Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

305 results about "Galega officinalis extract" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound health ginkgo powder and manufacturing method thereof

InactiveCN101637267ARich tasteImprove nutrition and health functionFood preparationAdditive ingredientSweetness

The invention provides compound health ginkgo powder and a manufacturing method thereof, belonging to the technical field of ginkgo processing. The compound health ginkgo powder is manufactured by thefollowing steps: adding plant fine powder or meat powder from other sources, processed ginkgo extractive, maltodextrin, salt, sweetener, flavoring agent, nutrition enhancer, various flavor substancesand other components in a proportion into the ginkgo powder which is manufactured by conventional working procedures; then carrying out granulation, subpackaging and other procedures to manufacture the compound health ginkgo powder which can be edible after pouring with boiling water directly. The compound health ginkgo powder strengthens the nutritional value of ordinary ginkgo powder, improveshealth care functions and enriches the flavor of ginkgo powder. The compound health ginkgo powder provided in the invention is manufactured by the following components by weight percent: 1-99% of ginkgo powder, 0-99% of plant fine powder of other sources, 0-30% of digested tankage, 0-20% of processed ginkgo extractive, 0-70% of maltodextrin, 0-30% of salt, 0-40% of sweetener, 0-5% of flavoring agent, 0-10% of nutrition enhancer and 0-30% of various flavor substances. The above materials are mixed and stirred for 5-60 min; water is added in the materials according to the a ratio of 1:5; granulation is carried out after mixing and stirring for 5-60 min; the compound health ginkgo powder can be obtained after drying until the water content is lower than 15%.

Owner:李奇峰

Anti-aging, wrinkle-eliminating and anti-wrinkle cosmetic composition

InactiveCN101766555AMeet safety requirementsNon-irritatingCosmetic preparationsToilet preparationsWrinkle skinSide effect

The invention discloses an anti-aging, wrinkle-eliminating and anti-wrinkle cosmetic composition, which comprises ganoderma lucidum extract, agrimony extract, gromwell extract, camellia extract, camomile extract, gingko extract and other cosmetic substrates, and the extracts respectively account for 1%-20% of the total weight of the composition. The preparation form of the composition can be selected from toner, moisture milk, cream, essence, massage cream, eye cream and jelly product. The invention adopts safe and pollution-free green cosmetic raw materials, is natural, nontoxic and nonirritant, has no side effect, has effective anti-aging, wrinkle-eliminating and anti-wrinkle effects, and meets the requirement on cosmetics safety of people.

Owner:YUNNAN HENGGUAN IND

Method for removing bitter and astrigent taste of ginkgo extract and its use

InactiveCN1554276AThe active ingredient remains unchangedSimple processFood preparationHas active ingredientCyclodextrin

Gingko extract is processed with cyclodextrin to eliminate its biter and astringent taste while maintaining the effective components, and the processed gingko extract may be added into food. The present invention has simple process and low cost, and adding the processed gingko extract into food or health product will not affect the taste of the food and health product.

Owner:易鹤翔

Gingko handmade soap and manufacturing method thereof

InactiveCN102732395AEasy to prepareColorful shapesSkin careSoap detergent compositionsWrinkle skinGlycerol

The invention belongs to the technical field of daily cleaning supplies and in particular relates to gingko handmade soap. The gingko handmade soap comprises the following components in percentage by weight: 70 to 99.5 percent of transparent soap base, 0.05 to 20 percent of gingko extract and 0.05 to 3 percent of essential oil or essence. Compared with the prior art, the gingko handmade soap has the advantages that the gingko extract is added into the handmade soap, and oxygen radicals can be effectively eliminated and growth of melanin can be suppressed through the trace elements such as flavone, zinc, manganese and molybdenum, and flavonoid glycosides and flavonol, so that the skin is cleaned, the effects of whitening the skin, resisting wrinkle and delaying senescence are achieved, and the gingko handmade soap is a natural good item of protecting the skin and beautifying; and moreover, the glycerol which is contained in the handmade soap and is hardly extracted has the effect of deeply moisturizing and has mild characteristics, so that the skin is moist, glossy and high in resilience. In addition, preservatives and other chemical substances are not required to be added into the handmade soap, and the handmade soap is healthy and environment-friendly. In addition, the invention also discloses a method for manufacturing the handmade soap.

Owner:东莞市隆威实业有限公司

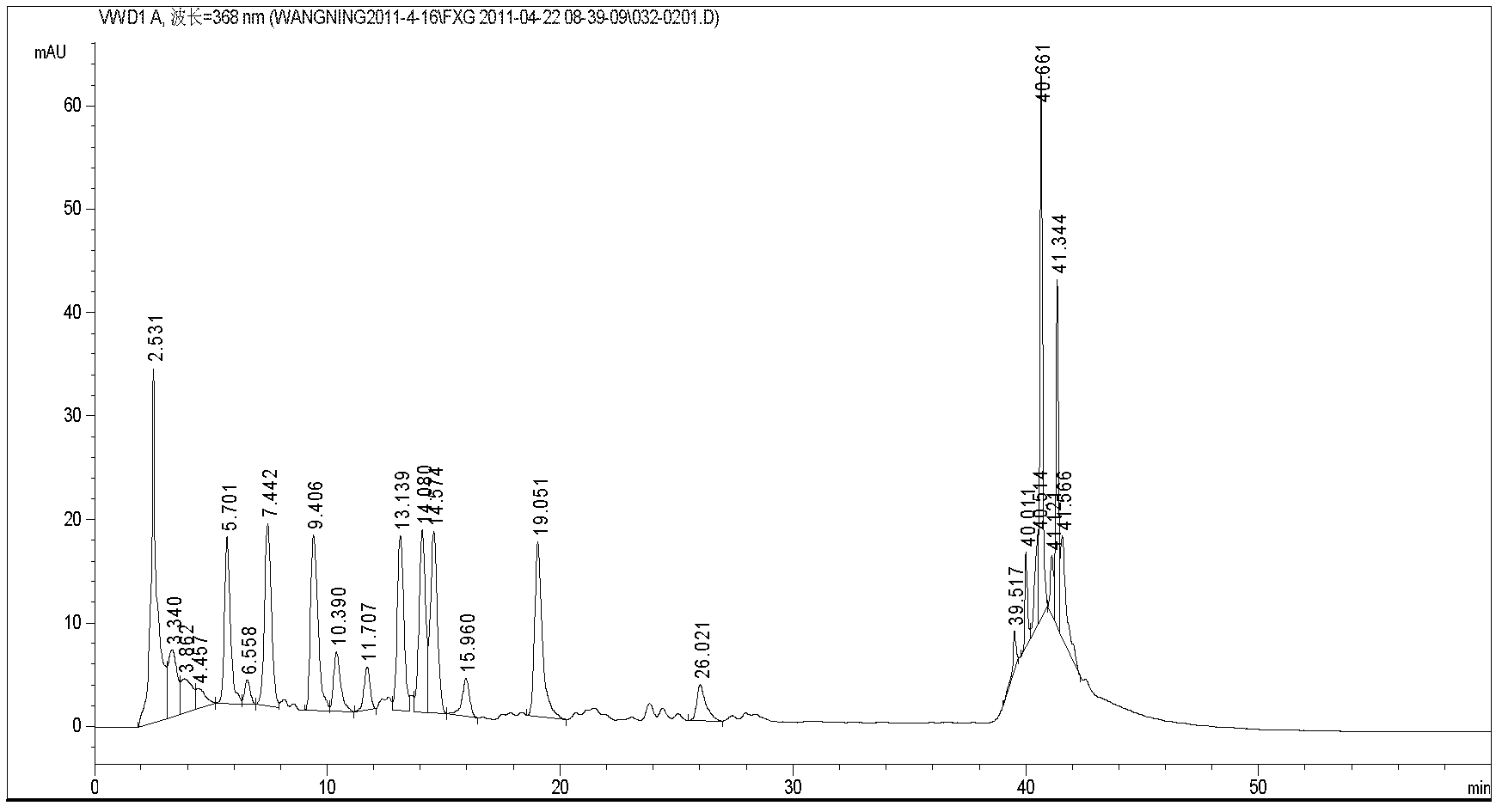

Method of preparing a plurality of active substances from ginkgo leaves

ActiveCN103130816AEasy high problemSolve the problem of highOrganic chemistryGinkgophyta medical ingredientsSeparation technologyReversed-Phase Liquid Chromatography

The invention discloses a method of preparing a plurality of activation materials from ginkgo leaves, and belongs to a manufacturing method of chemical substances or a manufacturing method of drugs. Strong polarity macroporous adsorption resin or polarity macroporous adsorption resin is adopted for separation, and is adopted to solve the problems that the amount of ginkgolic acid is high when the prior ginkgo extract is prepared, and solve the problems that a large amount of organic solvent is consumed when the prior ginkgo active substances are extracted and prepared, and accordingly the environment is polluted, or that a complex separation technology can not enlarge production, or that extraction efficiency is not high, and use ratio of raw materials is low and the like. The method of preparing the plurality of activation materials from the ginkgo leaves can simultaneously obtain a plurality of active substances such as ginkgo polysaccharide, ginkgol biloba extracts, ginkgol biloba general flavone, ginkgol biloba total lactones, gbilobalide A monosome, gbilobalide B monosome, gbilobalide C monosome and the like. The technical scheme is that the method comprises a raw material pretreatment step, an extraction step, a polysaccharide precipitation step, a macroporous resin separation step, a silica gel dry-column separation step, a reversed phase chromatography purification step, a crystallization step and the like, saves production cost, and improves work efficiency. The process of the method is simple and convenient to conduct. The method can be easily enlarged to the commercial process, and meanwhile greatly increase use ratio of raw materials.

Owner:HUBEI NUOKETE PHARMA

Technique for preparing gingkgo extractive with low content of ginkgolic acid

InactiveCN101091730AWork around temperature limitationsReduce manufacturing costOrganic compounds purification/separation/stabilisationSugar derivativesActive componentBilobalides

The present invention relates to an extraction technique of natural plant active component. In the concrete, it relates to a preparation process of ginkgo extract with low ginkgolic acid content. In the ginkgo extract obtained by adopting the invented preparation method the ginkgo total flavone content is 28-40%, bilobalide content is 6-14% and ginkgolic acid content is less than 5ppm. Its preparation method includes the steps of extraction, separation, purification, concentration and drying.

Owner:HAINAN MEDICAL COLLEGE

Gingko tea preparation and production process thereof

ActiveCN1729815ASignificant effectGood curative effectPre-extraction tea treatmentGinkgophyta medical ingredientsGinkgo bilobaCerebral arteriosclerosis

Disclosed is a gingko tea preparation whose effective compositions include ginkgo leaves extract and tea by the weight ratio of 1:160. The preparation process comprises the following steps: charging water into tea and boiling twice, merging the grilling liquid, filtering, concentrating the filtrate to clear grease with specific gravity of 1.05 at 60 deg C, spray drying, obtaining dried concrete, charging ginkgo leaves extract and auxiliary material, finally mixing to obtain the end product.

Owner:湖南春光九汇现代中药有限公司

Functional health care drink

The invention relates to a functional health care drink. The technical scheme adopted in the invention is that the functional health care drink is prepared from the following raw materials in parts by weight: 1 part of ginkgo biloba extract, 20-40 parts of L-arginine, 2-3 parts of ginseng extract, 2-10 parts of damiana leaf extract, 2-3 parts of complex vitamin and minerals, 2-3 parts of ganoderma extract, 0.5-1 part of sweetener and 40-50 parts of water. The functional health care drink in the invention can be used for effectively alleviating fatigue, enhancing the immunity of organism and enhancing the sexual function; and the anti-aging aim can be achieved after the drink is taken for a long time.

Owner:何伟

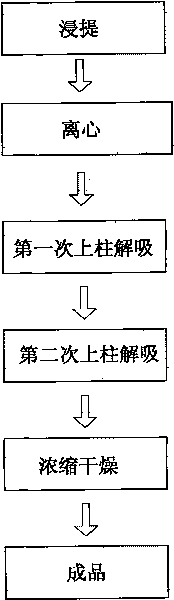

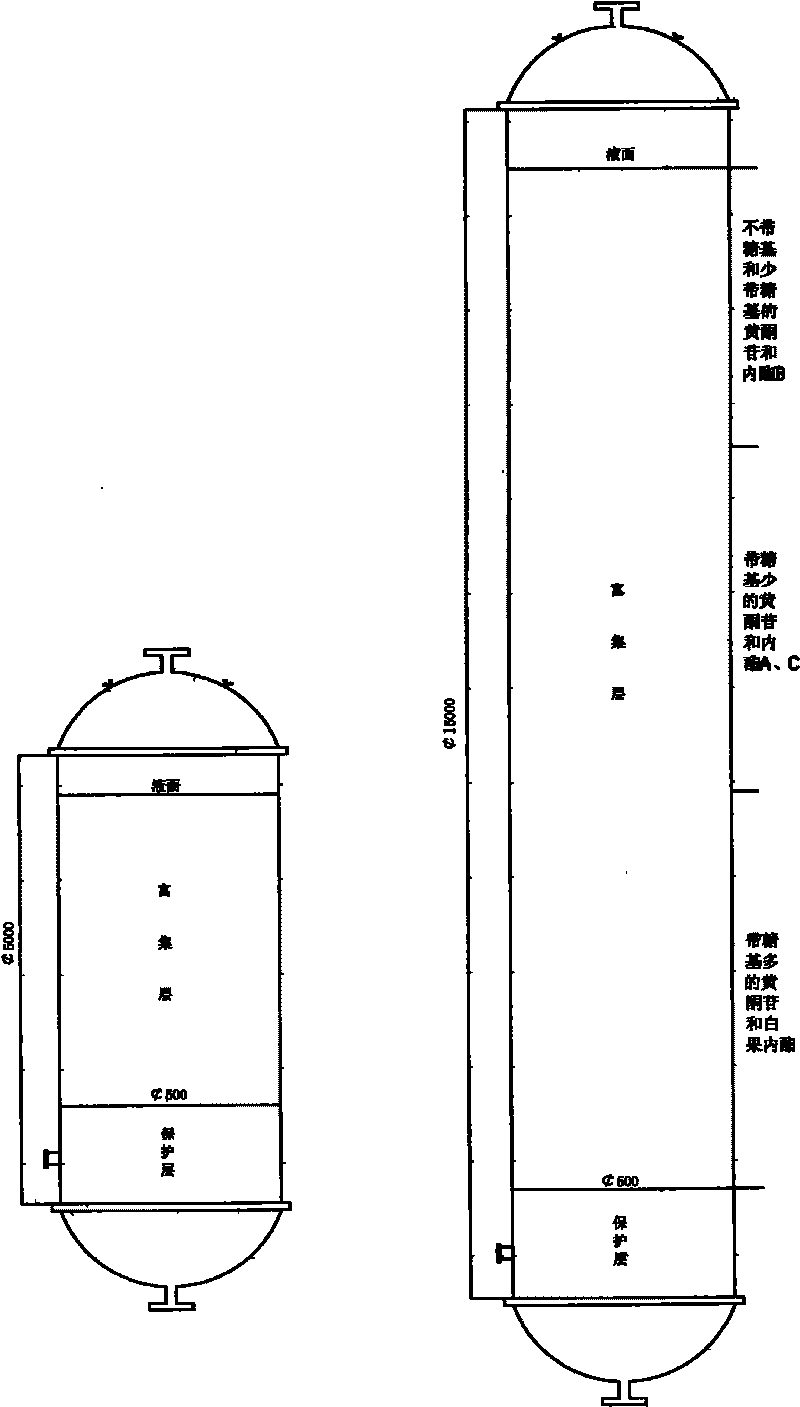

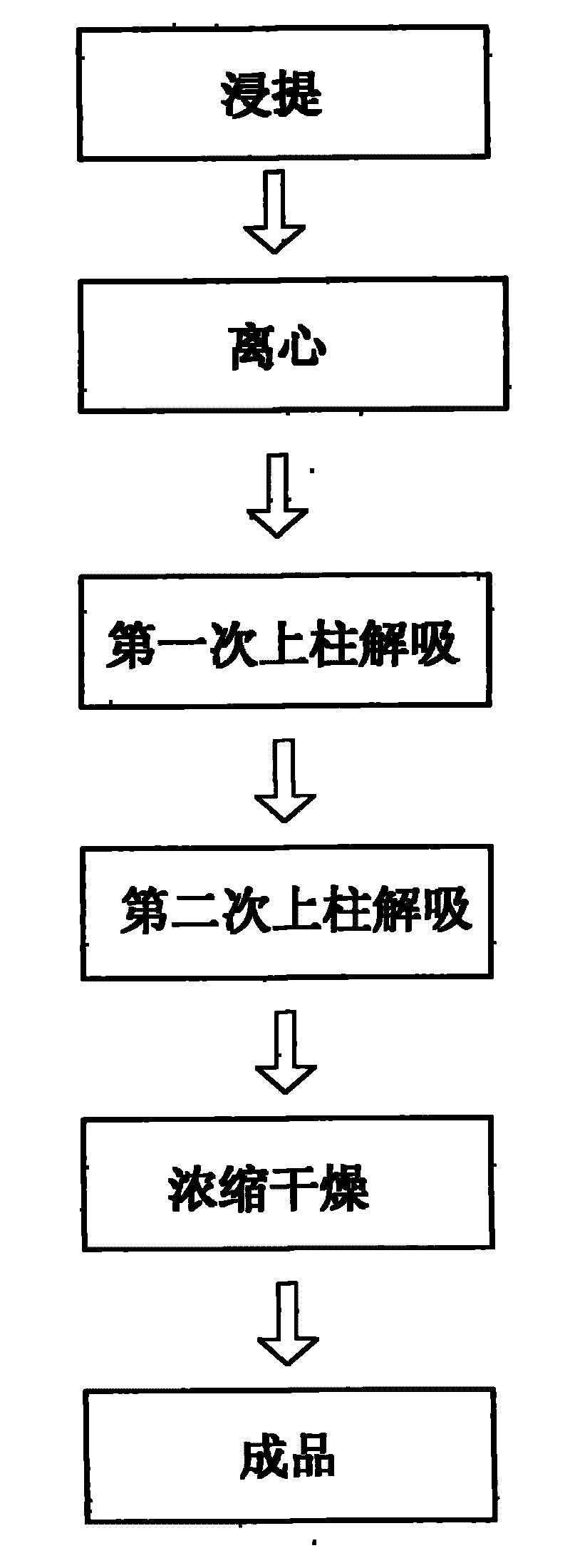

Process for producing ginkgo extract

InactiveCN101708195AExtract completelyHigh content of active ingredientsGinkgophyta medical ingredientsCardiovascular disorderDouble-timeDesorption

The invention relates to a process for producing ginkgo extract and belongs to the technical field of plan extraction. The process comprises the following steps of: adding ginkgo leaves serving as raw materials into 50 to 70 percent ethanol of which the weight is eight times that of ginkgo leaves serving as the raw materials to perform leaching three times, wherein the leaching temperature is 70 DEG C; collecting extracting solution, evaporating the extracting solution under vacuum, recovering ethanol, centrifuging the extracting solution and collecting supernatant solution; and subjecting the extracting solution to the centrifugal treatment by a macroporous resin chromatographic column of which the diameter-to-height ratio is 1:10, leaching the extracting solution in turn with 5 to 15 percent ethanol until the eluate is clear and bright, desorbing the extracting solution with 75 percent ethanol, after desorption, collecting desorbing solution, allowing the desorbing solution to pass through a macroporous resin chromatographic column of which the diameter-to-height ratio is 1:30, collecting the desorbing solution, decompression-recovering ethanol, condensing the desorbing solution into thick paste, and vacuum-drying the thick paste to obtain the ginkgo extract. The process adopts multiple leaching and multistage centrifuging, and also adopts a double-time desorbing method of coarse extraction and refined extraction, so that the contents of the active components are greatly improved; and the ginkgo extract with different ratios of active components can be prepared as required.

Owner:应维强

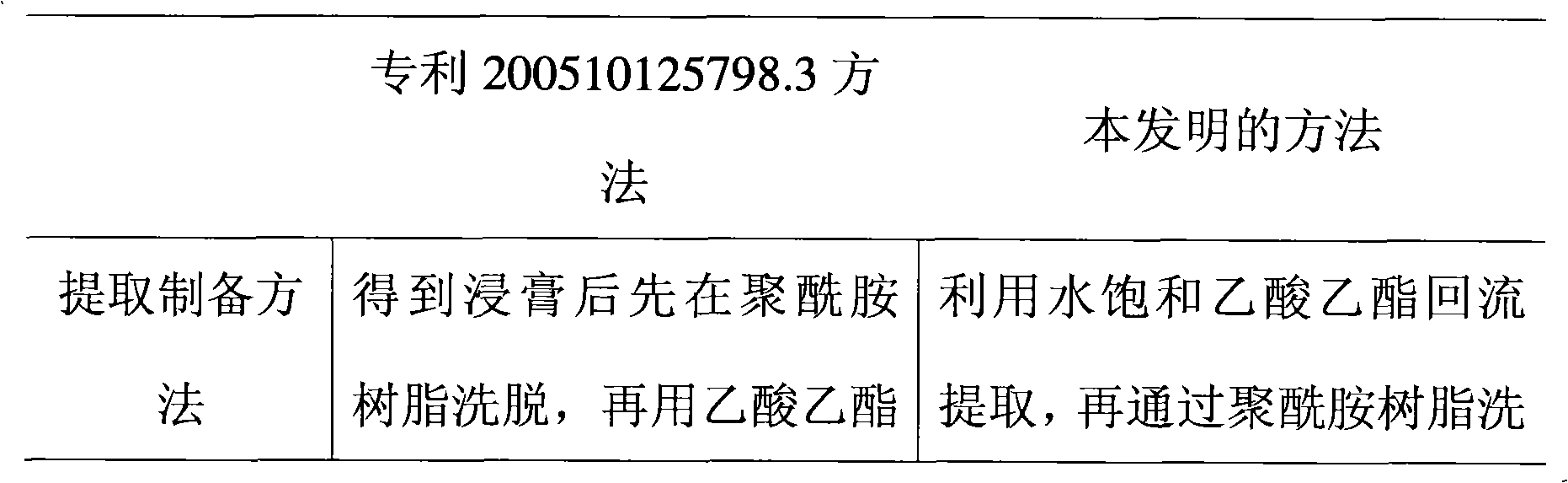

Extracting process for bilobalide A, B, C and its preparation

ActiveCN1491950AHigh extraction rateEasy to operateOrganic active ingredientsOrganic chemistryMethanol waterAlcohol

The extracting process of bilobalide A, B and C includes the polyamide column adsorption of the gingko extract as material, concentration and crystallization to obtain coarse crystal; or twice extraction of gingko leaf as material, concentration, filtering, polyamide column adsorption, collecting effluent, eluting polyamide column with alcohol, merging the effluent and the eluent, elution in macroporous resin column with alcohol, concentration and crystallization to obtain coarse crystal; and re-crystallizing the coarse crystal in methanol water to obtain bilobalide A, B and C. Bilobalide A, B and C may be produced into dripping pill, granule or capsule. The present invention has simple process, high yield, and product with bilobalide A, B and C content up to 70 %.

Owner:CHENGDU BAIYU PHARMA CO LTD

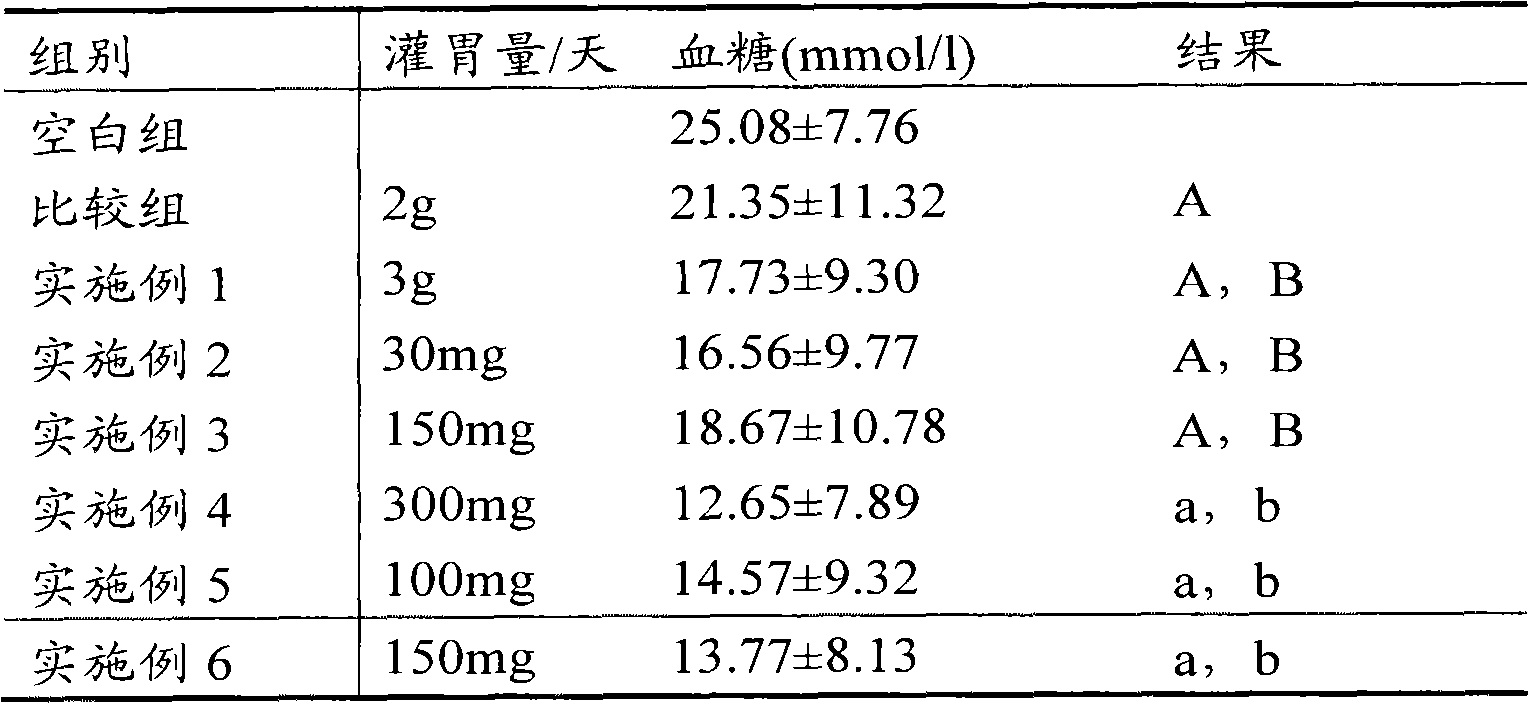

Hypoglycemic ferment compound

ActiveCN101658537AGood hypoglycemic effectBalanced nutritionHeavy metal active ingredientsOrganic active ingredientsPolygonum fagopyrumVitamin C

The invention provides a hypoglycemic ferment compound comprising the following components: 40-60 percent of protein, zinc (50-5000mg / kg), selenium (0.5-1000mg / kg) and chromium (0.5-1000mg / kg), wherein ferment is active ferment or inactive ferment. As a preference, the ferment compound further comprises one or more components selected from the following components: balsam pear or balsam pear extract, kudzu roots or kudzu root extract, gingko extract, green tea extract, ginseng or ginseng extract, glossy ganoderma or glossy ganoderma extract, glossy ganoderma leavening, glossy ganoderma spore powder, sealwort or sealwort extract, yam or yam extract, coix seed or coix seed extract, oats, tartary buckwheat, vitamin C, vitamin E, pearl powder, calcium and iron. The invention also relates to apreparation method of the ferment compound.

Owner:ANGEL NUTRITECH CO LTD

Nano silver face pack for beauty treatment

PendingCN101129308AGood effectReduce concentrationCosmetic preparationsToilet preparationsMedicineGreen tea extract

The invention discloses a multifunctional beauty treatment face pack which comprises the following constituents (by weight percent): nano colloidal silver 0. 0005-0. 0015%, aloe extract 4. 0-8. 0%, natto gum 0. 5-1. 55, ginkgo extract 0. 3-0. 5%, green tea extract 0. 1-0. 3% and lavandula angustifolia extract 0. 05-0. 15%.

Owner:全昌均 +1

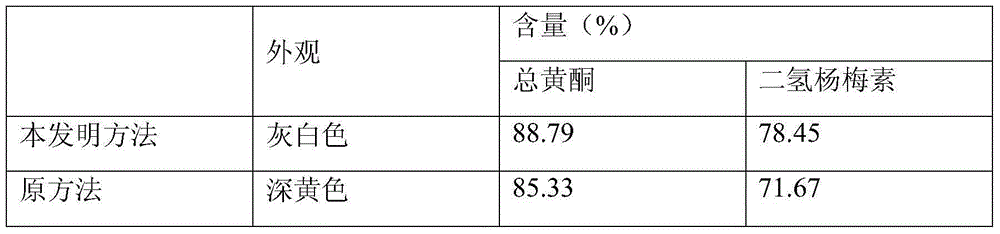

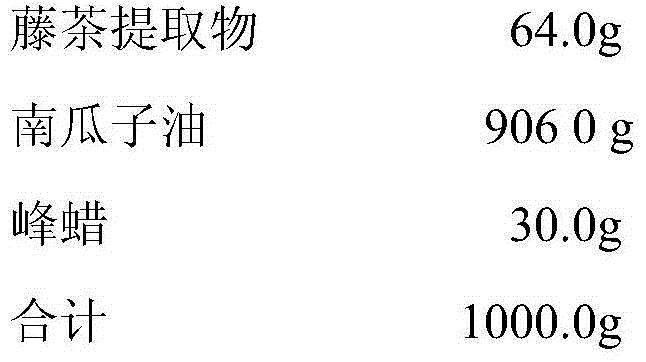

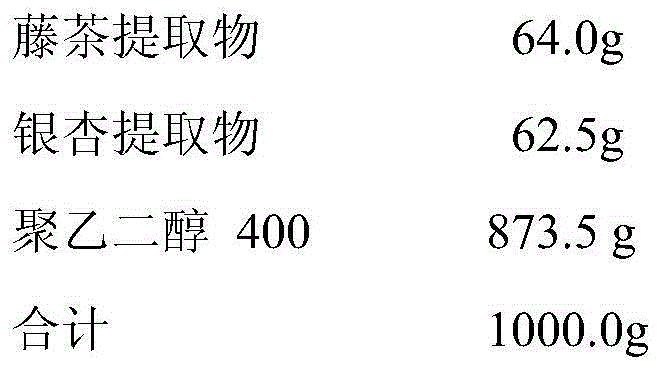

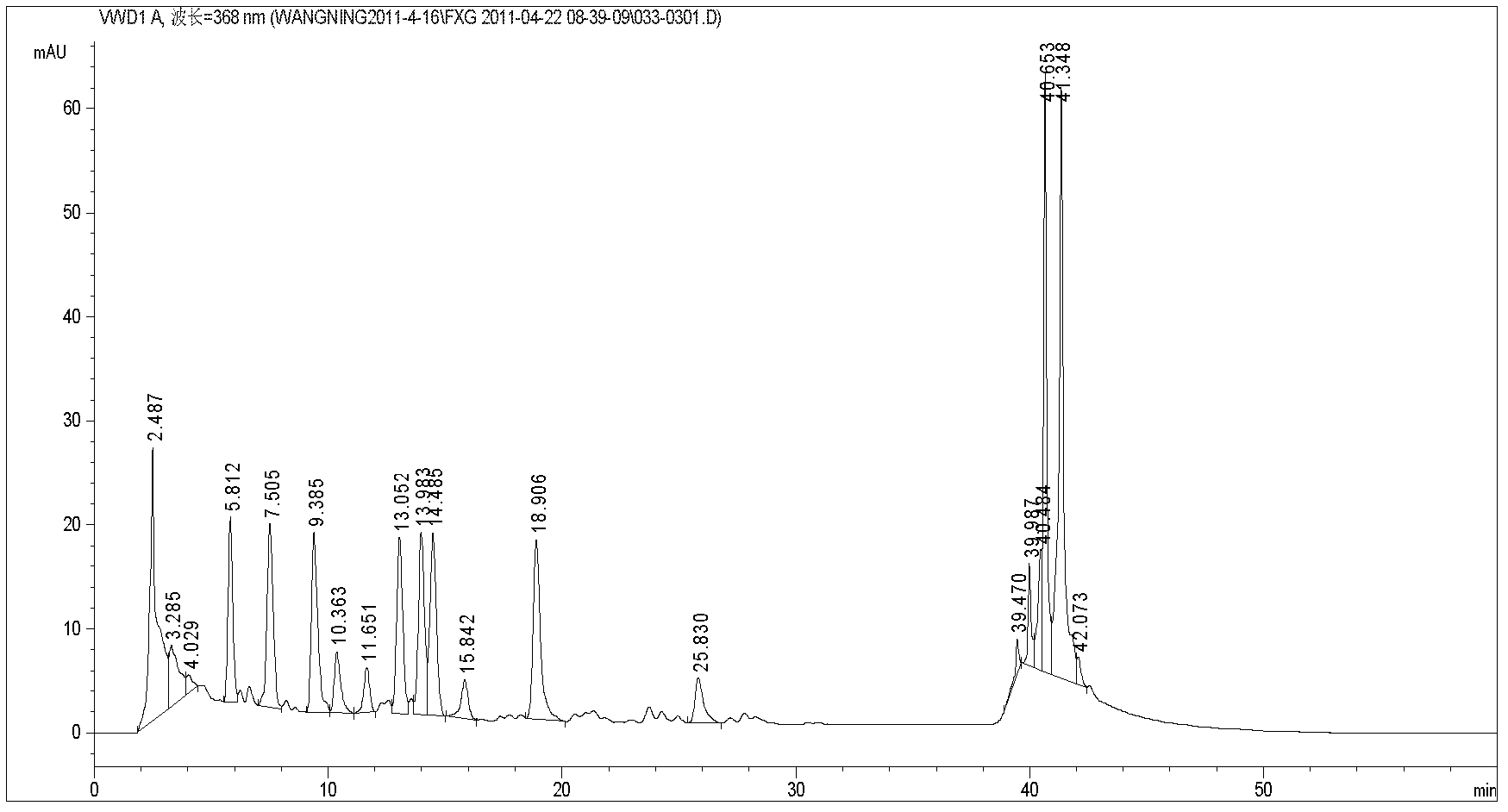

Vine tea extract and applications thereof

The invention provides a vine tea extract which is prepared by the following steps: adding a flavones protective agent into an aqueous solution during water extraction of the vine tea; heating and filtering; adding a co-precipitator into the filtrate for flocculation and sedimentation; and after filtering the precipitate, freezing the filtrate to crystallize and separate out the vine tea extract, wherein the vine tea extract comprises 80-90% of general flavones and 70-80% of dihydromyricetin based on general flavones. The invention further provides a composition which comprises the vine tea extract and a ginkgol biloba extract as well as an application of the composition in preparing foods, health foods and drugs for preventing and treating geriatric cognitive disorders. The invention further provides an application of the vine tea extract in preparing drugs for inhibiting prostatic hyperplasia and treating benign prostatic hyperplasia, as well as foods, health foods and drugs for reducing blood sugar, blood fat and blood pressure. Compared with the extract prepared by the existing method, the extract provided by the invention is improved in purity and white in luster. Clinical applications show that the vine tea extract has a certain function of improving getting up in the night to urinate. The vine tea extract combined with the ginkgo biloba extract can be used for preventing and improving geriatric cognitive disorders.

Owner:CHONGQING ZHONGBAO BIOLOGICAL PHARMA

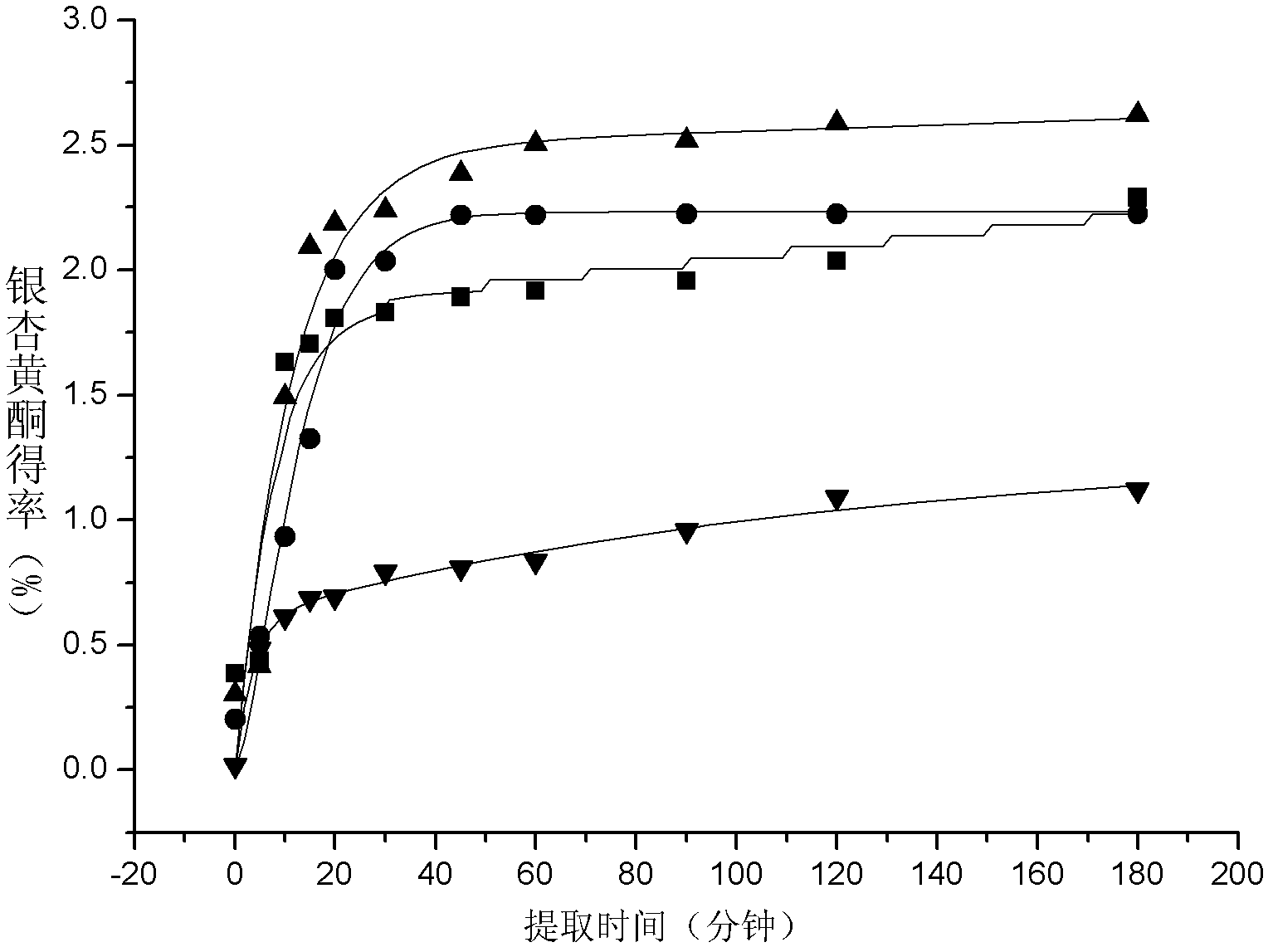

A kind of steam explosion pretreatment method of Ginkgo biloba

InactiveCN102274249ARemove the effect of dissolutionImprove dissolution efficiencyGinkgophyta medical ingredientsPretreatment methodMass ratio

In order to eliminate the influence of compact structures of cell walls of ginkgo leaves on the dissolution of active ingredients and improve the dissolution efficiency of ginkgo leaf extract, the invention provides a steam explosion pretreatment method for the ginkgo leaves. The method comprises the following steps of: adding absolute dry ginkgo leaves into solution in a mass ratio of 1:0-1:4, and soaking at normal temperature for 5 to 180 minutes; putting the soaked materials into a steam explosion tank, introducing a steam explosion medium, raising the temperature in the tank to 30 to 250 DEG C, keeping the temperature for 1 to 30 minutes, and performing steam explosion; and releasing pressure quickly, and releasing the treated materials in the steam explosion tank to a constant-pressure container to obtain the materials which is subjected to steam explosion pretreatment. By the steam explosion pretreatment, structures of the ginkgo leaves are loosened to form obvious porous structures, and the dissolution efficiency of active ingredients is improved, but the active ingredients in the raw materials are not damaged; and the active ingredients of the ginkgo leaves which are subjected to the steam explosion can be extracted or crushed or subjected to superfine crushing directly to prepare various ginkgo products.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

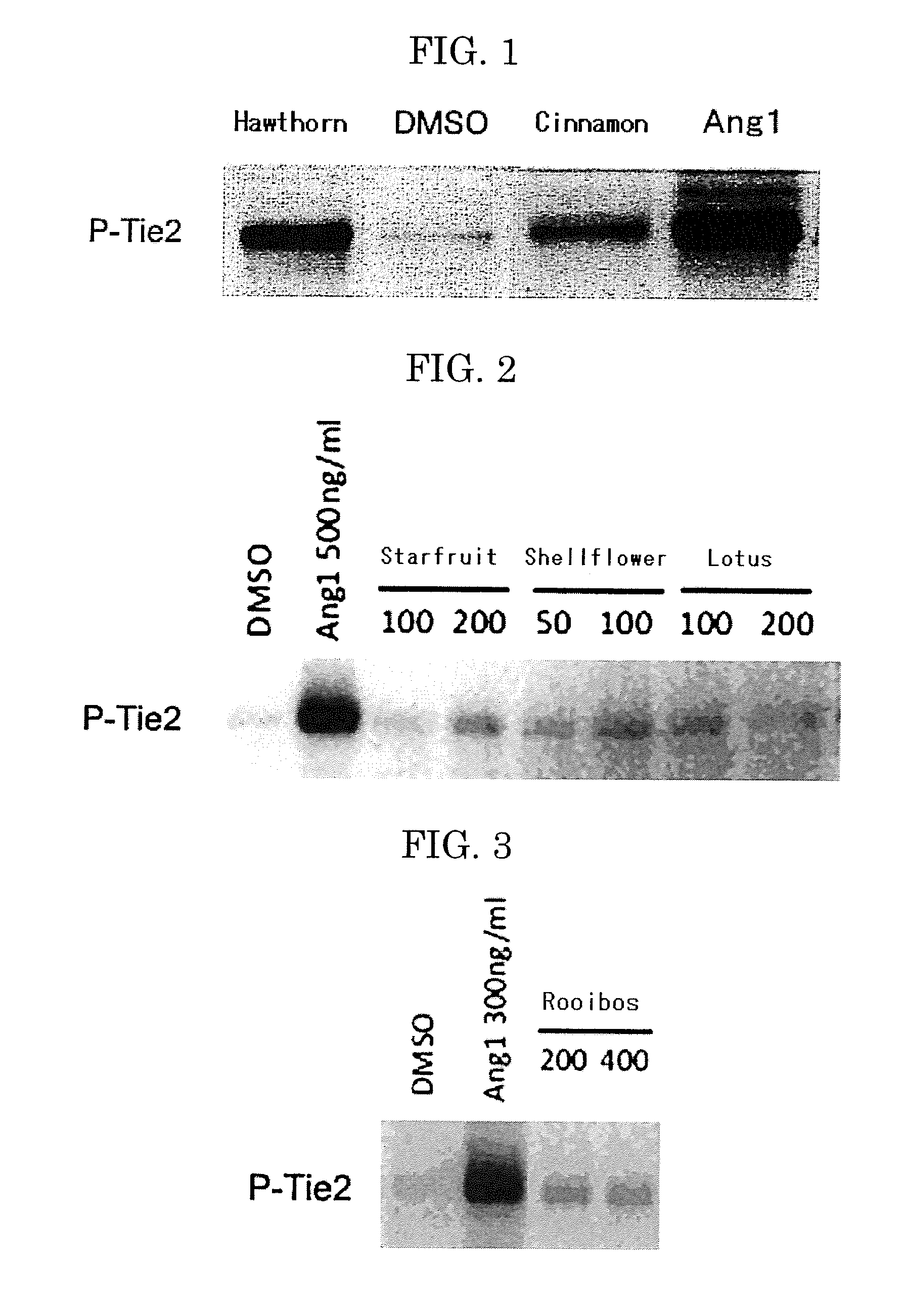

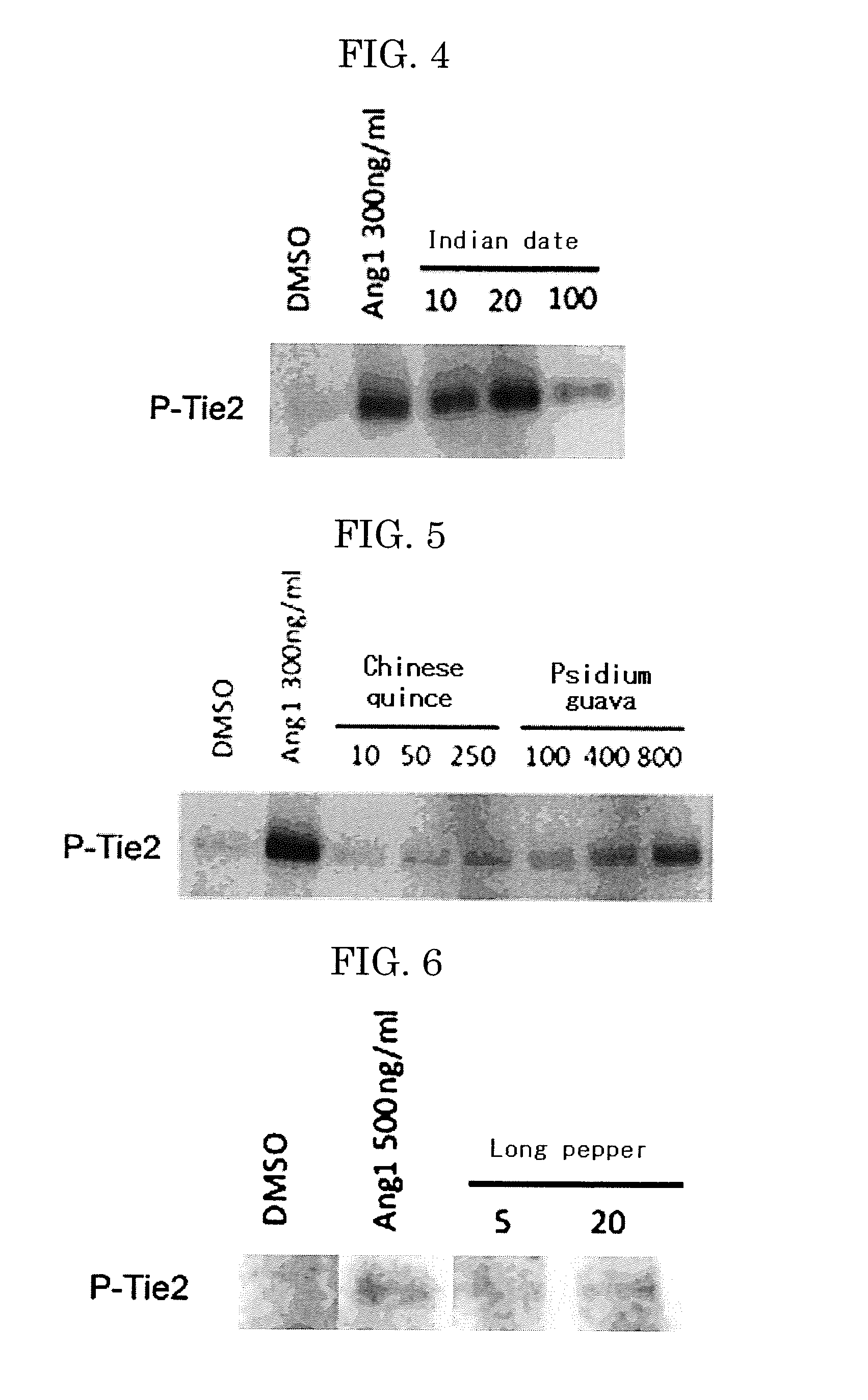

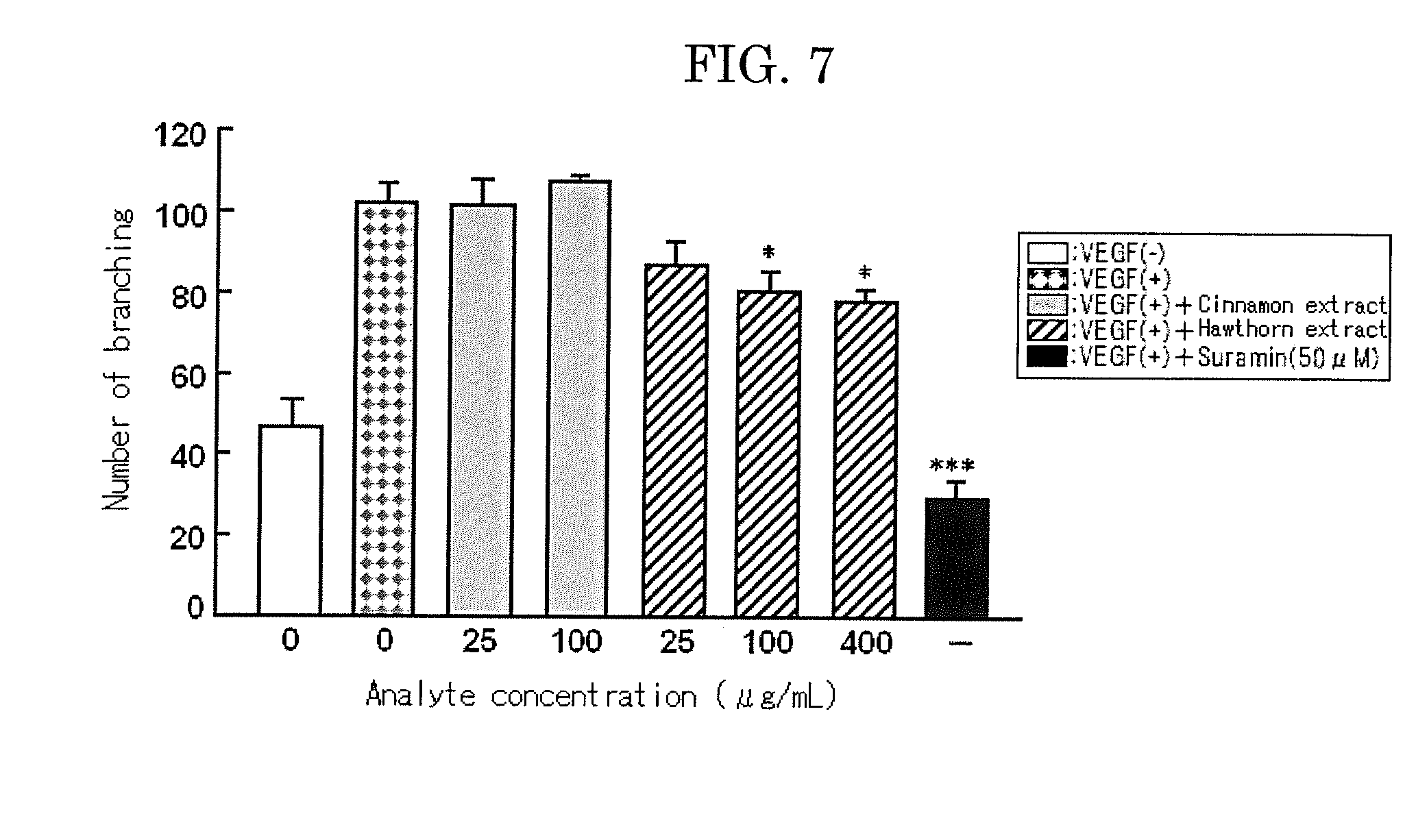

TIE2 Activator, Vascular Endothelial Growth Factor (VEGF) Inhibitor, Angiogenesis Inhibitor, Vascular Maturing Agent, Vascular Normalizing Agent and Vascular Stabilizing Agent, and Pharmaceutical Composition

InactiveUS20150125542A1Excellent Tie activating effectImprove securityBiocideAnimal repellantsQuillajaLong pepper extract

A Tie2 activator containing, as an active ingredient, a hawthorn extract, a starfruit extract, a shellflower extract, a lotus extract, a rooibos extract, an Indian date extract, a Chinese quince extract, a Psidium guava extract, a long pepper extract, a Quillaja extract, a Kouki extract, a ginkgo extract, an oyster extract, a turmeric extract, a chrysanthemum extract, a jujube extract, a Chinese wolfberry extract, a chamomile extract, or a Butcher's Broom extract, or any combination thereof.

Owner:MARUZEN PHARMA

Compositions for Alleviating Inflammation and Oxidative Stress in a Mammal

InactiveUS20140271944A1Increase SOD activityImprove the level ofBiocideMicrobiological testing/measurementMammalAntioxidant

An antioxidant-promoting composition that increases antioxidant defense potential in a subject is disclosed. The composition contains Bacopa monniera extract comprising a Bacopa monniera active ingredient; a Silybum marianum (milk thistle) extract comprising a Silybum marianum active ingredient; a Withania somnifera (ashwagandha) extract comprising a Withania somnifera active ingredient; aCamellia sinensis (green tea) extract comprising a Camellia sinensis active ingredient; a Curcuma longa (turmeric) extract comprising at least one Curcuma longa active ingredient, and optionally a Centella asiatica (Gotu kola) extract; a Ginko biloba extract; an Aloe vera extract; and N-acetyl cysteine. The process for quantifying Nrf2 transcription factor activating potential of the botanical extracts comprising the botanical active ingredients is described.

Owner:LIFELINE NUTRACEUTICALS CORP

Slimming and blood fat reducing preparation

ActiveCN1682887ANo side effectsLong-term useMetabolism disorderUnknown materialsGalega officinalis extractAdemetionine

The slimming and blood fat reducing preparation includes fine conjak powder, and one or several of haw flavone, gynostemma pentaphylla saponin, gingko extract, tea polyphenol, soybean saponin, fleeceflower root extract, cassia seed extract and corn embryo powder. The slimming and blood fat reducing preparation has medicine-food isogenesis components and may be taken for long time to result in health effect without toxic side effect.

Owner:HENAN JIUSHI PHARMA

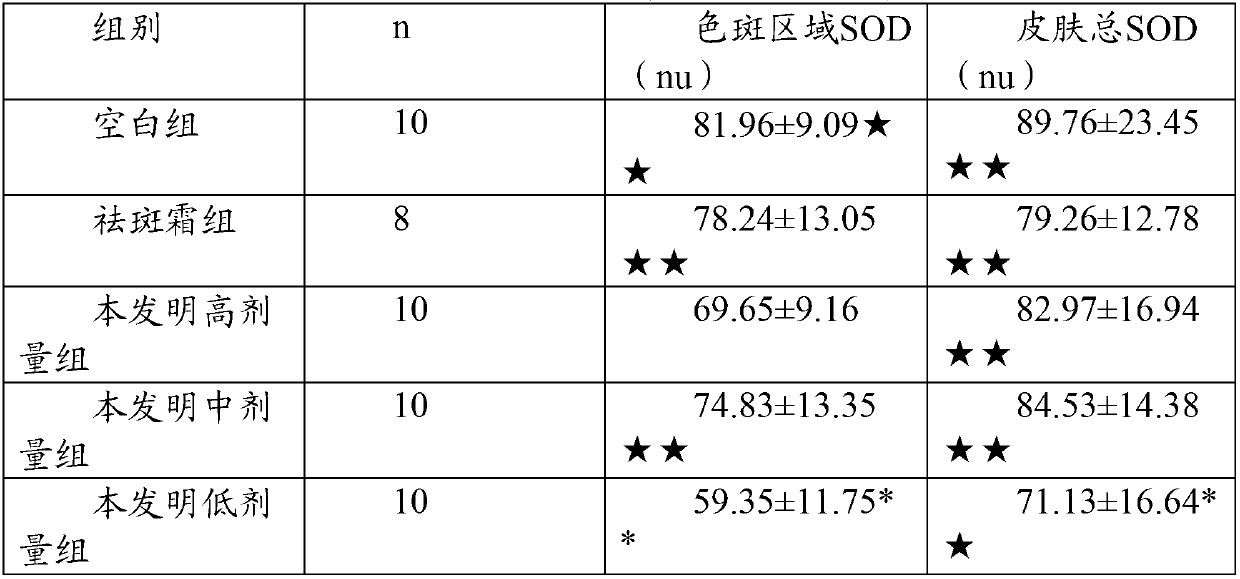

Ginkgo leaf freckle removing whitening cream and preparation method thereof

ActiveCN102988264AStrong free radical scavengerImprove antioxidant capacityCosmetic preparationsToilet preparationsAmino acid synthesisSalvia miltiorrhiza

The invention provides ginkgo leaf freckle removing whitening cream. Raw materials of the ginkgo leaf freckle removing whitening cream comprise, by weight, 10-30 parts of ginkgo leaf, 10-20 parts of leonurus, 10-20 parts of radix angelicae, 10-20 parts of angelica sinensis, 10-20 parts of rhizoma bletillae, 10-20 parts of salvia miltiorrhiza, 10-20 parts of peach blossom, 10-20 parts of rhizome atractylodis, 10-20 parts of myrrh, 10-20 parts of calendula, 10-20 parts of Chinese trumpet creeper, 10-20 parts of scutellaria baicalensis, 10-20 parts of radix paeoniae alba, 10-20 parts of honey suckle, 10-20 parts of albizia flower, 10-20 parts of propollis, 10-20 parts of caulis spatholobi, 10-20 parts of mint and 10-20 parts of pearl. Ginkgol biloba extract has a good effect of removing radical and an antioxidation effect. Yellow glycoside, amino acid and amino acid synthesis collagen in ginkgo leaves have a large effect on beautifying, restraining melanin and maintaining skin gloss and elasticity, and the cream is suitable for long-term use and suitable for use at night.

Owner:SANJIU JUNDA BIOTECH CO LTD GUANGDONG PROVINCE

Formula of acne dispelling liquid and preparation method of acne dispelling liquid

InactiveCN110368348AAdjust water and oil balanceRestore natural healthCosmetic preparationsToilet preparationsSalvia miltiorrhizaSide effect

The invention discloses a natural acne dispelling liquid without stimulation, wherein the ingredients used are extracted from plants, which avoids the side effects of traditional Chinese medicine components in market products and achieves the effect of pure natural acne dispelling without stimulation. The acne dispelling liquid comprises an acne dispelling composition A and an acne dispelling composition B, wherein the acne dispelling composition A includes a semen ginkgo extract, a dendrobium candidum extract, a palygorskite extract, a hedyotis diffusa extract, a salvia miltiorrhiza extract,a soaping extract, a tripterygium wilfordii extract, a flos lonicerae extract, a herba taraxaci extract, a portulaca oleracea extract and a mint extract; the acne dispelling composition B includes antibacterial peptide, bee milk, butanediol and water. By adding the mild plant extraction components and microbial fermentation products and cooperating with basic raw materials, the acne dispelling liquid can adjust the balance of skin water and oil, remove acne, dilute acne marks, restore damaged skin and restore the natural and healthy state of the skin.

Owner:广州重生化妆品实业有限公司

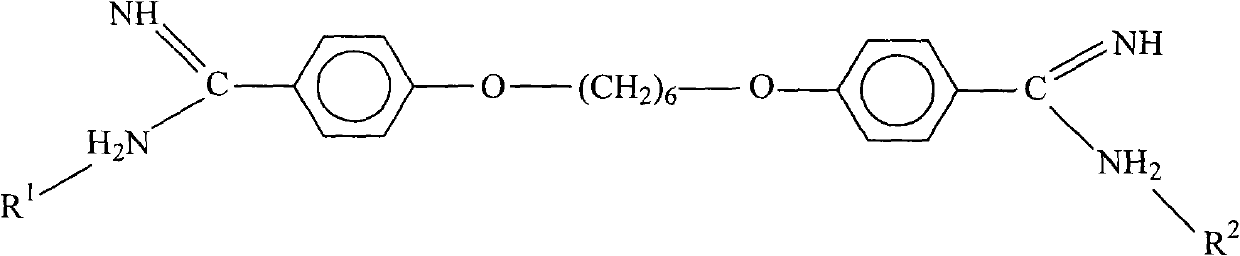

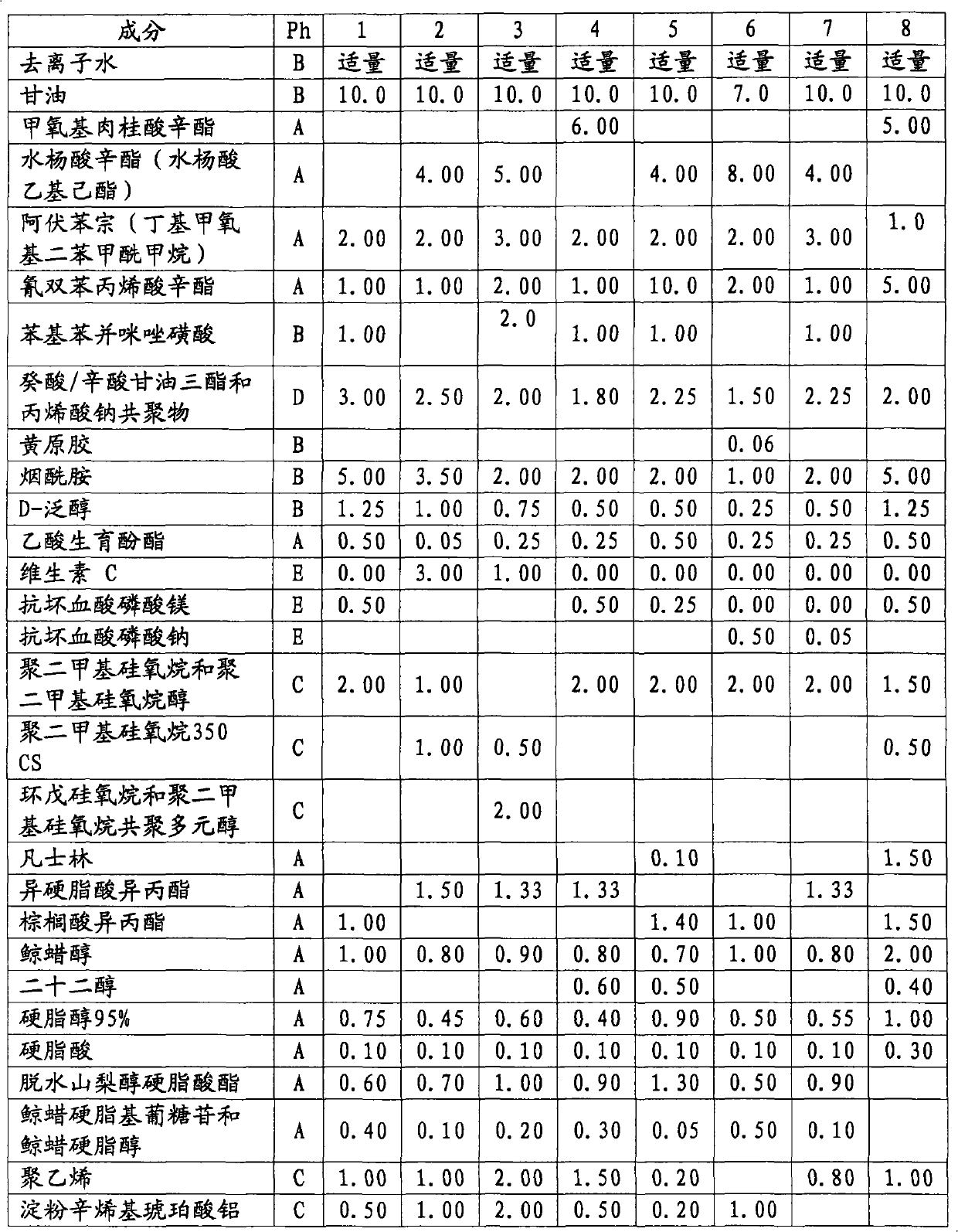

Cosmetic composition comprising gingko biloba and sunscreen agents

A cosmetic composition is provided comprising a Gingko biloba extract, an alkyl beta,beta-diphenylacrylate and / or alpha-cyano beta,beta-diphenylacrylate derivative, and a dibenzoyl methane derivative. A cosmetic use of that composition is also provided for preventing sun damage and photo ageing.

Owner:PROCTER & GAMBLE CO

Method for using bamboo leaf extract as acrylamide inhibitor for heat processing food

ActiveUS20090304879A1Inhibits the formation of acrylamideInhibition formationMilk preparationDough treatmentCrataegus extractApple polyphenol extract

A method for using a bamboo leaf extract as an acrylamide inhibitor for heat processing food, comprises adding to the bamboo leaf extract at least one selected from a group consisting of ginkgo extract, tea extract, rosemary extract, apple polyphenol extract, haw extract, onion extract, licorice extract, root of kudzuvine extract, grape seed extract and leech extract; and preparing a composition, in which the bamboo leaf extract takes up 34-95% of the total weight of the composition. The bamboo leaf extract used as the acrylamide inhibitor in food systems has an inhibiting rate to acrylamide formation of up to 15-98%.

Owner:ZHANG YING +5

Mesenchymal stem cell injection liquid and preparation method

InactiveCN107823632APromote growth and divisionPromote absorptionInorganic non-active ingredientsSulfur/selenium/tellurium active ingredientsHypopigmentationVitamin C

The invention provides mesenchymal stem cell injection liquid and a preparation method, which aim to solve the problem of how to use a mesenchymal stem cell to efficiently repair and improve damaged skin and fundamentally delay and stop skin cell aging. The injection liquid provided by the invention is prepared from the mesenchymal stem cell, DMSO, EGF, glutathione, vitamin C, human serum albumin,a ginkgo biloba extract and a menstruum. The mesenchymal stem cell is obtained through carrying out hungry culture on P2 to P5-generation mesenchymal stem cells and stimulating through an epidermal growth factor. The obtained mesenchymal stem cell has a good differentiative capacity and a good proliferation capacity, has a better differentiation potential, and is synergized with the DMSO, the EGF, the glutathione, the vitamin C, the human serum albumin and the ginkgo biloba extract, so that skin wrinkles and hyperpigmentation can be remarkably reduced.

Owner:南京九圣生物医学科技股份有限公司

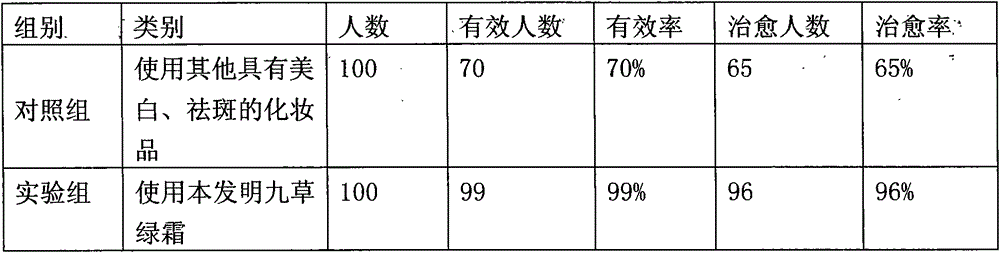

Nine-herb cream with effects of whitening and removing freckle marks and preparation method thereof

ActiveCN104434618AHigh activityPromote regenerationCosmetic preparationsToilet preparationsCentella asiatica extractRHODIOLA ROSEA ROOT

The invention discloses a nine-herb cream with effects of whitening and removing freckle marks. The cream is prepared from the following main raw materials in parts by weight: 30-50 parts of aloe juice spray dry powder, 35-60 parts of crocus sativus, 20-45 parts of rhodiola rosea, 19-32 parts of anoectochilus roxburghii, 16-42 parts of arbutin, 6-12 parts of centella extract, 3-9 parts of motherwort extract, 9-16 parts of gingko extract and 10-20 parts of citron. A whitening method for treating both symptoms and root causes is adopted, melanin of skin is completely extracted from inside to outside, the cream is capable of phagocytosing chromoplasts, improving cell activities, blocking spot formulation, promoting cytothesis and repairing injured skin out of freckles, so that the effect of treating and preventing freckles can be achieved, and various skin color problems, such as dark and dull skin, chloasma, freckles, dryness, uneven and lackluster skin tone, acne marks and the like can be finally repaired, and skin becomes white and tender as before, and is bright once again.

Owner:吴美英

Cosmetic self-tanning compositions

InactiveUS20070231279A1Easy to shapeIncrease moisture contentBiocideCosmetic preparationsMedicineDihydroxyacetone

A cosmetic self-tanning composition which comprises dihydroxyacetone and a ginkgo extract and / or grapeseed oil and / or a lotus blossom extract. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:BEIERSDORF AG

Method for using bamboo leaf extract as acrylamide suppressor for heat processing food

The invention disclose a method for using bamboo leaf extract as acrylamide suppressor for heat processing food, which comprises charging into bamboo leaf extract by ginkgo extract, tea extract, apple polyphenol extract, haw extract, onion extract, licorice extract, root of kudzu vine extract, grape seed extract, the bamboo leaf extract amounts to at least 34-95% of the total weight of the complex.

Owner:ZHEJIANG UNIV

Compositions and Methods for Improving Sleep Using A Nutraceutical Formulation

ActiveUS20150071993A1Reduce physical and psychological stressEnhance specificBiocideOrganic active ingredientsAdditive ingredientVitamin B12

Provided are supplemental compositions for a nutraceutical formulation and methods for administering the same to a user for inducing or maintaining sleep as well as for alleviating pain to improve sleep using a formulation of ingredients comprising of extract of ashwagandha, extract of lavender, extract of valerian, extract of hops, melatonin, magnesium, vitamin B12, and zinc, and / or devil's claw, bromelain and boswellia.

Owner:CREATIVE MEDICAL HEALTH

Method for preparing shikimic acid extract from chromatographic waste liquor of ginkgo biloba extract

InactiveCN109369373AReduce dosageReduce volumeOther chemical processesSilicon compoundsBenzeneAfter treatment

The invention discloses a method for preparing shikimic acid extract from chromatographic waste liquor of a ginkgo biloba extract. The method specifically comprises the following steps: taking waste liquor produced during preparation of the ginkgo biloba extract by macroporous resin column chromatography, and concentrating the waste liquor to the volume of 1 / 5 of the original volume so as to obtain pretreatment waste liquor; extracting the pretreatment waste liquor with chloroform so as to obtain an aqueous phase I; extracting the aqueous phase I with benzene to obtain an aqueous phase II; extracting the aqueous phase II with petroleum ether to obtain an aqueous phase III; diluting the aqueous phase III with water, adding a modified vermiculite adsorbent, stirring, standing, filtering andcollecting filter residues; adding water equivalent to an amount of 50 times that of the weight of the filter residues into the filter residues, performing ultrasonic treatment at a temperature of 60-80 DEG C, filtering after treatment completion, and collecting the filtrate; and performing vacuum concentration on the filtrate, and re-crystallizing, thereby obtaining the shikimic acid extract. According to the method disclosed by the invention, the shikimic acid in the waste liquor produced during preparation of the ginkgo biloba extract by the macroporous resin column chromatography can be well extracted, and the obtained product is high in quality and high in content and has wide application prospects.

Owner:YANGTZE NORMAL UNIVERSITY

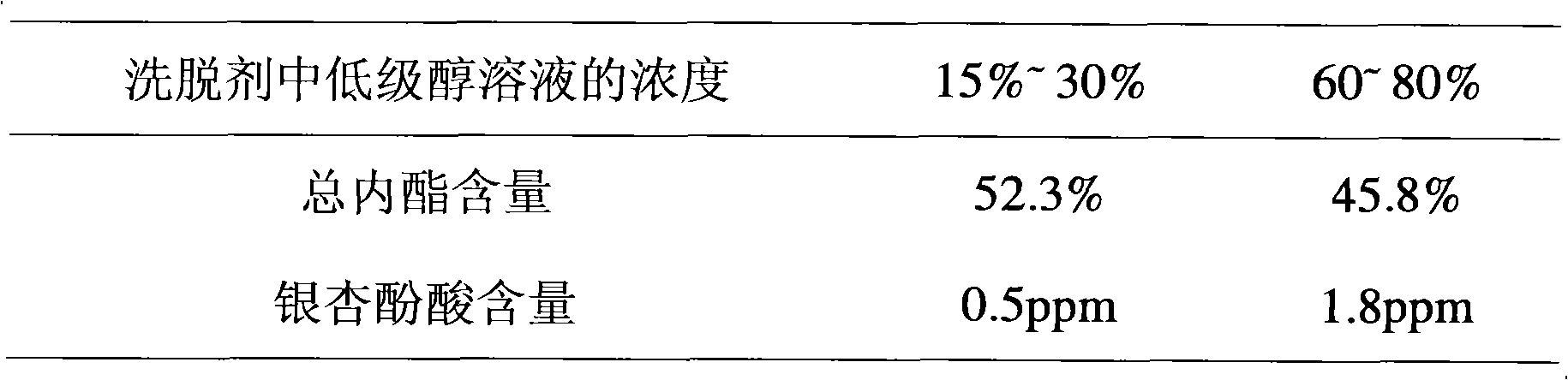

Preparation method of total terpene lactones with low phenolic acid

ActiveCN101773528AReduce extraction timeLow extraction temperatureGinkgophyta medical ingredientsBlood disorderEthyl acetateSolvent

The invention discloses a preparation method of total terpene lactones with low phenolic acid, which uses ginkgo biloba extract as a raw material, uses ethyl acetate backflow to extract and uses amide resin to purify and deacidify. The preparation method takes the ginkgo biloba extract as the raw material and water saturated ethyl acetate as a solvent; at the weight measurement ratio of extractives to the solvent of 1:1-15, the extractive and solvent are extracted for 0.5-5 hours at the temperature of 20-90 DEG C and filtered; filtrate is concentrated to obtain extractum; after the extractum is adsorbed by polyamide resin, the extractum is eluted by 10-50% of lower alcohol solution; fraction is collected, concerted and dried; and the fraction is smashed to obtain dry powder in which the total terpene lactone content is above 50% and ginkgoic acid is lowered than 1 ppm. The preparation process of the invention has short extract time, low extract temperature, high extract efficiency, small solvent amount, solvent and energy saveing and lowered production cost; the deacidifying process method is convenient to operate and can lower the ginkgolic acid below 1 ppm; and the technical method provided by the invention can effectively remove tannin and pigment in extractives.

Owner:GUANGZHOU HANFANG PHARMA

Synthesis for weak hydrophobic framework amide resin and application of the same in purifying gingko total lactone

InactiveCN101100495AGood use strengthGood synergyGinkgophyta medical ingredientsLactone synthesisFlavones

Synthesis of amide adsorptive resin with weak hydrophobic skeleton is carried out by co-polymerizing methyl acrylate with vinyl benzene to obtain ester-based resin, aminolyzing for ester base, acidylating to obtain amide adsorptive resin with weak hydrophobic skeleton, adsorbing flavone compound from Ginkgo extract onto resin by the resin and hydrogen bond synergistic function, flowing ginkgo-lactone, re-crystallizing and eluting to obtain final product. The purity is above 90%, it's simple and non-toxic, it has friendly environment and can be used to supply experimental samples for development of ginkgo lactone.

Owner:NANKAI UNIV

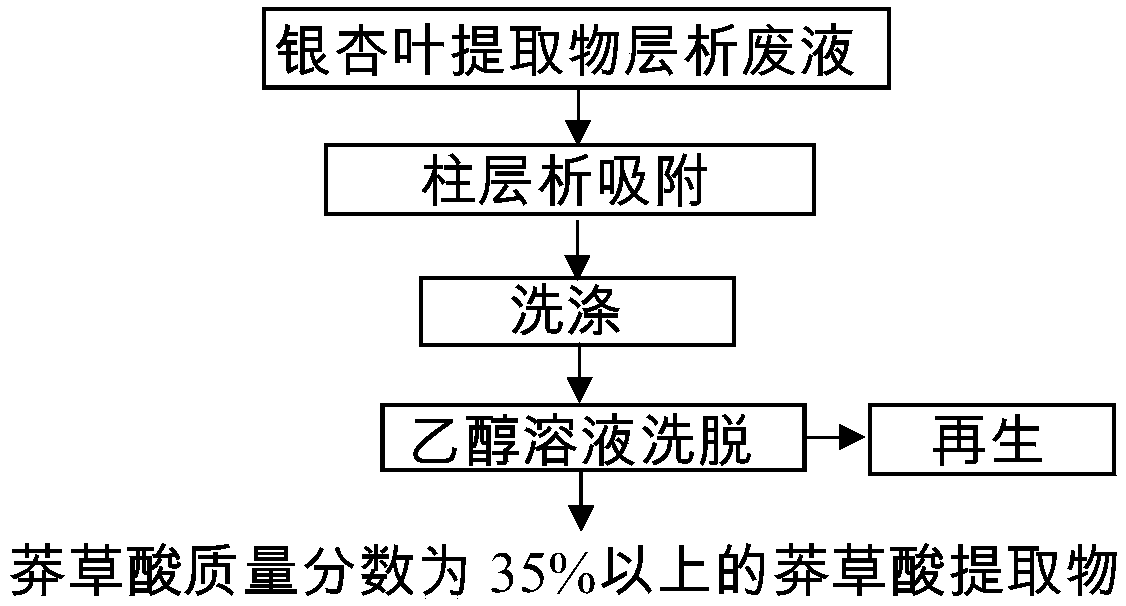

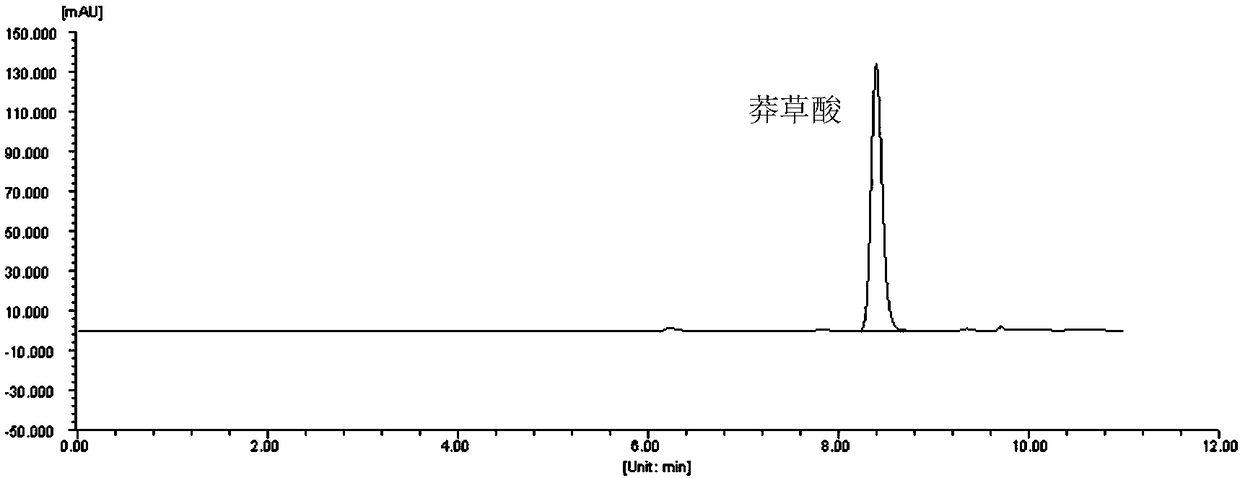

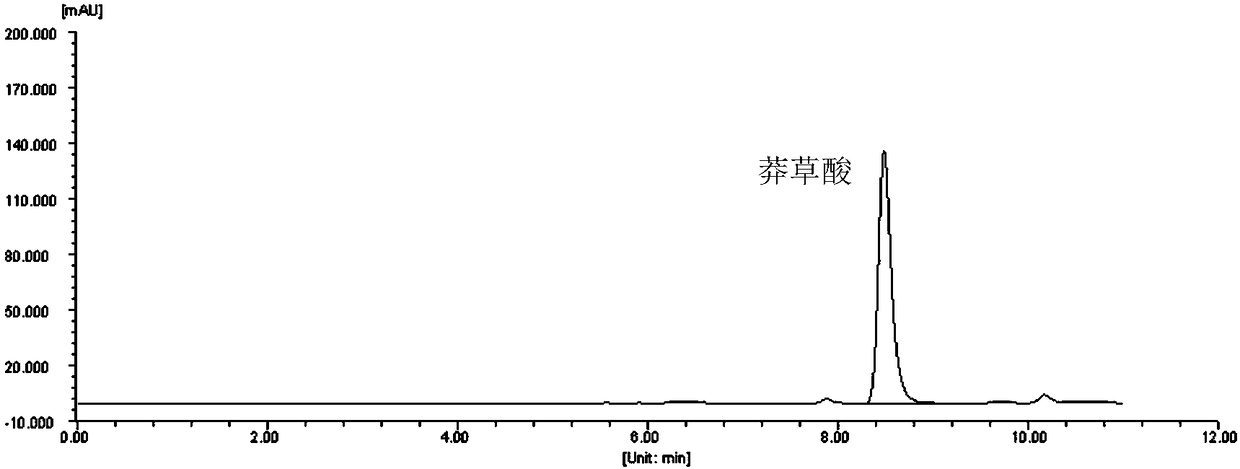

Method for preparing shikimic acid extract from folium ginkgo extract chromatography waste liquid

InactiveCN108191639ATake advantage ofHigh purityCarboxylic compound separation/purificationGinkgo bilobaShikimic acid

The invention relates to a method for preparing shikimic acid extract from folium ginkgo extract chromatography waste liquid. The method specifically comprises the following steps: 1) the shikimic acid extract is prepared from the waste liquid, generated during preparation of folium ginkgo extract with the chromatography technology, as a raw material, wherein the waste liquid comprises chromatography flow-through liquid or washing liquid in the chromatography process; 2) the folium ginkgo extract chromatography waste liquid is enriched and purified by a chromatography column, a washing liquidis added for impurity removal, shikimic acid is eluted with an eluent, an eluate is collected and concentrated, and the shikimic acid extract with shikimic acid mass fraction of 35% or higher is obtained.

Owner:ZHEJIANG WANBANG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com