Continuous dyeing process for curing white-core color yarn and equipment and fabric thereof

A technology of sulfur dyes and dyeing equipment, which is applied in dyeing methods, continuous processing of textile materials, textiles and papermaking, etc., and can solve the problems of fading and low indigo dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

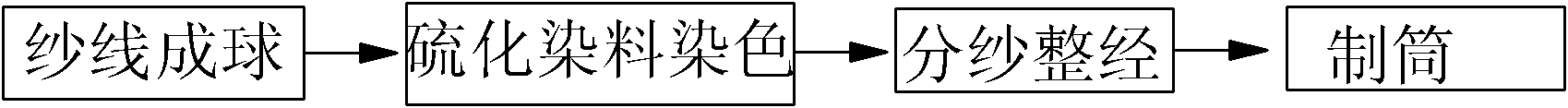

[0037] like figure 1 Shown is a continuous dyeing process of vulcanized white core colored yarn. The yarn is dyed with sulfur dye and then oxidized in ventilated air. Dyed yarn for denim fabric. Before dyeing with sulfur dyes, the yarn is firstly balled, and the dyed yarn after the drying step is divided and warped, and then the tube is made.

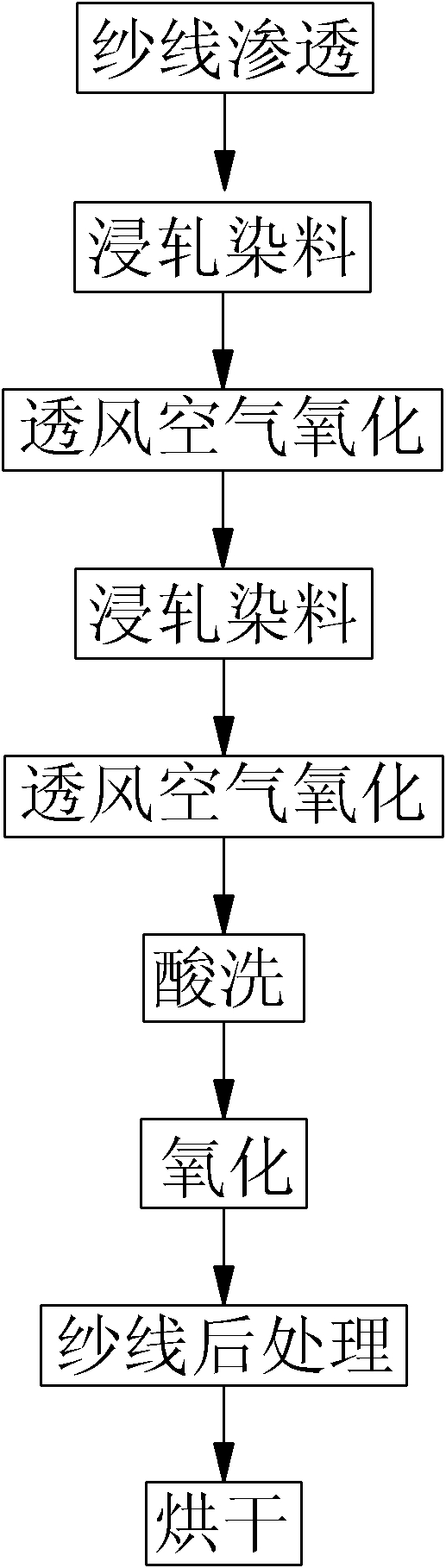

[0038] Process steps of sulfur dyeing:

[0039] 1) Yarn penetration;

[0040] Carry out infiltration treatment in the yarn assorted 100g / liter caustic soda;

[0041] 2) Padding dye:

[0042] The yarn is pad-dyed in a sulfur dye at 90°C±2°C;

[0043] 3) Ventilated air oxidation:

[0044] The dyed yarn is oxidized by ventilation air, and the ventilation oxidation time is about 1 minute;

[0045] 4) Padding dye:

[0046] The yarn oxidized by ventilated air is again pad-dyed in sulfur dye at 90°C±2°C;

[0047] 5) Ventilated air oxidation:

[0048] The dyed yarn is oxidized by ventilation air, and the ventilation oxidation time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com