Electrothermal micro-thruster

A micro-thruster and electric heating technology, applied in the field of nano-satellite micro-propulsion system, to achieve high efficiency, strong adaptability, and good propulsion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

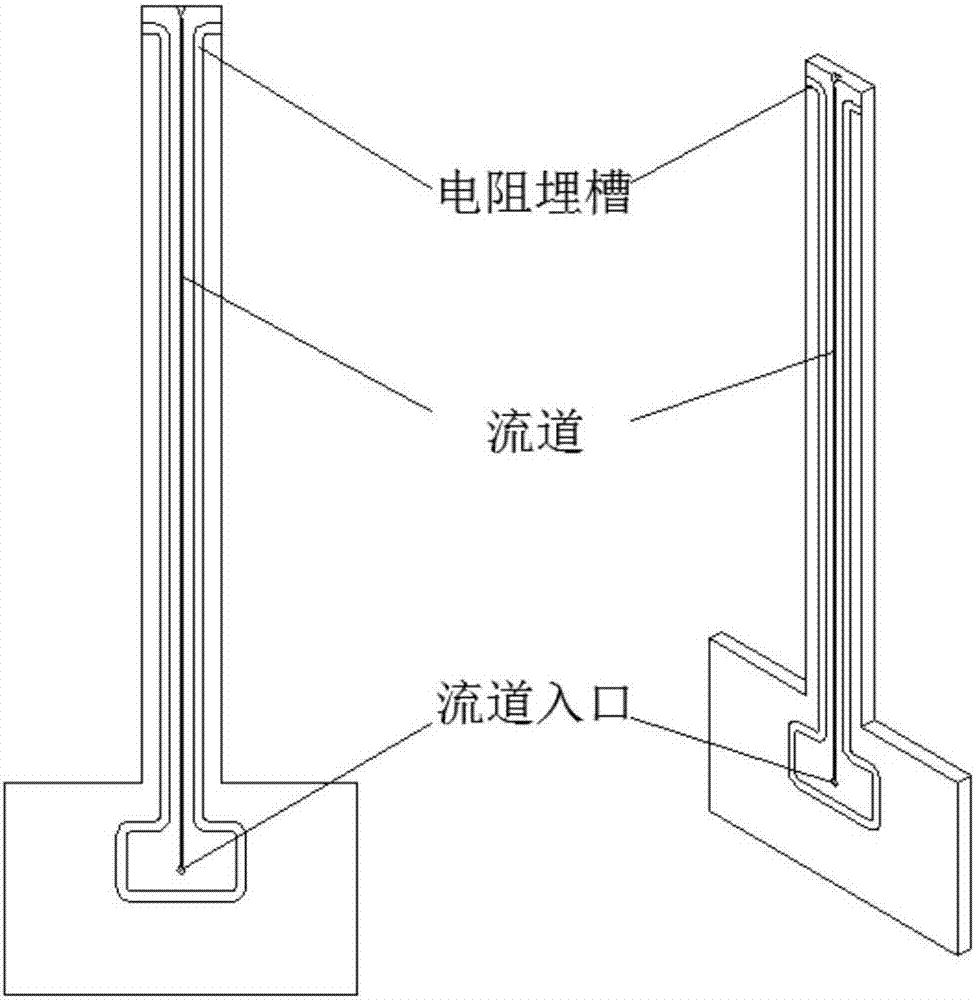

[0021] The present invention is a nickel micro-heating device, comprising:

[0022] A Pyrex glass substrate 2; and a silicon chip 4 anodically bonded on the Pyrex glass substrate 2;

[0023] A runner groove 3 is provided on the symmetry axis of the silicon chip, and the runner groove 3 is provided with a Laval spout 5 and a fluid inlet 8;

[0024] The device also includes: on the silicon chip 4, a resistor buried groove 6 is symmetrically arranged around the flow channel groove 3 and the fluid inlet 8; an insulating layer and a nickel resistor 7 are sequentially arranged in the resistor buried groove 6 from the inside to the outside;

[0025] The Pyrex glass substrate is provided with a pad 1 connected to the nickel resistor 7, and has an intersection with the nickel thin film resistor to form an effective contact;

[0026] The bonded surface of the Pyrex glass substrate 2 and the silicon chip 4 is: the grooved surface of the resistance buried groove 6 on the silicon chip 4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com