Method and system for purifying dust-containing and water-containing high-temperature oil gas to recover oil

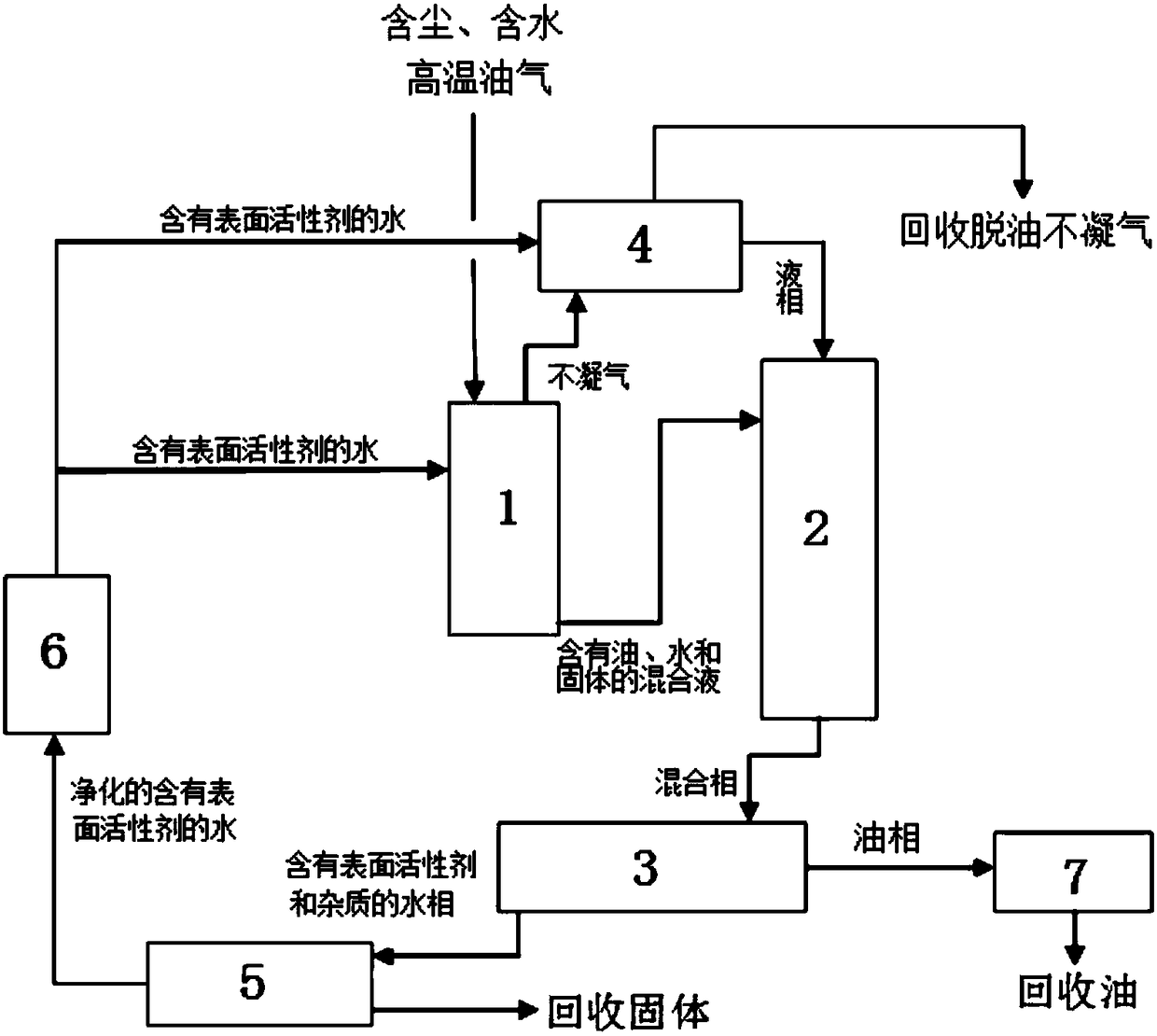

A technology for recovering oil and high temperature, which is applied in the fields of recovering oil from water-containing high-temperature oil and gas, and purifying dust. It can solve the problems of high solid content in recovered oil, incomplete separation of oil and water, and easy clogging of filters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

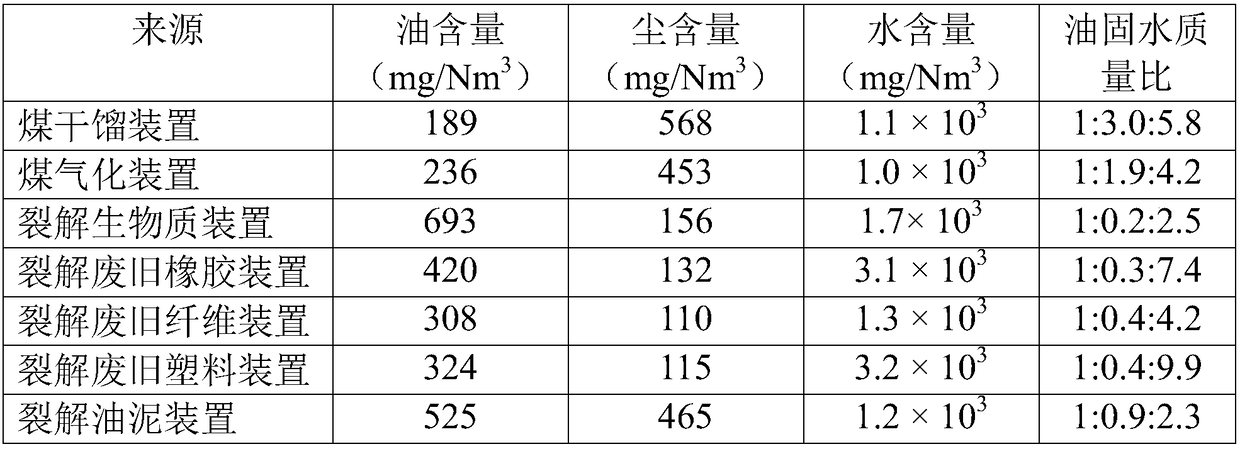

[0074] (1) Pass high-temperature oil and gas (from the coal dry distillation unit) into the quench tower, and spray FC-98 aqueous solution containing 0.05% mass concentration to it, and obtain a 100°C oil, water, and solid mixture after condensation, non-condensable gas Through the upper outlet on the top of the fiber liquid film contactor, it is passed into the washing tower, and after washing and cooling, the deoiled non-condensable gas (oil content 0.5mg / Nm 3 );

[0075] (2) The mixed liquid acts through the fiber liquid film contactor, and the fiber filaments in the mass transfer space cylinder of the fiber liquid film contactor are 316 series stainless steel wires. The length-to-diameter ratio of the mass transfer space of the cylinder is 20:1, the filling ratio of the cylinder is 5%, and the volume of the fiber liquid film contactor is 2L. Mix the liquid according to the feed rate of 1kg / h and the liquid hourly space velocity of 10h -1 Inject the contactor. The contac...

Embodiment 2

[0078](1) Pass high-temperature oil and gas (from the coal gasification unit) into the quench tower, and spray Zonyl FSN aqueous solution containing 0.05% mass concentration to it, and obtain a 110°C oil, water, and solid mixture after condensation, and the non-condensable gas is passed through The upper outlet at the top of the fiber liquid film contactor is passed into the washing tower, and the deoiled non-condensable gas (oil content 0.8mg / Nm 3 );

[0079] (2) The mixed liquid acts through the fiber liquid film contactor, and the fiber filaments in the mass transfer space cylinder of the fiber liquid film contactor are 316 series stainless steel wires. The length-to-diameter ratio of the mass transfer space of the cylinder is 20:1, the filling ratio of the cylinder is 5%, and the volume of the fiber liquid film contactor is 2L. Mix the liquid according to the feed rate of 1kg / h and the liquid hourly space velocity of 10h -1 Inject the contactor. The contact temperature ...

Embodiment 3

[0082] (1) Pass high-temperature oil and gas (from the pyrolysis biomass device) into the quench tower, and spray FC-006 aqueous solution with a mass concentration of 0.05% into it, and obtain a 120°C oil, water, and solid mixture after condensation, non-condensable gas Through the upper outlet on the top of the fiber liquid film contactor, it is passed into the washing tower, and after being washed with water and cooled, the deoiled non-condensable gas (oil content 0.6mg / Nm 3 );

[0083] (2) The mixed liquid acts on the fiber liquid film contactor, and the fiber filaments in the mass transfer space cylinder of the fiber liquid film contactor are glass fiber filaments. The length-to-diameter ratio of the mass transfer space of the cylinder is 30:1, the filling rate of the cylinder is 7%, and the volume of the fiber liquid film contactor is 2L. The mixed solution is 2.1kg / h according to the feeding amount, and the liquid hourly space velocity is 15h -1 Inject the contactor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com