Hot-stamping engine

A hot stamping and engine technology, applied in the field of ramjet, can solve the problems affecting the application of ramjet, high manufacturing technical requirements and cost, and complex system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

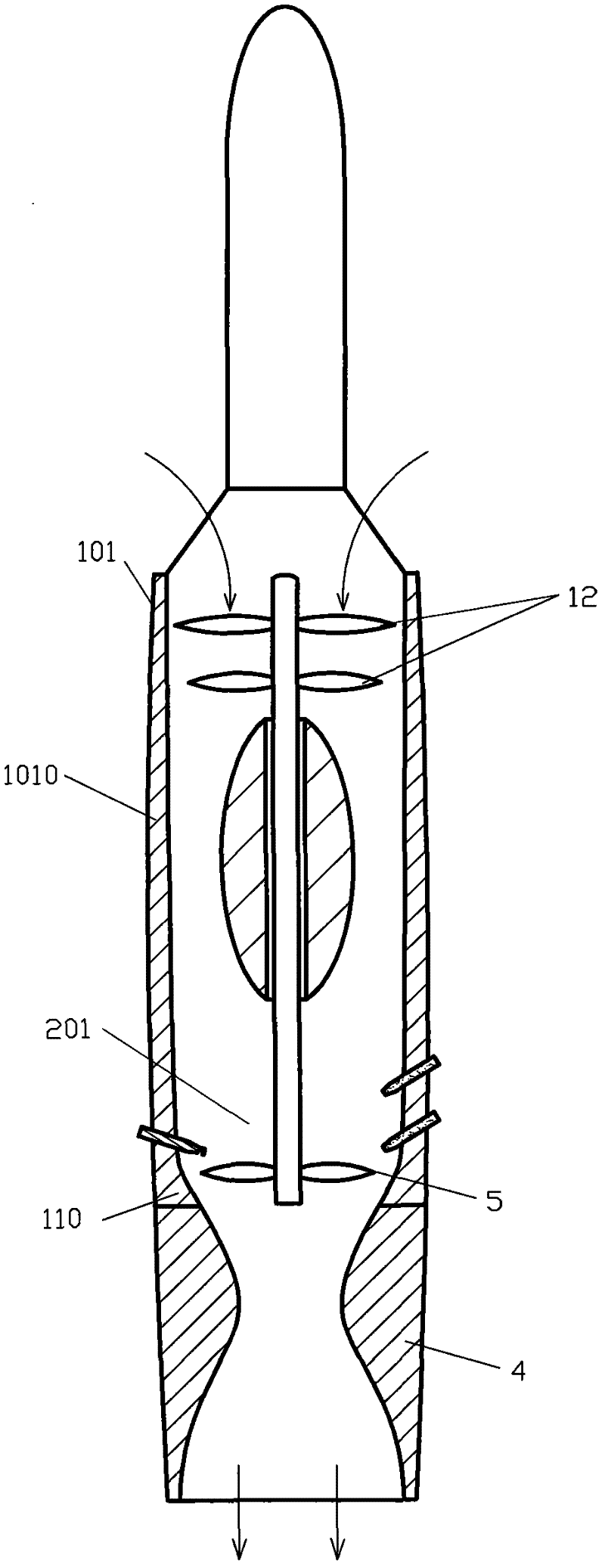

[0118] Such as figure 1 The hot ramjet engine shown includes a channel 1010 and a heating chamber 2, the channel 1010 includes a liquid inlet 101 and a gas outlet 110, wherein the gas outlet 110 is connected to the propulsion injection pipe 4; the heating chamber 2 is arranged in the Between the liquid inlet 101 of the channel 1010 and the gas outlet 110, a liquid propeller 12 is arranged between the liquid inlet 101 of the channel 1010 and the heating chamber 2, the gas outlet 110 of the channel 1010 and the heating chamber 2 A power turbine 5 is arranged between them, and the power turbine 5 outputs power to the liquid propeller 12, and the liquid entering the channel 1010 from the liquid inlet 101 of the channel 1010 is pressurized by the liquid propeller 12 and flows in the Gasification under the action of the heating chamber 2, after the gasification gas does work on the power turbine 5, it is ejected from the gas outlet 110 of the channel 1010 through the propulsion inj...

Embodiment 2

[0122] Such as figure 2 The difference between the shown hot ramjet engine and Embodiment 1 is that the heating chamber 2 is set as an internal gasification chamber 201, which is specifically used on a torpedo as a torpedo power plant, that is, the so-called torpedo engine of the present invention .

Embodiment 3

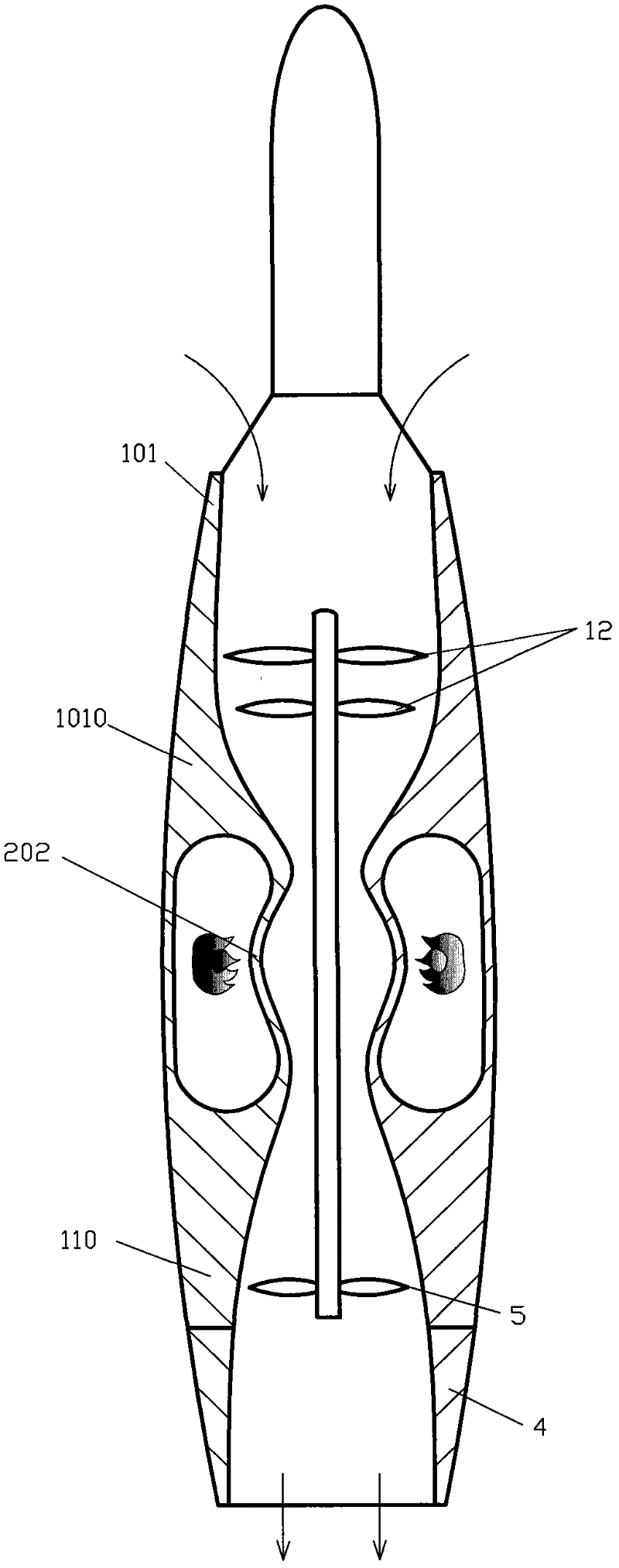

[0124] Such as image 3 The difference between the shown hot ramjet engine and Embodiment 2 is that the inner gasification chamber 201 is set as the outer gasification chamber 202 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com