Production technological process and production line of environment-friendly jean

A production process and production line technology, applied in dyeing, textile and papermaking, liquid/gas/vapor yarn/filament treatment, etc., can solve problems such as waste, high COD content in wastewater, and water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

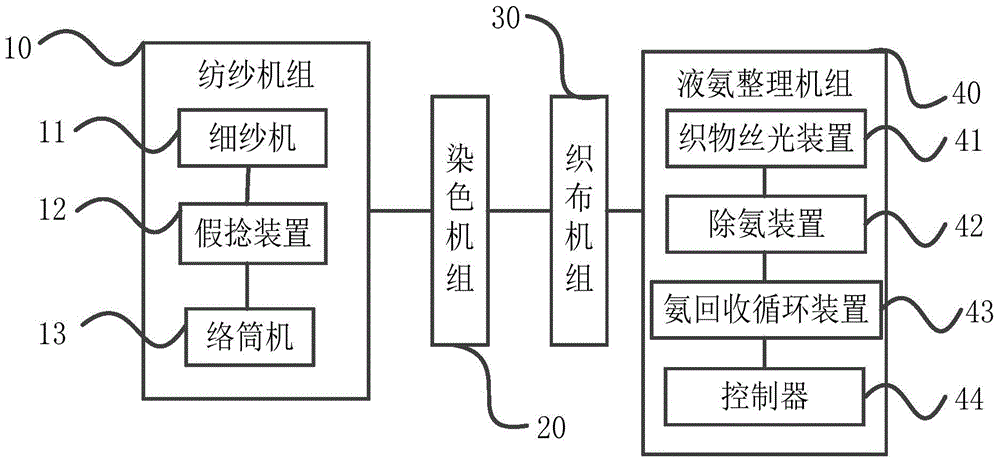

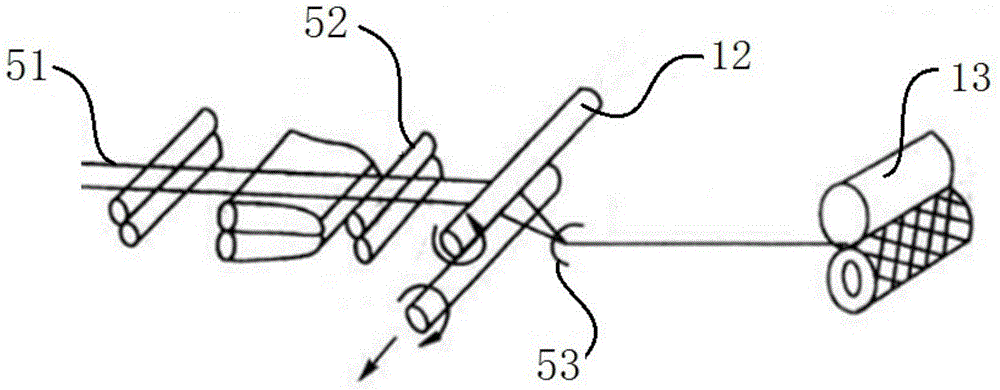

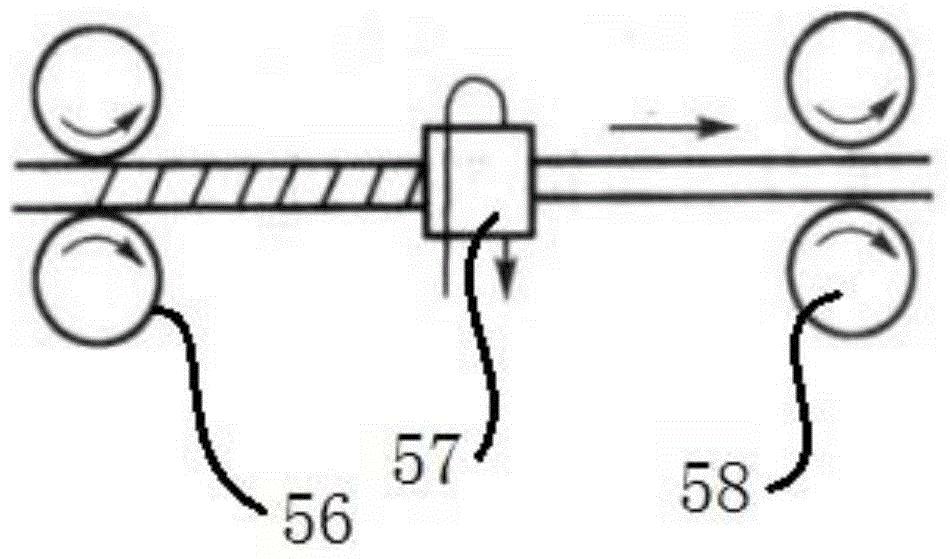

[0030] The invention provides a production process of environment-friendly denim, including the following steps: spinning → winding → dyeing → machine weaving → singeing → mercerizing → ammonia removal → shaping → weft adjustment → pre-shrinking → inspection → reel ; it is characterized in that a false twist process is added between the spinning process and the winding process, so that excessive pre-twisting occurs in the axial direction of the sliver, and an equal number of twists with different twist directions are produced on the sliver; In the process, the sulfur dyes containing glucose are first adsorbed in the 60-90°C rolling liquid, and then the color is fixed; the ammonia removal process is carried out in a high-temperature and high-pressure tank to evaporate the residual ammonia in the fabric. The ammonia process also includes collecting the evaporated ammonia, and sending it back to the mercerizing process for further use after being cooled and compressed.

[0031] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com