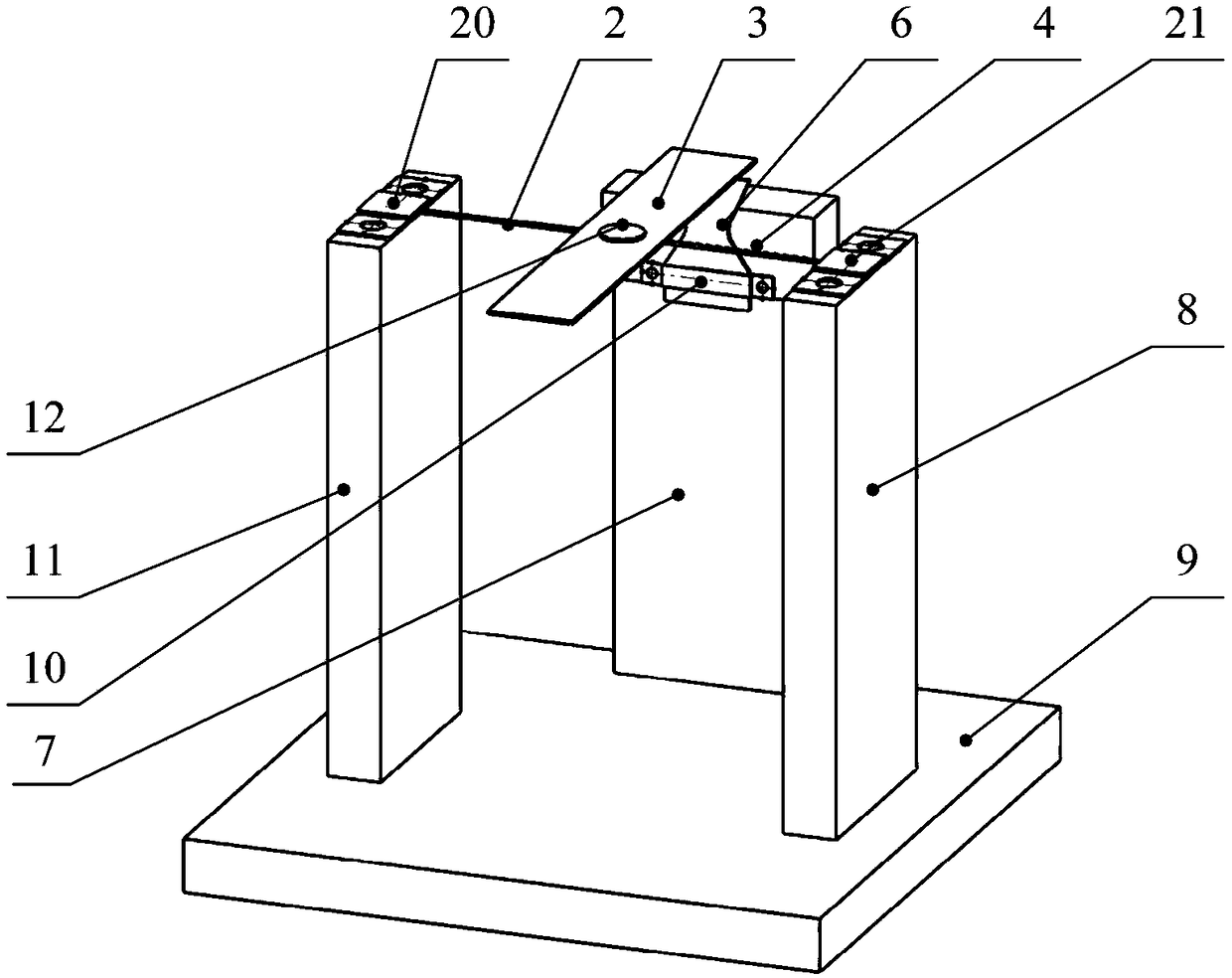

Micro-thrust measuring device that employs silicon torsion spring

A measuring device and micro-thrust technology, which are applied in measuring devices, force/torque/work measuring instruments, and force measurement by measuring the change of optical properties of materials when they are stressed, which can solve the difficulty of calibration and the influence of friction force measurement accuracy. and other problems, to achieve the effect of high sensitivity and simple and easy calibration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0037] The silicon torsion spring in the present invention can be made from a silicon wafer by a wet etching method, and the specific process flow is as follows:

[0038] (a) Attached Figure 7 , cleaning the silicon wafer 22, and drying;

[0039] (b) Attached Figure 8 , oxidized at a furnace temperature of 1000 ° C for about 20 minutes, and oxidized a layer of silicon dioxide 23 on the surface of the silicon wafer 22;

[0040] (c) Attached Figure 9 , deposit a layer of silicon nitride 24 of about 0.6 μm-0.8 μm on the surface of silicon dioxide 23;

[0041] (d) Attached Figure 10 , preheating the silicon wafer 22 at 200°C for 20min, then spin-coating a positive photoresist 25 with a thickness of about 2μm-3μm, and pre-baking at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com