Dye compound reducing agent and method of using the same

A reducing agent and dye technology, applied in the field of vat dye dyeing and fiber dyeing, can solve the problems of high energy consumption, decreased leather strength, increase vat dye leuco, leuco acid stability, etc., to improve the color yield. efficiency, increase stability, and avoid the effects of environmental protection and human body hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

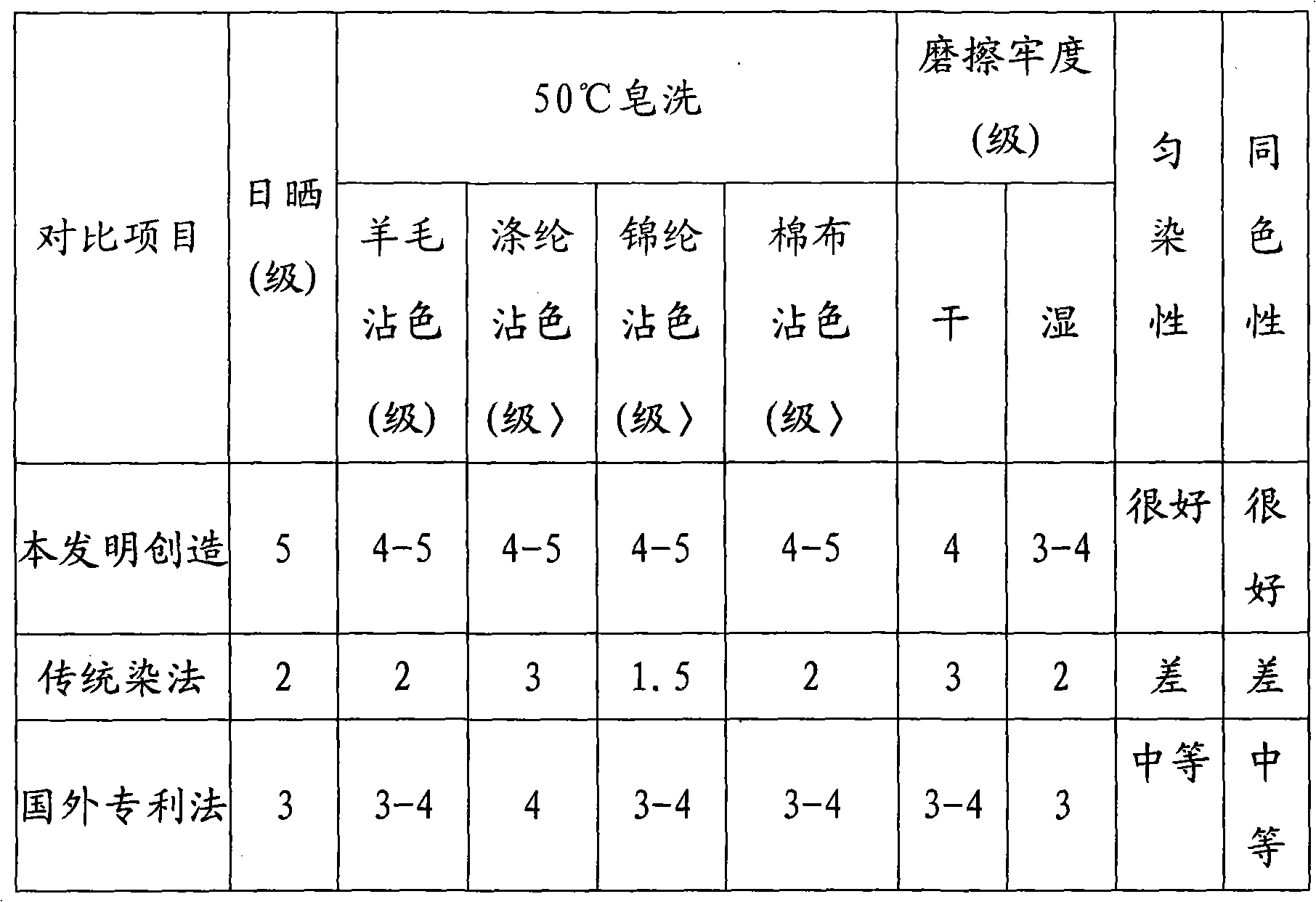

[0066] Embodiment 1: Polyester fiber and polyurethane composition synthetic leather dyeing

[0067] Synthetic leather composed of 0.02 denier polyester fiber and polyurethane, unit weight 700g / M 2 , Dye with C.1.VAT.Brown.5#, 6% (2006.11 / 22) with vat dye leuco, leuco acid dyeing process.

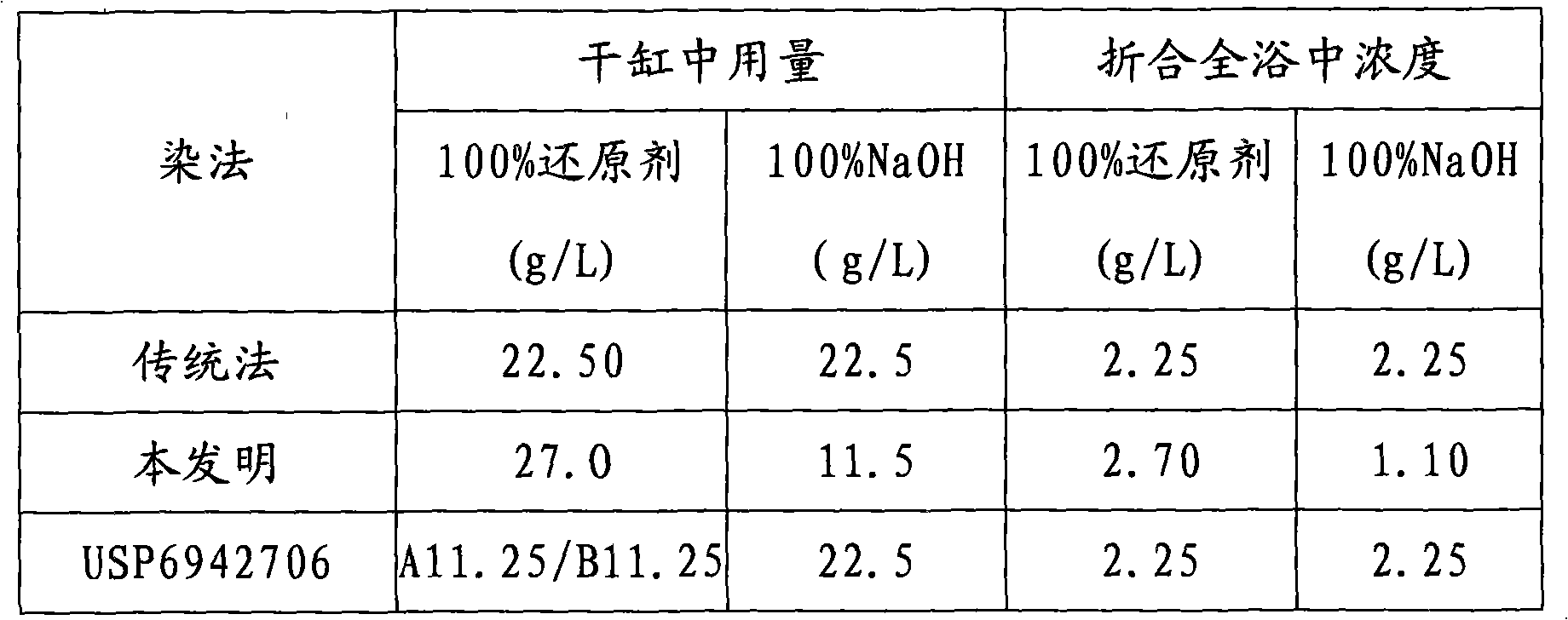

[0068] (A) make the reducing leuco body of the present invention according to Table 1, i.e. the three compound reducing agents, solid NaOH and water to prepare the reducing solution, wherein the concentration of the three compound reducing agents is 27.0g / L (i.e. 10.8g / L hydrosulfite plus 10.8g / L thiourea dioxide and 5.4g / L sodium sulfite, totally 27.0g / L), NaOH concentration is 11.5g / L; With dry cylinder method, the leucosome is modulated to dye reduction, reducing solution: dye=37.5: 1 (weight Ratio), after 8 minutes, heat the water (1:1 with dye-reduced leuco body fluid), and make the mixing temperature 50°C for use;

[0069] (B) Add the dispersant lignosulfonate ammonium salt to the dy...

Embodiment 2

[0076] Embodiment 2: Synthetic leather dyeing composed of superfine polyamide and polyurethane

[0077] A blended fiber in a ratio of 0.02 denier ultrafine polyamide:polyurethane=65%:35% (weight ratio) was dyed.

[0078] Prepare reducing solution of the present invention according to Table 1, wherein hydrosulfite: thiourea dioxide: sodium sulfite=1.0: 1.0: 1.0, the dyeing process is the same as in Example 1, except that step (B) dyeing pre-dyeing step lye in Example 1 is not used to adjust the dye bath pH treatment, directly add acidic buffer solution in the reducing leuco body, adjust the dye into leuco acid, add the osmotic swelling agent of the present invention: 0.00025 parts by weight of lauryl azone, 2.0 parts by weight of N-methylpyrrolidone, diacetone alcohol 8.0 parts by weight, 10.0 parts by weight of ethyl salicylate, 9.0 parts by weight of isopropyl salicylate, dye with leuco-chromic acid, heat up to 105°C at 1°C / 2min, and keep warm for 40 minutes. The color fastn...

Embodiment 3

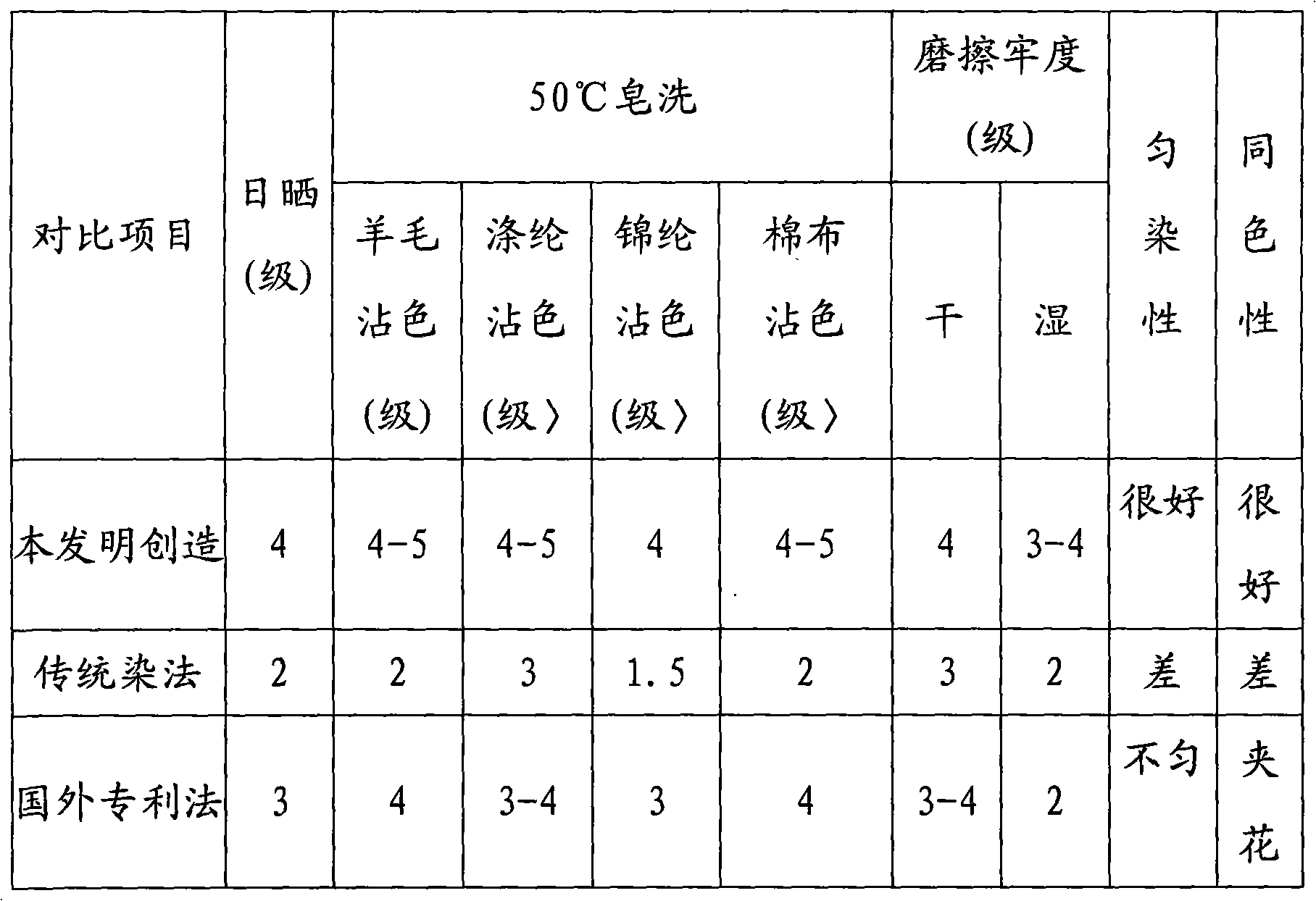

[0083] Embodiment 3: Polyurethane polymer composition synthetic leather dyeing

[0084] Polyurethane polymer dyed. Prepare reducing solution of the present invention by table 1, wherein hydrosulfur powder: thiourea dioxide: sodium sulfite=2: 4: 1, dyeing process is the same as embodiment 1, just do not pass through step (B) dyeing pre-dyeing stage in embodiment 1 and adjust with lye Dyeing bath pH treatment, in the step (A) in embodiment 1, directly add acidic buffering agent, adjust dyestuff into leucoic acid, add osmotic swelling agent of the present invention: lauryl azone 0.0002 weight part, N-methyl 4 parts by weight of pyrrolidone, 6.0 parts by weight of diacetone alcohol, 8.0 parts by weight of ethyl salicylate, 10.0 parts by weight of isopropyl salicylate, dyed with reduced leucochromic acid, 1 ° C / 2 min to 85 ° C, at 85 ° C Keep warm for 45-60 minutes for dyeing, the color fastness is very good.

[0085] The following table 4 is the dyeing result of the present em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com