Process for comprehensively treating sulfur dye waste water

A technology of sulfur dyes and treatment process, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high operating costs, high costs, waste of resources, etc., and achieve fixed Low investment, low operating cost, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

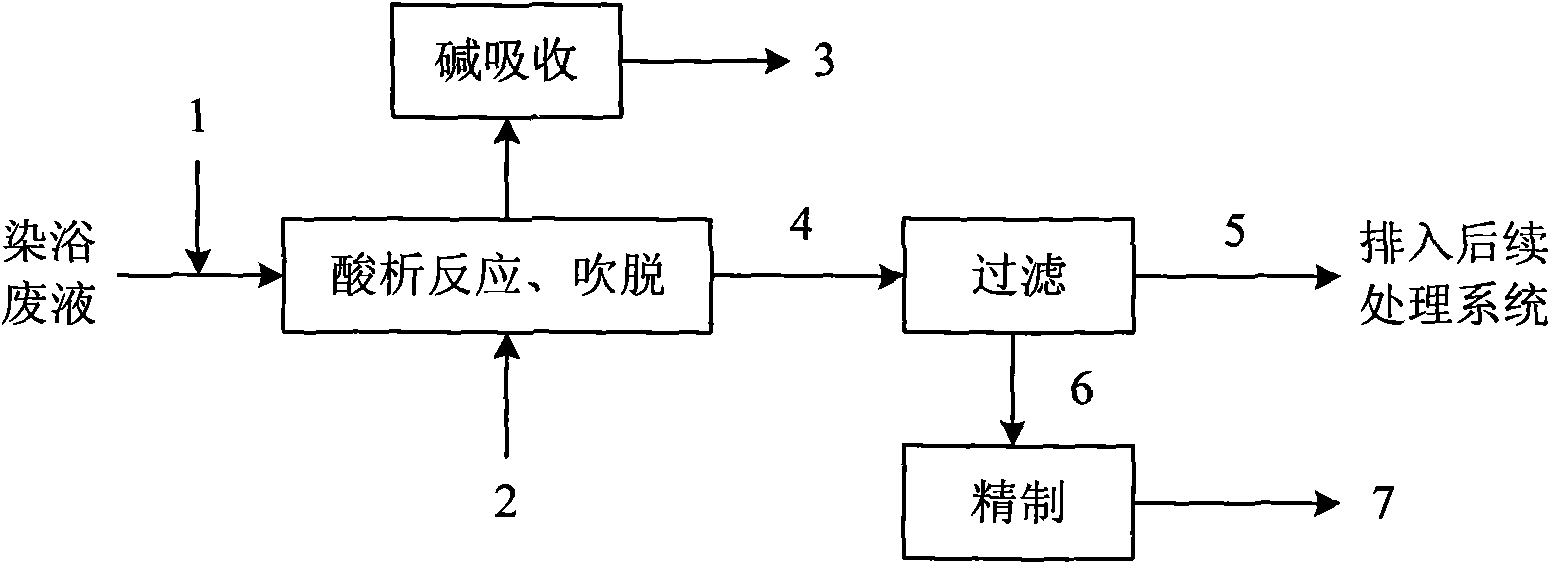

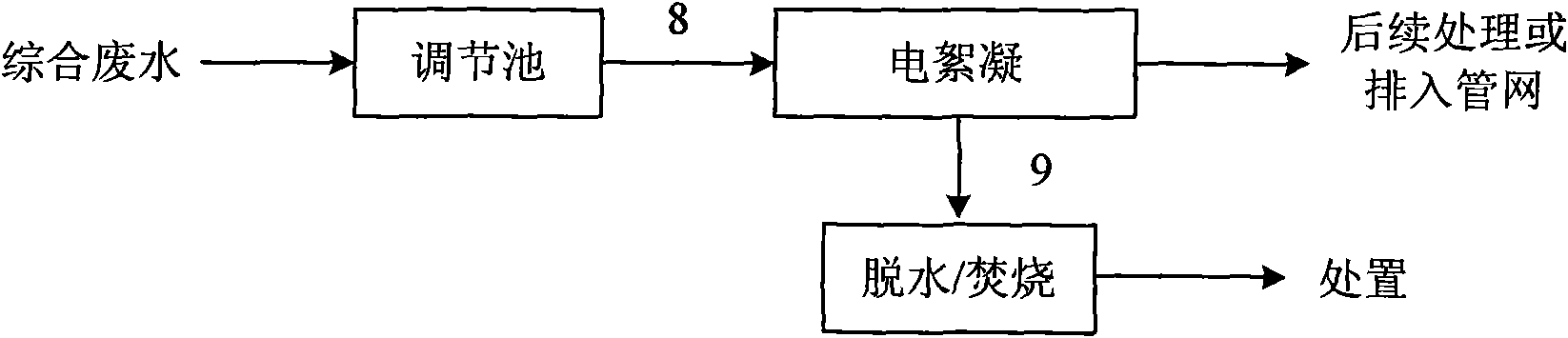

[0026] Embodiment: Sulfur black is used to configure simulated wastewater according to the actual printing and dyeing process, wherein the dye bath waste liquid contains 1% sulfur black, 2% sodium sulfide, and 3% sodium chloride, and the low-concentration comprehensive wastewater COD600mg / L, chroma 200 times, sulfide The substance is 20mg / L, and the conductivity is greater than 10mS / cm. The dye bath waste liquid is first acidified with sulfuric acid to a pH value of about 3, then nitrogen gas is introduced to carry out stirring reaction and stripping, the hydrogen sulfide produced is absorbed by sodium hydroxide to recover alkali sulfide, and the reaction mother liquor is filtered to recover sulfur black and sulfide The recovery rate can reach 85%, and the recovery rate of sulfur black can reach more than 95%. The comprehensive wastewater is treated by electrocoagulation. After treatment, the COD of the effluent is less than 300mg / L, the chroma is less than 20 times, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com