Continuous production method of undercalcined magnesia kiln

A light-fired magnesia and production method technology, which is applied in the production of magnesia and lime, can solve the problems of reducing the service life of refractory linings and furnace bars, affecting the production efficiency of kilns, and large temperature fluctuations, so as to improve the firing rate. The effect of product quality and production efficiency, avoiding heat loss, and complete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

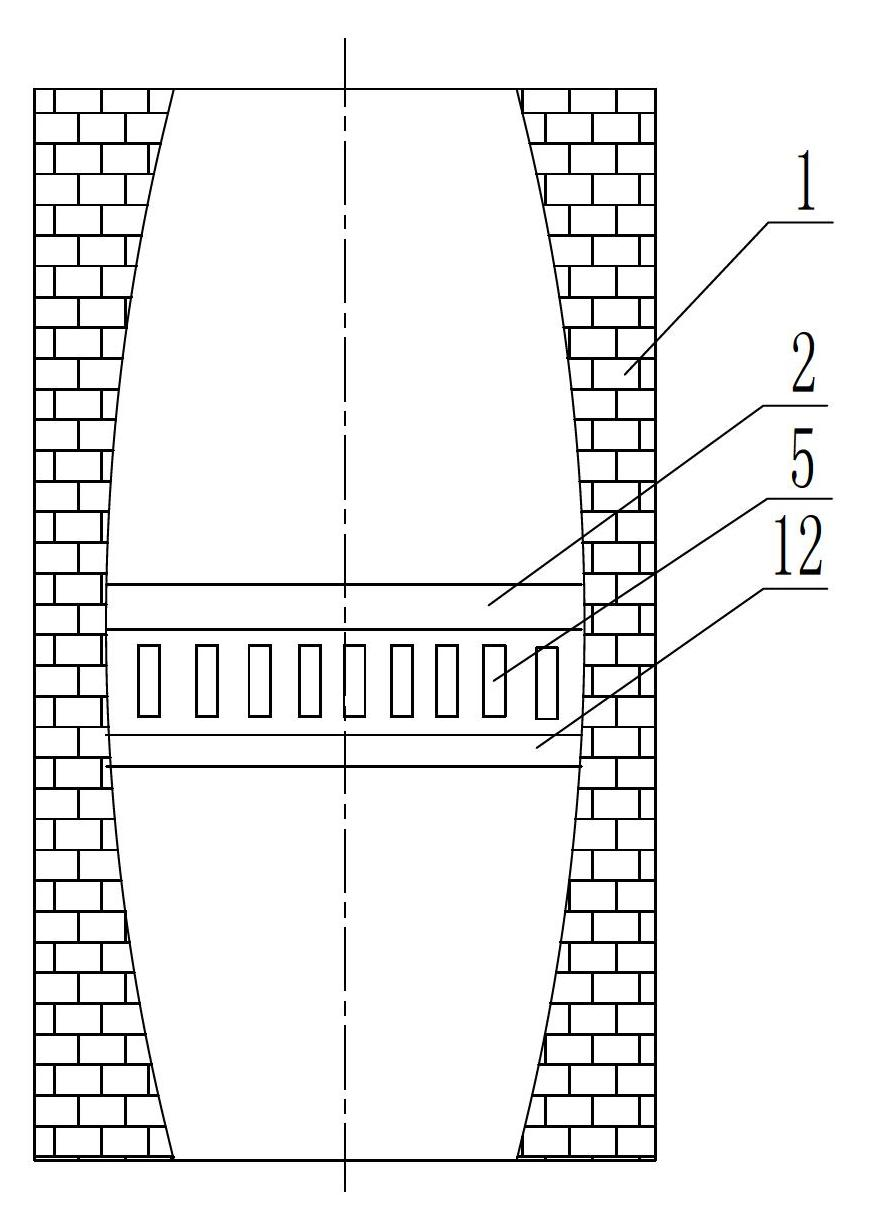

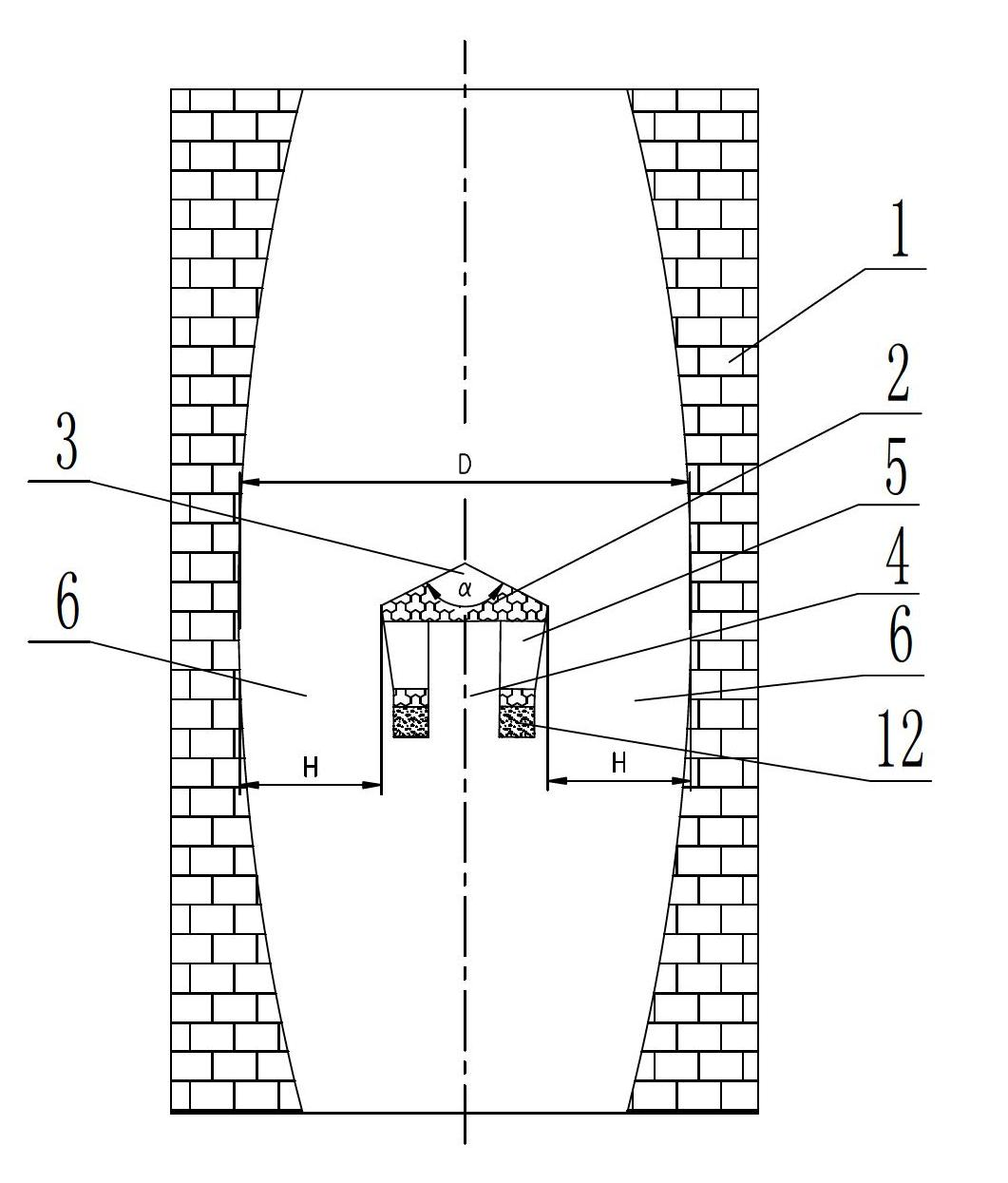

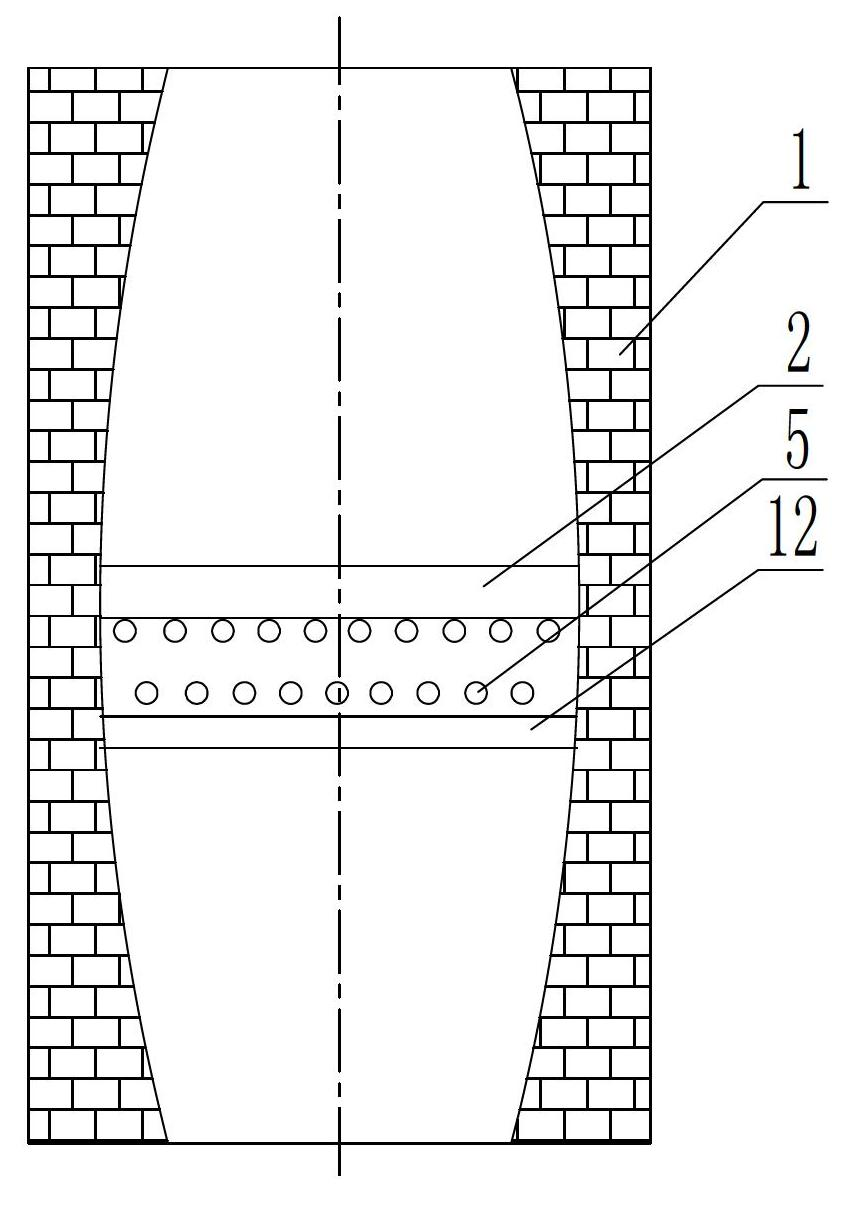

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0030] See figure 1 , figure 2 , is a structural schematic diagram of a light-fired magnesia kiln embodiment of the present invention, a tunnel burner 2 is arranged in the vertical furnace body 1, and the burner 2 is seated on the lintel 12, and the two ends of the lintel 12 are connected to the furnace body 1 respectively. The inner walls are connected, and a discharge channel 6 is respectively set between the two sides of the burner 2 and the inner wall of the furnace body 1, and the fired material is automatically moved down through the discharge channel 6, thereby realizing continuous production. The burner 2 is 50-200cm high, and the top of the burner 2 is provided with a sharp ridge 3 along the length direction of the burner, and the angle α between the sharp ridge 3 is 120°; A spout 5 communicating with the gas channel is provided. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com