Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

237 results about "Hollander beater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Hollander beater is a machine developed by the Dutch in 1680 to produce paper pulp from cellulose containing plant fibers. It replaced stamp mills for preparing pulp because the Hollander could produce in one day the same quantity of pulp it would take a stamp mill eight days to prepare.

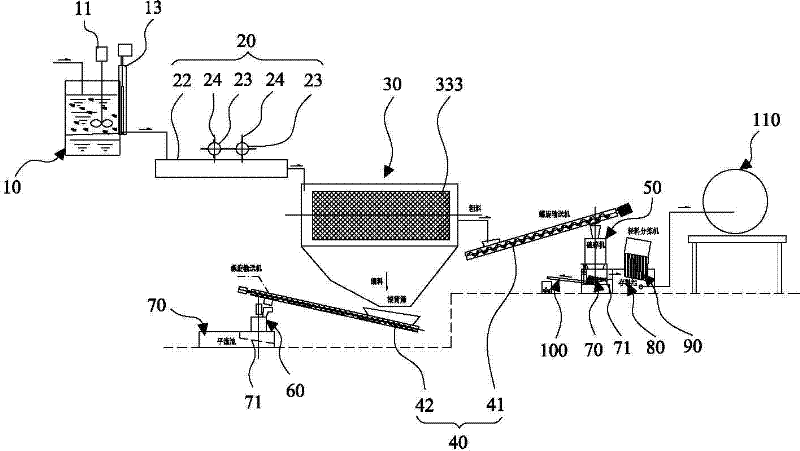

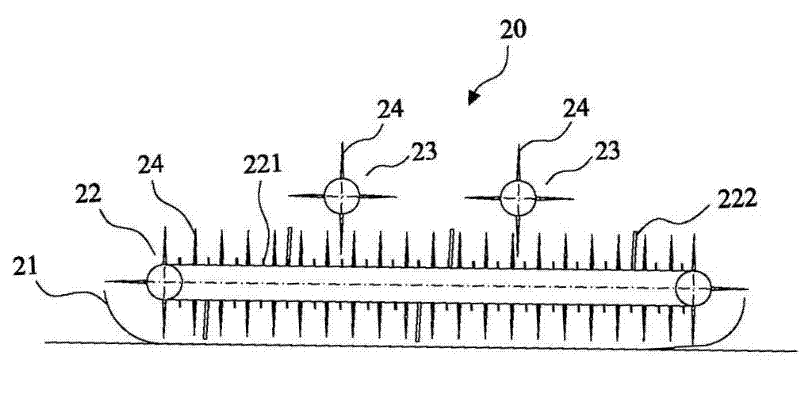

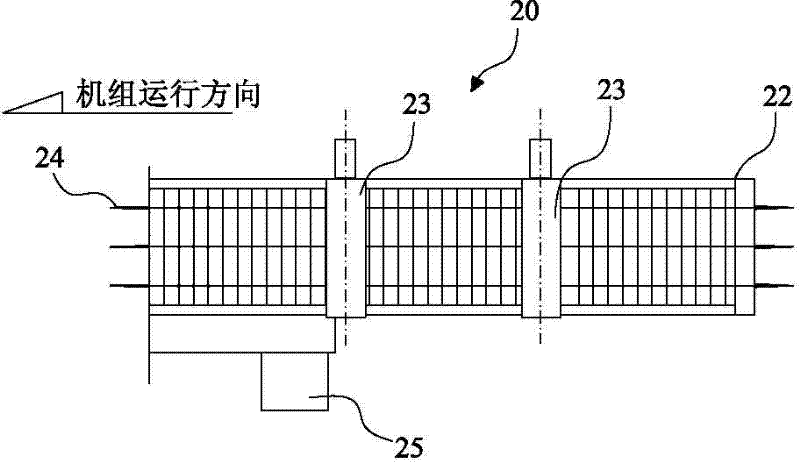

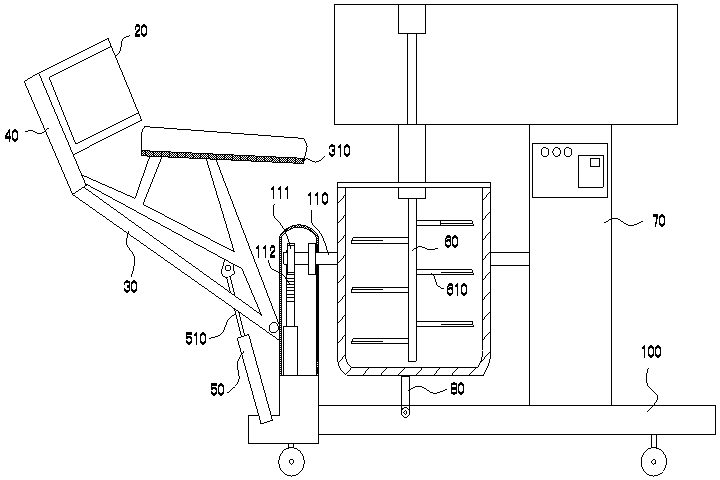

Restaurant-kitchen garbage sorting system

InactiveCN102327890AImprove processing efficiencyAccurate classificationSievingScreeningPlastic packagingProcess engineering

The invention discloses a restaurant-kitchen garbage sorting system. The system orderly comprises a scrubbing oil groove for separating grease from residues, a bag breaking conveyor for tearing a plastic package and a drum screening machine for screening the residues into coarse material and fine material, and a coarse material outlet and a fine material outlet are arranged on the drum screening machine, a coarse material spiral conveyor and a fine material spiral conveyor are respectively arranged corresponding to the coarse material outlet and the fine material outlet, a crusher is arranged at an outlet of the coarse material spiral conveyor, a pulping machine is arranged at an outlet of the fine material spiral conveyor, and a horizontal flow pool for dividing the pulp from the crusher and the pulping machine into light material and heavy material. Therefore, the restaurant-kitchen garbage sorting system can effectively treat the bagged garage without manual operation, and improve the garage processing efficiency; and the garage can be classified so as to be convenient for recycle.

Owner:DONGGUAN CAMDA GENERATOR WORK

Method for preparing orange peel paste

The invention relates to a production method of a citrus peel paste, firstly fresh and non-perishable citrus peels (dry peels after the air-drying needs to be soaked and softened by clean water) is selected, cleaned by the clean water, cut into blocks or silks by a knife, the blocks or the silks are put into a stainless steel pot or an aluminum pot, 2 percent salt water is added for boiling for 30 minutes twice, and the blocks or the silks are bailed, soaked and rinsed to eliminate bitterness. The pulp making is carried out on the well processed citrus peels by using a pulping machine or a mincing machine, white sugar is then added according to the paste / sugar ratio of 1: 0.6, then heating is carried out for 30 minutes in the pot, 0.7 percent-1 percent citric acid is added, the heating is continued till pulp juice is condensed into the paste, and then the paste is removed out of the pot and bottled. The peels of oranges and grapefruits can be processed into the citrus peel paste as a daily table condiment, thereby changing waste into valuable.

Owner:胡义庭

Novel beater

InactiveCN103638847ARealize flipping and unloadingEasy to transportRotary stirring mixersMixer accessoriesStructural engineeringMechanical engineering

The invention provides a beater. A stirring shaft capable of stretching into a stirring barrel is arranged above the stirring barrel, a stirring paddle is arranged on the stirring shaft, a support is arranged at the front side of the stirring barrel, an overturning rack is articulated with the support, a feeding guide plate is arranged on the overturning rack, a pair of charging skip fixing rods forming an obtuse angle with a material guide plate are connected at the upper end of the overturning rack, a charging skip is arranged on the charging skip fixing rods, the bottom of the overturning rack is connected with a driving mechanism for driving the overturning rack to rotate at the articulated position, and the front end of the overturning rack is leveled with the ground when rotating to be close to the ground. The beater has a simple structure, can realize charging and stirring integration, greatly facilitates conveying materials for the beater and improves the production efficiency and the safety.

Owner:FUZHOU JIN XIANG FOOD MACHINERY & EQUIP TECH

Preparation of carbon nano tube/acrylic carbon fiber composite carbon fiber paper and use

InactiveCN1986961AImprove conductivityGood flexibilityChemical/biochemical paper treatmentSynthetic cellulose/non-cellulose material pulp/paperFiberAdhesive

A process for making the composite carbon nanotube-acrylonitrile based carbon fiber paper includes such steps as immersing the acrylonitrile based carbon fibers and carbon nanotubes in the solution of activating agent for 1-3 hr, water washing until they become neutral, proportioning, pulping, adding disperser solution and adhesive, and conventionally making paper by wet method. The resultant paper can be used as antistatic packing material, planar heating material, novel energy source material, electrochemical material, electromagnetic shielding material, high-fidelity sounding material, etc.

Owner:DONGHUA UNIV

Method for preparing raw apple pulp

The invention discloses a method for preparing raw apple pulp, which comprises the following steps of: taking fresh and mature apples with sugar degree greater than or equal to 12-DEG Brix as a raw material, conveying the apples to a crushing machine, and crushing the apples into 1-3 cm particle size; beating the crushed apples in a beating machine, and adding VC (Vitamin C) accounting for 0.01-0.5% of the apples by weight for color protection during beating; heating the pulp to 80-100 DEG C, and maintaining the temperature for 5-10 min; then, beating the hot pulp in a double-way beating machine, temporarily storing the pulp for 10-30 min, and homogenizing the pulp under the pressure of 5-10 MPa; and degassing the pump by using a degassing machine after homogenizing, filtering the pulp, and performing pasteurization to obtain the raw apple pulp. The obtained raw apple pulp does not have obvious caking or layering and has white or slight yellow color, the apple pulp has unique taste and aroma of mature apples and palatable sweet and scour taste and does not have bad smell caused by fermentation or other causes, and no additive such as essence, pigments, preservatives and the like is added.

Owner:LINGBAO BRANCH OF SHAANXI HAISHENG FRESH FRUIT JUICE CO LTD

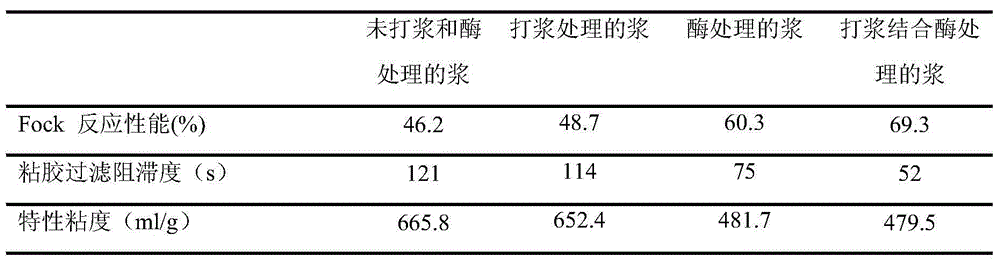

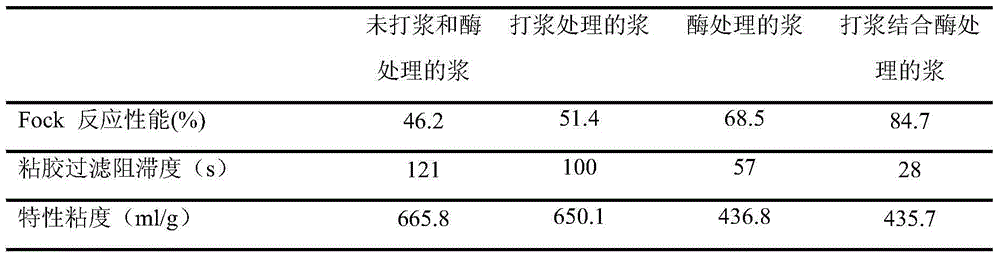

Method for improving reactive performance of prehydrolysis sulfate dissolving pulp

InactiveCN104452397AImprove responseGuaranteed viscosityMicroorganism/enzyme additionPulp beating methodsWater bathsSulfate

The invention discloses a method for improving the reactive performance of prehydrolysis sulfate dissolving pulp. The prehydrolysis sulfate dissolving pulp of needle leaf wood or broad leaf wood with the concentration of 30 percent is adopted, 18 L of water are firstly added to a pulp tank of a pulping machine, the pulp is added slowly, water is supplemented, so that the concentration of the pulp reaches 1.57 percent, pulping is carried out for 10-90 minutes, the pulp is concentrated to the concentration of 20 percent, then the pulp is taken and transferred into a polyethylene plastic bag with a sealing opening, distilled water and cellulase liquid are added to dilute the pulp to the concentration of four percent, enzyme / bone dry pulp is 3.0 u / g-4.0 u / g, the pH value is adjusted to be three to six, and the pulp is placed in a water bath kettle to be treated. Suction filtration is carried out on the treated pulp, water of 90 DEG C is added to the pulp until the concentration of the pulp is four percent, heating is carried out for 30 minutes, and the pulp is air-dried to the concentration of 95 percent under the condition of constant temperature and constant humidity. The method has the advantages that the reactive performance of the dissolving pulp is improved by combining mechanical treatment and enzyme treatment, and the reactive performance of the prehydrolysis sulfate dissolving pulp can be improved.

Owner:FUJIAN AGRI & FORESTRY UNIV

Processing method of purple sweet potato sauce

InactiveCN104026427AGreat tasteDelicate tasteFood ingredient functionsFood preparationWater basedAdditive ingredient

The invention discloses a processing method of purple sweet potato sauce. The processing method comprises the following steps: (A) preprocessing, namely washing selected fresh purple sweet potatoes to remove silt from skins of the purple sweet potatoes, peeling, crushing the peeled purple sweet potatoes into purple sweet potato slices; (B) pulping, namely, deactivating and steaming the purple sweet potato slices obtained in the step (A), adding 70-200% of water based on the weight of the purple sweet potatoes, rapidly heating the mixture to 80-95 DEG C, adding the mixture into a pulping machine, and pulping to obtain purple sweet potato pulp; (C) carrying out dosing and homogenizing, namely adding a mixture consisting of a seasoning agent, a stabilizing agent and an acidity regulator into the purple sweet potato pulp obtained in the step (B), carrying out vacuum stirring and blending, and carrying out homogenizing by virtue of a homogenizing machine; and (D) heating and sterilizing the homogenized materials obtained in the step (C), and cooling to obtain the purple sweet potato sauce. Compared with the prior art, the processing method has the advantages that by utilizing a closed processing manner, the mechanical degree is high, a fermentation step is omitted, the production cycle is short, the sauce is nutrient and healthy, and nutrition ingredients such as dietary fiber, pectin and protein in the purple sweet potato are preserved.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

Slow-release fragrance-type antibacterial super-hydrophobic processing method for decorative paper

InactiveCN110777567AMeet the intensitySatisfy breathabilitySurface covering paperReinforcing agents additionCelluloseKaolin clay

The invention discloses a slow-release fragrance-type antibacterial super-hydrophobic processing method for decorative paper. The method comprises the steps: immersing bleached softwood pulp and bleached hardwood pulp in water, performing defibering by using a beater, starting beating, adding a titanium dioxide-kaolin composite suspension, a wet strength agent and a retention aid to the pulp, preparing sheets by using a standard paper sheet former, performing vacuum drying and moisture balancing so as to obtain decorative base paper, immersing the obtained decorative base paper in a slow-release fragrance-type antibacterial microcapsule solution, taking the immersed paper out, performing natural drying so as to obtain slow-release fragrance-type antibacterial processed decorative paper, putting hydrophobic-modification cellulose nanoparticles, methyltrimethoxysilane and water in a closed reactor for a reaction, adding the reaction product into tetrahydrofuran, performing ultrasound treatment so as to obtain a super-hydrophobic coating, spraying the coating uniformly to the slow-release fragrance-type antibacterial processed decorative paper by using a spray gun, and performing curing in an oven so as to obtain the slow-release fragrance-type antibacterial super-hydrophobic decorative paper.

Owner:刘丹丹

Waste leather treatment method

ActiveCN107287975AEasy to handleIncrease profitMonocomponent protein artificial filamentOrganic non-cellulose fibresFiberBacillus licheniformis

The invention discloses a waste leather treatment method. The method comprises steps as follows: (1), leather pretreatment: cleaned leather is soaked in acid liquor and then is cleaned and spin-dried, and the leather is cut into pieces and subjected to coarse grinding for standby application; (2), beating: the ground leather is soaked in alkali liquor for 3-5 h at the temperature of 30-40 DEG C, then the leather is soaked in an aqueous solution containing bacillus subtilis and bacillus licheniformis for fermentation, the leather and bacterium-containing water are put in a beater and subjected to beating, and pasty collagenous fibers are obtained; (3), wringing and stretching: the pasty collagenous fibers are laid on a pass-type wringing machine and wrung by the pass-type wringing machine, and the moisture content of the wrung collagenous fibers is 80%; (4), papermaking: the wrung collagenous fibers are added to softwood pulp, and paper is made. The bacillus subtilis and the bacillus subtilis are adopted for fermenting the leather, so that the extraction rate of the collagenous fibers can be increased, the leather treatment effect is good, the utilization value is high, and no secondary pollution is produced.

Owner:台州中知英健机械自动化有限公司

Light soft sound-insulating high-adhesion wallpaper and manufacturing method thereof

InactiveCN107366195AWell mixedPlay a sound insulation effectSpecial paperNon-macromolecular organic additionCelluloseFiber

The invention discloses light soft sound-insulating high-adhesion wallpaper and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) smashing wood pulp cellulose and cellulose acetate butyrate, and uniformly mixing; (2) adding a wood pulp cellulose and cellulose acetate butyrate mixture to water, pulping by a beater, and preparing mixed slurry; (3) papermaking, pressing and drying the mixed slurry, to obtain base paper of the wallpaper; and (4) soaking the base paper of the wallpaper by acetone solution, drying, and preparing the light soft sound-insulating high-adhesion wallpaper by a reeling working procedure. The wallpaper has the characteristics of soft hand feel, light texture, good adhesion with the wall surface, long service time, and better sound-insulating effect.

Owner:武汉菡美洛建筑材料有限公司

Autoclave aerated concrete block produced from waste glass and production method thereof

InactiveCN105236905ASmall finenessHigh strengthSolid waste managementAutoclaved aerated concreteAluminium

The invention provides an autoclave aerated concrete block produced from waste glass and a production method thereof. The concrete block is prepared from desert fine sand, cement, quicklime, waste glass and aluminum powder paste. The main preparation steps include: (1) grinding the desert fine sand and waste glass into powder by a ball mill, and conducting beating with a beater for standby use; (2) crushing the quicklime with a crusher, and then performing grinding into powder by the ball mill; (3) putting the beat desert fine sand and waste glass powder, the ball milled quicklime, cement and aluminum powder paste in a stirrer, adding water and stirring the materials fully, thus obtaining a mixture; (4) casting the mixture in a mold, performing initial setting to obtain a large block blank; (5) cutting the large block blank, and then conducting static maintenance; and (6) performing autoclave curing, thus obtaining the product concrete block at the end.

Owner:DINGSHENG INC

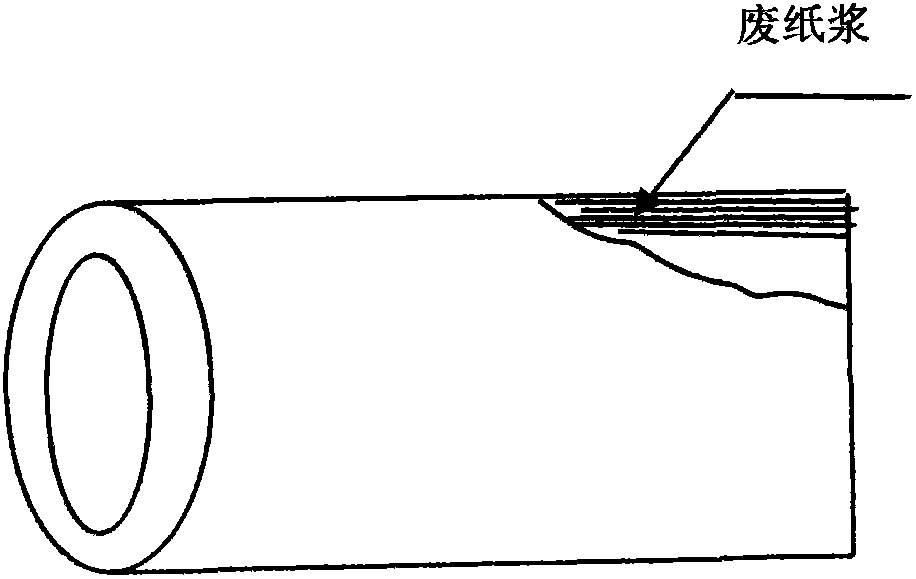

Method for producing paper tubes by waste paper pulp

InactiveCN102700174ALow costHigh speedEnvelopes/bags making machineryPaperboardPulp and paper industry

The invention relates to a method for producing paper tubes by waste paper pulp. The method is characterized in that the waste paper pulp used as a raw material is blended with glue and stone powder to produce the paper tubes by a squeezing method. Paper pulp is manufactured by steps including 1, uniformly grinding the waste paper pulp disposed during production of a paper mill by a grinder; 2, beating waste paperboards by a beater to obtain paper pulp; and 3, mixing the waste paper pulp and the paper pulp manufactured from the waste paperboards into mixed waste paper pulp. The glue is manufactured by steps including 1, boiling water and adding polyvinyl alcohol into the water to prepare glue; and 2, adding borax and caustic soda flakes into corn starch to prepare glue. The paper tubes made of the waste paper pulp have the advantages of low production cost, fast speed, good quality, simplicity in operation, wide production range and high applicability, and have an excellent commercial prospect, and the method is an ideal paper tube production method at present.

Owner:任立群

Preparation process of walnut cake

The invention discloses a preparation process of a walnut cake. The reparation process comprises the following steps of (1) pre-processing auxiliary materials, i.e. adding white sugar, syrup, ammonium carbonate, sodium bicarbonate, edible salt, spices, baking powder and water into a high-speed beater, and mixing the materials for 5 to 7 minutes to obtain mixed pulp; (2) transferring the mixed pulp to a dough mixer, adding flour, edible oil and chicken extract into the mixed pulp, slowly beating the mixed pulp for 2 to 3 minutes at the rotation speed of 30 to 35 revolutions per minute, and quickly beating the mixed pulp for 3 to 5 minutes at the rotation speed of 50 to 60 revolutions per minute to obtain a mixed material; (3) molding the mixed material in a die; (4) baking the molded walnut cake for 5 to 6 minutes in a section type oven, wherein the oven is sequentially divided into four areas, the temperature of the first area is controlled to be between 200 and 220 DEG C, the temperature of the second area is controlled to be between 220 and 250 DEG C, the temperature of the third area is controlled to be between 160 and 180 DEG C; the temperature of the fourth area is controlled to be between 120 and 140 DEG C; (5) cooling the walnut cake and shaping the walnut cake. The walnut cake prepared by the method is good in molding, loose in mouthfeel, thick in fragrance and unique in taste, does not have the taste of baking powder and sodium bicarbonate, and can be eaten by old people and children.

Owner:安徽顶能食品有限公司

Textile printing technology

InactiveCN108221406ARealize the printing jobImprove general performanceDyeing processTO-18Textile printer

The invention provides a textile printing technology and solves the technical problems that an existing printing technology only can be applied to printing Dacron textiles, has singleness in use and the like. The textile printing technology comprises the following steps: a, in parts by weight, putting 10 to 18 parts of natural dye, 20 to 26 parts of printing gum, 2 to 3 parts of sodium salicylate,8 to 12 parts of dye fixing agent, 1 to 4 parts of dispersant, 1 to 3 parts of defoaming agent, 0.5 to 1.5 parts of anti-wrinkle agent and 70 to 80 parts of water into a pulping machine to be pulpedto prepare printing paste; b, directly printing the textile to be printed by the printing paste in the step a; c, drying the printed textile by an oven; d, putting the dried textile into a steaming box to be steamed twice, steaming at high temperature at first and then steaming at low temperature; e, cleaning the steamed textile in water in which 1.5 to 3.5g / L alkali agent and 0.5 to 1.5g / L surface active agent are added; f, shaping and drying the cleaned textile at the temperature of 142 to 148 DEG C. The textile printing technology disclosed by the invention has the advantage of strong universality.

Latex fiberboard recycling and reusing method and recycling and disposal system applying same

The invention relates to the production field of latex fiberboards, in particular to a latex fiberboard recycling and reusing method and a recycling and disposal system applying the same. The latex fiberboard recycling and reusing method comprises the following steps that (a) the latex fiberboards are put into a crushing machine, and crushing treatment is performed to obtain a crushed board material; (b) the crushed board material is put into a hydropulper, and pulping treatment is performed to obtain a pulp material; (c) the pulp material is put into a beating pond, and a beating machine is adopted to perform beating treatment so as to obtain a primary pulp material; (d) the primary pulp material is subjected to filtration treatment to obtain a refined pulp material for storage and stand by application; (e) the refined pulp material in a pulp storage pond is taken out and delivered to a pulp preparing system. The recycling and disposal system can efficiently recover and reuse a large area of latex fiberboards in a low-energy-consumption mode, on the one hand, the production cost is saved, and on the other hand, waste and environmental pollution are also avoided.

Owner:GUANGDONG WALKKIND SPECIAL FIBERBOARD TECH

Method for preparing dye by plum peel and application thereof

The invention discloses a method for preparing dye by plum peel and application thereof, which is characterized in that industrial salt or acetin and water are used for preparing the fixative of dye. The method for preparing the dye comprises the following steps: peeling the plum by a fruit huller; separating out the plum peel; pulping the plum peel into fine slurry by a beater; adding 6-8 times of water in a reaction kettle; and filtering impurities by a filter screen to prepare dye solution. The application of preparing dye by the plum peel is characterized in that natural cellucotton, hemp, silk and the like which are to be dyed are dipped into the prepared fixative and are slowly decocted with slow fire for about one hour, and then the obtained product is cleaned; and the cleaned natural fiber is dipped ito plum dye solution and is slowly decocted for one hour until the fiber is dyed into red.

Owner:ZHANGJIAGANG HONGZUAN TRADE

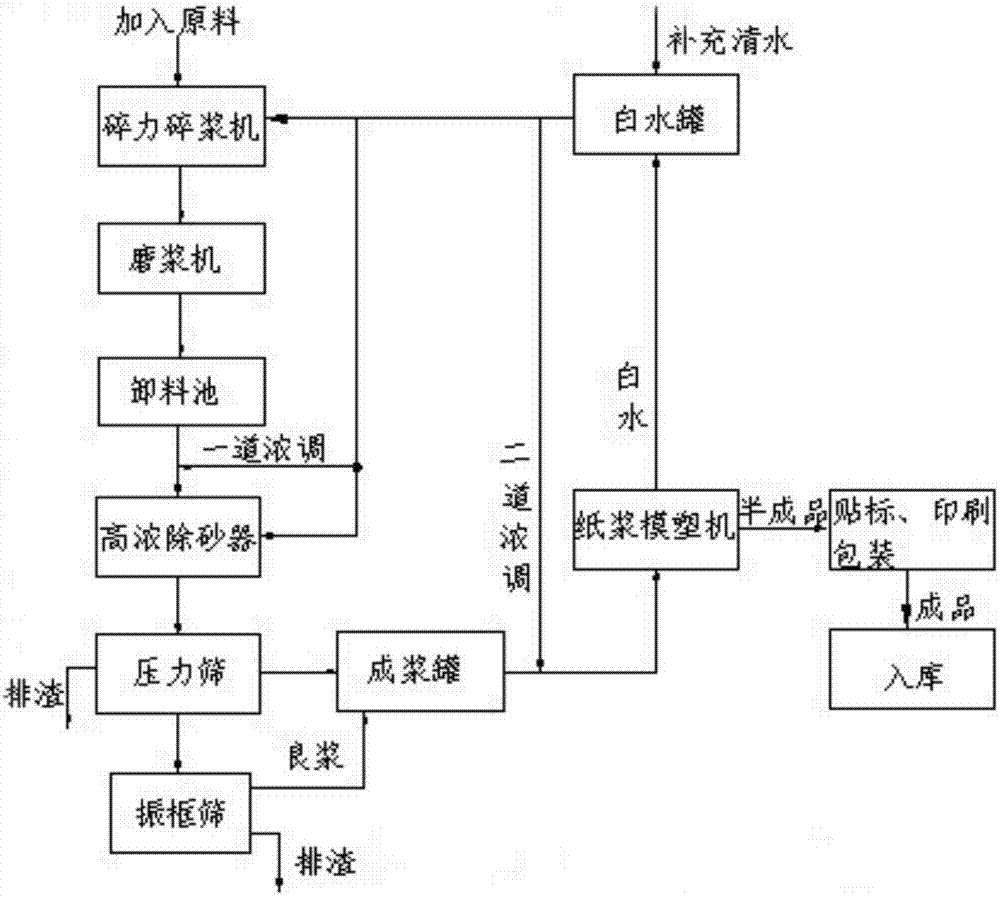

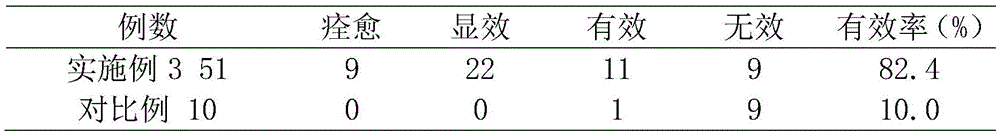

Novel paper pulp molding processing technology and molding die thereof

InactiveCN107354825AImprove water resistanceIncreased ring compressive strengthTextiles and paperHigh concentrationFiber

The invention relates to a novel paper pulp molding processing technology and a molding die thereof. The technology comprises the steps of conducting beating on plant fiber slurry by a beater; diluting paper pulp; adding the paper pulp into a pulp grinder to be ground; diluting the paper pulp to have the concentration of 3% by concentration adjustment equipment; screening heavy impurities out by a high-concentration slag remover; conducting screening by a pressure sieve, and making the paper pulp enter a slurry forming tank after screening; conducting screening by a vibrating frame sieve, and making the paper pulp enter the slurry forming tank after screening; conducting secondary dilution on the slurry by the concentration adjustment equipment, controlling the concentration of the slurry within 1-1.5%, and completing slurry preparation; utilizing a vacuum die suction machine to adsorb the slurry, and conducting dehydration to form wet ground paper; adsorbing the wet ground paper onto a molding die arranged in a multi-layer and stage-division mode to be molded through different stages, and obtaining the multi-layer wet paper die; bonding and extruding the multi-layer wet paper die; heating, drying and shaping the wet paper die to form paper pulp molded products. The products produced through the adoption of the technology are higher in thickness, better in waterproof performance, and suitable for large toys, real-person models and the like.

Owner:张宝华

Hollowed wampee sauce and preparation method thereof

ActiveCN105639599ANarrow particle distributionImprove uniformityFood ingredient functionsEmulsionHigh pressure

The invention discloses a hollowed wampee sauce and a preparation method thereof. The method comprises the following steps: 1) selecting a raw material and treating; 2) performing high-speed dispersion emulsifying treatment: crushing hollowed wampee fruit obtained from step 1) with a beater, then adding pure water of the same weight, putting in a high-speed dispersion emulsifier to give a high-speed dispersion emulsion; 3) performing pressurized extraction: putting the emulsion treated in step 2) in a high pressure tank, pressurizing to 4kg / cm<2>, so that the pressure is uniform, and maintaining for 10-15min, then restoring to normal pressure in 1-3s, and obtaining a pulp extract mixture; 4) pickling: adding salt into the pulp extract mixture obtained from step 3) to be sealed in a container 3-4 months, 5) adding ingredients for pickling: taking out the pickled material obtained from step 4), adding the ingredients and mixing well, then adding to the sealed container to be pickled for 1-2 months; 6) subpackaging and sterilizing to obtain a finished product.

Owner:江苏大墩子银杏生物科技有限公司

Environment-friendly ceramic material and preparation method thereof

The invention discloses a ceramic material including the ingredients in percentages by weight as follows: 250%-60% of SiO, 10%-20% of Al2O3, 1%-10% of Fe2O3, 1%-3% of TiO20, 13%-20% of CaO, 0.5%-5% of MgO, 0.5%-5% of K2O, and 0.5%-5% of Na2O. The preparation steps includes (a) firstly making molds for production from sculptured prototypes by using sand silica gel, wherein the molds are silica gelsoft molds and a mold groove made of gypsum is arranged at the lower surface of each soft mold and fixedly provided with a silica gel mold internally; (b) pouring the ingredients into a bucket, adding appropriate amount of water, stirring to be uniform by a beater, pouring the slurry into four molds respectively for only one third, moving the molds into a vacuumizer for vacuumizing for 30 seconds, then moving the molds back to a working table, and pouring the left slurry into the molds for left two thirds to full; (2) pressing and embedding a prepared back plate into the slurry, scraping the surplus slurry to be flat with a scraper, solidifying for 20-30 minutes, and then demolding; (d) fully grinding the convex surplus slurry at the back part of the product to be flat, wherein the bottomgrinding time is within 4 hours; (e) filling pores which are caused by the reason that part of air bubbles of the product formed by slip casting of atomic putty are not discharged completely, finishing particles or mold lines on the surface of a green body to be smooth and drying for 16-48 hours naturally; (f) spraying paint or adhering pattern paper on the product and then drawing at drawing parts, and (g) packaging after product inspection. The environment-friendly ceramic material has the advantages of strong adaptability to environment, degradability, and no folds in shape.

Owner:DONGGUAN QUANXIANG CERAMIC MATERIAL

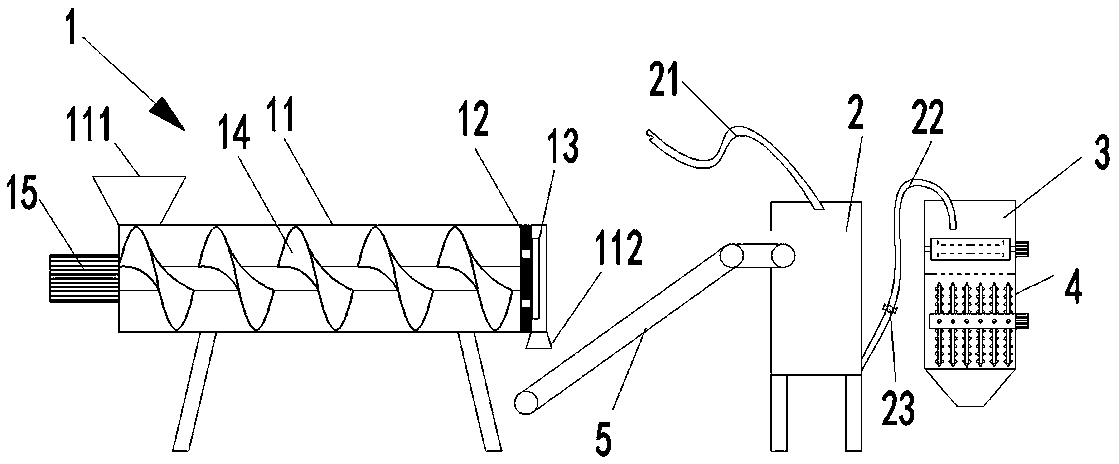

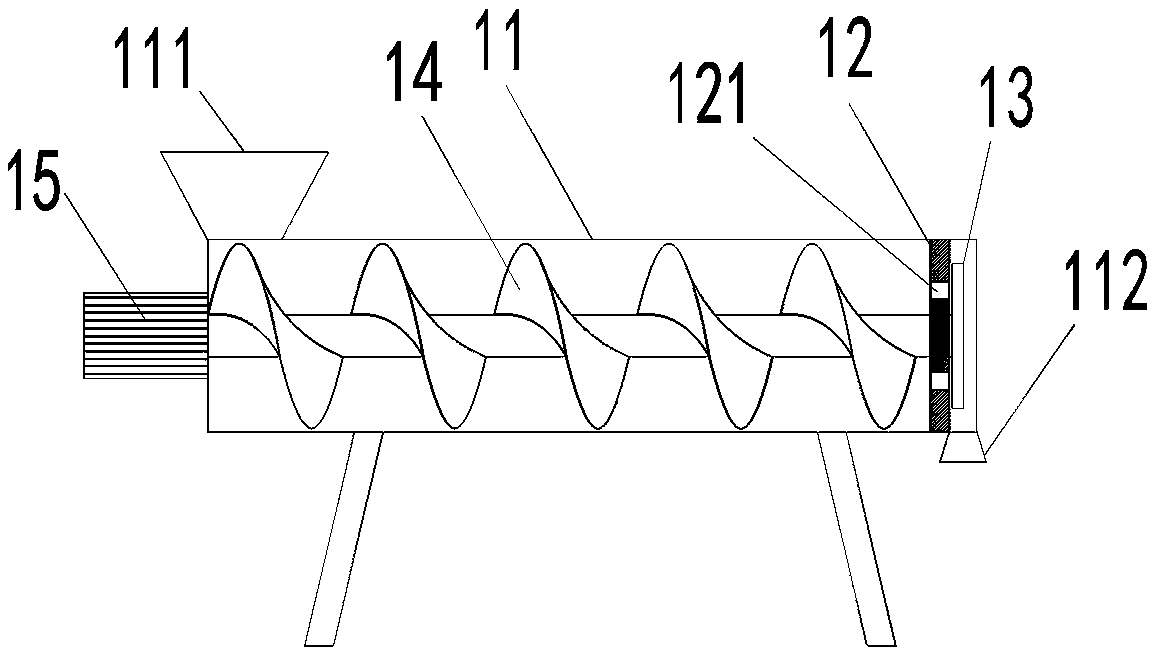

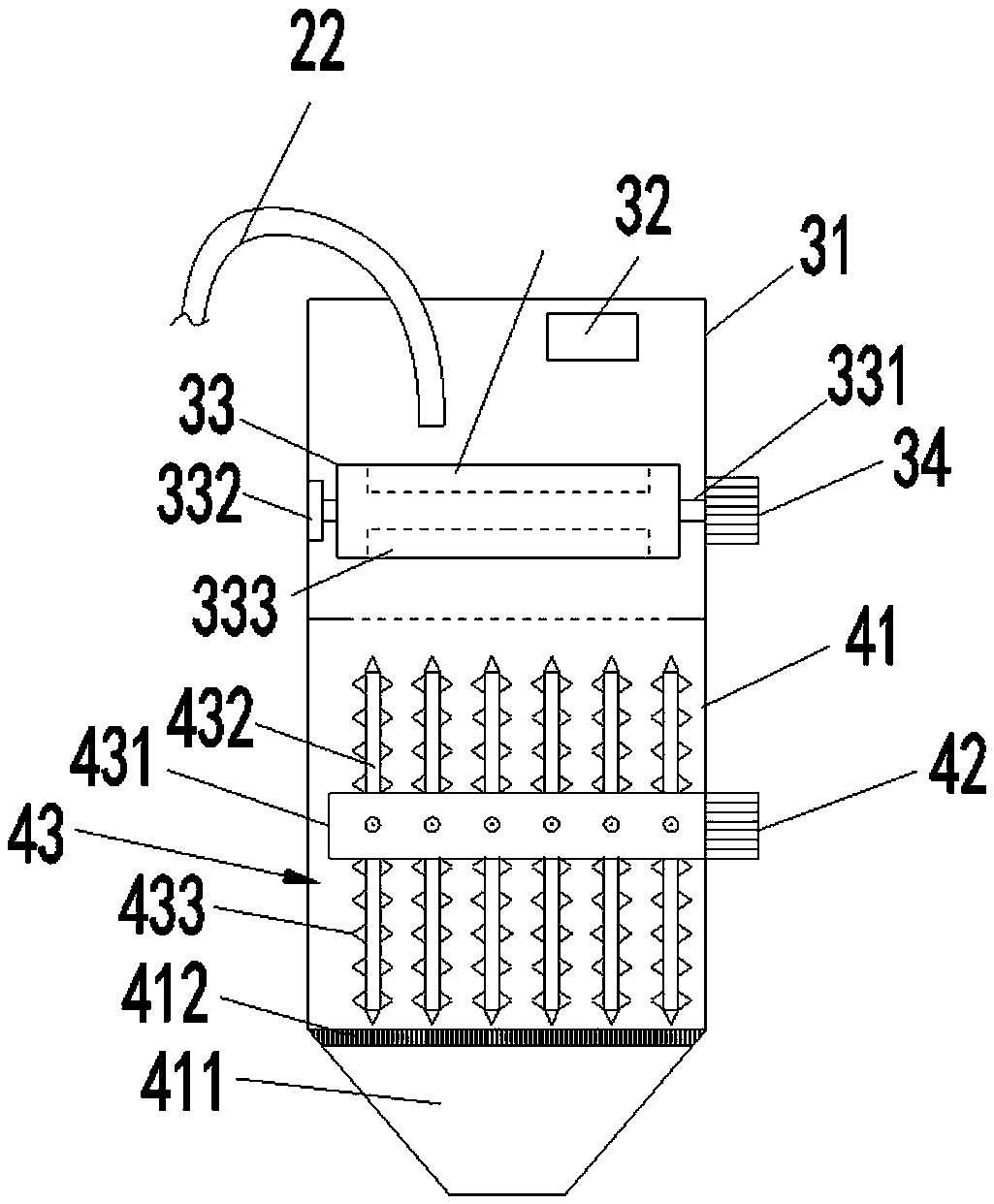

Pleurotus geesteranus powder preparation device

PendingCN107692190AIncrease productionReduce workloadDrying gas arrangementsFood treatmentElectric machineStructural engineering

The invention relates to a pleurotus geesteranus powder preparation device which comprises a shredding device, a beating machine, a drying device and a crushing device successively arranged. The shredding device comprises a shredding barrel, a reamer disc, a double-edge reamer, an auger shaft which is horizontally arranged in the shredding barrel and is rotatably connected to the shredding barreland a first rotating motor arranged on one side of the shredding barrel. The reamer disc is fixedly arranged in on end portion, far from the first rotating motor, of the shredding barrel; a pluralityof guide ports are formed in the reamer disc, one end of the auger shaft is connected to the output shaft of the first rotating motor while the other end penetrates through the reamer disc and is fixedly connected to the double-edge reamer; a climbing conveyor belt is arranged below a discharge port and transmits a material to the input port of the beating machine, and the beating machine which mixes and beats a pleurotus geesteranus material with water outputs the mixture to the drying device through a conveying pipeline; and the drying device dries the slurry to blocks, and the crushing device is arranged at the lower end of the drying device, and crushes the dried solid blocks into powder.

Owner:福建省百谷农业发展有限公司

Ginger terrestrial stem paper and manufacturing process thereof

InactiveCN101435170AAvoid pollutionLow costPretreatment with water/steamPulp beating methodsWater dischargeWastewater

The invention discloses ginger terrestrial stem paper and a manufacturing process thereof, included material is ginger terrestrial stem; the material is added with a paper making addition agent; and the manufacturing process comprises the following steps of: (1) selecting dried ginger terrestrial stem as the paper making material; (2) pulping: a. the dried ginger terrestrial stem is crashed to obtain crashed material; b. the crashed material is arranged in water for soaking; and c. the soaked crashed material is arranged in a beating machine for pulping, thus obtaining paper making pulp; and (3) carrying out papermaking and drying to obtain the finished product of paper. No distinction exists between the characteristic and use of the paper and that of wood pulp paper, and compared with the wood pulp paper, the cost thereof is reduced by about 60 percent. The paper making process adopting the ginger terrestrial stem as the material does not need the procedures of high-pressure stewing, preserving and washing, thus completely avoiding waste water discharge after washing by adopting chemical addition agents during stewing and preserving, and having no pollution to the environmental; the whole paper making process has no injurant discharge and greatly improves the production efficiency; simultaneously, the process also has the advantages of easily obtainable material and low cost.

Owner:董维德 +1

Preparation method of ready-to-eat dandelion paper

The invention discloses a preparation method of ready-to-eat dandelion paper. The preparation method comprises the following steps: performing material selection: selecting well-grown fresh and tender dandelion leaves without plant diseases and insect pests, and cleaning the leaves; covering the dandelion leaves with a freshness retaining film, and putting the leaves with the film into a refrigerator for freezing; defreezing, draining the leaves, putting into a pulping machine for pulping, and adding water for blending to obtain paste; weighing the paste type dandelion pulp, adding starches and salt, uniformly stirring, coating a baking board with the mixture, baking into paper, and riving off the paper to obtain the ready-to-eat dandelion paper. By the procedures of material selection, freezing, homogenization, baking and the like, fresh dandelions are prepared into ready-to-eat vegetable paper, so that the paper is convenient to eat, and the original flavor and the nutritional health component are retained; meanwhile, long-time storage is facilitated.

Owner:XIAN UNVERSITY OF ARTS & SCI

Process for producing paper pulp, compressed paperboard prepared with paper pulp and application of paperboard

InactiveCN102108647AAchieve recyclingSolve processing problemsFibreboardSludge treatmentHollander beaterPaper mill

The invention discloses a process for producing paper pulp, a compressed paperboard prepared with the paper pulp and application of the paperboard. The process is characterized by firstly pretreating the sewage discharged from the paper mill in the production process, collecting the slurry, adding short velveteen to the slurry to obtain the pulp to be beaten, then beating the pulp to be beaten by adopting a hydraulic beater to fully mix and stir the pulp to prepare paper pulp and carrying out vibration screening and residue removal on the paper pulp to obtain the needed paper pulp. By adopting the process, not only can the problem of treatment of sewage in the paper mill be solved, but also the waste velveteen and sawdust are adopted as the raw materials, thus not only ensuring low cost, but also realizing recycling of the wastes, being beneficial to environmental protection and creating economic values. The compressed paperboard is non-toxic and harmless, has low cost and better economic value, can be suitable for many aspects and is beneficial to large-scale popularization.

Owner:莫少莲

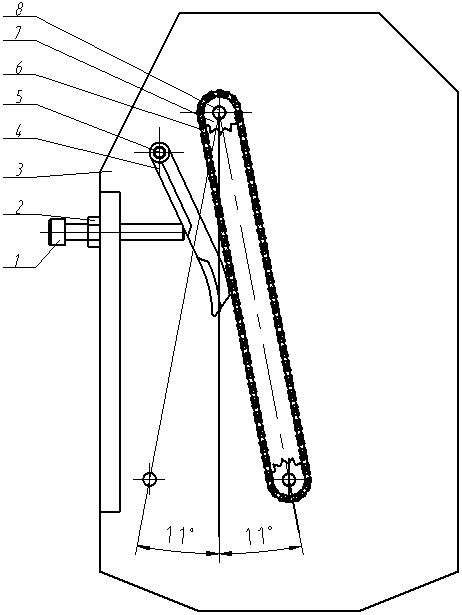

Chain transmission stretching device of beating machine

The invention provides a chain transmission stretching device of a beating machine. The chain transmission stretching device comprises a bolt, a fastening cap, an installing plate, a stretching plate, a hinge pin, a chain, a chain wheel and a chain transmission shaft and is characterized in that the stretching plate is shaped and can be rotated around the hinge pin; the chain wheel passes through the chain transmission shaft to drive the chain to achieve the driving effect; the included angle between the chain transmission shaft and the lower chain transmission shaft is (+-11 degrees); the stretching plate is adjusted through the bolt and fixed through the fastening cap after being adjusted to a proper position; and the stretching plate is in clearance matching with the hinge pin. The chain transmission stretching device for the beating machine has the advantages of simple structure, and is safe and reliable, and easy to operate.

Owner:江苏威迪农业装备科技股份有限公司

Mulberry fruit pulp as well as preparation method and applications thereof

The invention discloses mulberry fruit pulp as well as a preparation method and applications thereof. The mulberry fruit pulp is prepared by the following steps: 1) blanching: a citric acid solution is boiled and added into cut mulberries, continuous heating is carried out till the solution is boiled again, heating is continuously carried out for 1-3 minutes, and mulberries are fished out, and peeled; 2) pulping and colloid milling: peeled mulberries are pulped by a beater, wherein mulberry pulp and water are according to a weight ratio 1:1-2, vitamin C is added and grinding is carried out with a colloid mill, and the mulberry fruit pulp is obtained. A beverage which employs mulberry fruit pulp as a main component comprises the following substances in parts by weight: 100 parts of mulberry fruit pulp, 10-12 parts of sucrose, 0.31-0.32 parts of malic acid, and 0.01-0.015 parts of a composite stabilizing agent. The mulberry fruit pulp has stable color and flavor, and can be kept at a normal temperature for one year or above; the beverage which employs mulberry fruit pulp as a main component is in orange color, and besides common effects of beverages, the beverage also has functions for moistening lung and clearing heat.

Owner:QIDONG QINGQING VEGETABLE & FRUIT RURAL LAND STOCK PROFESSIONAL COOP

Industrial method for preparing polyimide fiber insulation paper in inclined-wire forming method

InactiveCN107217530AGood strength performanceImprove electrical performanceSynthetic cellulose/non-cellulose material pulp/paperPaper-making machinesWastewaterPulp and paper industry

The invention discloses an industrial method for preparing polyimide fiber insulation paper in an inclined-wire forming method. The industrial method comprises the following steps: dispersing polyimide chopped fibers in a dispersing tank to obtain suspension containing the chopped fibers, diluting with water until the concentration of the polyimide chopped fiber suspension is 0.5 to 6 thousandth by weight; pulping pulp by adopting a pulping machine, then adding into the suspension containing the chopped fibers, and uniformly mixing to obtain pulp suspension, wherein the pulp is one or more of aramid pulp, polysulfonamide pulp and polyimide pulp; forming polyimide body paper from the pulp suspension by adopting an inclined-wire forming process; and thermally pressing the body paper, and cooling to obtain a polyimide paper finished product. By adopting the inclined-wire forming process, a purpose of long-fiber papermaking under lower concentration is realized. No chemical additive is added in the preparation process, the production cost can be effectively decreased, the waste water treatment difficulty and the environmental pollution are alleviated, the influence of the chemical additive on dielectric properties of the product can be avoided, and the selection range of the high-temperature-resistant insulation composite material industry can be increased.

Owner:连云港纤维新材料研究院有限公司 +1

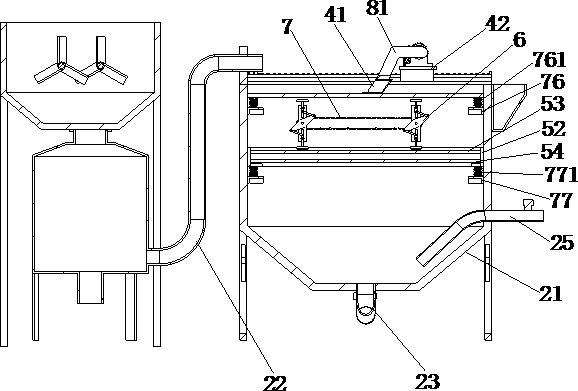

Environment-friendly corrugated carton sewage treatment device

ActiveCN110981036AAvoid damageTroubleshoot technical issues with clearingWater/sewage treatment by centrifugal separationTreatment involving filtrationActivated carbonMicroorganism

The intention discloses an environment-friendly corrugated carton sewage treatment device, and belongs to the technical field of corrugated cartons, the environment-friendly corrugated carton sewage treatment device comprises a rotational flow sand setting device, a filter box, a paper pulp beating mechanism, a corrugated paper pulp removing mechanism and a sewage purifying mechanism, the bottom of the filter box is provided with a mud discharge funnel communicated with the interior of the filter box; a liquid outlet pipeline is arranged at the lower section of the rotational flow sand settingdevice, the sewage purifying mechanism comprises a reciprocating vibration assembly, a large particle filtering grid, a mounting frame, a microorganism filtering net and an activated carbon net, andthe reciprocating vibration assembly is arranged between the large particle filtering grid and the mounting frame. Paper pulp fibers accumulated on the large-particle filter grid and floating on sewage can be automatically fished through the corrugated paper pulp removing mechanism, and sand-water separation can be achieved through the rotational flow sand setting device; and the reciprocating vibration assembly can enable impurities blocked in filter holes of the large-particle filter grid, the microorganism filter screen and the activated carbon net to be vibrated down.

Owner:福建省群英箱聚印刷有限公司

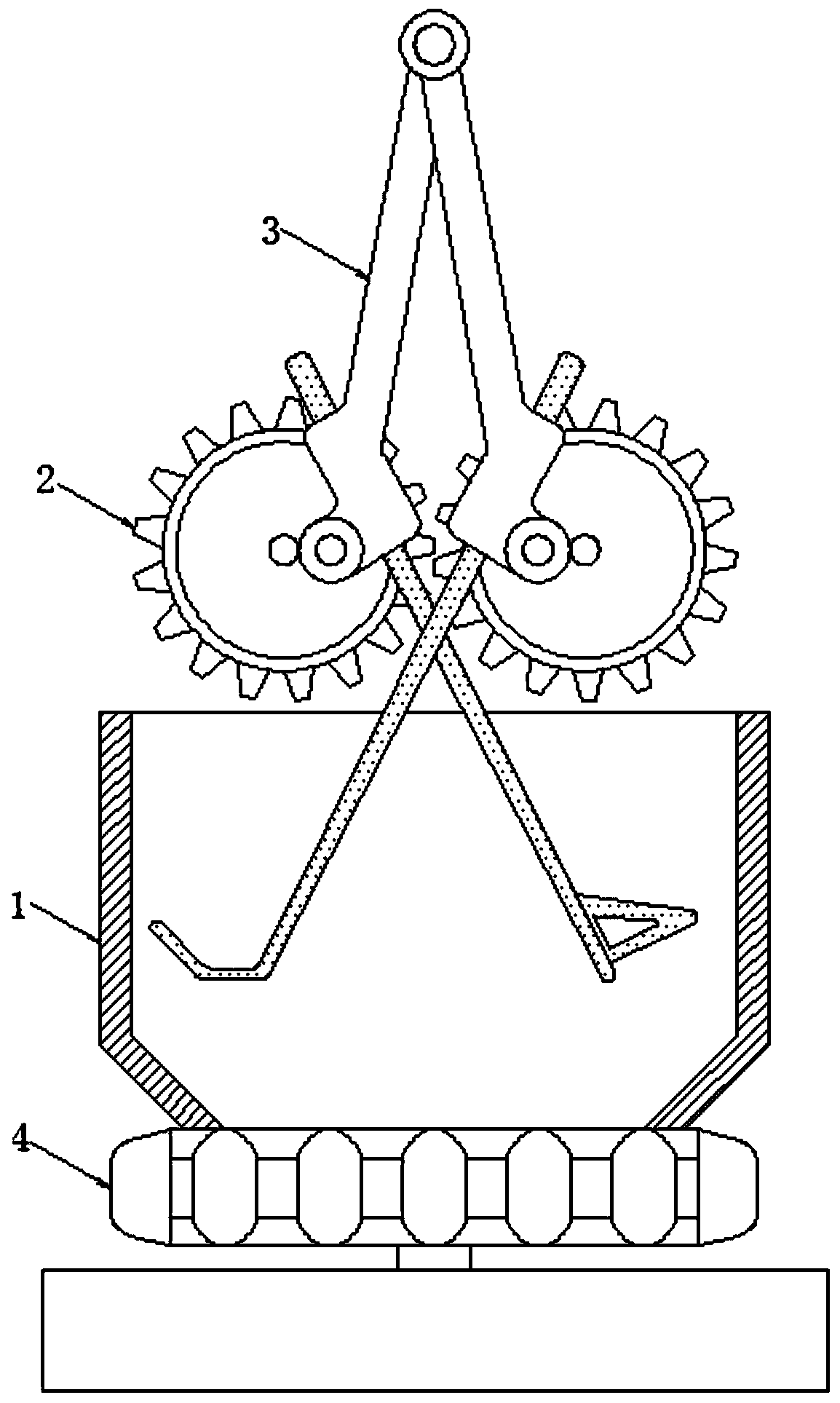

Waste paper deinking equipment used for beater and capable of realizing uniform stirring through intermittent material falling

The invention relates to the technical field of stationery commodities, and discloses waste paper deinking equipment used for a beater and capable of realizing uniform stirring through intermittent material falling. The equipment comprises a stirring bin, wherein first gears are movably connected above the stirring bin. According to the invention, a screw rod rotates to drive first rotating rods to continuously get close to and get away from each other so as to drive stirring rods to continuously stir materials in the stirring bin, and the stirring bin rotates to be matched with the shovelingof the stirring rods, so that the stirring rods comprehensively stir a mixture in the stirring bin so as to uniformly stir the mixture; the screw rod rotates to drive a second rotating disc to intermittently rotate to provide power for subsequent discharging control so as to facilitate follow-up operation, increase the linkage between structures and achieve convenient operation, a third rotating disc rotates to drive a baffle to continuously get close to and get away from a material outlet pipe so as to make the materials fall intermittently, and by cooperating with stirring operation, unevenmaterial mixing caused by continuous falling of the materials is avoided, and the mixing quality of the materials is improved.

Owner:义乌拓延贸易有限公司

Preparation method of mica paper pulp

InactiveCN111395032AEfficient reuseHigh tensile strengthNon-macromolecular organic additionPaper recyclingSocial benefitsPaper production

The invention discloses a preparation method of mica paper pulp. Leftover materials, waste materials or damaged materials obtained on a mica paper production line are used as raw materials. The preparation method comprises the following steps: removing impurities, cutting into pieces, soaking in alkali liquor, putting into a beater, pulping, carrying out enzymolysis treatment, cleaning the enzymolysis product, carrying out vacuum heat preservation treatment with cationic starch, washing with running water, drying, and carrying out microwave ball milling to obtain processed mica powder; and mixing the processed mica powder with mica cooked powder with the same particle size range value according to the ratio of 1: 2-1: 3, and adding an auxiliary agent and / or a reinforcing material to prepare the mica paper pulp material capable of being directly used for the mica paper machine. The process can effectively improve the utilization rate of mica paper waste and reduce the raw material costand has considerable economic and social benefits.

Owner:倚天云母科技(廊坊)有限公司

Production process for environment-friendly wallpaper

InactiveCN103225236AReduce production processEasy to operateSpecial paperPaper/cardboardFiberProcess engineering

The invention discloses a production process for environment-friendly wallpaper. The production process successively comprises a first step of selecting raw materials which comprises natural wood pulp, resin fiber, water and a bleaching agent; a second step of mixing the natural wood pulp, the resin fiber, the water and the bleaching agent together according to a weight ratio of 4 : 4 : 1 : 1; a third step of putting the mixture on a filter screen, filtering and removing impurities; a fourth step of putting the mixture after filtration in a beating machine for beating; a fifth step of putting a mixture after beating in a water extractor for dewatering; a sixth step of drying the dewatered mixture at a high temperature, wherein the temperature is 50 DEG C-60 DEG C; a seventh step of putting the dried mixture on a shaping machine for flattening so as to obtain a semi-finished product, wherein the thickness of the semi-finished product is 1 cm-2 cm; and an eighth step of cutting the semi-finished product to prepare a finished product. The production process is simple, has no toxicity, and is odorless and environment-friendly.

Owner:汤汉忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com