Method for improving reactive performance of prehydrolysis sulfate dissolving pulp

A reactive performance, sulfate technology, applied in pulp beating method, non-fibrous pulp addition, textiles and papermaking, etc., can solve the problem of low reactive performance of dissolving pulp, and achieve the effect of improving reactive performance and improving reactive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

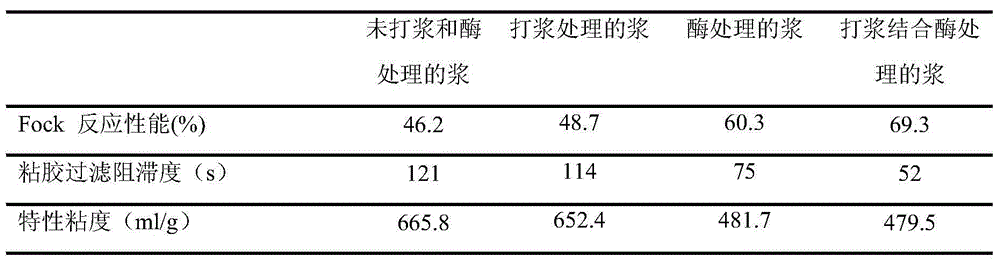

[0028] Example 1: Poplar prehydrolyzed sulfate-dissolving pulp, beating time 30 minutes, enzyme dosage 3.0u / g dry pulp, pH 5, temperature 55°C, treatment time 120 minutes, enzyme-treated pulp concentration 4%. The measurement results are shown in Table 1.

[0029] Table 1

[0030]

Embodiment 2

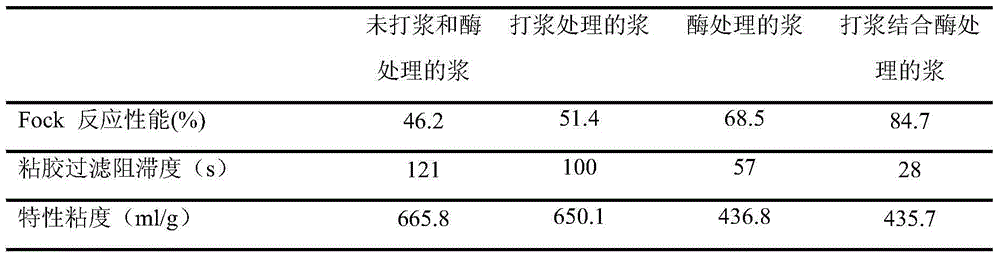

[0031] Example 2: Poplar prehydrolyzed sulfate-dissolving pulp, beating time 60 minutes, enzyme dosage 3.0u / g dry pulp, pH 6, temperature 55°C, treatment time 60 minutes, enzyme-treated pulp concentration 4%. The measurement results are shown in Table 2.

[0032] Table 2

[0033]

Embodiment 3

[0034] Example 3: Poplar prehydrolyzed sulfate-dissolving pulp, beating time 80 minutes, enzyme dosage 4.0u / g dry pulp, pH 5, temperature 60°C, treatment time 90 minutes, enzyme-treated pulp concentration 4%. The measurement results are shown in Table 3.

[0035] table 3

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com