Industrial briquette for molten iron production and gas generator and preparation method thereof

A technology for producing gas and briquette, which is applied in the field of industrial briquette and its preparation, can solve the problems of corrosion of production equipment and use equipment, difficulty in pipeline transportation, etc., and achieves the effects of convenient addition, saving equipment investment and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

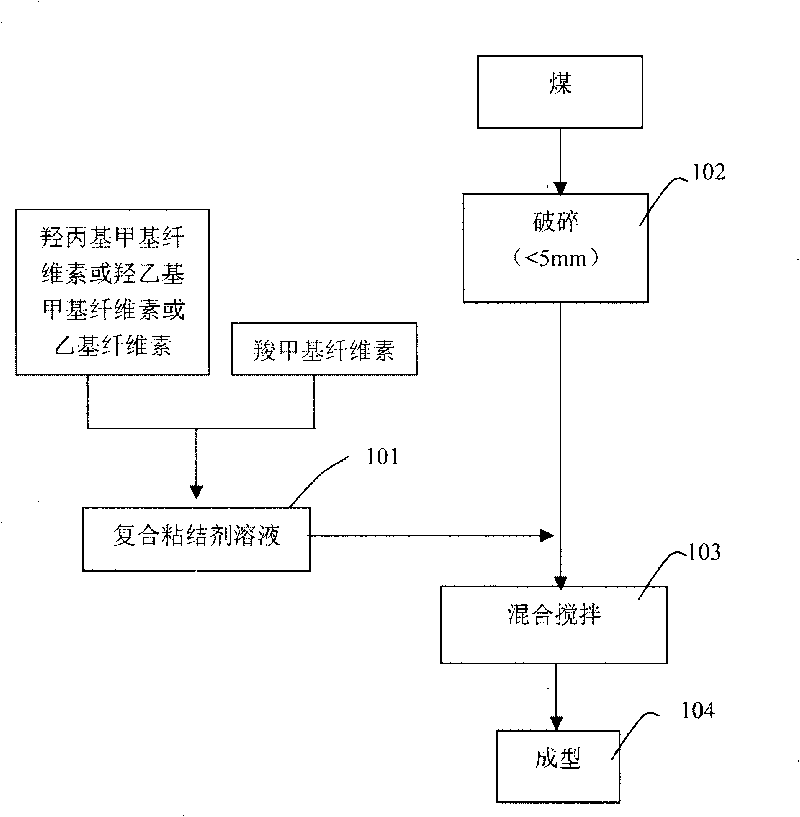

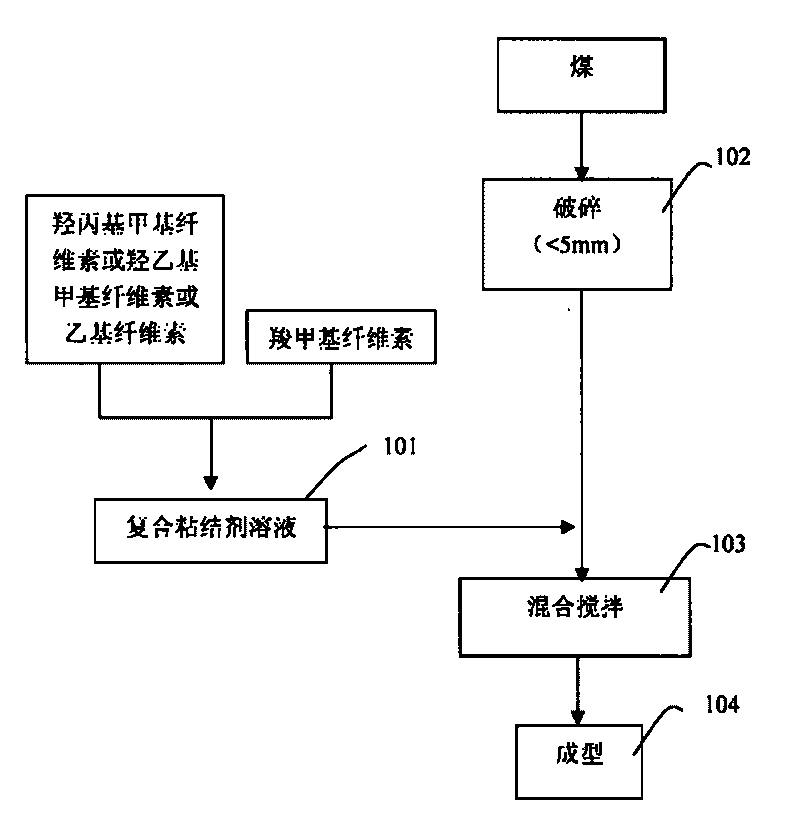

[0022] see figure 1 , the preparation method of the industrial briquette that is used for molten iron production or gas-making of the present invention, it comprises the steps:

[0023] 1. Preparation of composite binder: carboxymethyl cellulose and hydroxypropyl methyl cellulose or hydroxyethyl methyl cellulose or ethyl cellulose are compounded into a 0.5-5.0% aqueous solution; in this aqueous solution, carboxymethyl cellulose Methyl cellulose accounts for 0.3~3%, hydroxypropyl methyl cellulose or hydroxyethyl methyl cellulose or ethyl cellulose accounts for 0.2~2%, by mass percentage; (step 101)

[0024] 2. Coal powder preparation: after crushing and sieving, obtain coal powder with a particle diameter below 5mm; (step 102)

[0025] 3. Mix the composite binder with the coal powder, stir evenly (step 103), and press into a certain size of briquette by a double-roll forming machine (step 104).

[0026] The drop strength is used as an index to measure the quality of coal briq...

Embodiment 1

[0028] The composite binder is composed of carboxymethylcellulose CMC450 and hydroxypropylmethylcellulose HPMC. Firstly, CMC450 and HPMC were made into solutions with a concentration of 6% and 4%, respectively, and then the two solutions were mixed in a ratio of 1:1 to form a composite binder. Every 100 parts by weight of coal powder is mixed with 10 parts by weight of the composite binder and stirred evenly, and then the coal is molded by a molding machine.

[0029] After testing, the crush resistance of the briquettes is 90.1% after being formed for 4 hours.

Embodiment 2

[0031] The composite binder is composed of carboxymethylcellulose CMC450 and hydroxypropylmethylcellulose HPMC. First, 95 parts by weight of water, 3 parts by weight of CMC450 and 2 parts by weight of HPMC were mixed to make a composite binder. Every 100 parts by weight of coal powder is mixed with 10 parts by weight of the composite binder and stirred evenly, and then the coal is formed by a forming machine.

[0032] After testing, the crush resistance of the briquettes after 2 hours of molding is 93.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com