Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88 results about "Sulfur dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfur dyes are the most commonly used dyes manufactured for cotton in terms of volume. They are inexpensive, generally have good wash-fastness, and are easy to apply. Sulfur dyes are predominantly black, brown, and dark blue. Red sulfur dyes are unknown, although a pink or lighter scarlet color is available.

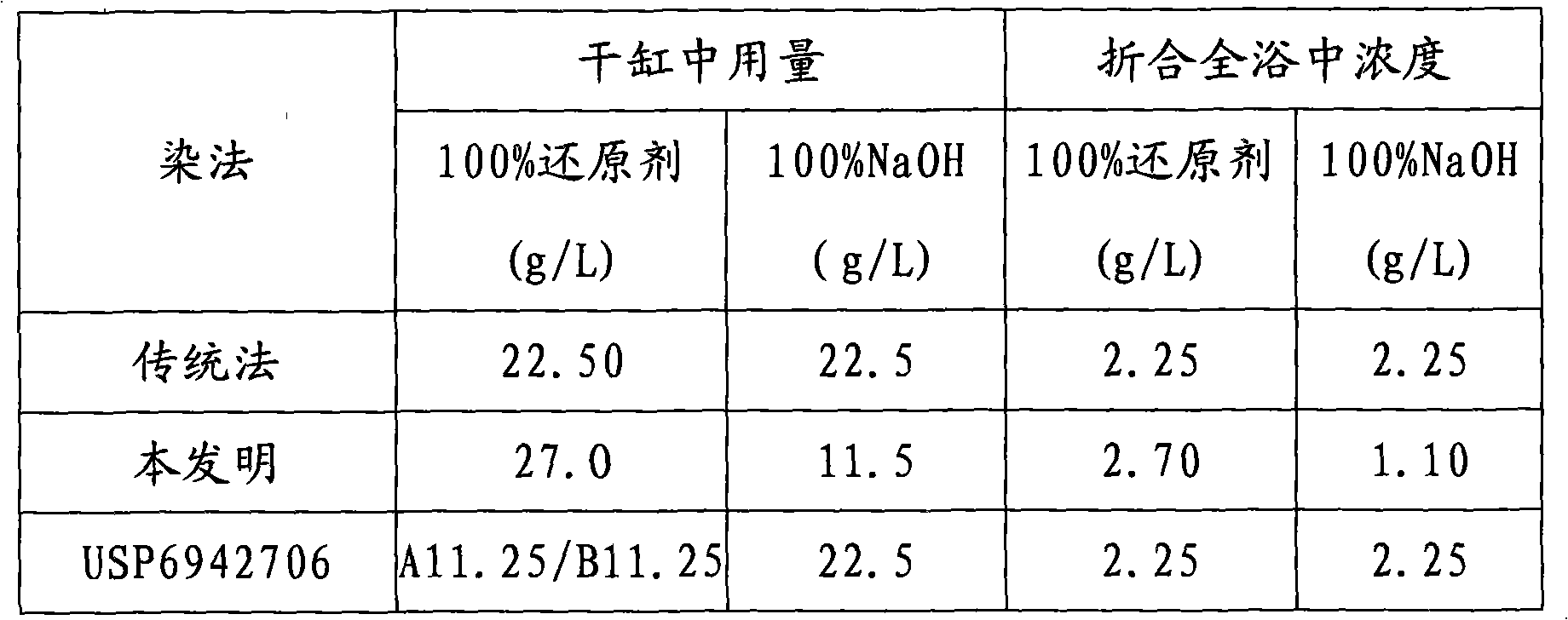

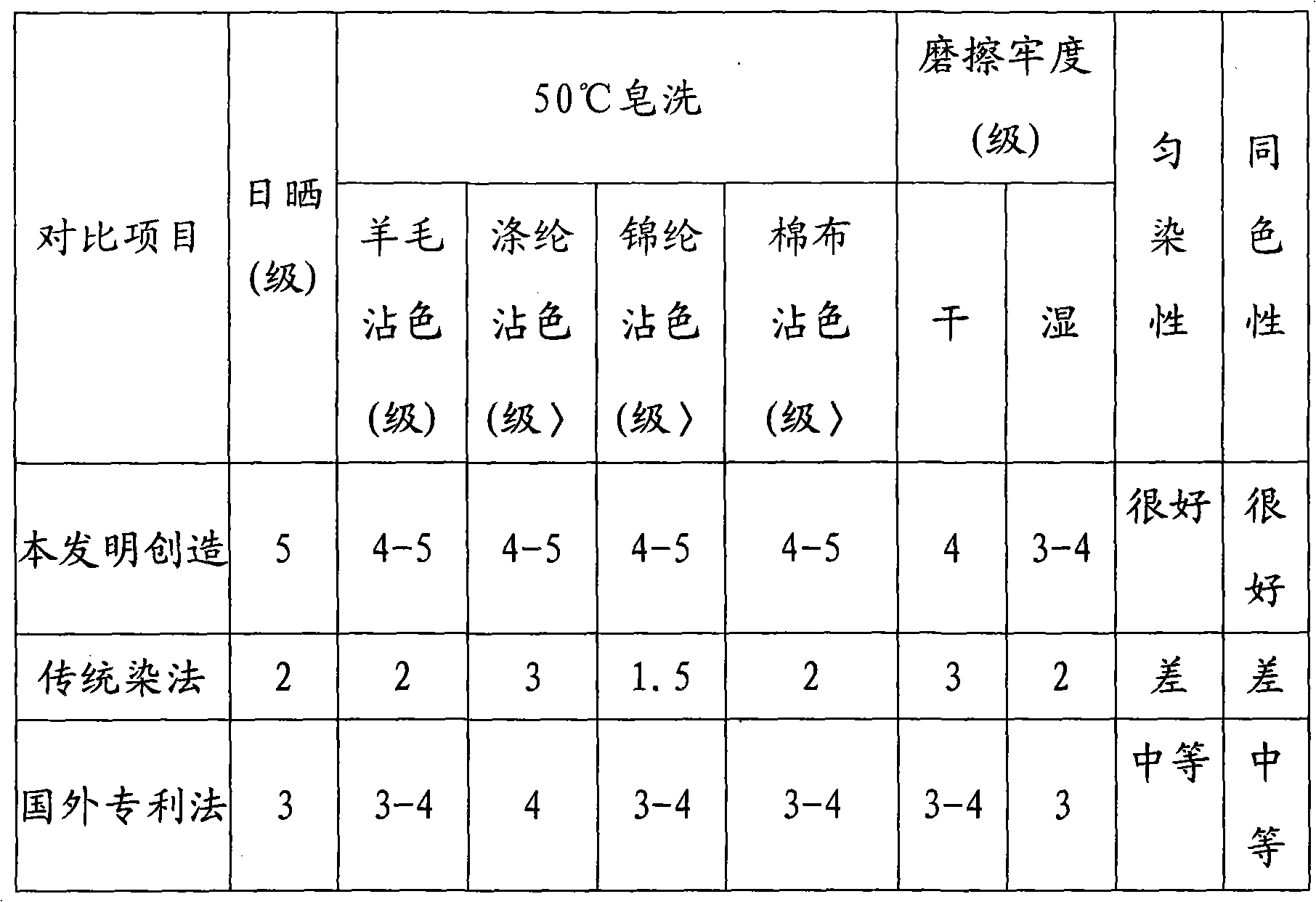

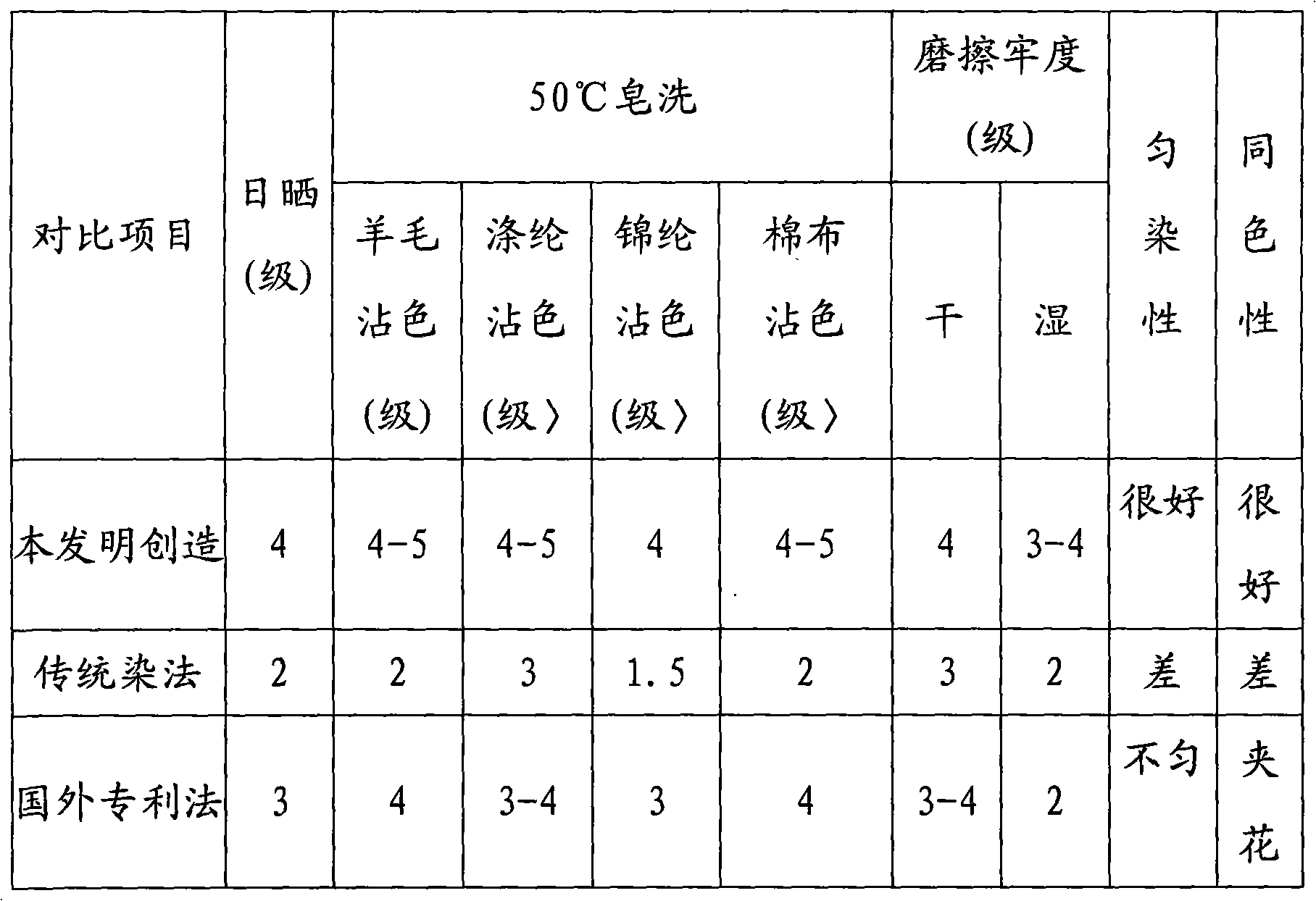

Dye compound reducing agent and method of using the same

The invention discloses a composite reducing agent for dye, comprising the following compositions in weight portion: 8 to 20 portions of vat powder, 5 to 40 portions of thiourea dioxide, and 5 to 15 portions of sodium sulfite. The invention also discloses a method for dyeing by the reducing agent, comprising the following steps that: a reducing agent and sodium hydrate are used for reducing the dye by a vatting method; the weight ratio of a reducing solution to the dye is 37.5: 0.8 to 2.0 and the mixture is for later use; a leveling agent and the fiber penetrating swelling agent are added to dye or a buffering agent is added to adjust the pH value and is dyed by vat acid, the temperature is reduced and the mixture is washed; the mixture is subjected to oxidization to develop color, fixing, reducing temperature and washing; the fresh water bath is performed, the dye composite reducing agent is reduced and washed, and the temperature is reduced and the fiber penetrating swelling agent is produced. The composite reducing agent for the dye is a special reducing agent used for reducing the dye, a sulfur dye, a perylene dye and a leuco body, and improves the stability of the leuco body, color yield percentage, the color reproducibility, the color fixation and the color evenness degree, meanwhile, the dye composite reducing agent avoids the harm of formaldehyde on the environment and the human body.

Owner:SHANGHAI TEXTILE GRP DETECTION STANDARD CO LTD

Method for preparing alkali sulphide by using sulfur dye waste gas

InactiveCN101654226AReduce emission concentrationSolve processing problemsAlkali metal sulfides/polysulfidesSodium bicarbonateReaction temperature

The invention discloses a method for preparing alkali sulphide by using sulfur dye waste gas, which is characterized in that the sulfur dye waste gas containing hydrogen sulfide is used as a raw material and added with alkali to perform reaction at the reaction temperature of between 60 and 85 DEG C, the reaction products are cooled to between 30 and 50 DEG C after the reaction reaches a final point, and the reaction products are filtered to form the alkali sulphide. The alkali added into the sulfur dye waste gas containing the hydrogen sulfide may be one or a mixture of more than two of sodium hydroxide, potassium hydroxide, sodium carbonate, sodium bicarbonate and potassium carbonate, and the ratio of the adding amount of the alkali to the weight of the waste gas is (0.8-1.4): 1. The pressure in the reaction process is -0.12 to -0.06MPa. The alkali sulphide is sodium sulphide and potassium sulfide. The method changes waste into valuable, effectively solves the problem that the sulfurdye waste gas is difficult to treat, reduces the discharge concentration of hydrogen sulfide in the waste gas, achieves the aims of environmental protection, energy conservation and discharge reduction, substance recycle and clean production, has large economic benefit and social benefit, and has the advantages of effectively reducing environment pollution and having less energy consumption.

Owner:蔡瑞琳 +2

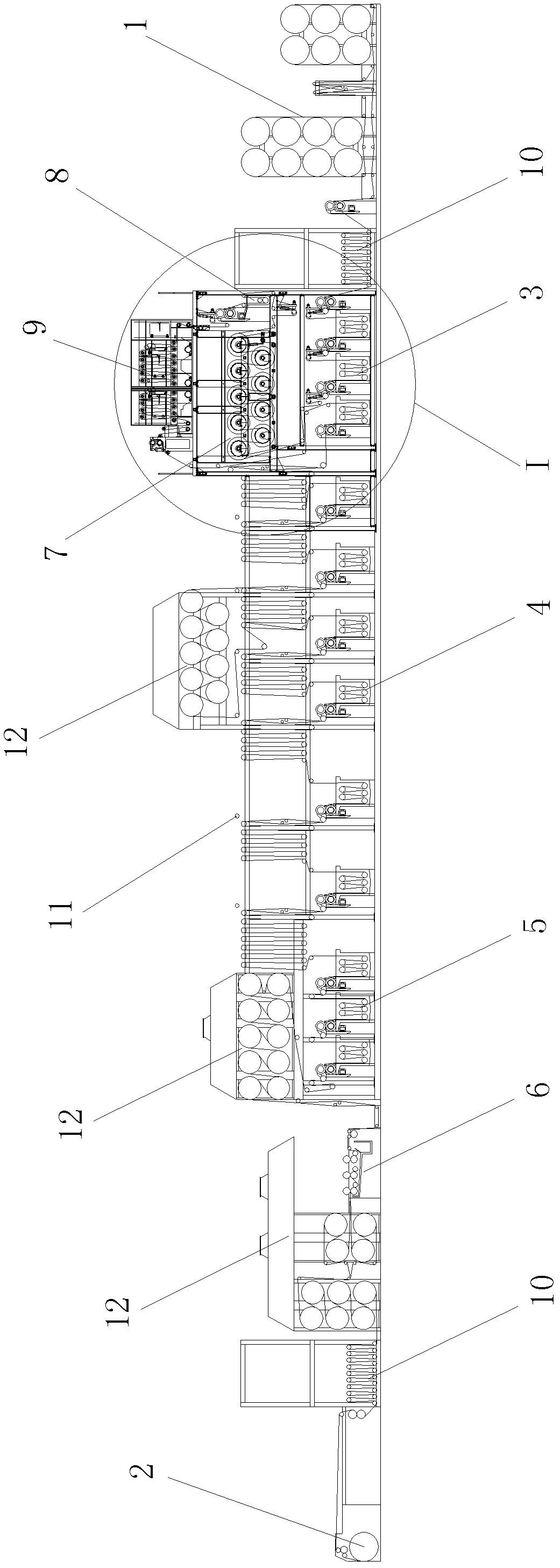

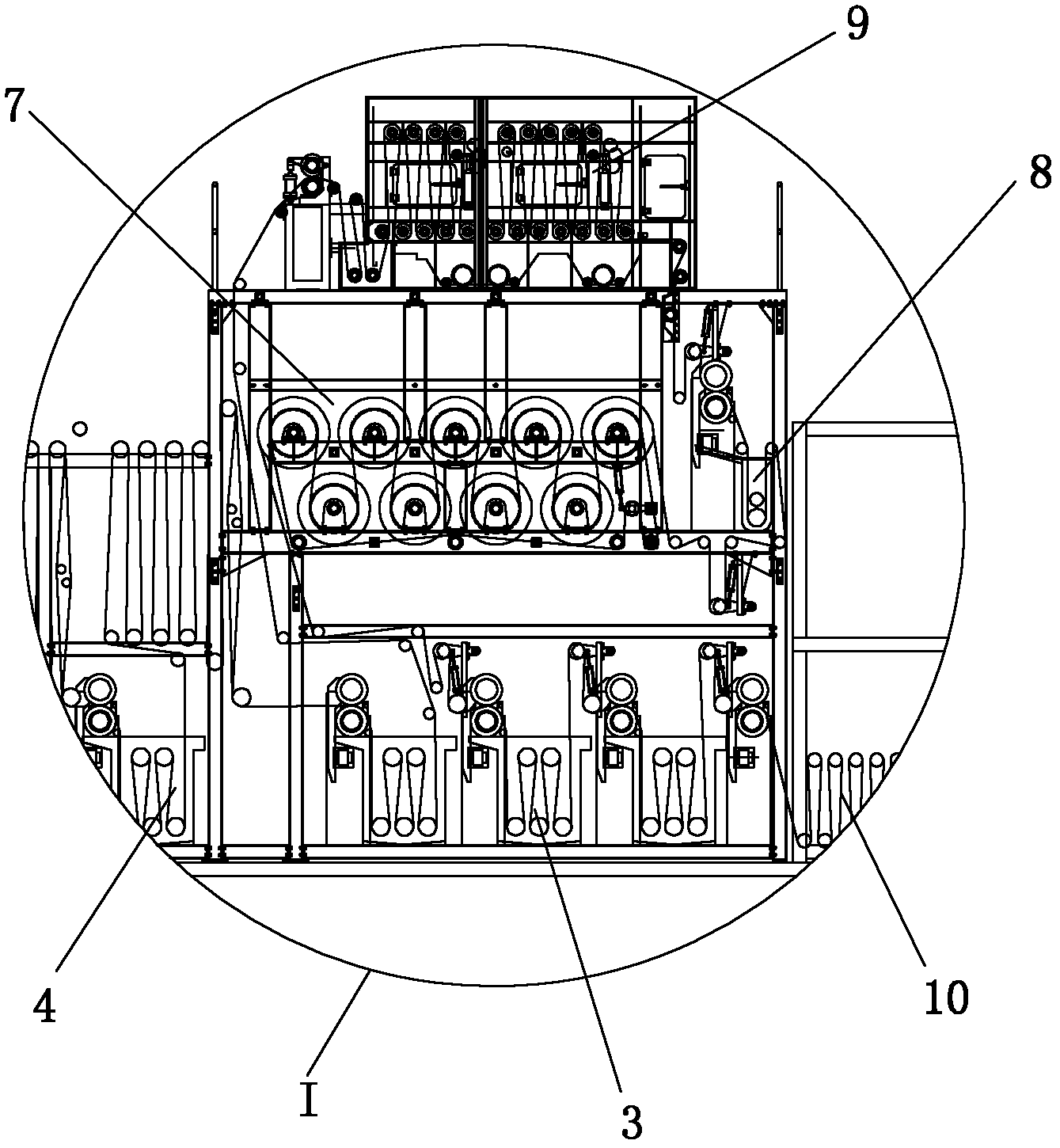

Multifunctional denim warp dyeing machine

InactiveCN102605582ARealize compound dyeingImprove dyeing effectSucessive textile treatmentsLiquid/gas/vapor removalPulp and paper industryPre treatment

The invention provides a multifunctional denim warp dyeing machine, which comprises a to-be-dyed warp rack and a dyed warp reel. A warp pretreatment tank, a warp dyeing groove, a washing tank and a slashing tank are successively arranged between the to-be-dyed warp rack and the dyed warp reel, wherein the warp pretreatment tank is used for removing impurities of warps and washing the warps, the warp dyeing tank is used for dyeing the warps by indigo dyes or sulfur dyes, the washing tank is used for washing the dyed warps, a combined drying barrel, a small colorful dyeing tank and a steaming box are successively disposed between the warp pretreatment tank and the warp dyeing tank, the combined drying barrel is used for colorfully dyeing the warps, and the small colorful dyeing tank dyes the warps by reduced dyes. The problems that when warps are dyed, a color selection range is narrow, color fastness is poor, and the warps cannot be dyed by bright-colored dyes are resolved; after the dyed warps are woven into denim, the characteristics that the warps of the denim are colorful while wefts of the denim are white can be kept; composite dyeing by the aid of the indigo dyes or the sulfur dyes can be realized, and a dyeing effect is good.

Owner:HAINING DENIM WEAVING CO LTD

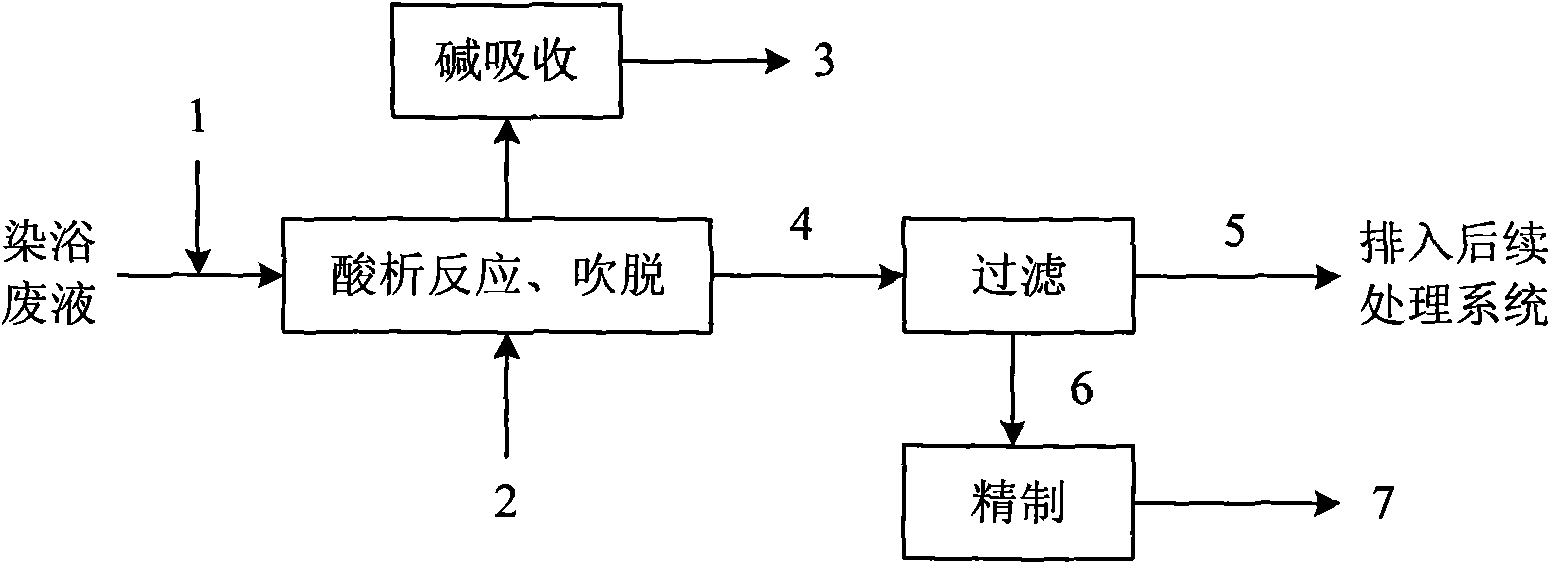

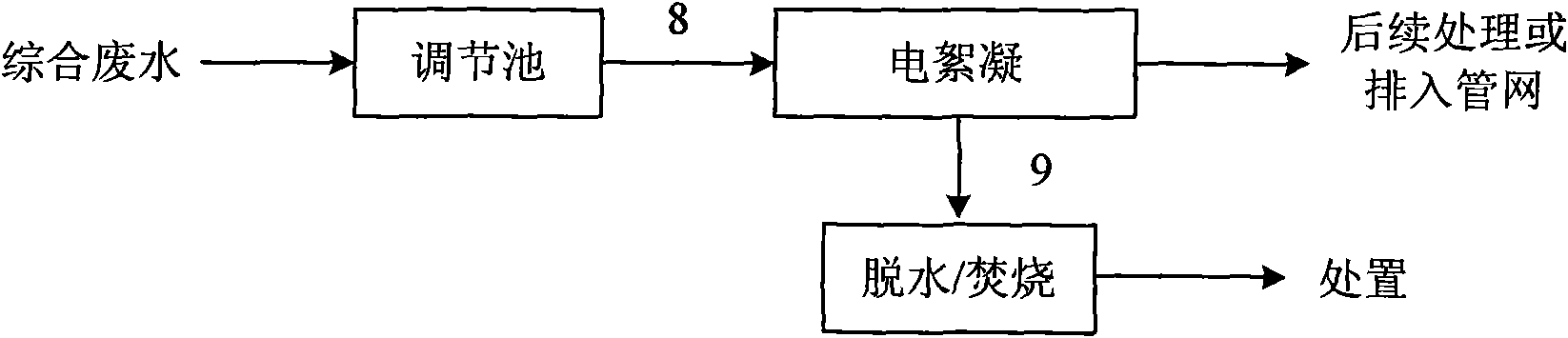

Process for comprehensively treating sulfur dye waste water

InactiveCN102399040ASimple processLess investmentMultistage water/sewage treatmentLiquid wasteHigh concentration

The invention relates to a process for comprehensively treating sulfur dye waste water. The process of the invention uses a split-flow scheme which comprises that dye bath strong liquor with high concentration can be recycled and the comprehensive waste water with low concentration can be collected. The process of the invention comprises the following steps: acidifying the dye bath strong liquor with high concentration, blowing and recovering sodium sulfide, filtering and recovering the sulfur dye, wherein the recovery rate of the sodium sulfide and the sulfur dye can respectively reach more than 85% and 95%, collecting a filtrate into a waste water treatment system for treating; pretreating the comprehensive waste water with low concentration by an electrocoagulation process and discharging or carrying out biochemical treatment. Compared with the current art, the process of the invention has the advantages of high resource recovery rate, simple flow, less equipment, less land occupation, simple operation and maintenance and the like, and is suitable for recycling and treating the sulfur dye waste water.

Owner:SHENYANG POLYTECHNIC UNIV

Method for treating sulfides in waste streams

ActiveUS20170073257A1Non toxicWaste water treatment from quariesWater treatment compoundsWaste streamWastewater

A method for treating sulfide in an aqueous fluid comprises contacting the fluid with an oxidizer in the presence of a sulfur dye or sulfurized vat dye. In one embodiment, the method comprises treating sulfide contaminated water by contacting the contaminated water with air in the presence of a sulfur dye or a sulfurized vat dye. The method is useful for remediating industrial, agricultural, and municipal waste water.

Owner:BILL ARCHER LLC

Stabilized aqueous polymer compositions and their use

Disclosed are stabilized aqueous polymer compositions containing A) a stabilizing amount of a least a sulfur dye or containing a stabilizing amount of a sulfur dye with a compound comprising a heterocyclic system containing nitrogen and sulphur as ring heteroatoms and B) at least one polymer comprising groups which are capable of complex formation with ions. The aqueous polymer compositions are stabilized against thermal or other degradation processes of the polymer by addition of component A) to allow their use even under harsh conditions.

Owner:TOUGAS OILFIELD SOLUTIONS GMBH

Dyeing processing method of knitted denim fabric

ActiveCN106245354AHigh color fastnessGood dimensional stabilityFibre treatmentTwo or more solvent application treatmentEngineeringSulfur dye

The invention discloses a dyeing processing method of a knitted denim fabric. The method is characterized in that the whole dyeing process specifically includes the steps of: knitting, pretreatment, pre-fixation, dyeing, dehydration, scotching, drying, color fixing and shaping. Through treatment of the knitted denim fabric with pre-fixation, dyeing, and color fixing and shaping three processes, the reduction process necessary to the traditional of sulfur dye is abandoned, the whole dyeing processing does not involve sulphide, simplifies and omits some necessary processes and a lot of environmentally-unfriendly chemical products required by the traditional process, the whole dyeing processing process is short and efficient, energy saving and environment-friendly, and the processed knitted denim fabric has rich and soft colors, stable cloth cover quality, novel and unique appearance, and has good visual and tactile affinity.

Owner:SHENGZHOU SHENGTAI KNITTING

Distressed processing method for colored fabric

ActiveCN101748601AAdd cationic modificationEvenly colored surfaceFibre treatmentDyeing processRing dyeingTreatment effect

The invention discloses a distressed processing method for colored fabric, which is characterized in that a cation modification technology of yarn is added before the traditional yarn dyeing processing technology, so that the whole processing technology comprises the following steps in sequence: yarn preparation, cation modification of yarn, yarn dyeing processing, sizing, preshrinking, washing and finished products. The distressed processing method has the advantages that the surface layer of the yarn colors up uniformly, and the inner layer of the tarn maintains the original white core, so a clear skin - core effect is formed; the processed fabric has uniform ring dyeing and a uniform distressed treatment effect; by the combination application of a cation modifier and reactive dyes, the dyed fabric achieves the effect which sulfur dyes or indigo dyes can just achieve; and the distressed processing method greatly reduces energy consumption, reduces environmental pollution, ensures the stability and the production efficiency of dyeing, and enhances the quality of products.

Owner:浙江盛泰服装集团股份有限公司

Dyeing process using reducing and bleeding

InactiveCN101768876ASatisfaction with faded distressed casual styleHeating/cooling textile fabricsDyeing processState of artEngineering

The invention discloses a dyeing processing using reducing and bleeding, which is realized by the following scheme: obtaining semi-finished product of plain white cloth, and working procedures of padding dye solution, steaming, washing, oxidizing, soaping, washing, drying, padding and softening, tentering, shrinking and obtaining a finished product. Another drying working procedure and the working procedure of padding reducing solution are sequentially added between the working procedures of padding dye solution and the steaming; and dye used by the working procedure of padding dye solution is a mixture of reducing dye the weight ratio of which is 2:3-3:2 and sulfur dye. By the invention, the reducing dye with excellent color fastness and sulfur dye which is easy to bleed are mixed and compounded according to a certain proportion to obtain new bleeding and reducing dye; and two kinds of dye can be simultaneously dyed on the cloth cover by adding a reducing agent suitable for the sulfur dye in a reducing solution prescription and using a one-step dyeing method. Compared with the prior art, clothes made of fabrics dyed by the process can obtain satisfied bleeding, traditional and leisure style after being subject to simple washing with enzyme; and in addition, the light fastness in the medium-light colors can reach 3-4 levels.

Owner:FUJIAN XIESHENG XIEFENG PRINTING & DYEING IND CO LTD

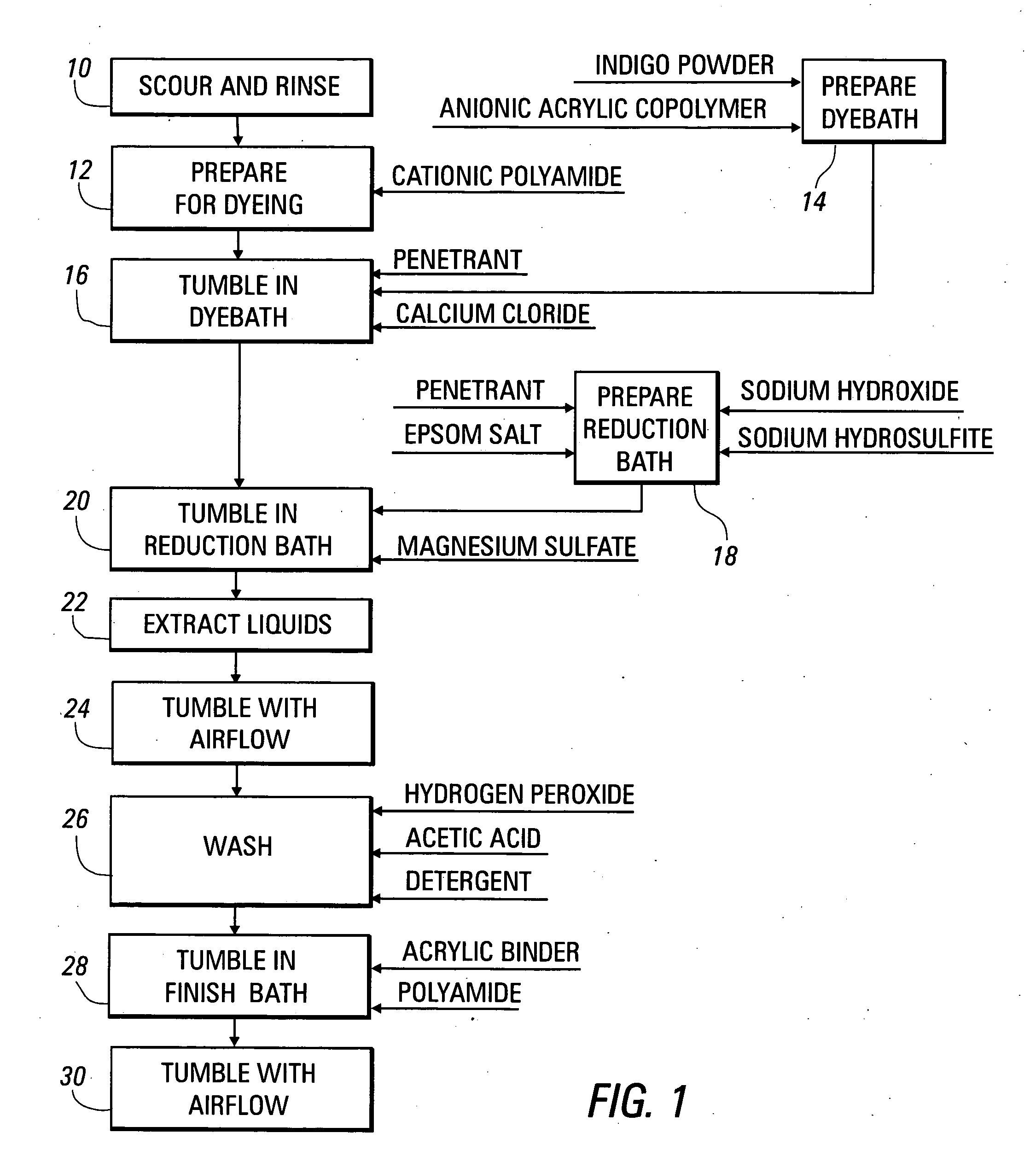

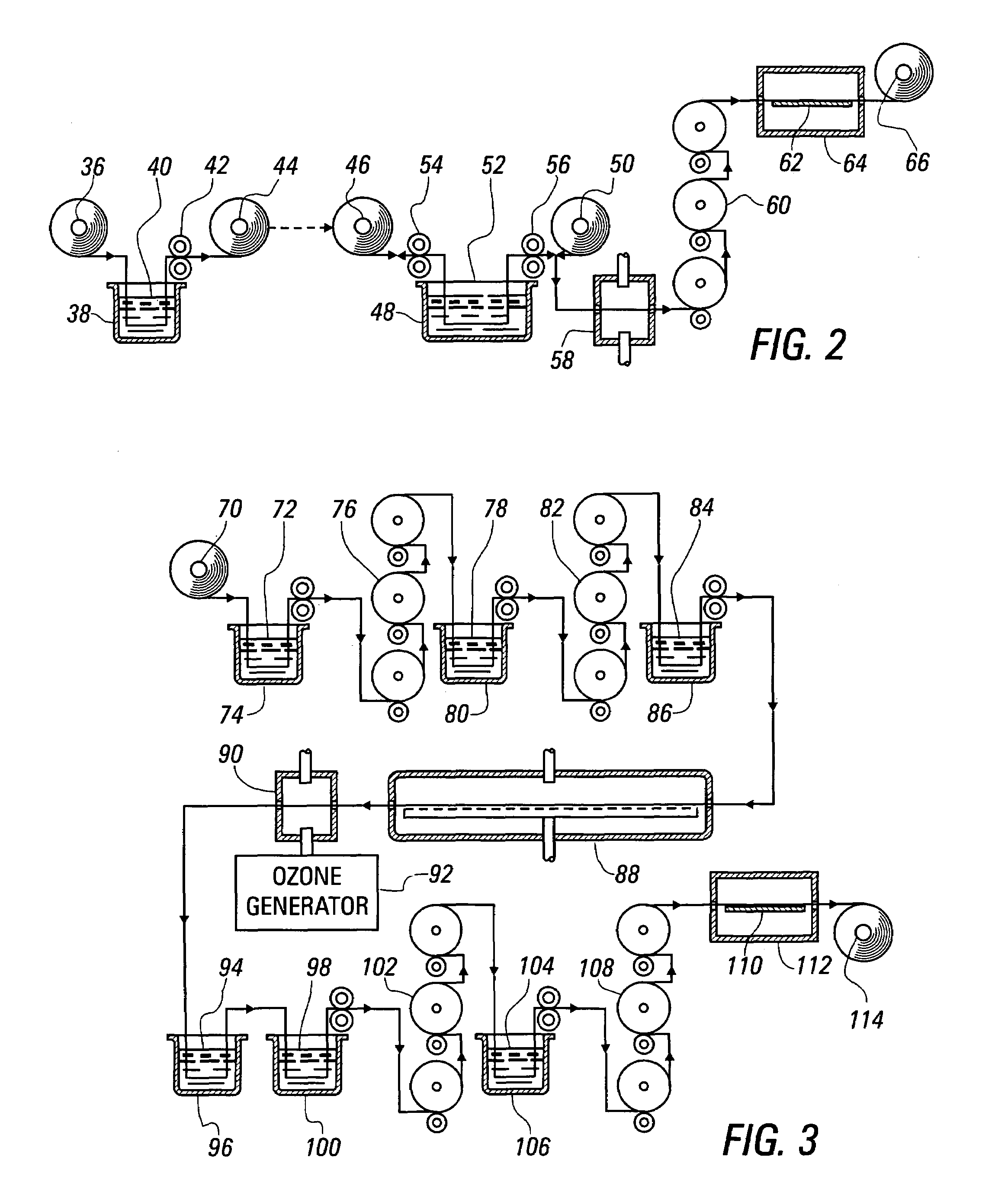

Method for dyeing fabric materials with indigo, other vat dyes, and sulfur dyes

A method for surface dyeing a range of textile materials, in the form of yarn, fabric, or garments, includes: a) preparing a dyebath including dye particles and an additive, such as an anionic acrylic copolymer, causing the particles to become charged; b) preparing the textile material by applying an additive, such as a cationic polyamide, forming a substrate with a charge attracting the particles, c) immersing the textile material in the dyebath; d) chemically reducing the dye particles retained on the textile material to a leuco form; and e) oxidizing the dye material.

Owner:ALPERT MELVIN

Method for preparing sulfur and sulfur dioxide from sulfur dyes waste water

InactiveCN101186278ASolve processing problemsSulfur preparation/purificationWater/sewage treatmentChemical reactionReaction temperature

The invention relates to a sulfur and sulfur dioxide preparation method using sulfur dye waste water, which belongs to the comprehensive treating technical field of the byproducts of chemical dyeing materials. The sulfur dye waste water containing sodium thiosulfate after processed is used as raw materials, which are added with acid for reaction, or the waste water is added to the acid for reaction, with a reaction temperature of 20 to 105 DEG C. The sulfur dioxide produced in the reaction is absorbed by alkali or salt to produce sulfur dioxide derivant. When the reaction is carried out to the final state, elemental sulfur is precipitated. Then the elemental sulfur is cooled to be 10-90 DEG C, filtrated and washed in water to obtain sulfur. In the invention, the sulfur dye waste water containing sodium thiosulfate is decolored and done with other certain treatment and added with the acid to react chemically with each other; the sulfur dioxide is absorbed by alkali or salt to produce the sulfur dioxide derivant and the sulfur is obtained after being precipitated an filtrated. The invention can effectively resolve the difficult problem of wastewater treatment, utilizes the waste to get valuable and has great economic and environmental benefits.

Owner:浙江长征化工有限公司

Active dye dyeing process of jean fabric

ActiveCN103757943AVariety of colorsUniform and stable colorBiochemical fibre treatmentDry-cleaning apparatus for textilesPre treatmentDyeing wastewater

The present invention discloses an active dye dyeing process of a jean fabric. According to the present invention, a series of processes such as pre-treatment process, pre-shaping, dyeing, color fixation, post-finishing, water washing and air-drying are adopted, a double-active group active dye is adopted to replace the previous indigo blue dyeing solution and the sulfur dye, and the reasonable dyeing process condition is assistedly adopted to carry out the special dyeing process for the jean fabric; and the prepared finished product has advantages of rich color, uniform and stable color, color losing resistance during the water washing process, and the like, and the active dye is used, such that the amount of the discharged printing and dyeing wastewater in the previous dyeing process is substantially reduced so as to easily achieve the ecology environment.

Owner:佛山瑞纺染整有限公司

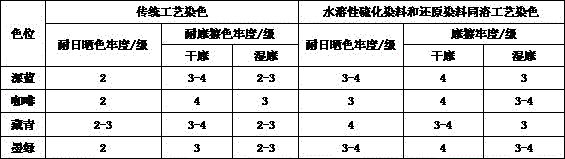

One-bath garment dyeing technology of reduced dye and water-soluble sulfur dye

InactiveCN105463876AGood vintage distressed effectGood color fastness indexDyeing processWater solubleCellulase

The invention discloses a one-bath garment dyeing technology of a reduced dye and a water-soluble sulfur dye. The one-bath garment dyeing technology comprises a pre-treatment procedure, a dyeing procedure, a soaping procedure, a sodium hypochlorite washing procedure and a cellulase enzyme washing procedure, which are sequentially carried out on a to-be-dyed garment, wherein a dyeing work reagent used in the dyeing procedure comprises the following components in percentage by weight: 1%-5% of the water-soluble sulfur dye and 0.5%-4% of the reduced dye. The nostalgic style of traditional garment dyeing is reserved by the dyed garment; compared with a traditional garment dyeing product, the physical indexes of the light fastness, the rubbing fastness and the like of the product disclosed by the invention are greatly improved; the garment produced by the technology can be further intensively processed; and the one-bath garment dyeing technology is especially applicable to the dyeing and processing requirements of various garment production and dyeing factories on clothes.

Owner:FUJIAN ZHONGHE

Method for dyeing fabric materials with indigo, other vat dyes, and sulfur dyes

A method for surface dyeing a range of textile materials, in the form of yarn, fabric, or garments, includes: a) preparing a dyebath including dye particles and an additive, such as an anionic acrylic copolymer, causing the particles to become charged; b) preparing the textile material by applying an additive, such as a cationic polyamide, forming a substrate with a charge attracting the particles, c) immersing the textile material in the dyebath; d) chemically reducing the dye particles retained on the textile material to a leuco form; and e) oxidizing the dye material.

Owner:ALPERT MELVIN

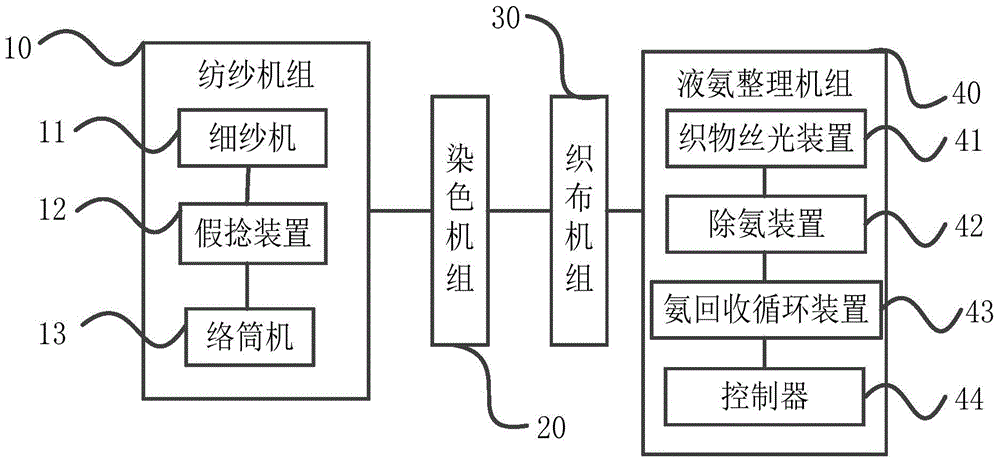

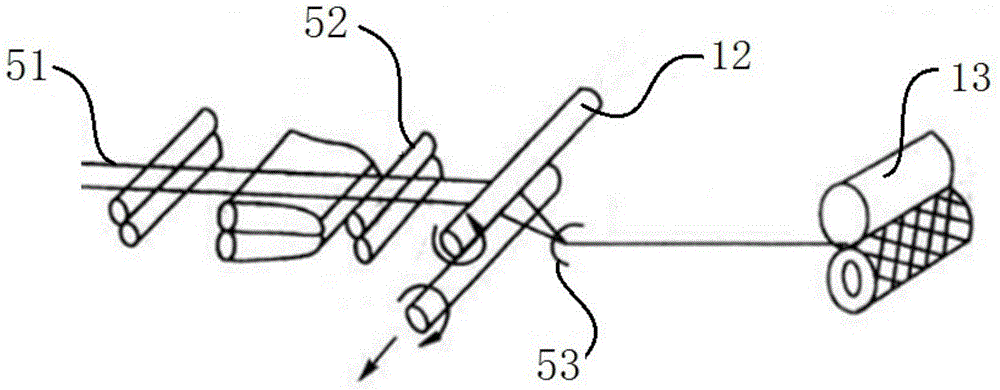

Production technological process and production line of environment-friendly jean

ActiveCN104452333ADyeing processLiquid/gas/vapor yarns/filaments treatmentElectricityProduction line

The invention provides a production technological process of environment-friendly jean. The production technological process of the environment-friendly jean is characterized in that a false twisting process is added between a spinning process and a spooling process, slivers are excessively pre-twisted in the axial direction, and twisting turns of the same numbers but in different twisting directions are formed on the silvers; in a dyeing process, sulfur dye containing glucose is adsorbed; an ammonia removal process is conducted in a high-temperature high-pressure tank, so that remaining ammonia in fabric is evaporated, and the evaporated ammonia is collected and delivered back to a mercerizing process so as to be continuously used. The invention further provides a production line of the environment-friendly jean. The production line comprises a spinning unit with a false twisting device, a dyeing unit for conducting the dyeing process and a liquid ammonia finishing unit composed of a fabric mercerizing device, an ammonia removal device, an ammonia recovery circulating device and a controller. The use amount of electricity, water and chemical articles can be saved, production efficiency is improved, labor resources are saved, and the discharging amount of sewage and pollutants is reduced.

Owner:开平奔达纺织有限公司

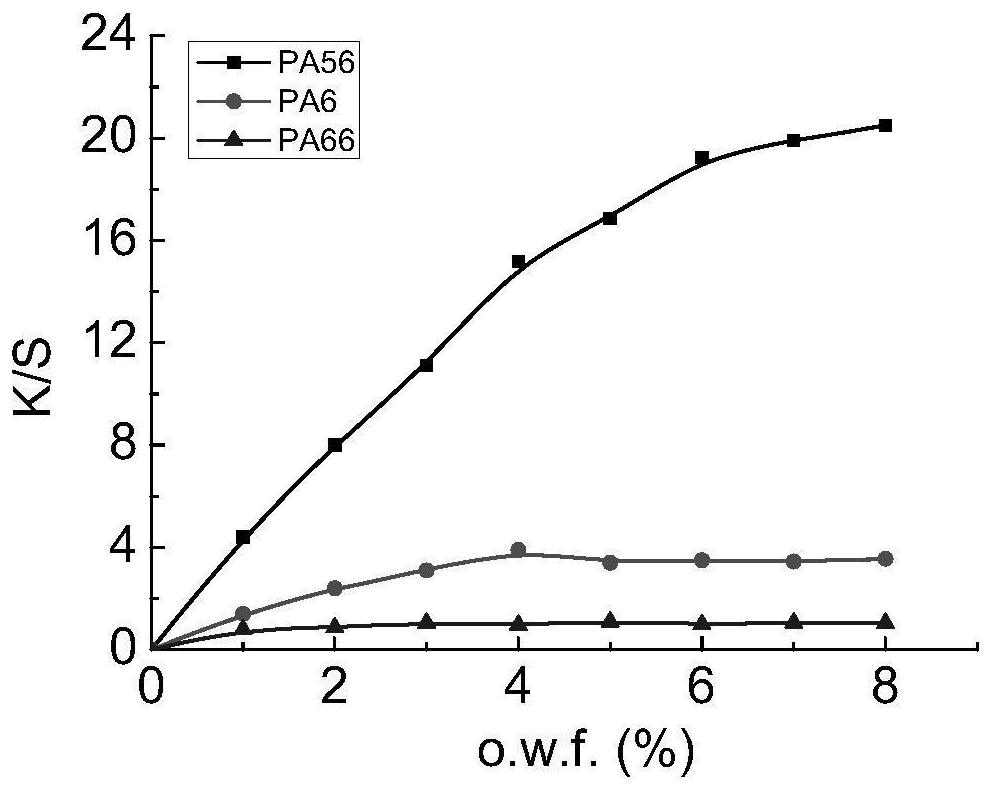

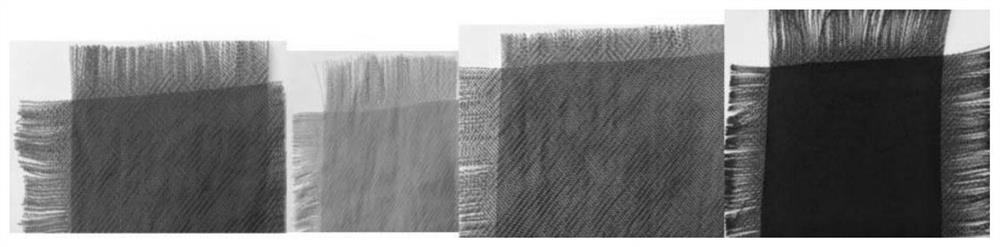

Alkaline dip dyeing method for polyamide 56 fibers and fabrics

The invention discloses an alkaline dip dyeing method for polyamide 56 fibers and fabrics. The method has the beneficial effects that (1) the method is applicable to multiple dyestuffs and capable ofrealizing the dyeing of the polyamide fibers through reduced dyes, reactive dyes, direct dyes and sulfur dyes, so that a dyed fabric is bright and deep in color; (2) the color fastness is good, the test results of color fastness, such as resistance to rub, soaping, alkali and perspiration, and sunlight of the dyed fabric can meet the operating requirements, the resistance to friction and soaping reaches up to more than 3 to 4 class, and the color fastness to sunlight can reach up to more than 5 class; (3) the process is simple, quick dyeing can be realized at a low temperature condition, and energy conservation and emission reduction are realized; and (4) by adopting biology-based polyamide fabrics as raw materials, the requirements of green, environmental protection and sustainability aremet, so that the method has an important practical significance.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

Continuous color knitted jean fabric pad dyeing process

ActiveCN104790151ACan't solveReduce energy consumptionSucessive textile treatmentsSingeingEngineeringProcess engineering

The invention relates to a continuous color knitted jean fabric pad dyeing process. The process comprises the following working procedures of cloth knitting, singeing, scouring and bleaching, dyeing, combining and finishing, and finished cloth obtaining. An open-width open fire singeing method is adopted in the working procedure of singeing. A continuous open-width scouring and bleaching method is adopted in the working procedure of scouring and bleaching, and countercurrent flushing is carried out through under-liquid soaking and up-liquid spraying by means of a drum; the rolling and drying process is adopted for dyeing in the working procedure of dyeing, an evenness calender is used for padding dye on cloth, and a steam drying cylinder is utilized for drying the cloth. According to the process, in the whole process, the open-width continuous production process is adopted, the production working procedures are reduced or combined, the problem that sulfur dyestuff color series can not be used for needle dyeing and cloth knitting of a rope-like dyeing machine for many years is solved, and the low-emission and low-energy-consumption continuous color knitted jean fabric pad dyeing process is achieved.

Owner:JIANGYIN FUBO TEXTILE CO LTD

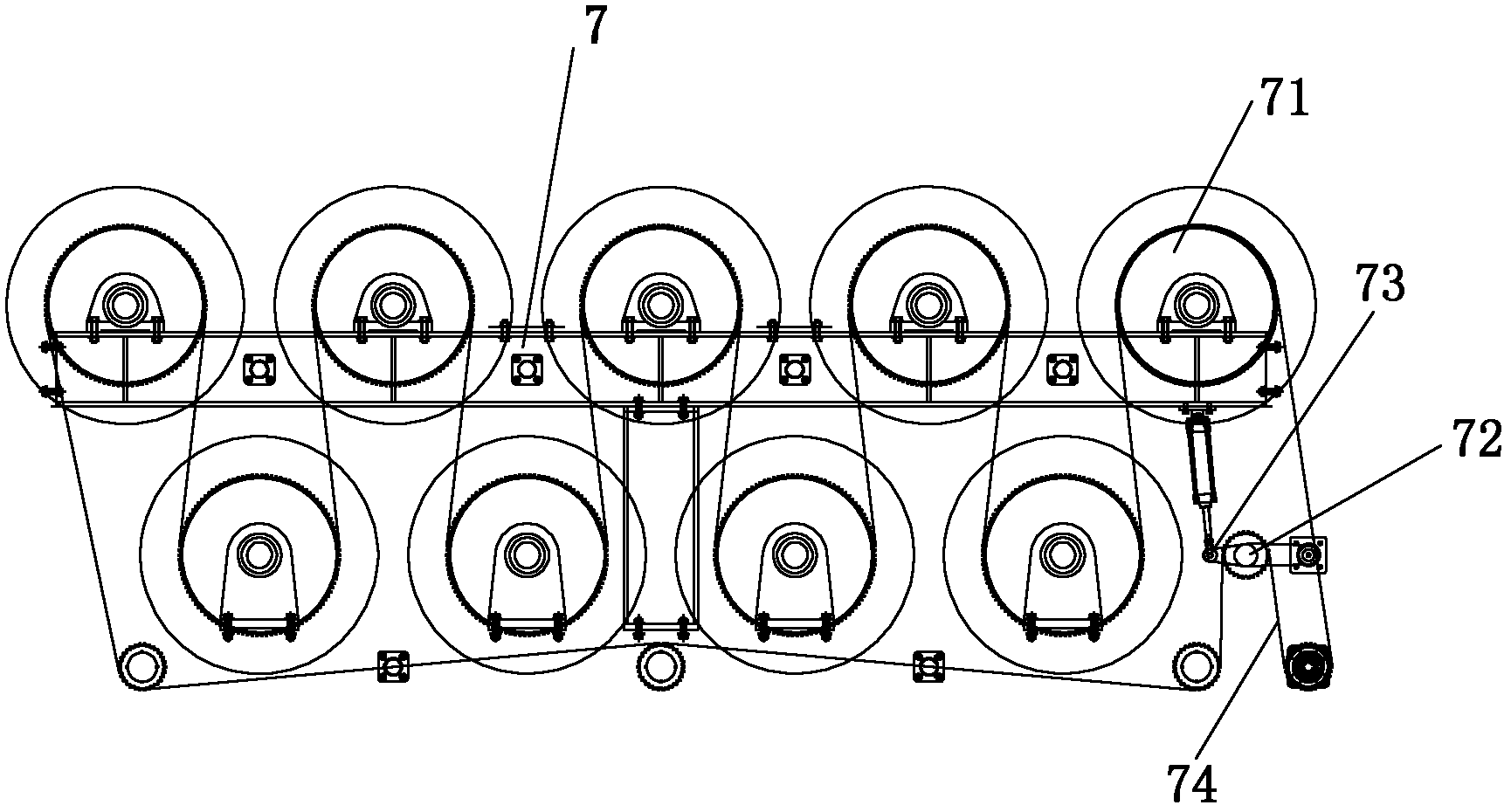

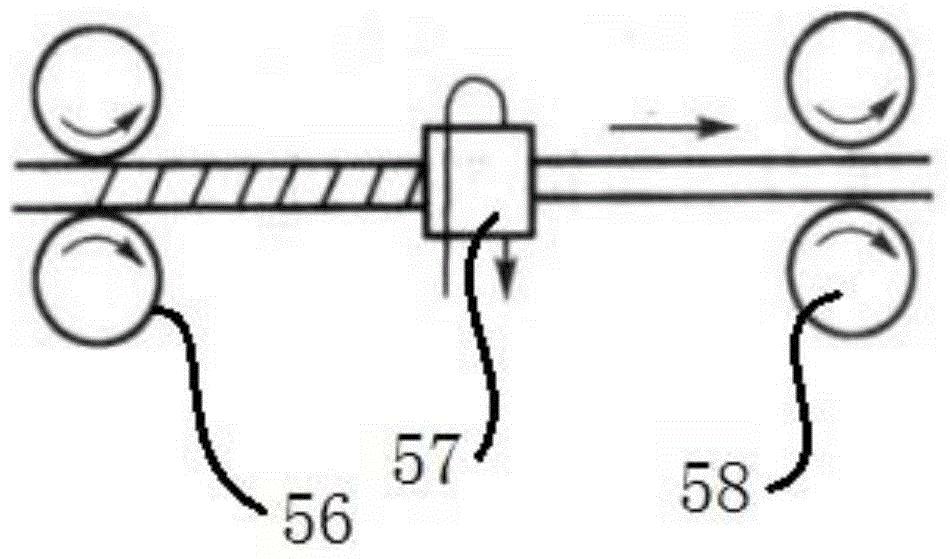

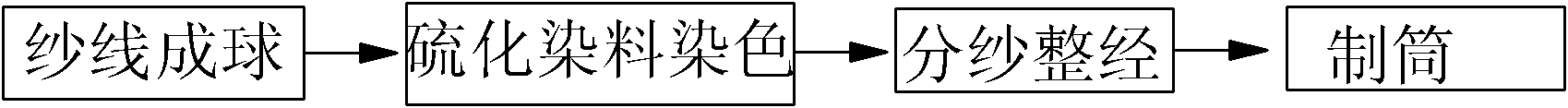

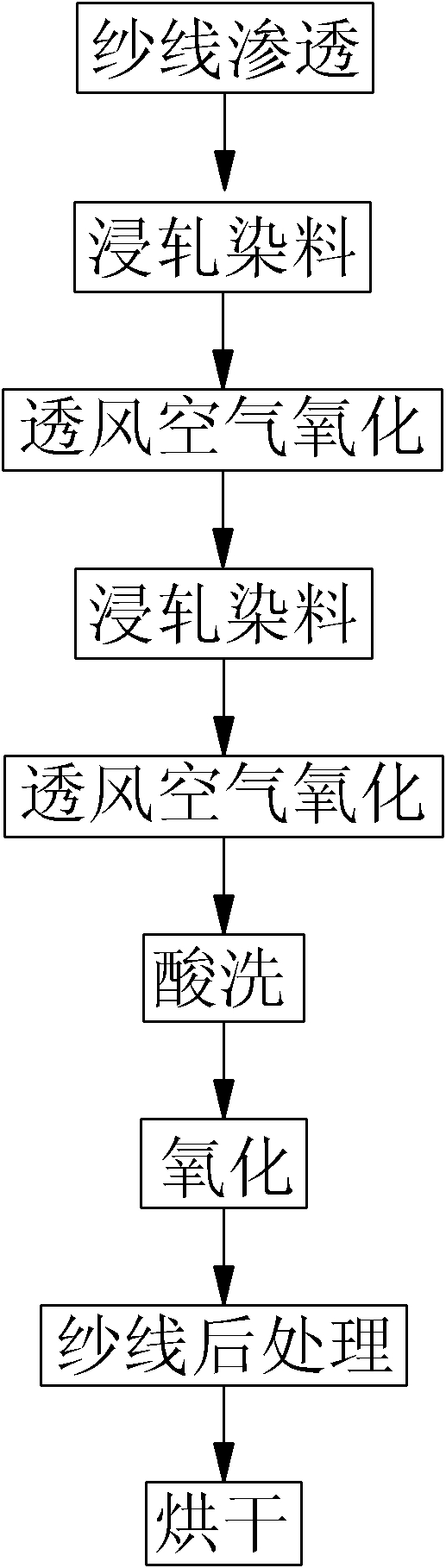

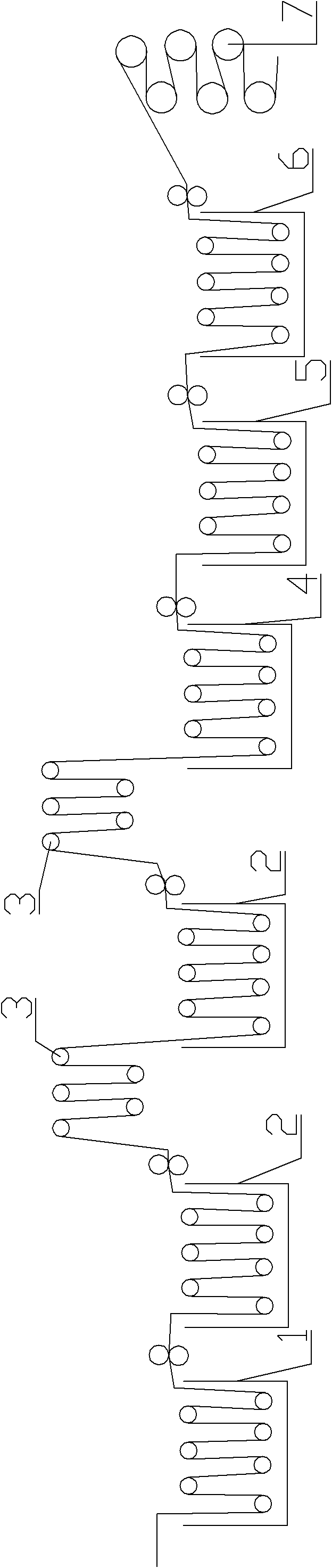

Continuous dyeing process for curing white-core color yarn and equipment and fabric thereof

The invention relates to the technical filed of white-core color yarn dyeing, in particular to a continuous dyeing process for curing white-core color yarn and equipment and a fabric thereof. The continuous dyeing process is as follows: the yarn is dyed with sulfur dyes and subjected to ventilated air oxidation, and is then dyed with sulfur dyes and subjected to ventilated air oxidation again, thus obtaining the color yarn for denims having a white core in the middle through dyeing. The fabric is formed by weaving the color yarn obtained by the dyeing process. The continuous dyeing equipment comprises a permeability device, a curing dyeing device, a ventilated air oxidation device, a curing dyeing device, a ventilated air oxidation device, a pickling device, an oxidation device, a yarn post-treatment device and a drying device which are sequentially arranged to form the whole yarn continuous dyeing equipment. The invention has the advantages that: knitted denims with different colors can be produced; the color fastness of the color yarn is high; the color does not fade after washing; and the denims can be washed together with any other fabric and can be washed into jeans having various obsolescence senses.

Owner:杨洋

Printing and dyeing process of denim

InactiveCN103643545AObtain a hazy three-dimensional effectDry-cleaning apparatus for textilesDyeing processPulp and paper industryOxidizing agent

The invention discloses a printing and dyeing process of denim. The printing and dyeing process comprises the following steps: (1) treating grey cloth by using alkaline, a refining agent and hydrogen peroxide, dehydrating and shaping; (2) mixing paste and printing; (3) ageing at the temperature of 115-120 DEG C for 12-15min; (4) washing by using a continuous rope washing machine, and dehydrating by using a centrifugal machine, wherein cold water is adopted in the former two washing processes, hot water of 85-90 DEG C is adopted in the third washing process, and cold water is adopted in the later two washing processes; (5) spraying 50-60g / L saturated potassium permanganate solution by using a spray gun; (6) washing by using hot water of 75-80 DEG C, adding 5-6g / L oxalic acid, cleaning by using cold water, and then, dehydrating; (7) shaping. The printed denim obtained through carrying out spray treatment by using an oxidant after printing the denim by using sulfur dye has a hazy three-dimensional effect similar to that of tie-dyeing.

Owner:CHANGSHU JUNYU KNITTING

Method for Dyeing Aramid Fibers and Dyed Aramid Fibers

InactiveUS20140020190A1High color fastnessDyeing qualityFibre treatmentOrganic dyesColour fastnessAramides

Methods for dyeing aramid fibers, and the dyed arimid fibers produced by these methods, which comprises a dye providing step in which a vat dye or a sulfur dye is provided to aramid fibers, a solvent treatment step in which the aramid fibers are treated by a treating solution containing a polar solvent, and after the solvent treatment step, a heat treatment step in which the aramid fibers are subjected to a heat treatment, if necessary, and having one or more dyeing operations comprising the combination of the respective steps dyeing operations. The dyeing methods can be applied to either of the para-type aramid fibers, the para-type copolymerized aramid fibers and the meta-type aramid fibers, which can be dyed to a practical color depth required for developing new applications of the aramid fibers. Colorfastness of the dyed product, in particular, colorfastness to light, is improved.

Owner:TOKAI SENKO KK

Sulfur dye protection systems and compositions and methods employing same

InactiveUS20050177956A1Increased bleach stabilityImprove propertiesInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBleachPhysical interaction

The present invention relates to sulfur dye protection systems and compositions and methods employing same, as well as processes for making sulfur dyes, especially bleach stable sulfur dyes, processes for dying textiles with sulfur dyes and textiles dyed by such processes. More particularly, the present invention relates to modifying existing dyes and / or making newly formed sulfur dyes. Even more particularly, the present invention relates to materials that can chemically or physically interact with sulfur dyes to protect the sulfur dyes from oxidation by oxidizing agents, such as bleaching agents.

Owner:BOARD OF RGT UNIV OF NEBRASKA

One bath process desizing and dyeing technology of viscose leather base cloth

ActiveCN103669009AGood desizingImprove refining effectBiochemical fibre treatmentDyeing processWater bathsDesizing

The invention discloses a one bath process desizing and dyeing technology of viscose leather base cloth. The desizing and dyeing processes of the viscose leather base cloth are finished in the same water bath. If the viscose leather base cloth is a light-color variety dyed by reactive dye, when in desizing and dyeing, the technology comprises the following steps: adding a composite desizing enzyme accounting for 1.5-3.5% of the viscose grey cloth in the weight and an anionic surfactant accounting for 0.5-2% of the viscose grey cloth in the weight into a water bath; adding an intermediate-temperature reactive dye; starting dyeing at 60 DEG C and keeping the temperature for 3-6 times; and adding sodium carbonate for color fixing in the final 2-3 times. If the viscose leather base cloth belongs to a black deep-color variety dyed by sulfur dye, when in desizing and dyeing, the technology comprises the following steps: adding a functional pretreatment agent accounting for 1-4% of the viscose grey cloth in the weight and 0.5-2% of an anionic surfactant accounting for 0.5-2% of the viscose grey cloth in the weight into a water bath; adding a sulfur dye; starting dyeing for 2-4 times at 75 DEG C; and heating to 98 DEG C and keeping the temperature for 3-6 times. The technology disclosed by the invention realizes one bath process of desizing and dyeing of the viscose leather base cloth, reduces the production time of the viscose leather base cloth, improves the production efficiency and remarkably reduces the total production cost.

Owner:福建福能南纺卫生材料有限公司

Printing and dyeing process of denim

The invention discloses a printing and dyeing process of denim. The printing and dyeing process comprises the following steps: (1) grey cloth pretreatment; (2) paste mixing and printing: mixing printing paste, cooperatively using pigment printing paste and sulfur dye printing paste, controlling the viscosity at 40000-45000Pa.S, printing by using a flat screen printing machine, and drying at the temperature of 100-105 DEG C, wherein the pigment printing paste is prepared from the following components in parts by mass: 14-16 parts of pigment color paste, 30-35 parts of waterborne polyurethane binder, 45-50 parts of emulsified paste and 7-9 parts of urea; the sulfur dye printing paste is prepared from the following components in parts by mass: 7-8 parts of sulfur dye, 25-30 parts of sodium formaldehydesulfoxylate dehydrate, 30-35 parts of etherified starch paste, 12-14 parts of sodium carbonate, 8-9 parts of glycerin and 16-18 parts of warm water; (3) ageing; (4) oxidant spraying; (5) washing; (6) shaping. The printing and dyeing process is simple in operation, little in environment pollution, rich in design and color and favorable in printing and spraying effects.

Owner:CHANGSHU XIONGFA KNITTING PLUSH

Garment dyeing method of vat dye or sulfur dye

ActiveCN110106723ALower color yieldSolve the phenomenon of premature oxidationDyeing processPre washingProcessing cost

The invention provides a garment dyeing method of a vat dye or sulfur dye. The method comprises the following steps: a, pre-washing a garment; b, dyeing the pre-washed garment; c, dyeing and post-processing the garment: after a dye liquor is discharged, enabling the garment in a cylinder to run with the empty cylinder 10-30 minutes for oxidization or adding an oxidizing agent for washing and oxidization, executing soaping and drying treatment after the color is stabilized to finish dyeing of the garment. The method is simple and easy to implement, has the low requirement for equipment performance and can greatly reduce the processing cost, and the phenomenon is successfully solved that dye liquor is oxidized in advance in the dyeing process of a vat dye or sulfur dye.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Dyed textiles and method of producing the same

Slasher machines and rope dyeing machines are the main dyeing machine that is used to continuously dye yarn fabrics for denim using indigo dyes. In denim dyeing, indigo (blue color VAT) and some sulfur dyes are mixed together to achieve blue / black / brown color denim fabrics. This invention is the achievement of dyeing reactive / direct / pigment / acid / disperse and other non VAT / sulfur OR its combinations of non VAT / sulfur dyes OR combinations between VAT / sulfur dyes and VAT / sulfur dyes on continuous yarn dyeing machines and relevant apparatus. Its products are also very distinguishable, especially its combinations, hence is a part of the invention.

Owner:LEE SHAN JAMES

Sustainable range of sulfur dyes for textile and paper dyeing

The invention refers to the manufacturing of a novel group of sulfur dyes in which are used, as raw material, different kind of natural “biomass”, usually existing in the nature, and transforming them into soluble dyestuffs, capable to dye textile fibers, preferably cellulose fibers and derivatives, as cotton, viscose, paper, tencel, with high strength and fast color properties. For this purpose, the concept “Biomass”, is defined as the residual product obtained from the usual human crop activities, in agricultural and forestry sectors.

Owner:ARCHROMA IP GMBH

Composition, set and treating method for treating sulfur dyestuff dyed textile

ActiveCN104947434AImproved anti-pilling propertiesIncrease dosageBiochemical fibre treatmentTreatment effectSulfur

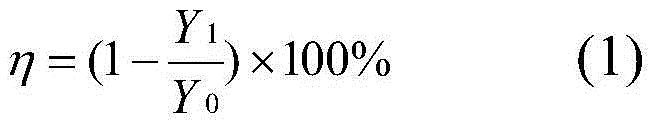

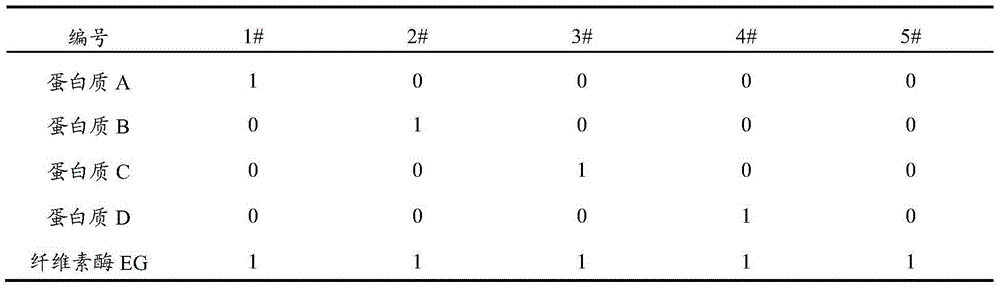

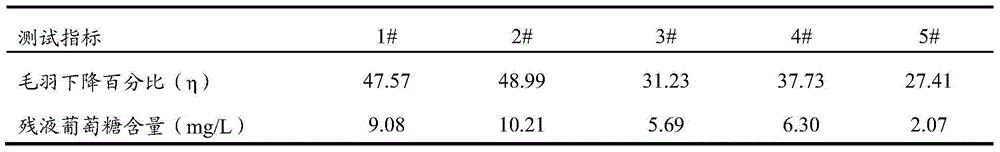

The invention belongs to the technical field of biological finishing of textiles and particularly relates to a composition, a set and a treating method for treating a sulfur dyestuff dyed textile. The composition comprises protein with 3%-15% of aspartic acid and cellulase. Before the protein and the cellulase are used for treating surface hairs of the textile, the protein and the cellulase are mixed in advance; or when the surface hairs of the textile are treated, an enzyme treatment solution containing the protein and the cellulase is temporarily formed. The use amounts of the protein and the enzyme in the enzyme treatment solution are 0.01-5.0g / L respectively and the enzyme treatment solution is used for treating for 30-90 minutes at the pH of 4.5-7.0 and the temperature of 40-60 DEG C. According to the composition, the enzyme and the specific protein are mixed; compared with the single utilization of the cellulase, the enzyme treatment effect can be greatly improved, and the adverse factors that the enzyme use amount is great, the textile hair removing rate is low, hair bulbs are easily formed and the wearing performance of clothes is influenced and the like in a process of carrying out cellulase treatment on the sulfur dyestuff dyed textile are overcome; and the composition has the characteristics of stable efficiency, environmental friendliness, simplicity in operation, low cost and the like.

Owner:石家庄美施达生物化工有限公司

Sulfur dye mixed dyeing composition and dyeing process

InactiveCN111286996AWith indigo dyeing shade effectGood color fastness to dry and wet rubbingDyeing processColour fastnessEngineering

The invention discloses a sulfur dye mixed dyeing composition. The sulfur dye mixed dyeing composition comprises the following components based on base solution mass concentration of 80-120g / L of sulfur blue and 20-40g / L of sulfur blue black. Through mixed dyeing of sulfur blue and sulfur blue black with specific concentration compound ratio, and then through compounding with a reducing agent anda surfactant at certain concentration, next, and adopting an alkali solution or a pH regulator to regulate the pH value of the dye, the prepared jean fabric has an indigo blue dyeing color effect, isfree of aniline by-product and is safe and environment friendly; and the dry and wet friction color fastness of the jean fabric is higher and the fabric bottom staining is less under the same dyeing depth.

Owner:韶关市北纺智造科技有限公司

A kind of reactive dye dyeing process of denim fabric

ActiveCN103757943BVariety of colorsUniform and stable colorBiochemical fibre treatmentDry-cleaning apparatus for textilesDyeing wastewaterPre treatment

The present invention discloses an active dye dyeing process of a jean fabric. According to the present invention, a series of processes such as pre-treatment process, pre-shaping, dyeing, color fixation, post-finishing, water washing and air-drying are adopted, a double-active group active dye is adopted to replace the previous indigo blue dyeing solution and the sulfur dye, and the reasonable dyeing process condition is assistedly adopted to carry out the special dyeing process for the jean fabric; and the prepared finished product has advantages of rich color, uniform and stable color, color losing resistance during the water washing process, and the like, and the active dye is used, such that the amount of the discharged printing and dyeing wastewater in the previous dyeing process is substantially reduced so as to easily achieve the ecology environment.

Owner:佛山瑞纺染整有限公司

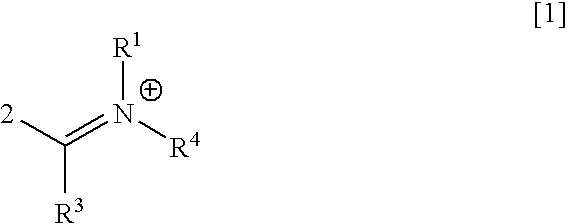

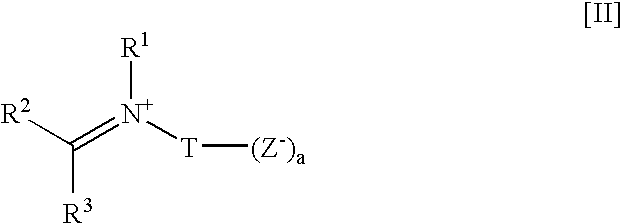

Composite flocculant for treating dye wastewater as well as preparation method and application of composite flocculant

ActiveCN114751499AGood removal effectEasy to shapeWater contaminantsWaste water treatment from textile industryDisperse dyeMeth-

The invention belongs to the technical field of flocculants, and particularly relates to a composite flocculant for treating dye wastewater as well as a preparation method and application of the composite flocculant. The flocculating agent is prepared from the following raw materials in parts by weight: 0.5 to 0.8 part of cationic polyacrylamide, 7 to 9 parts of chlorinated poly 2-hydroxypropyl-1, 1-N-dimethyl ammonium, 3 to 5 parts of hexadecyl trimethyl ammonium bromide, 3 to 4.5 parts of poly dimethyl diallyl ammonium chloride, 0.8 to 1.5 parts of polyethyleneimine, 5 to 7 parts of ferrous sulfate, 2 to 2.5 parts of sodium silicate, 8 to 10 parts of polyaluminum ferric sulfate and 0.05 to 0.1 part of polyacrylic acid. The composite flocculant disclosed by the invention has a relatively good removal effect on disperse dyes, sulfur dyes and reactive dyes; the preparation method of the composite flocculant for treating the dye wastewater is simple in process and easy to realize industrial production, and the flocculant prepared by the method is stable in effect and wide in application range.

Owner:山东艾维斯特精细化工有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com