Device for deep recovering light oil from dry distillation gas

A recovery device and a technology for dry distillation of gas, which are applied in the recovery of liquid hydrocarbon mixtures, the treatment of hydrocarbon oil, and the petroleum industry. It can solve the problems of inability to recover light oil and waste of resources, and achieve low resistance, high oil recovery efficiency, and good benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

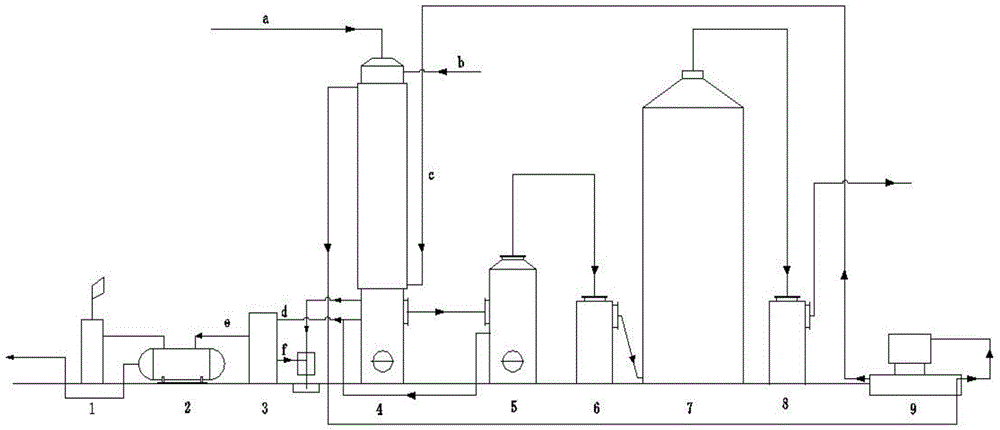

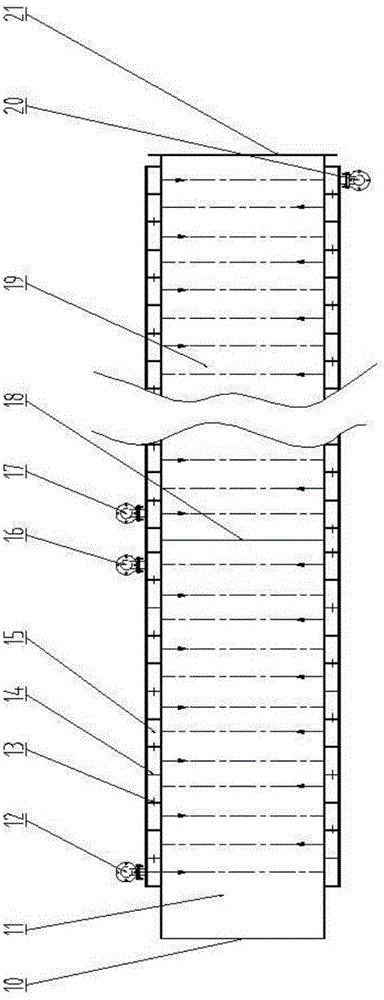

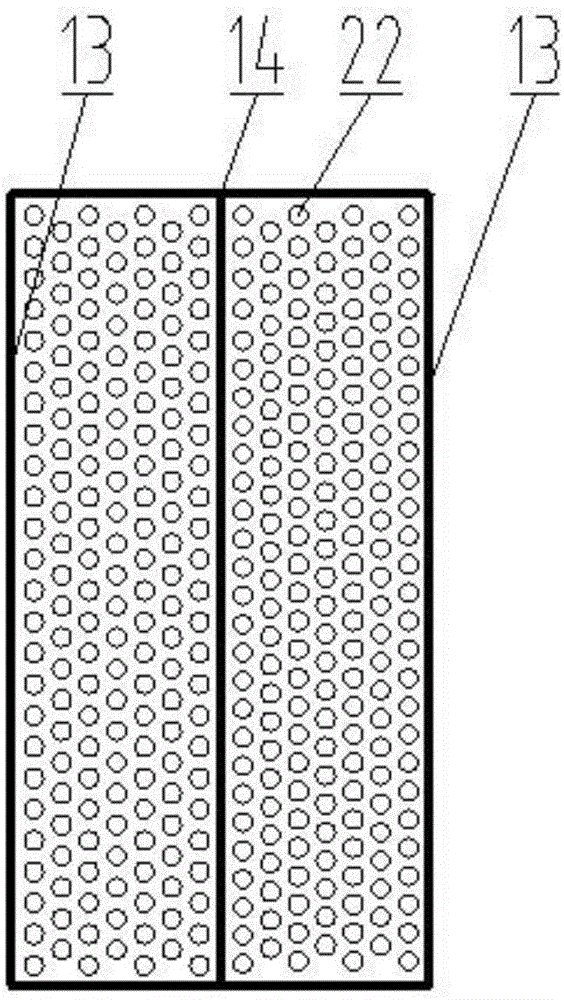

[0037]The technical solution adopted by the embodiment of the present invention to solve the technical problem is: use the refrigeration cycle to lower the temperature of the dry distillation gas tail gas, condense the light oil and water vapor in the tail gas, and then separate the oil from water to recover the light oil. The device of the present invention includes: a breathing tank, an intermediate oil tank, an oil-water separator, a high-efficiency heat exchanger, an oil mist filter, a cooling tower, a steam type lithium bromide absorption refrigeration unit, an oil pump, a cooling tower feed water pump, and a circulating water pump. Considering that the current systems used by semi-coke and oil shale enterprises include electric tar catchers, the process of the present invention also includes electric tar catchers. In fact, high-efficiency heat exchangers and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com