Piezoelectric valve

A valve and piezoelectric technology, applied in the direction of valve details, valve devices, valve operation/release devices, etc., can solve the problems of insufficient control accuracy, low pressure resistance, large volume and quality, etc., and achieve compact structure, reduced The effect of volume and mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

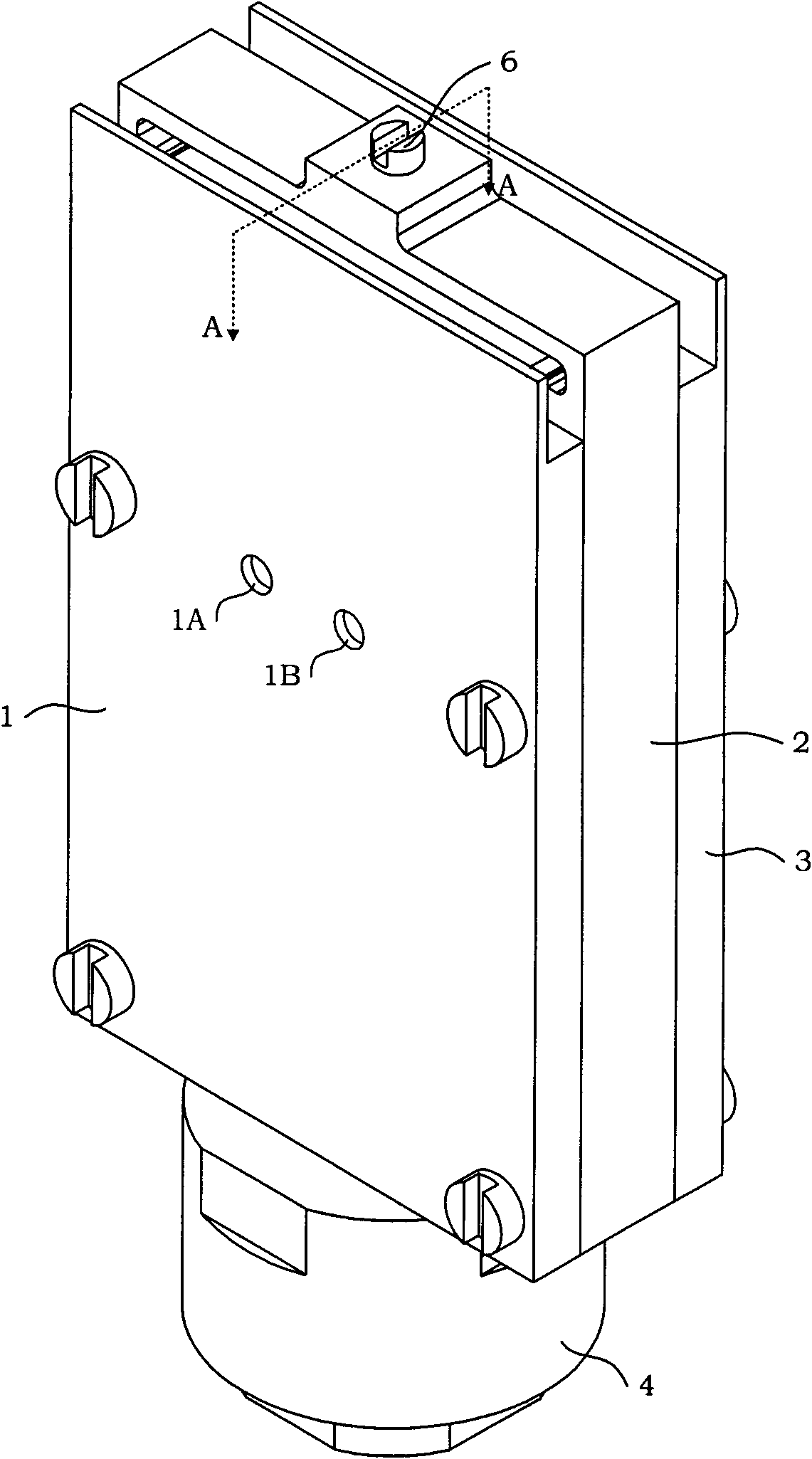

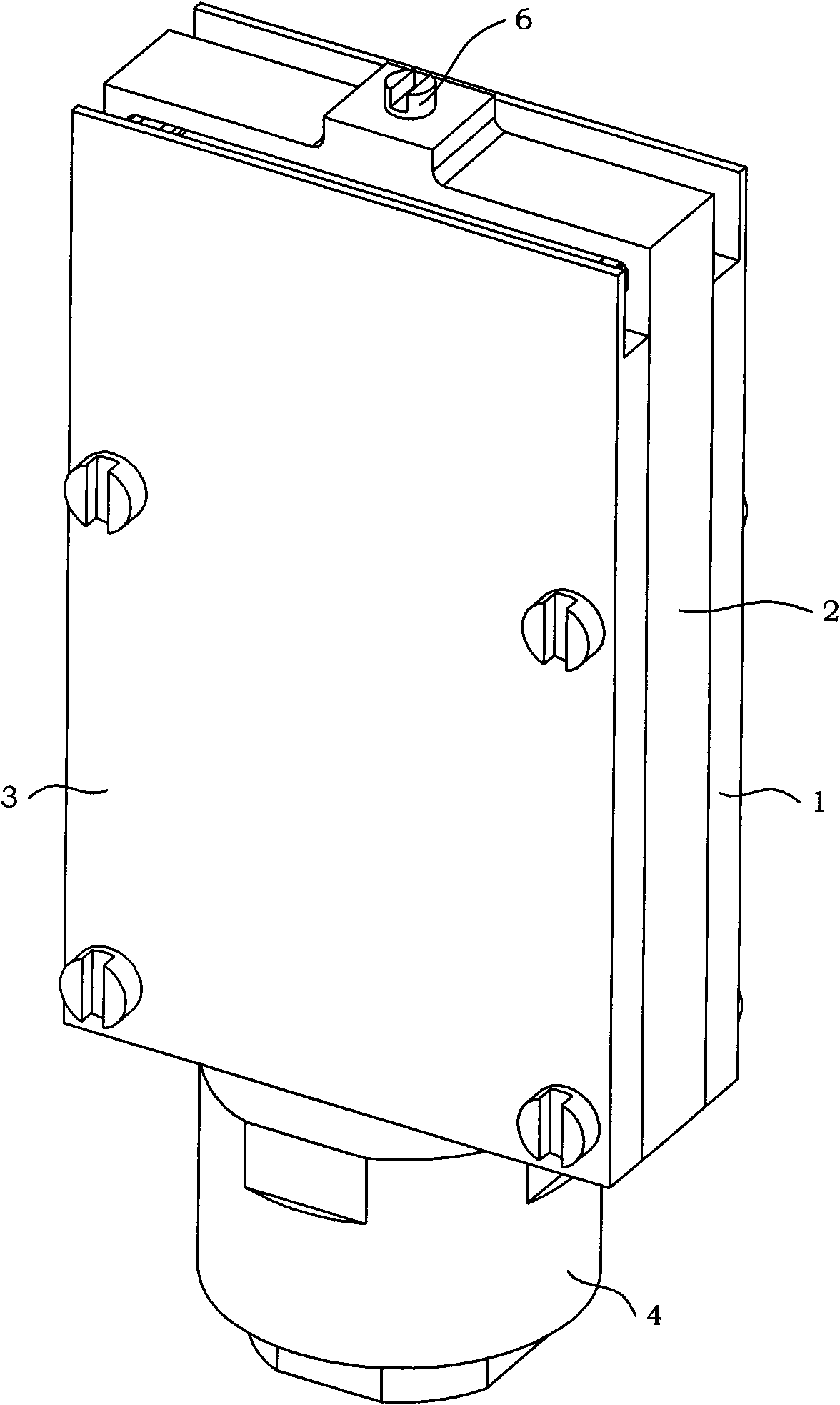

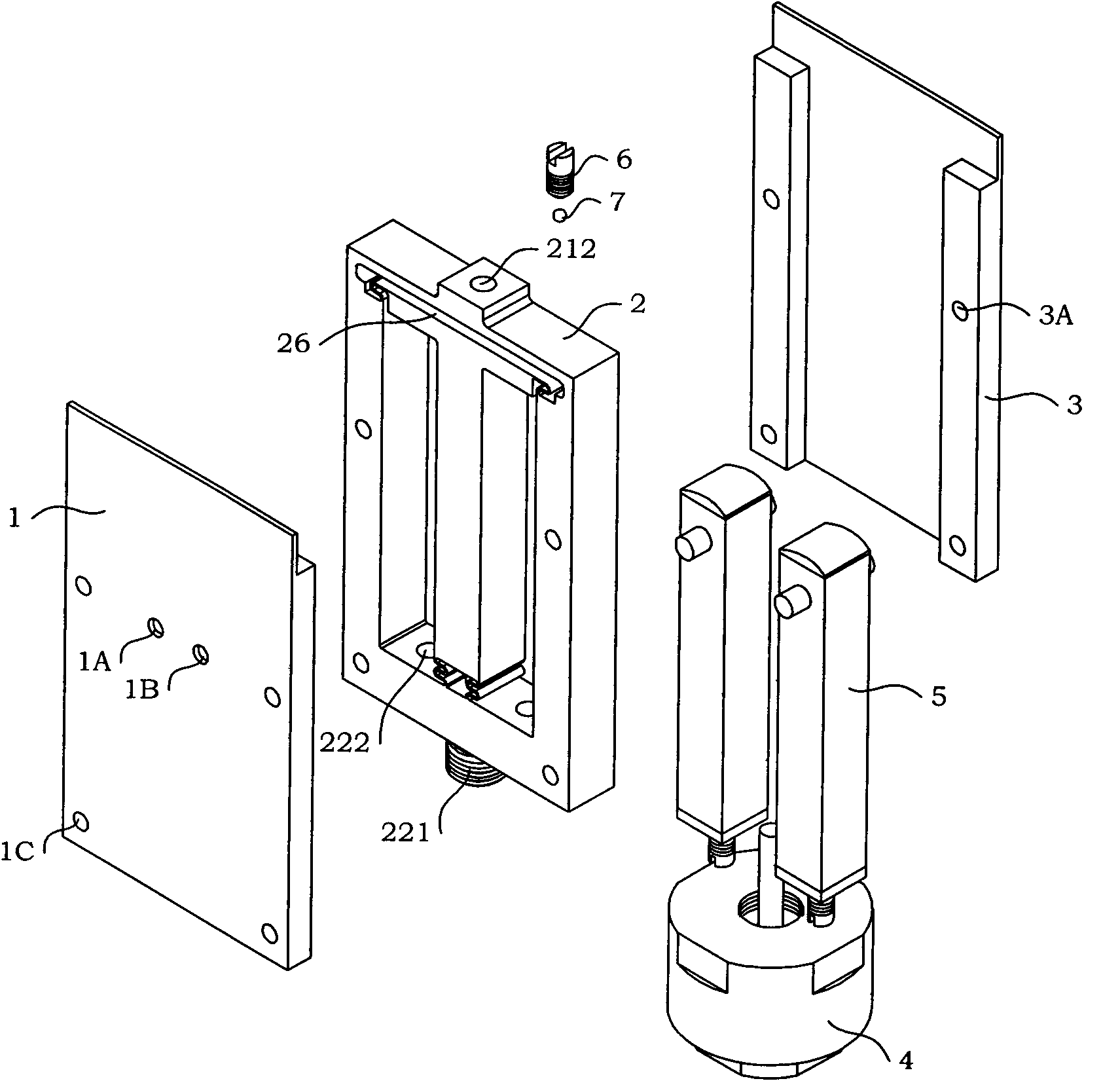

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0051] The piezoelectric valve designed by the present invention adopts a micro-manufacturing process to manufacture the key sealing parts spool 410 and valve seat 411 in the valve body assembly 4, and the rest of the valve body assembly 4 is manufactured using a traditional manufacturing process; a flexible support is manufactured using a traditional manufacturing process T-shaped flexible member 25 in 2, and three hinges. The sealing key parts made by the micro-manufacturing process overcome the difficulty of the small displacement of the piezoelectric actuator 5, and can ensure that the valve body assembly 4 has good sealing performance and high control accuracy, and can reduce the valve body to a certain extent. The volume and quality of the body assembly 4; the flexible bracket 2 and the rest of the valve body assembly 4 made by tradition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com