Gas generating agent for gas generator and manufacturing method thereof

A technology of gas generating agent and gas generator, applied in the field of gas generating agent, can solve the problems of many process control links, many material components, unfavorable cost, etc., and achieve the effects of wide source, fast gas production speed, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

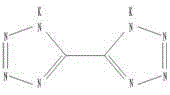

Image

Examples

Embodiment 1

[0055] 23% bistetrazole potassium salt; 71% modified ammonium nitrate, wherein the content of potassium nitrate in the modified ammonium nitrate is 12%; 6% pottery clay; add the powder into the mixer in turn, use ceramic balls as the mixing medium, and mix , the mixing time is 120min, and a uniform powder is obtained after mixing; the dry granulation process is used for granulation, and after granulation, a 100-ton hydraulic press is used for pressing the medicine, and after pressing, place it in an oven at 75°C±2°C for 35 hours to dry; Then the tablets were taken for DSC analysis at -40°C to 160°C, and the endothermic peak appeared at 116°C. Then put the tablet into the gas generator, heat it at -35°C, +23°C, and +85°C for 4 hours and then ignite it. The outgassing time is less than 100 milliseconds, there is no obvious residue, and the generator is complete.

Embodiment 2

[0057]25% potassium salt of bistetrazole; 65% modified ammonium nitrate, wherein the content of potassium nitrate is 10%; 5% talcum powder; 5% potassium chlorate; add the powder into the mixer in turn, use ceramic balls as the mixing medium, and mix. The mixing time is 120 minutes, and a uniform drug powder is obtained after mixing; the granulation is carried out by using the water-soluble spray drying granulation process, and the heating temperature is 150°C. Leave to dry for 35 hours; then take the tablet for DSC analysis at -40°C to 160°C, and the endothermic peak appears at 114°C. Then put the tablet into the gas generator, heat it at -35°C, +23°C, and +85°C for 4 hours and then ignite it. The outgassing time is less than 100 milliseconds, there is no obvious residue, and the generator is complete.

Embodiment 3

[0059] 17% potassium salt of bistetrazole; 68% modified ammonium nitrate, wherein the content of potassium nitrate is 10%; 5% white carbon black; 10% potassium perchlorate; the powder is added to the mixer in turn, and the ceramic ball is used as the mixing medium to carry out Mixing, the mixing time is 120 minutes, after mixing, a uniform powder is obtained; the water-soluble spray drying granulation process is used for granulation, and the heating temperature is 160°C. Place in an oven for 35 hours to dry; then take the tablet for DSC analysis at -40°C to 160°C, and the endothermic peak appears at 115°C. Then put the tablet into the gas generator, heat it at -35°C, +23°C, and +85°C for 4 hours and then ignite it. The outgassing time is less than 100 milliseconds, there is no obvious residue, and the generator is complete.

[0060] In a word, the present invention completely burns the nitrogen gas generating agent, and at the same time produces a large amount of gas; it has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com