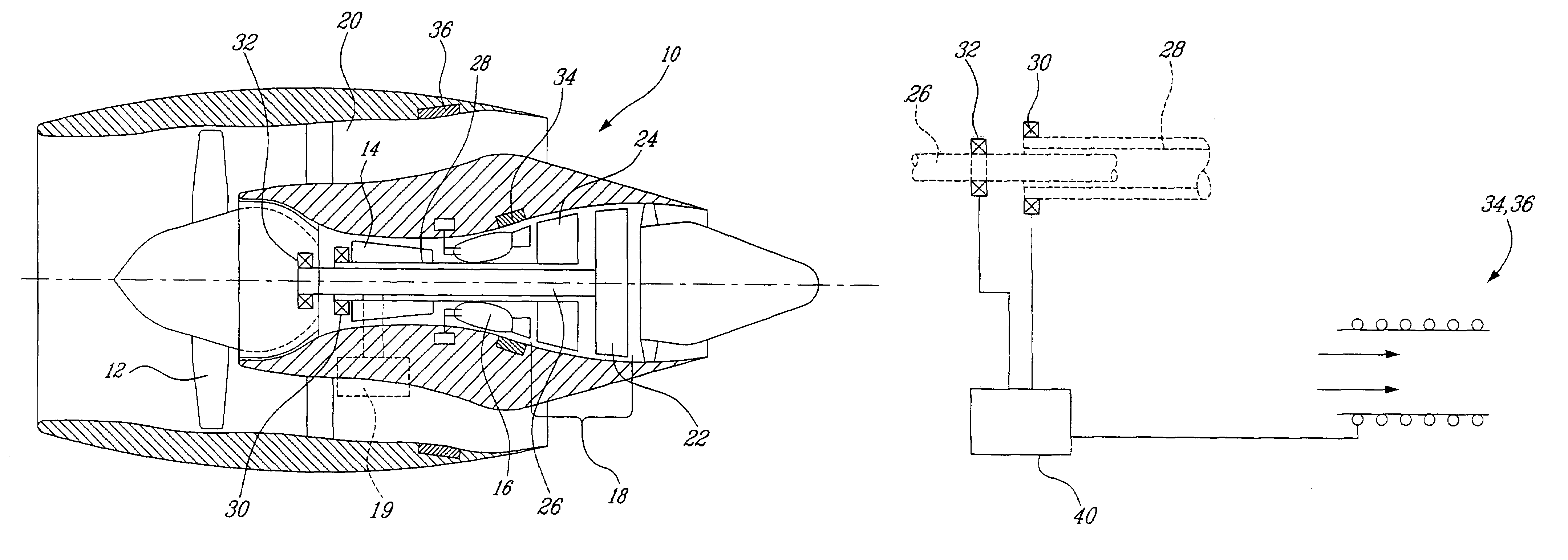

Gas turbine engine including apparatus to transfer power between multiple shafts

Owner:PRATT & WHITNEY CANADA CORP

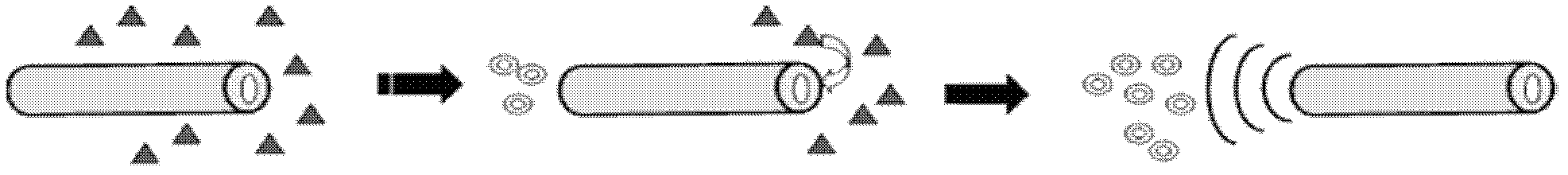

Preparation method of artificial microtube and application of artificial microtube as micromotor

InactiveCN102674242AEasy to operateGood size controlMachines/enginesMicrostructural devicesMicro nanoOxygen

The invention relates to a preparation method of an artificial microtube and the application of the artificial microtube as a micromotor. The invention relates to the preparation method and the application of the artificial microtube and solves the technical problems of high cost, small one-time synthetic quantity and large difficulty of the operation requirement of a particle beam injection method in the existing electrochemical deposition method for synthesizing a micro nano motor. The method comprises the steps of: preparing metal catalytic particles, assembling polyelectrolyte into the holes of a template layer by layer and assembling the metal catalytic particles to obtain the artificial microtube. For the application of the artificial microtube as the micromotor, the artificial microtube is put into a hydrogen peroxide solution, oxygen is generated via catalyzing hydrogen peroxide, and bubbles are used as impetus to drive the motor. The method is easy to operate, controllable in sizes, low in cost and large in one-time synthetic quantity. The artificial microtube provided by the invention can be used as the micromotor in the medical field.

Owner:HARBIN INST OF TECH

Mass retentive linear impeller

A mass retentive linear impeller is used to convert rotational energy into directional, linear energy. The mass retentive linear impeller comprises a plurality of tracks with a plurality of torque carriages located on the tracks. The torque carriages further comprise two counter rotating flywheels, which are located on a framework. Two rotating arms are located inside of the flywheel and are attached to a center motor of the flywheel, which act as a central axis for the rotating arms. A weight is located at the distal end of each rotating arm. The rotating arms induce a centrifugal force, which creates a temporary pull in one direction. This produces a sequence of forward and backward thrusts.

Owner:KEEFE ALLEN

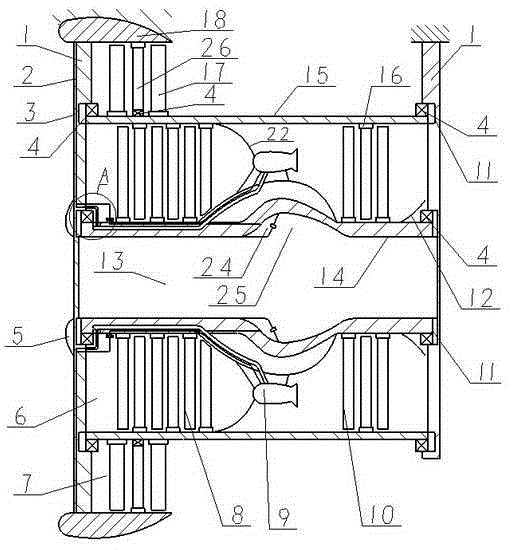

Contra-rotating outer framework water-air dual-purpose engine

InactiveCN104481696AReduce the size of the axial structureIncrease thrust-to-weight ratioGas turbine plantsReactive propulsion thrust deviceAbsolute rotationCombustion chamber

The invention discloses a contra-rotating outer framework water-air dual-purpose engine. The engine mainly structurally comprises a supporting frame, an oil electric pipeline, a front thrust bearing, a peripheral bearing, a radome, an inner duct, an outer duct, a gas compressor, a ring-shaped combustion chamber, a worm wheel, a rear thrust bearing, a convergent tail spray tube, a central duct, an inner rotor, an outer rotor, a blade tongue-and-groove, a fan, an engine cover, a power transmission circuit, a conductive slide ring, an oil conveying pipeline, a convergent channel, a rotary joint, a metal fuel cavity, a metal-water reaction combustion chamber and a fan stator blade. The gas compressor and the worm wheel of the engine are not provided with a stator blade, and an outer frame rotor and an inner rotor are in counter rotating in an air working state, so that the gas compressor and the worm wheel can realize counter rotating, the absolute rotation speed of the rotor is lowered when the engine efficiency is improved, the axial dimension of the engine is shortened and the structure weight is reduced. When the engine works in water, the ring-shaped combustion chamber does not work, the inner and outer rotors are static, and power is produced by the metal-water reaction combustion chamber, so that water-spraying propulsion is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

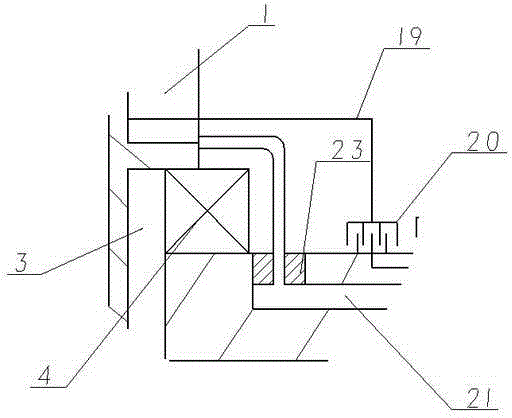

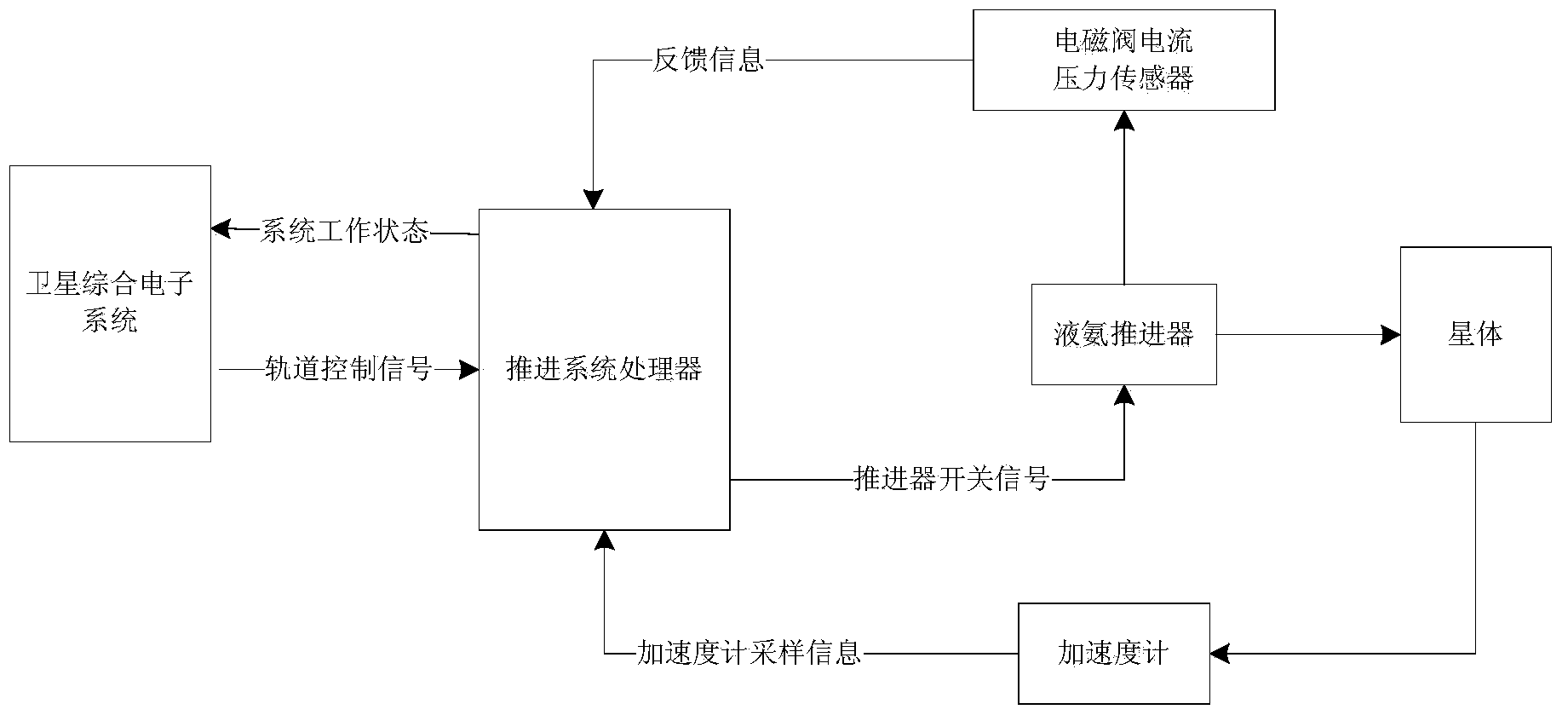

Liquid ammonia propulsion system for pico-satellite or nano-satellite

ActiveCN104358663AUniversal applicabilityReduce volumeCosmonautic power supply systemsContainer filling methodsDigital signal processingSolenoid valve

The invention discloses a liquid ammonia propulsion system for a pico-satellite or a nano-satellite. The liquid ammonia propulsion system comprises a digital signal processing circuit and a micro-propulsion device, wherein the micro-propulsion device comprises a propulsion system storage tank used for storing liquid ammonia, a thruster communicated with the propulsion system storage tank, and a solenoid valve mounted between the propulsion system storage tank and the thruster; the digital signal processor comprises an information monitoring module, a control switch module and an interface communication module; the information monitoring module is used for monitoring the current operation state of the propulsion system; the control switch module is used for controlling the solenoid valve so as to turn on or turn off the thruster; the interface communication module is used for feeding back information on the current operation state of the propulsion system to the satellite and receiving remote control commands sent by the satellite. The liquid ammonia propulsion system has the characteristics of small size, light weight, low power consumption, high specific impulse, simple structure, short development period, high safety performance, multi-functional integration, space plug and play function, universal applicability to 10 kg-magnitude pico-satellites and nano-satellites, and the like.

Owner:ZHEJIANG UNIV

Switchable article and device to generate a lateral or transverse Casimir force for propulsion, guidance and maneuvering of a space vehicle

ActiveUS8317137B2Cosmonautic vehiclesCosmonautic propulsion system apparatusEngineeringNanostructure

An article and device are provided comprising a switchable microstructure or nanostructure array of non-parallel conducting plates, supported by a plurality of shaped prismatic oxide stages upon layered conductive and substrate-base materials, for directly generating a lateral or transverse Casimir force. Illustrative embodiments include a device for switchable generation of lateral or transverse Casimir force components that work in an orthogonal direction to normal Casimir forces which can be externally switched “on” or “off” electronically, mechanically or thermally by using a semiconductor PN-junction or superconductor to produce a thrust for guidance, maneuvering and propulsion of a manned or unmanned space vehicle, or in other novel applications requiring generation of precisely switched or continuous forces.

Owner:CORMIER DENNY CHARLES

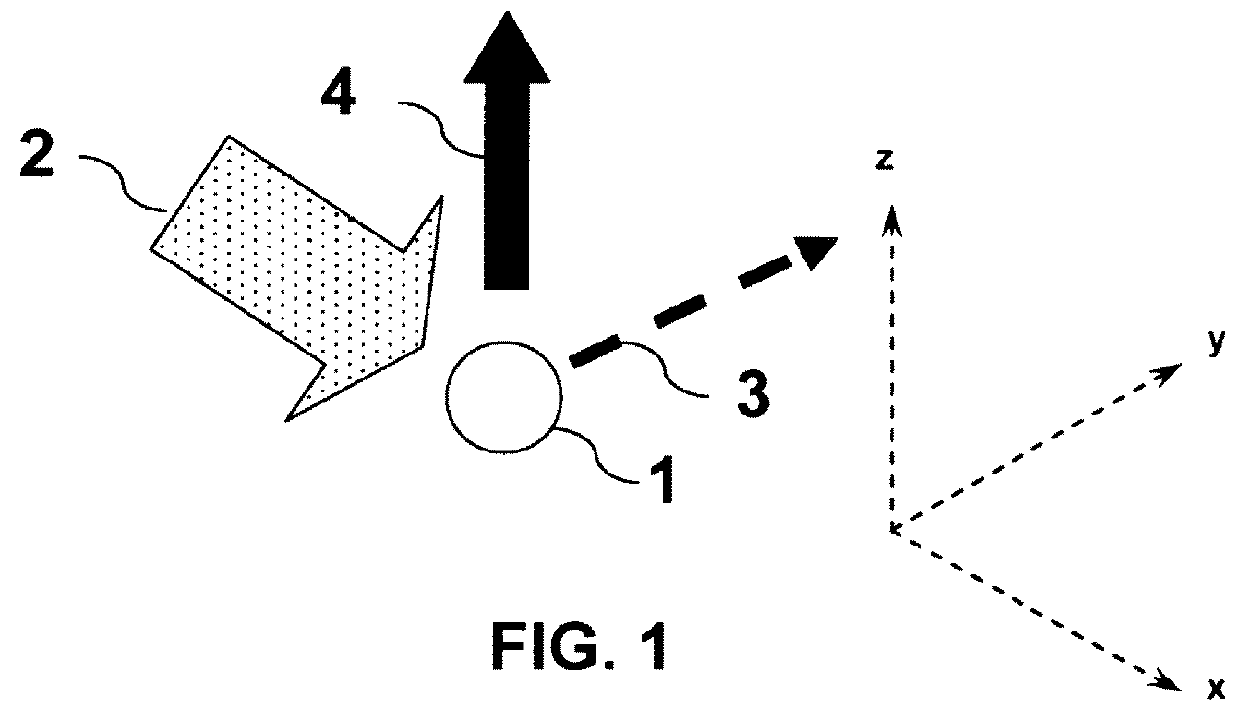

Navigation Body, Navigation Device, and Space Navigation Device

InactiveUS20090108136A1Cosmonautic vehiclesInstruments for comonautical navigationEngineeringSpin axis

The present invention provides a thrust generator capable of generating thrust without using reaction of a combustion product, and a navigation body utilizing the same. The thrust generator has a rotation axis, a plurality of tops arranged symmetrically around the rotation axis, and a motor device for rotating the tops around the rotation axis. The spinning axis of the top is arranged along the radial direction of the rotation axis. The “top” generates a force by which it rises perpendicularly from the ground, that is, so-called couple of forces. By using the couple of forces, thrust is generated.

Owner:SUZUKI KAZUYOSHI

Method and Device to Generate a Transverse Casimir Force for Propulsion, Guidance and Maneuvering of a Space Vehicle

InactiveUS20080296437A1Cosmonautic vehiclesCosmonautic propulsion system apparatusSpacecraft propulsionTransverse force

Method and device for directly generating a transverse Casimir force comprising a technique for fabricating a microstructure array of non-parallel conducting plates held in place by an insulating material and affixed either to a conducting or insulating substrate are disclosed. As described by the illustrative embodiment, the lateral or transverse force component generated by the present invention works in an orthogonal direction to the normal Casimir force, thereby allowing its use as a means of vectored thrust for precise positioning, guidance, maneuvering and propulsion in a manned or unmanned space vehicle, or any application requiring precise forces.

Owner:COMEGA TECH

Gas turbine engine including apparatus to transfer power between multiple shafts

Owner:PRATT & WHITNEY CANADA CORP

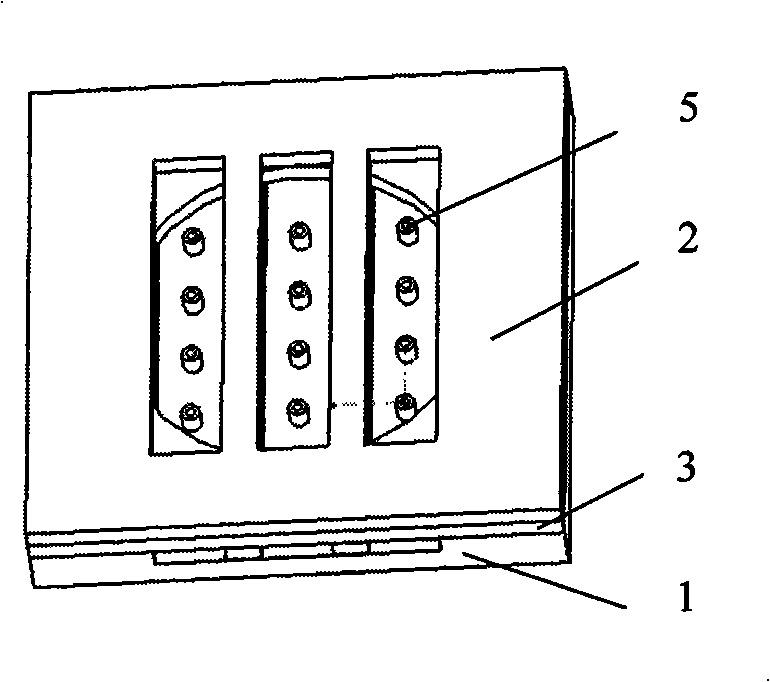

Micro array type colloid propeller

InactiveCN101539127APrevent outflowWon't overflowMachines/enginesReactive propulsion thrust deviceSputteringPropeller

The invention relates to a micro colloid propeller, in particular to a micro array type colloid propeller. The micro array type colloid propeller realizes micromation and microthrust, solves the problems of difficult control of liquid supply and jetting of a nozzle of a jetting pole and the like and comprises the jetting pole, a drawing pole and a glass supporting frame body; a base plate of the jetting pole is etched with a plurality of tubular nozzles which are arranged in row, and is also etched with a plurality of strip etching grooves which are parallel; each strip etching groove is internally provided with a row of tubular nozzles; the bottom of each etching groove and the top part of the tubular nozzle are sputtered with an aluminium layer; one end of each etching groove respectively provided with a terminal communicated with the aluminium layer at the bottom of the groove; the inside of a liquid delivery channel of the tubular nozzle is processed into a porous silicon structure by adopting HF etching technique; the drawing pole is paliform, and strip grid seams thereof face the etching grooves of the jetting pole. The micro array type colloid propeller has the advantages of stable performance, high aligning precision, convenient processing and easy control for liquid supply and jetting and the like and can realize the purpose of controlling jetting of the nozzle by batches.

Owner:ZHONGBEI UNIV

Fluidic zero-point power and propulsion units

InactiveUS20130283797A1High energyReciprocating combination enginesCombination enginesSpinsRenewable resource

Disclosed are devices which provide a practical means of extracting energy from the electromagnetic zero-point energy which permeates the universe. This is done by exploiting the Casimir-van der Waals' forces to accelerate a fluid through the device and exhaust it with a higher velocity and energy than that with which it entered. This kinetic energy gained by the fluid may then be used to do work, such as spin a turbine for power generation, or provide thrust for direct propulsion. These devices do not consume fuel nor any non-renewable resources during operation and they are capable of generating significantly more energy than they require to start or to be manufactured.

Owner:SHIVA SCI & TECH GRP

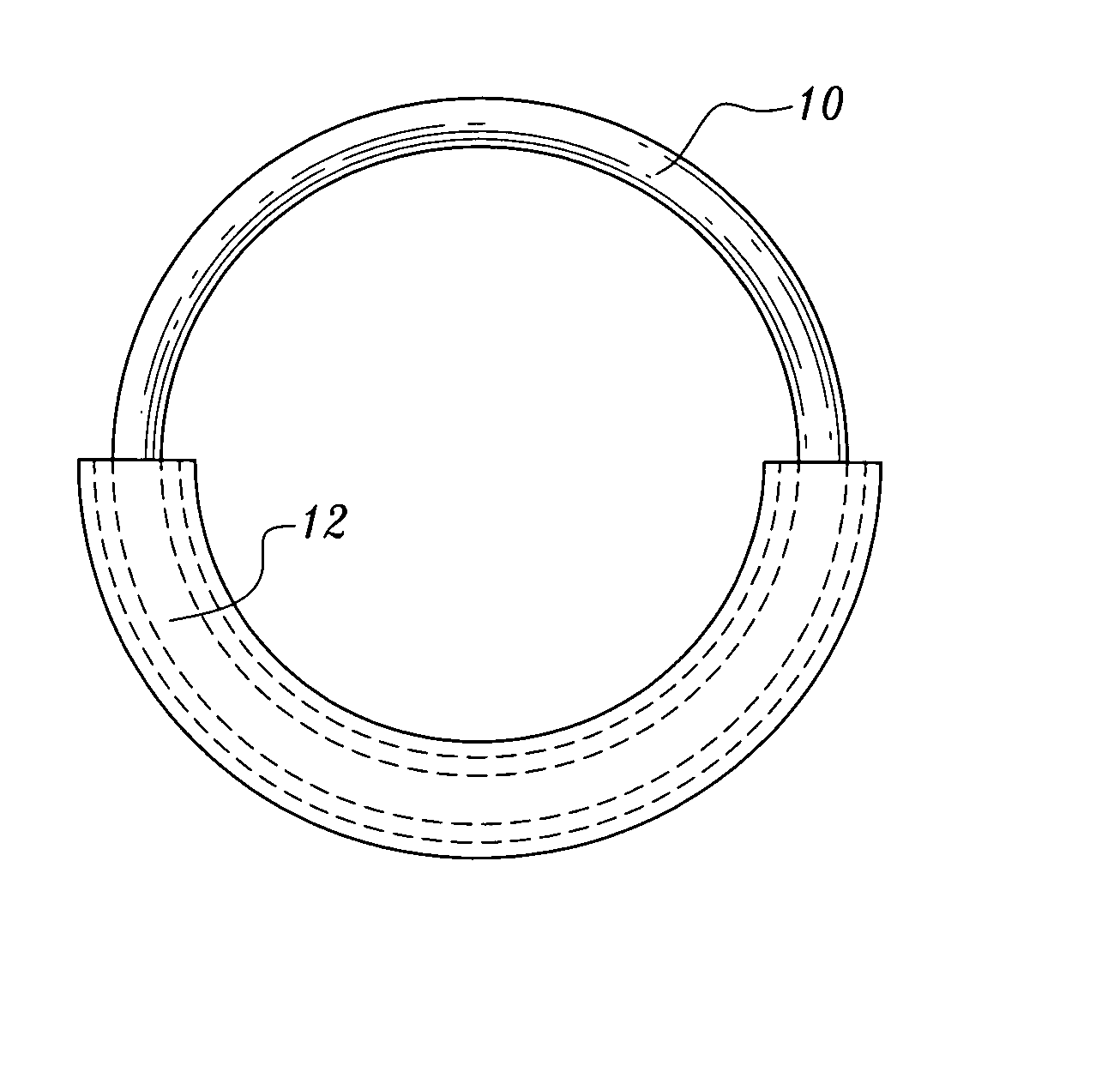

System utilizing the earth's magnetic field to generate a force in opposition to the force of gravity

ActiveUS7446636B1Reducing apparent weightReduce appearance problemsFlying saucersCosmonautic vehiclesGravitational forceCondensed matter physics

A loop of superconducting material forms a continuous current flow path. A portion of the loop is shielded from the Earth's magnetic field and another portion is unshielded. Charged particles flowing through the unshielded portion cooperate with the Earth's magnetic field to create an upward force on said loop.

Owner:BELOW III JOHN F AND BELOW HOLLY E AS TRUSTEES OF THE BELOW 1999 TRUST DATED SEPTEMBER 15 1999

Electromagnetic segmented-capacitor propulsion system

Owner:PURVIS JAMES WAYNE

Particle accelerator space engine

InactiveUS20050056729A1Cosmonautic vehiclesCosmonautic propulsion system apparatusAviationRotational axis

The invention provides two methods of propulsion for vertical and horizontal aerospace flight. Both methods manipulate the mass of a moving particle stream to achieve a desired result. In vertical propulsion, the invention circulates matter, within the confine of a machine, such that a portion of particle speed, which is perpendicular to gravity, is greater than the magnitude of velocity required for circular orbit of the planet, so as to develop radial acceleration relative to the planet center, creating a vertical force, associated with the mass of the particle stream times the radial acceleration, thereby generating vertical thrust. This methodology shall be referred to as “Gyroscopic Lift”. This invention also provides an additional method of horizontal propulsion. In horizontal propulsion, the invention may alternate acceleration and deceleration of matter, as it travels in a circulatory system, so as to create changing centripetal acceleration, and a directional imbalance of forces, thereby developing an outlet to be employed in horizontal thrust. As particles accelerate to the rear during the first ½ cycle an opposite but equal reaction causes forward horizontal propulsion. As particles decelerate in the 2nd ½ cycle, the opposition to slowing down causes forward horizontal propulsion. On port and starboard sides, forces causing particle stream acceleration or deceleration are balanced so as to cancel each others effect. This method of alternating acceleration and deceleration shall be referred to as “Impulse Propulsion”. Although the particular embodiment shown utilizes particles traveling perpendicular to gravity, it should not be concluded that this is the only arrangement possible. Whenever a particle has a component of velocity perpendicular to gravity in excess of circular orbit velocity, it is suitable to provide some measure of vertical thrust. Thus many particle accelerator designs utilizing this feature are feasible for the present invention. As an example, a particle accelerator whose axis of rotation is not aligned with the z axis should provide vertical lift and possibly other precession types of motion for a vehicle. As an alterative embodiment of this invention it provides some measure of gyroscopic lift that may be harnessed. Another example; If the circulatory path of the doughnut is comprised of a shape other than a circle it may increase the potential effect of impulse propulsion, but reduce gyroscopic lift efficiency. A shape comprised of two half circle accelerators, linked into a circulatory pattern by two parallel linear accelerators, would increase the potential horizontal thrust of impulse propulsion. Such is an alternative embodiment of this invention. Thus the invention embraces all space engines which utilize the principles of Gyroscopic Lift, or Impulse Propulsion. Obviously, many modifications and variations of the present invention are possible in the light of the above teachings. It is therefore to be understood that within the scope of the appended claims, the invention may be practiced other than as specifically described.

Owner:FOSTER JOHN P

Mobile object with force generators

A mobile object being a vehicle of any type includes a plurality of force generators, enclosed in a hermetically sealed generator chamber filled with a pressurized gas, and a plurality of engines. Each force generator being a lift device comprises a rotor, which includes a shaft, a rotary shell having an open bottom, and a means supporting the gas in relative equilibrium inside said rotary shell, and a stationary means closing said open bottom of said rotary shell. The specific coordination of the members of said force generator supports the gas on the lower surfaces of the force generator in relative equilibrium and hence produces the maximum difference between the pressures of the gas acting on the lower and upper surfaces of said force generator, i.e. the maximum lift. The force generators, enclosed in said generator chamber, produce the self-action force of said mobile object in accordance with the self-action principle of a solid-fluid body that has been established recently. By controlling the direction of the shafts and angular velocities of the force generators the mobile object can accelerate momentarily in any direction in space. The enclosure of the force generators in the generator chamber makes the self-action force of the mobile object independent of outer environment surrounding it. Any source of energy can be used for self-propulsion of the mobile object due to the direct conversion of the rotational energy into the self-action force without the use of material jets, reactive or external forces.

Owner:MINH VU XUAN

Centrifugal force amplification method and system for generating vehicle lift

A method and system generate lift for a vehicle relative to a planetary body rotating at a rotational speed. The vehicle incorporates two concentric lift rings in a common plane. The lift rings are positioned such that their common plane is approximately perpendicular to a force of gravity on the planetary body. The hit rings are rotated M opposing directions at speeds that are at least 20 times greater than the rotational speed of the planetary body.

Owner:CROWE WILLIAM R

Propellant self-driven device of MEMS electrospray thruster

InactiveCN108313332AReduce volumeReduce weightCosmonautic vehiclesCosmonautic propulsion system apparatusSupply managementPotential difference

A propellant self-driven device of an MEMS electrospray thruster comprises a storage box (1), a connecting device (2), a porous emitter electrode (3), an insulating alignment frame (4), a mounting silicon frame (5) and an extraction electrode (6), wherein propellant liquid is stored in the hollow part inside the storage box (1); the insulating alignment frame (4) is mounted at the upper part of the storage box (1); the extraction electrode (6) is mounted on the insulating alignment frame (4) through the mounting silicon frame (5) mounted at the edge of the extraction electrode (6); the porousemitter electrode (3) and the connecting device (2) are mounted between the extraction electrode (6) and the storage box (1); the porous emitter electrode (3) is connected to the upper part of the storage box (1) through the connecting device (2); and there is a potential difference between the porous emitter electrode (3) and the extraction electrode (6). The propellant self-driven device of theMEMS electrospray thruster solves the problem that an original electrospray propulsion system needs to be equipped with special propellant supply management devices such as a micro pump and a micro valve, and that the thrust precision is largely limited by the propellant supply precision of the micro valve and other mechanisms.

Owner:BEIJING INST OF CONTROL ENG

Hot-stamping engine

The invention discloses a hot-stamping engine which comprises a converging-diverging channel and a heating chamber, wherein a high-pressure fluid guide outlet is arranged on a high-static pressure region of the converging-diverging channel, a fluid nozzle is arranged on a low-static pressure region of the converging-diverging channel, the spraying direction of the fluid nozzle uses the flowing direction of the fluid at the periphery of the fluid nozzle as a total direction, in which the fluid nozzle is positioned, the high-pressure fluid guide outlet is communicated with the fluid nozzle through a fluid communicating channel, and a heating chamber is arranged on the fluid communicating channel. Under the premise of no moving parts, the hot-stamping engine can generate a spraying thrust power or rotation power.

Owner:靳北彪

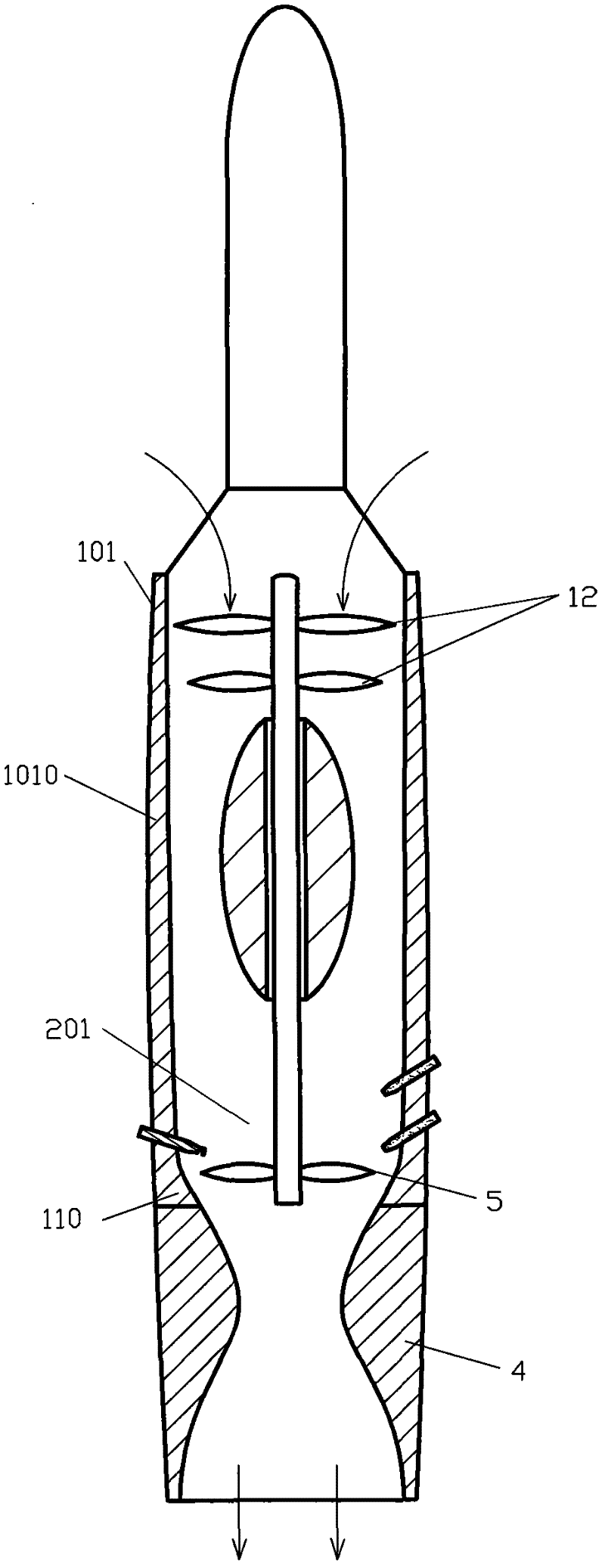

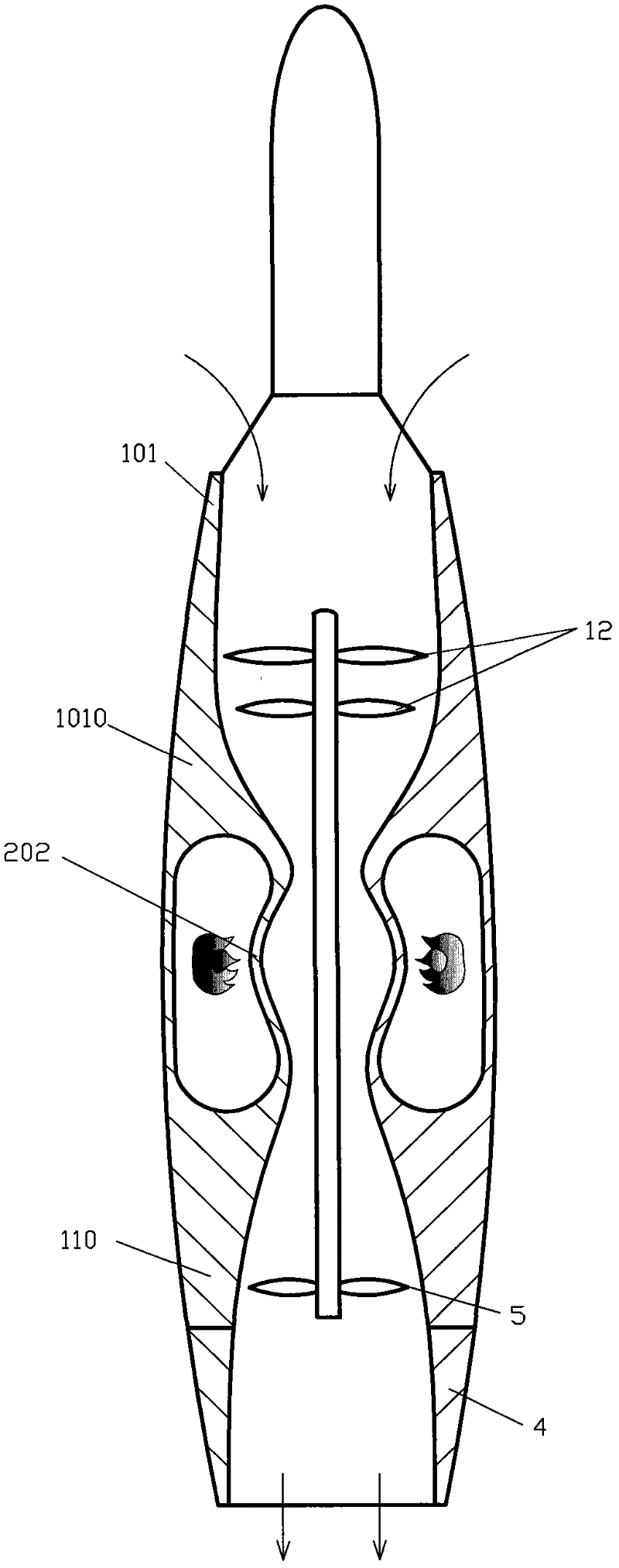

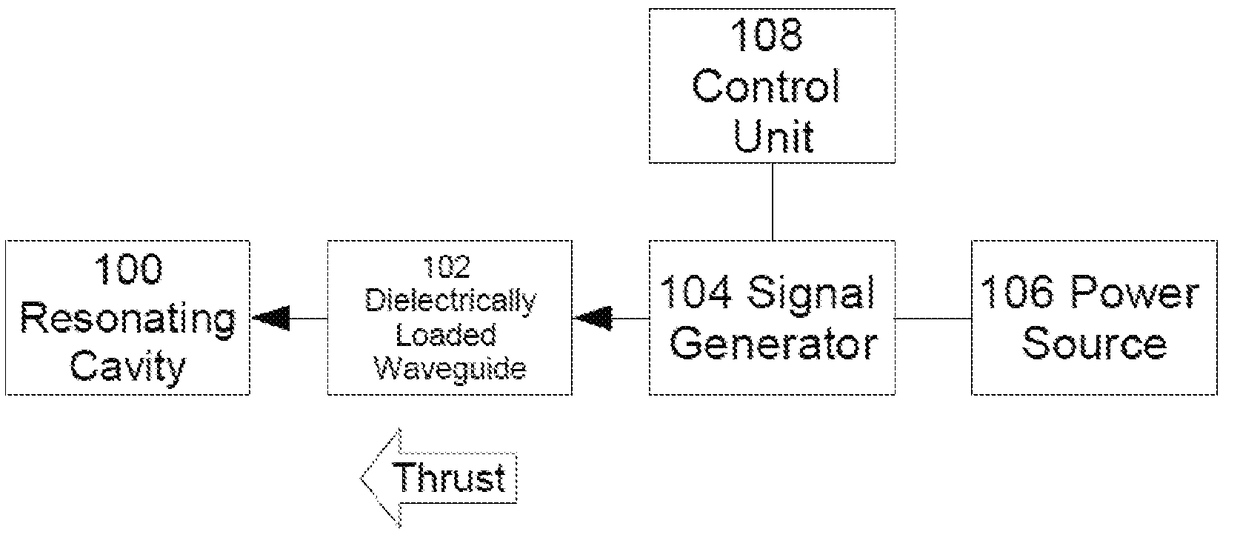

Electromagnetic thrusting system

InactiveUS20170158359A1Cosmonautic vehiclesCosmonautic propulsion system apparatusElectricityElectromagnetic electron wave

Thrusting systems and vehicles are disclosed. One thrusting system includes a signal generator and a waveguide. The signal generator is configured to generate an electromagnetic wave. The waveguide is coupled to the signal generator to receive the electromagnetic wave such that at least a portion of electric and magnetic components of the electromagnetic wave extend in a direction transverse to a wave axis of the electromagnetic wave. The waveguide includes a dielectric material positioned to extend in a direction of the wave axis along a portion of the waveguide. An interaction between the electromagnetic wave and the waveguide induces a net force on the waveguide. One vehicle includes a thrusting system substantially as described above.

Owner:CANNAE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com