Ignition circuit for solid micro-propeller and manufacturing method of ignition circuit

An ignition circuit and micro-propeller technology, applied in jet propulsion, mechanical equipment, machine/engine, etc., can solve the problems of high ignition voltage and high ignition power, and achieve the effect of improving consistency and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

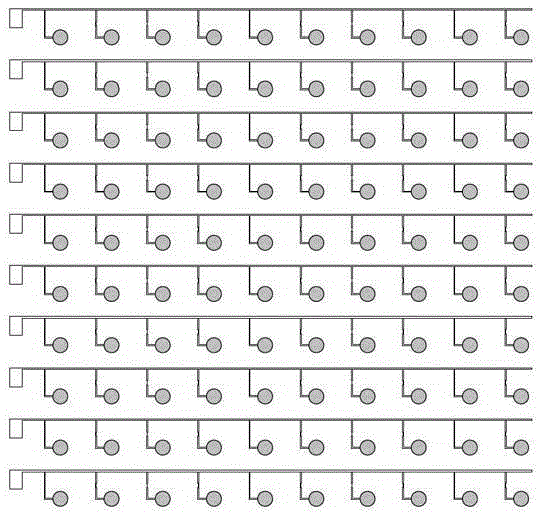

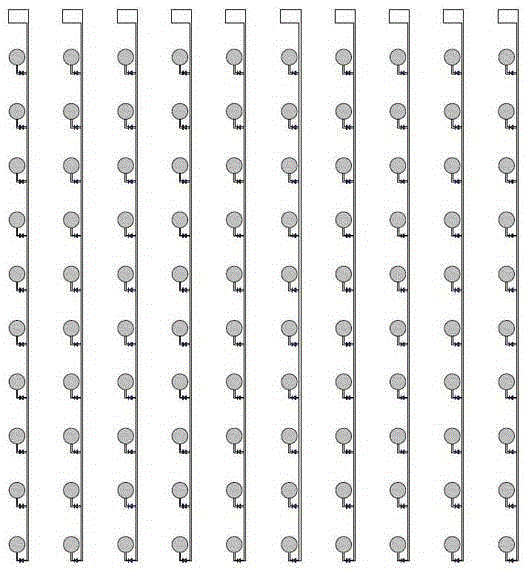

[0036] A kind of ignition circuit for solid micro-propeller of the present invention, as Figure 1 to Figure 5 As shown, the ignition circuit is set on the substrate (the substrate is in Figure 1~5 are omitted), the ignition circuit is a propulsion array with 10 rows and 10 columns consisting of 10×10 ignition units. Each ignition unit includes an ignition resistor 1 and a diode 2, the ignition resistor 1 is a NiCr alloy film resistor, the ignition resistor 1 is arranged on the front of the substrate, the diode 2 is arranged on the back of the substrate, and a 10×10 a metallized via hole 3, the ignition resistor 1 in each ignition unit is connected in series with the diode 2 on the back of the substrate through the corresponding metallized via hole 3, and is used to realize the electrical interconnection between the ignition resistor 1 and the diode 2 even.

[0037] In this embodiment, one end of the ignition resistor 1 is connected to one end of the diode 2, the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com