Alkaline dip dyeing method for polyamide 56 fibers and fabrics

A dyeing method and technology of nylon, applied in the field of textile dyeing and finishing, can solve problems such as unfavorable application, high dyeing temperature, fiber and fabric mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

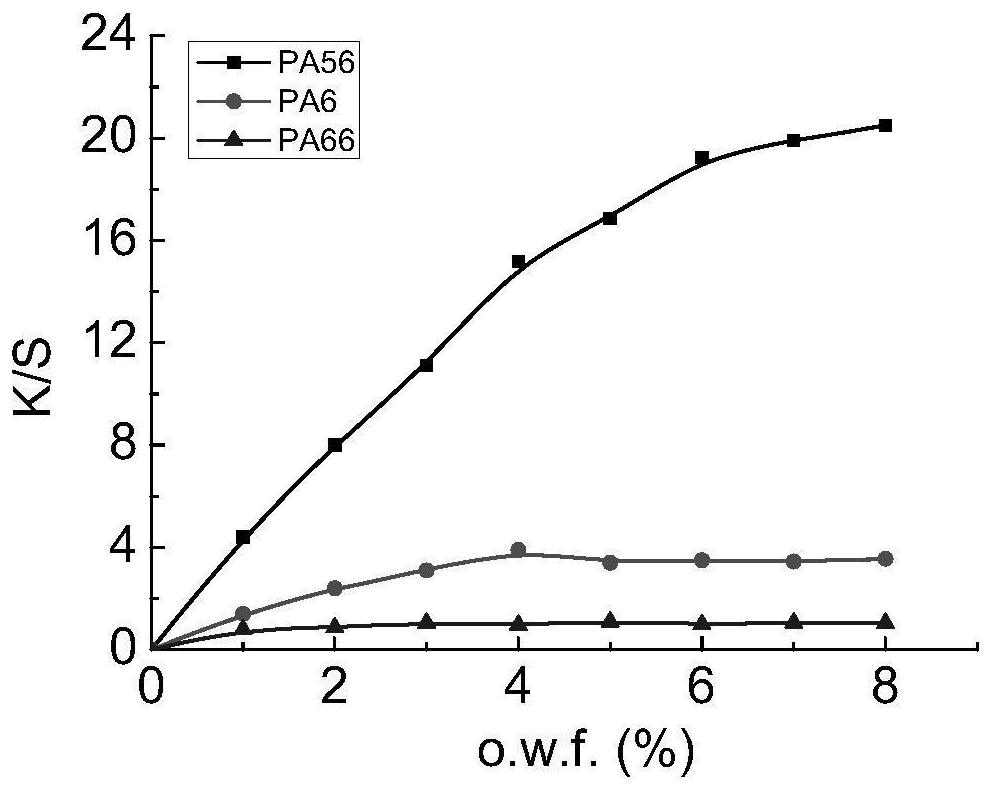

[0082] Example 1. Dyeing enhancement experiment of nylon 56 fiber reduced and exhausted by vat dyeing dry cylinder method

[0083] Dye drying cylinder reduction method: According to the bath ratio of 1:5, take the amount of vat blue RSN dye (1-8)% (o.w.f), caustic soda (2g / L) of 2 / 3 of the total dyeing amount, and 2 / 3 of sodium hydrochloride ( 2g / L), 1 / 3 of water, at 50°C, reduce for 10 minutes to prepare a reducing solution, which is prepared and used immediately;

[0084] Exhaust dyeing process: add 0.2% (o.w.f) retarder JV-905, the remaining 1 / 3 caustic soda, 1 / 3 hydrosulfite, 2 / 3 water when reducing the dye, the pH of the dyeing solution is 8.3, add 2g of the dyed material, and 8°C / min to raise the temperature to 60°C, keep it warm for 20min, cool down and take out the sample, oxidize it in 1g / L hydrogen peroxide at 50°C for 10min, take out the sample and wash it with hot water at 50°C, soaping (soap flakes 1g / L, anhydrous sodium carbonate 1g / L, 50℃, 10min, bath ratio 1:1...

Embodiment 2

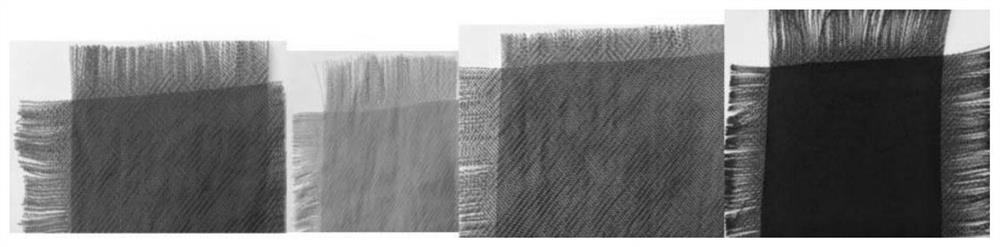

[0091] Embodiment 2: dyeing nylon 56 fabric and nylon 66 fabric with different vat dyes

[0092]Full-bath reduction: bath ratio 1:5, take 1.0% (o.w.f) dye vat dye, 3g / L caustic soda, 3g / L hydrosulfite, water at 45°C for 15 minutes to prepare a reducing solution, which is prepared and used immediately;

[0093] Exhaust dyeing process: add 1% (o.w.f) leveling agent MCH-312 to the dyeing solution, the pH of the dyeing solution is 8.1, add 2g of the dyed material, raise the temperature to 60℃ at 5℃ / min, keep it warm for 30min, take out the sample after cooling down, and take out the sample at 50℃ Oxidation treatment in 1g / L hydrogen peroxide at ℃ for 10min, take out the sample and wash it with hot water at 50℃, soaping (soap flakes 3g / L, anhydrous sodium carbonate 3g / L, 50℃, 10min, bath ratio 1:10), rinse with water at room temperature , dry, and finish the staining. Fabric test results after dyeing are shown in Table 3, and the dyeing and penetration results are shown in image...

Embodiment 3

[0096] Embodiment 3, reactive dyes to nylon 56, nylon 66 dyeing rate experiment

[0097] Prepare 1g / L Arnosol Brilliant Blue RV100% dye standard dye solution, prepare 10 groups of 2mL standard dye solution dye baths, fiber 0.2g, bath ratio: 1:500, and 10g / L Yuanming powder, adjust the obtained dye solution When the pH value of the dye reaches 7.5, put it into the dyeing machine with the dyeing temperature set at 60°C, take out the samples after dyeing for 5min, 10min, 15min, 20min, 30min, 45min, 60min, 75min, 90min, and 120min, and rinse them with room temperature water , after drying, strip the color to test its dyeing rate curve.

[0098] The dyeing rate curves of nylon 56 and nylon 66 dyed with reactive dyes are as follows Figure 4 As shown, the dyeing kinetics data of reactive dyes are calculated according to the dyeing rate curve and are shown in Table 4.

[0099] Reactive dye dyeing kinetics data under table 4 alkaline bath

[0100]

[0101] Depend on Figure 4 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com