Composition, set and treating method for treating sulfur dyestuff dyed textile

A sulfur dye and fabric treatment technology, which is applied in the fields of biochemical fiber treatment, fiber treatment, textile and paper making, etc., can solve the problems of poor biological finishing effect of sulfur dye dyed fabrics, improve the anti-pilling performance, enhance the vitality, The effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

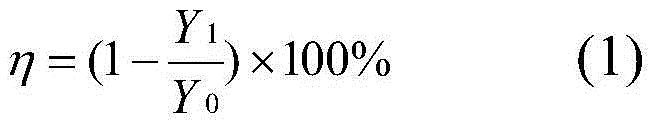

Problems solved by technology

Method used

Image

Examples

Embodiment 1

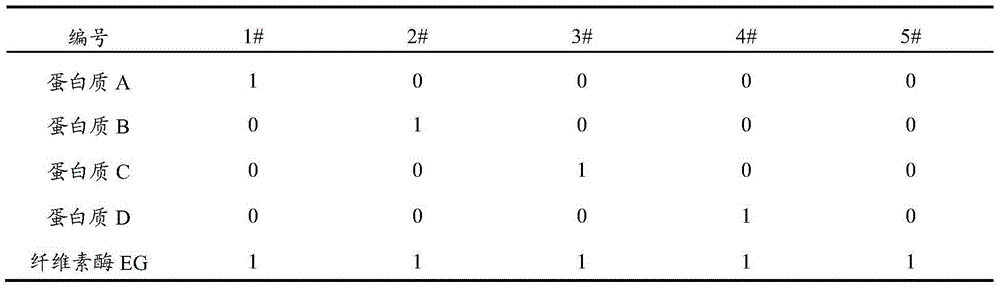

[0038] Take 5 dyeing cups (numbered from 1# to 5#), add various components to the 5 dyeing cups in sequence according to the mass ratio listed in Table 2, add 150mL distilled water, and adjust the pH to 5.0, set the weight to 400g, so that the composition of the enzyme treatment liquid contains 0.01-5.0g / L of protein and 0.01-5.0g / L of cellulase. Then add 20g of knitted weft-knitted fabric dyed with sulfur black, and process it in the dyeing machine for 60min.

[0039] Treatment liquid composition table in the embodiment 1 of table 2

[0040]

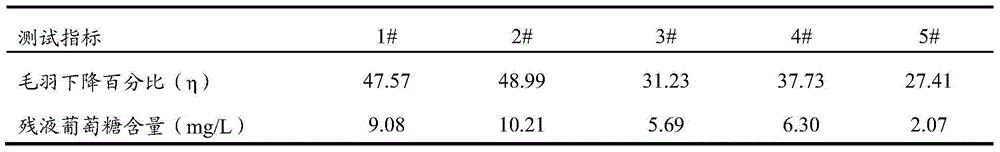

[0041] After the treatment, take out 2mL of the treatment solution to measure its glucose content. Then add 2g / L Na to the treatment solution 2 CO 3 , Continue to process for 10 minutes, take out the cloth sample, wash it twice with clean water, and test the hairiness removal rate of the fabric after drying. The results are shown in Table 3.

[0042] Table 3 embodiment 1 enzyme treatment effect index comparison

[0043]

[0...

Embodiment 2

[0046] Cellulase 325i and proteins A, B, C, and D are respectively in a weight ratio of 1:1, mixed evenly in advance, and left for 30 days. Take 5 dyeing cups (numbered from 6# to 10#), according to Table 4 Add various components to 5 dyeing cups in turn, add 150mL of distilled water, adjust the pH to 5.0 with acetic acid and sodium acetate solution, and set the weight to 400g, so that the composition contains 0.01-5.0g / L of protein, cellulase 0.01-5.0g / L enzyme treatment solution, add 20g of knitted weft-knitted fabric dyed with sulfur black, and treat it in the dyeing machine for 60min.

[0047] Treatment liquid composition table in the embodiment 2 of table 4

[0048]

[0049] After the treatment, take 2mL of the treatment solution to measure its glucose content. Add 2g / LNa to the treatment solution 2 CO 3 , Continue to process for 10 minutes, take out the cloth sample, wash it twice with clean water, and test the hairiness removal rate of the fabric after drying. Th...

Embodiment 3

[0055] Cellulase 325i and proteins A, B, C, and D were mixed at a weight ratio of 1:1, and then divided into five samples (numbered 11# to 15#) and left for 30 days. Add 60kg of jeans dyed with sulfur black to a 500-pound industrial washing machine, add 600kg of water, heat up to 55°C, add various components to the washing machine in sequence according to the mass parts in Table 6, and adjust the pH to 6.5-7. Enzyme treatment solution containing 1.0-2.0 g / L of protein and 1.0-2.0 g / L of cellulase was obtained in the washing machine, and continued to run for 60 minutes. Take 2mL of the treatment solution to measure its glucose content. Drain the residual liquid, wash the clothes twice with clean water, and after centrifugal dehydration, dry them to test the hairiness removal rate of the fabric. The results are shown in Table 7.

[0056] Treatment liquid composition table in the embodiment 3 of table 6

[0057]

[0058] Table 7 embodiment 3 enzyme treatment effect index co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com