Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "ETO - Ethylene oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene oxide (EtO) is produced in large volumes and is primarily used as an intermediate in the production of several industrial chemicals, the most notable of which is ethylene glycol.

Recycling method of ethylene oxide-containing organic waste gas

InactiveCN104815535AReduce contentReduce environmental disposal costsDispersed particle separationHydration reactionResource utilization

The present invention discloses a recycling method of ethylene oxide-containing organic waste gas. The specific technical scheme comprises that: ethylene oxide in ethylene oxide-containing organic waste gas is subjected to circulation absorbing in a hydrolysis tower by using dilute sulfuric acid with a certain concentration as an absorbent so as to produce a hydration reaction to generate ethylene glycol, the ethylene glycol is conveyed into an ethylene glycol solution storage tank after the ethylene glycol in the solution achieves a certain concentration, a sodium hydroxide solution is added to neutralize, one part of the neutralized ethylene glycol solution is used for the acid gas washing process, the other part is conveyed to the product separation and recovery, the tail gas discharged from the hydrolysis tower enters a reactor to carry out deep oxidation, an acid gas washing treatment is performed, the treated standard tail gas is discharged into the atmosphere, and the absorbing liquid is recycled to the ethylene glycol solution storage tank. According to the present invention, the method has characteristics of short process and simple operation, and with the treatment of the present invention, the ethylene oxide content in the organic waste gas tail gas does not exceed 1 ppm, and a certain amount of the ethylene glycol solution is recovered so as to achieve the resource utilization of the waste gas.

Owner:SHANXI DATONG UNIV

Process for the production of ethylene oxide

InactiveUS9260366B2Simple processLess equipmentOrganic compound preparationHydrocarbon from oxygen organic compoundsPolymer scienceEthylene oxide

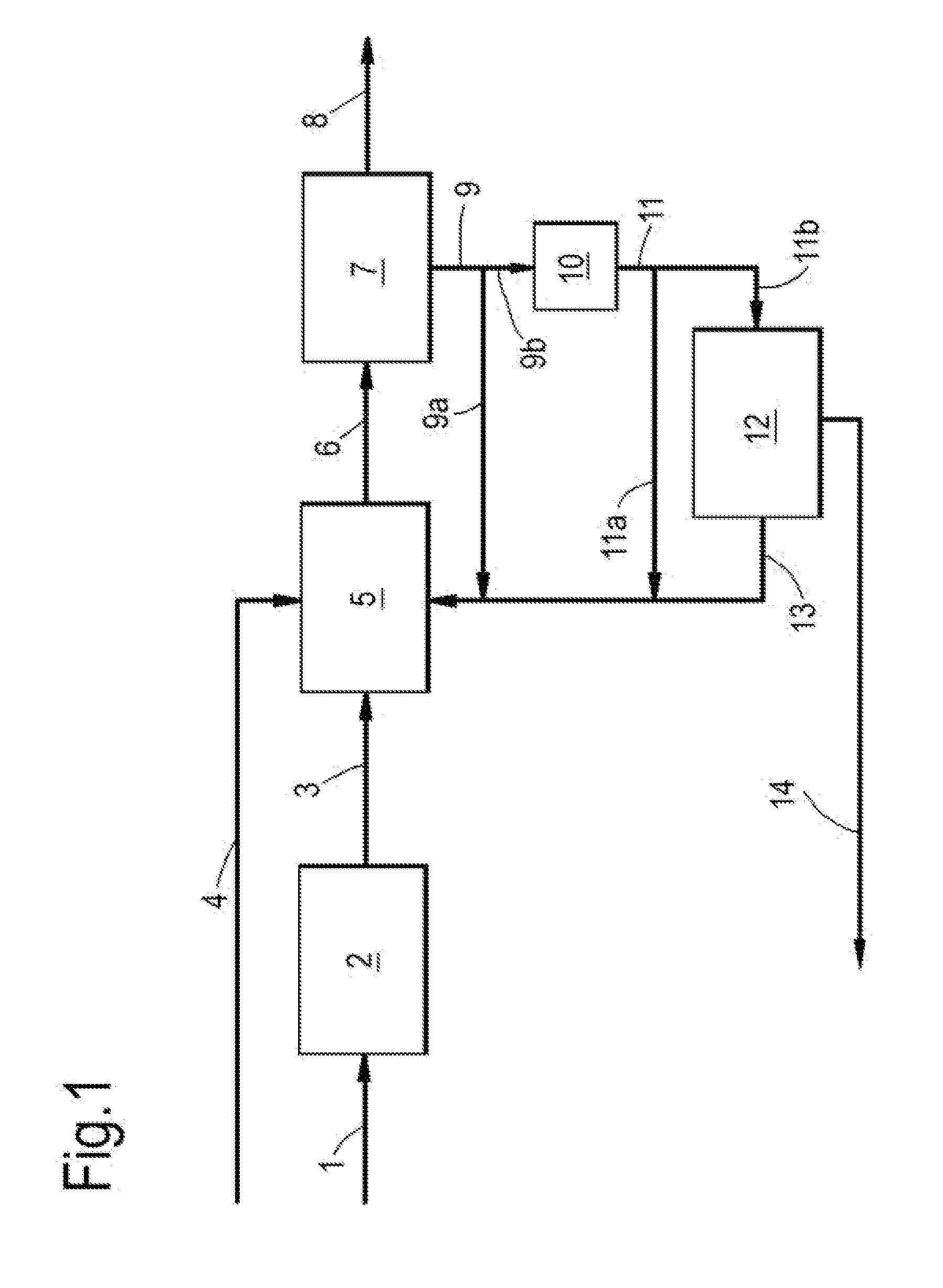

The invention relates to a process for the production of ethylene oxide, comprising the steps of: producing ethylene by converting a stream comprising an oxygenate into a stream comprising ethylene and ethane; producing ethylene oxide by subjecting ethylene and ethane from the stream comprising ethylene and ethane to oxidation conditions resulting in a stream comprising ethylene oxide, unconverted ethylene and ethane; and recovering ethylene oxide from the stream comprising ethylene oxide, unconverted ethylene and ethane.

Owner:SHELL OIL CO

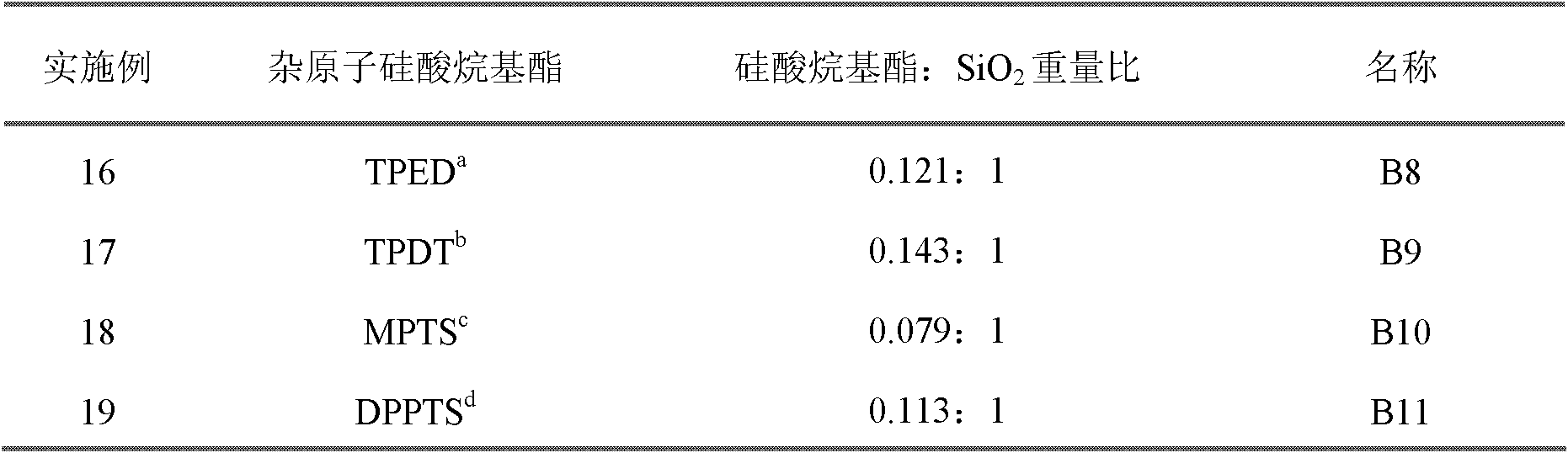

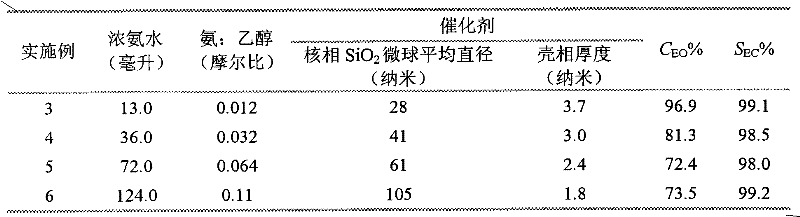

Core-shell catalyst for preparing ethylene carbonate from ethylene oxide and carbon dioxide and preparation method thereof

ActiveCN102294264AHigh N contentHigh activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyMicrosphere

The invention relates to a nuclear-shell catalyst applied to preparation of ethylene carbonate from epoxy ethane and carbon dioxide and a preparation method thereof, which are mainly used for solving the problems of low catalyst activity and easy loss of active ingredients existing in the prior art. In the preparation method, SiO2 microspheres of which the average diameter is 15-500 nanometers are taken as a nuclear phase, and metal salt MYn compounded with polyethylene imine is taken as a shell phase, wherein M is Ni, Zn, Cu, Fe or Co; Y is Cl, Br or I; n is 2 or 3; the periphery of the nuclear phase SiO2 microspheres is coated with a metal salt shell phase compounded with polyethylene imine; the thickness of the shell phase is 0.5-8 nanometers; the weight ratio of polyethylene imine to the metal salt in the shell phase is 0.3-10; and the weight ratio of the nuclear phase to the shell phase is 45:55-99.5:0.5. By adopting the technical scheme, the problems are well solved; and the nuclear-shell catalyst can be applied to industrial production of ethylene carbonate prepared from epoxy ethane and carbon dioxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

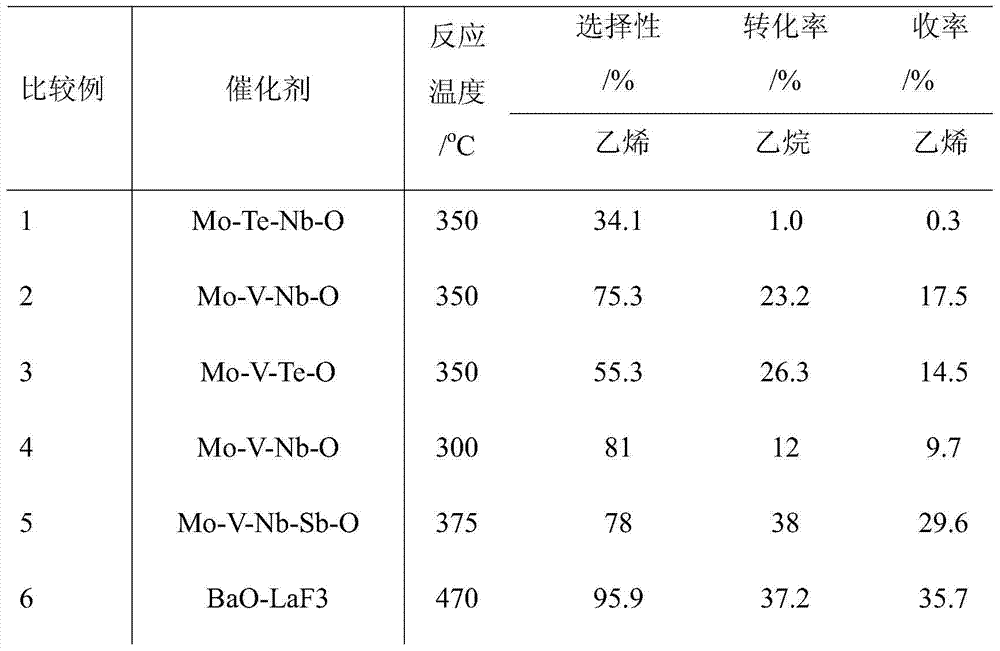

Molybdenum vanadium tellurium niobium oxygen catalyst for ethane to ethylene, preparation method and application thereof

ActiveCN105080575BPhysical/chemical process catalystsHydrocarbonsElemental compositionBULK ACTIVE INGREDIENT

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Treatment method of waste gas containing ethylene oxide and propylene oxide

The invention relates to a treatment method of waste gas containing ethylene oxide and propylene oxide, mainly solving the problems in the prior art that the consumption of washing water is great and wastewater obtained by washing is difficult to treat. By adopting the treatment method of the waste gas containing ethylene oxide and propylene oxide, provided by the invention, the waste gas enters a waste gas absorption tower and is in contact with washing water to be washed; washed waste gas is discharged into the atmosphere from the top of the waste gas absorption tower; washing rich liquid at the bottom of the waste gas absorption tower passes through a waste water pump and then enters a wastewater pre-heater and a secondary pre-heater in sequence, and then enters a hydration reactor to be subjected to a catalytic hydration reaction; after ethylene oxide and propylene oxide in the hydration reactor are subjected to catalytic conversion reaction, the wastewater is conveyed into the wastewater pre-heater and is used as a heat source for pre-heating the washing rich liquid; and at least one part of the wastewater is treated by a lithium bromide freezer and then the treated wastewater is used as the washing water and enters the waste gas absorption tower. By adopting the technical scheme, the problems are solved very well; and the treatment method can be used for treating the waste gas containing ethylene oxide and propylene oxide.

Owner:SINOPEC SHANGHAI ENG +1

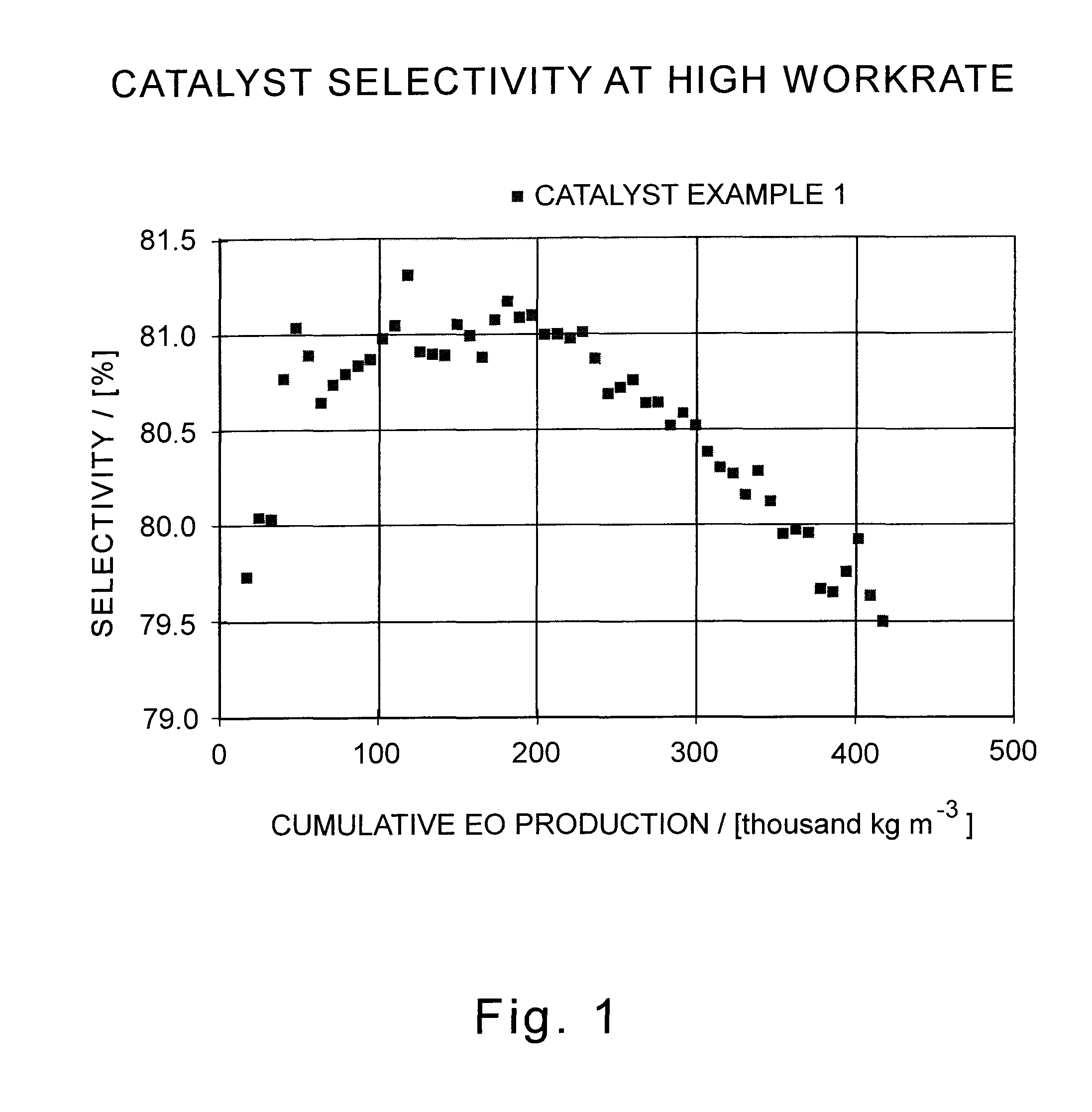

Alkylene oxide catalyst and use thereof

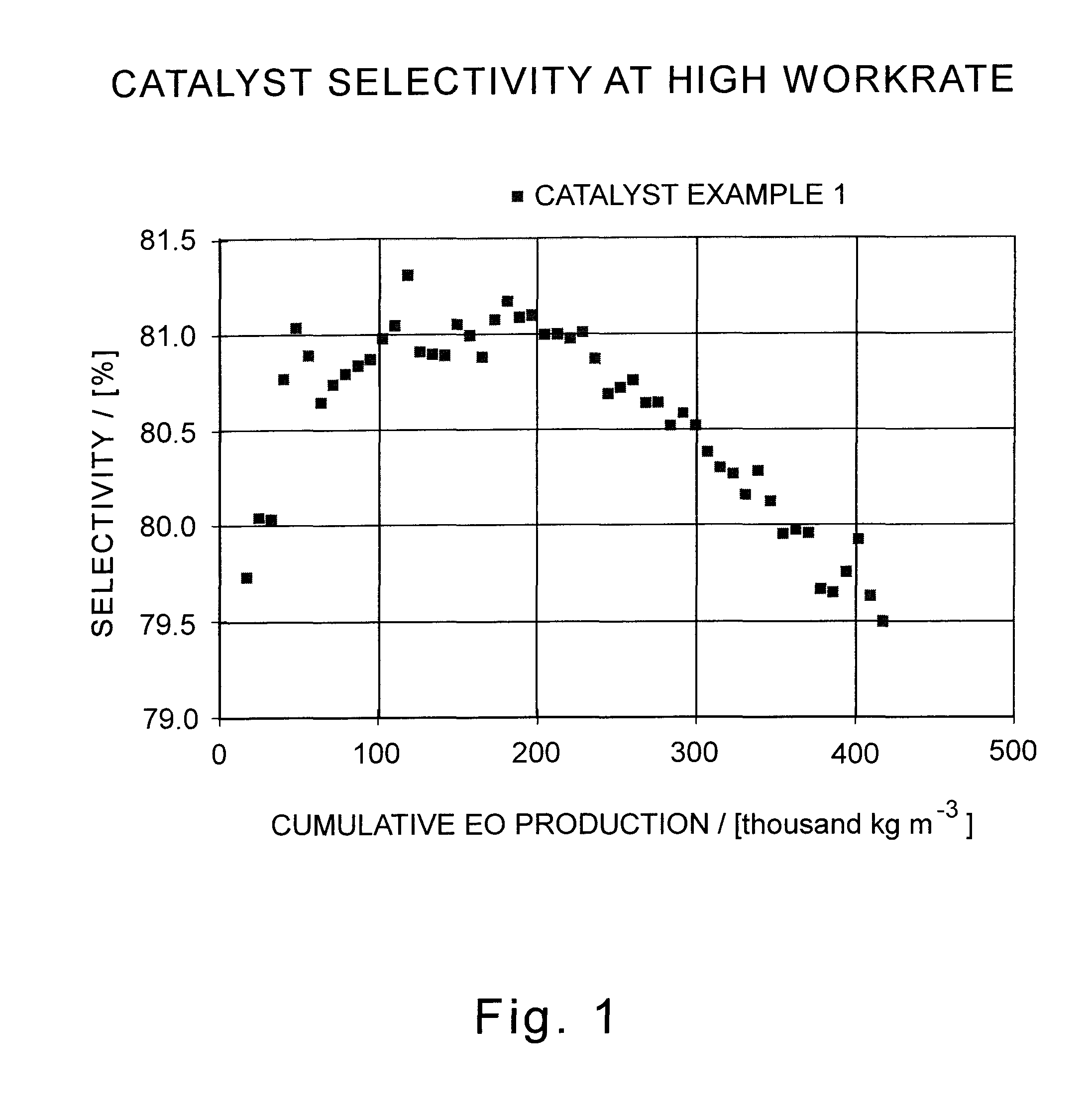

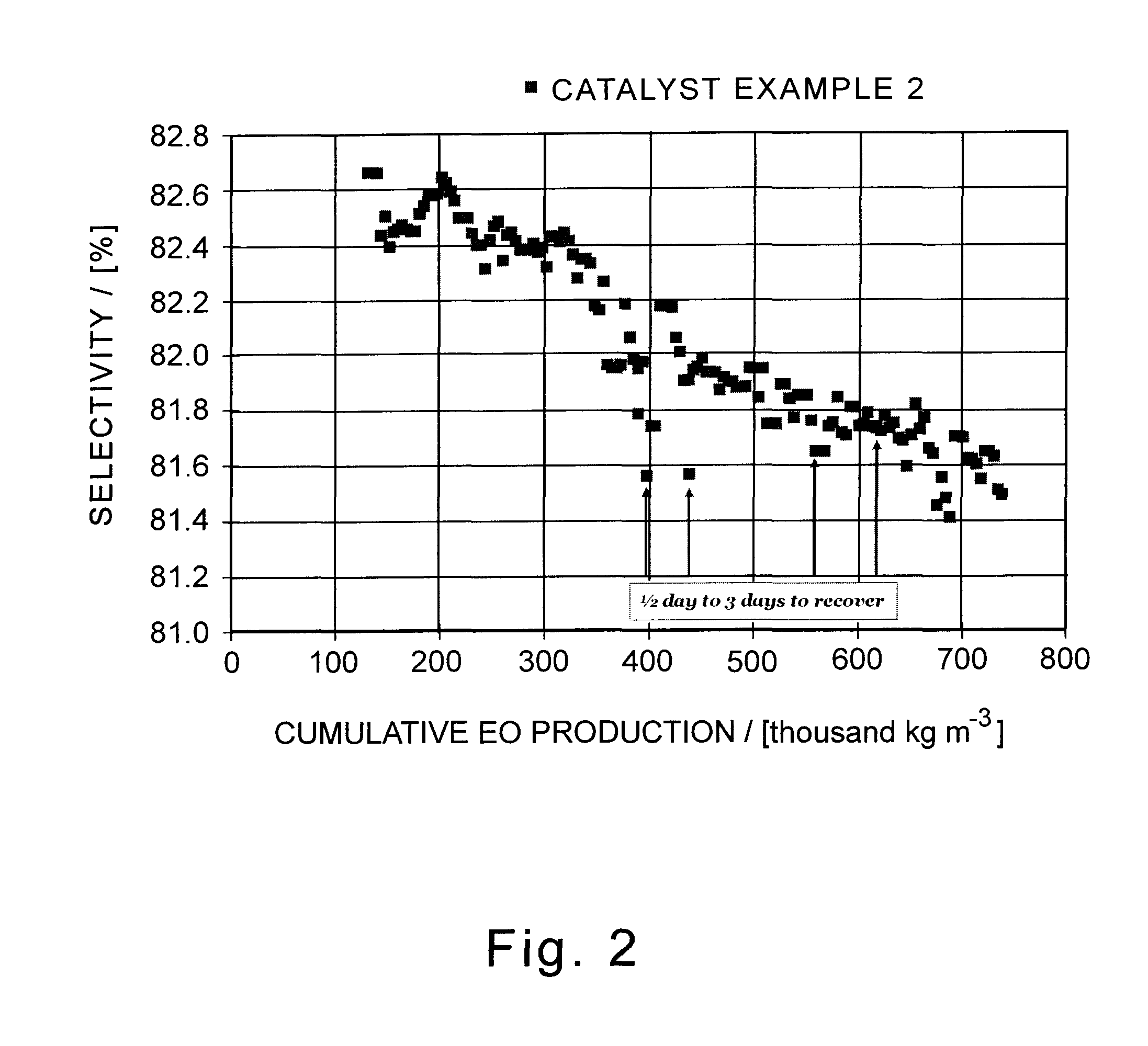

ActiveUS20140088316A1Selectivity towards ethylene oxide formation is optimalGood choiceOrganic compound preparationCatalyst activation/preparationEthylene DibromideOxygen

A supported silver catalyst and use thereof in a process for producing an alkylene oxide, such as ethylene oxide, by the direct oxidation of an alkylene with oxygen or an oxygen-containing gas, wherein the catalyst provides improved stability and improved resilience to reactor upsets and timely recovery to substantially pre-upset levels of catalyst activity and / or efficiency. In some embodiments, the catalyst also exhibits improved activity. A catalyst capable of producing ethylene oxide at a selectivity of at least 87 percent while achieving a work rate of at least 184 kg / h / m3 at a temperature of no greater than 235° C. when operated in a process where the inlet feed to a reactor containing the catalyst comprises ethylene, oxygen, and carbon dioxide, wherein the concentration of carbon dioxide in the inlet feed is greater than or equal to 2 mole percent.

Owner:DOW GLOBAL TECH LLC

Ethylene oxide sterilization process

InactiveCN109806424AGuaranteed to stay out of explosive limitsStrong penetrating powerChemicalsEthylene Oxide SterilizationAir cleaning

Owner:常熟荣瑞灭菌技术有限公司

A kind of method that catalyzes hydrocyanic acid and oxirane to synthesize 3-hydroxy propionitrile

ActiveCN106883142BSubtractive synthesis processReduce operational riskOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by cyanide reactionInorganic saltsCatalytic method

The complex of boron trifluoride and 1,2-pentanediol immobilized on activated alumina is used to catalyze the reaction of hydrogen cyanide and ethylene oxide to synthesize 3-hydroxypropionitrile. Utilizing this method, there is no need for a large amount of acid to neutralize the reaction mixture during the reaction, and a large amount of inorganic salts are not produced. It is a reaction with 100% atom economy. It has a short reaction route, few operating steps, and easy product separation, making it a simple and easy-to-operate reaction. ; Under low-temperature reaction conditions, there is no risk of large amounts of hydrogen cyanide overflowing in the system, and it is a safe reaction to operate.

Owner:FUSHUN SHUNTE CHEM

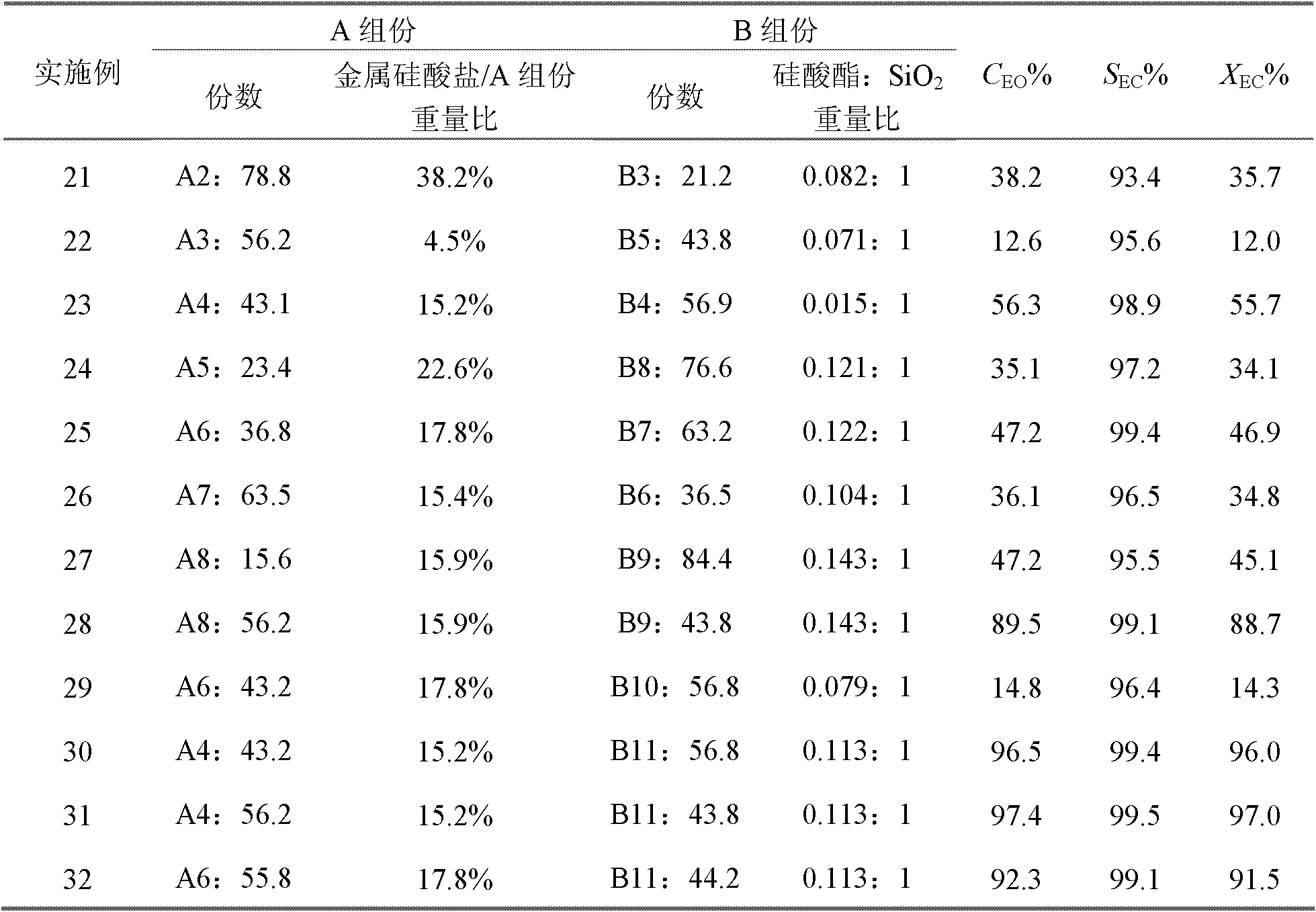

Catalyst for preparing ethylene carbonate by using ethylene oxide and carbon dioxide

ActiveCN103028404AHigh activityReduced activityProductsMolecular sieve catalystsActive componentEthylene oxide

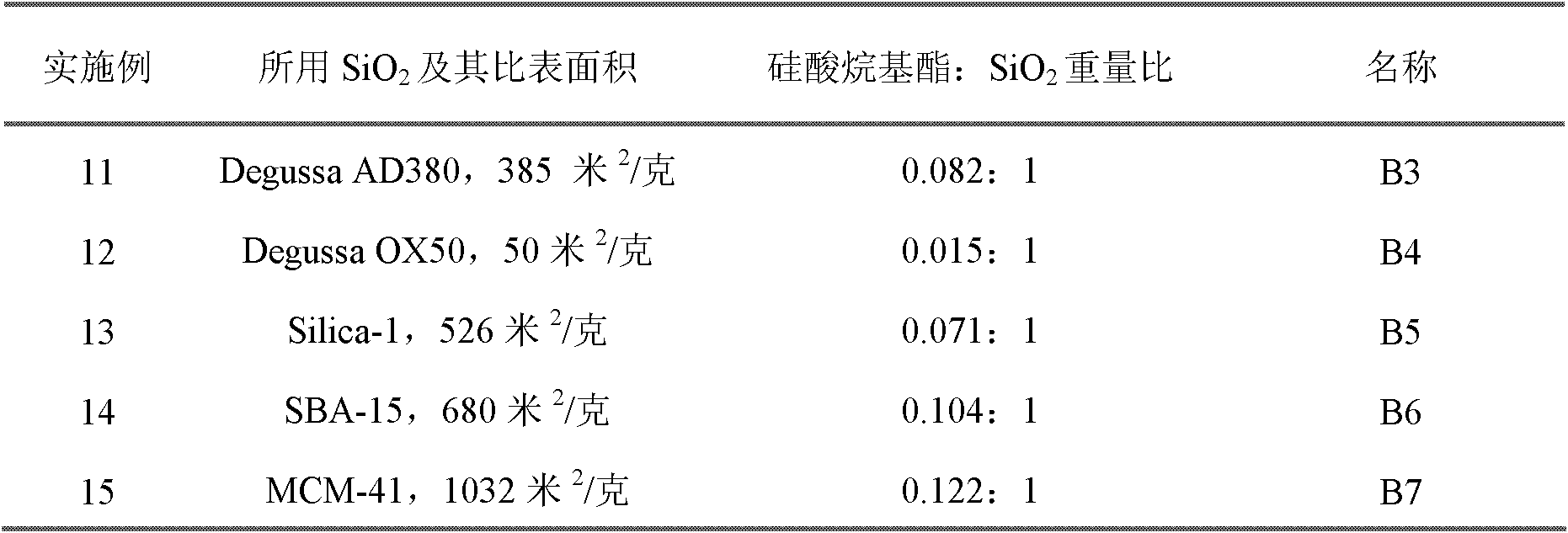

The invention relates to catalyst for preparing ethylene carbonate by using ethylene oxide and carbon dioxide, mainly aiming at solving the problems that the activity of the existing catalyst is low and the active components are apt to lose in the prior art. The catalyst comprises the following components in parts by weight: a component A: 10-80 parts of metal silicate which is loaded on SiO2 carriers, wherein the weight of the metal silicate is 1-50 percent of the total weight of the component A; and a component B: 20-90 parts of SiO2 which is grafted with alkyl ester silicate CaHbXcSi(OR)3, wherein a is equal to 3-23, b is equal to 7-33, c is equal to 1-3, X is N, P or S, R is -CH3 or -CH2CH3, and the weight ratio of the grafted alkyl ester silicate to the SiO2 is (0.002-0.15):1. By adopting the technical scheme, the problems are better solved and the catalyst can be used for the industrial production of the ethylene carbonate which is prepared by using the ethylene oxide and the carbon dioxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

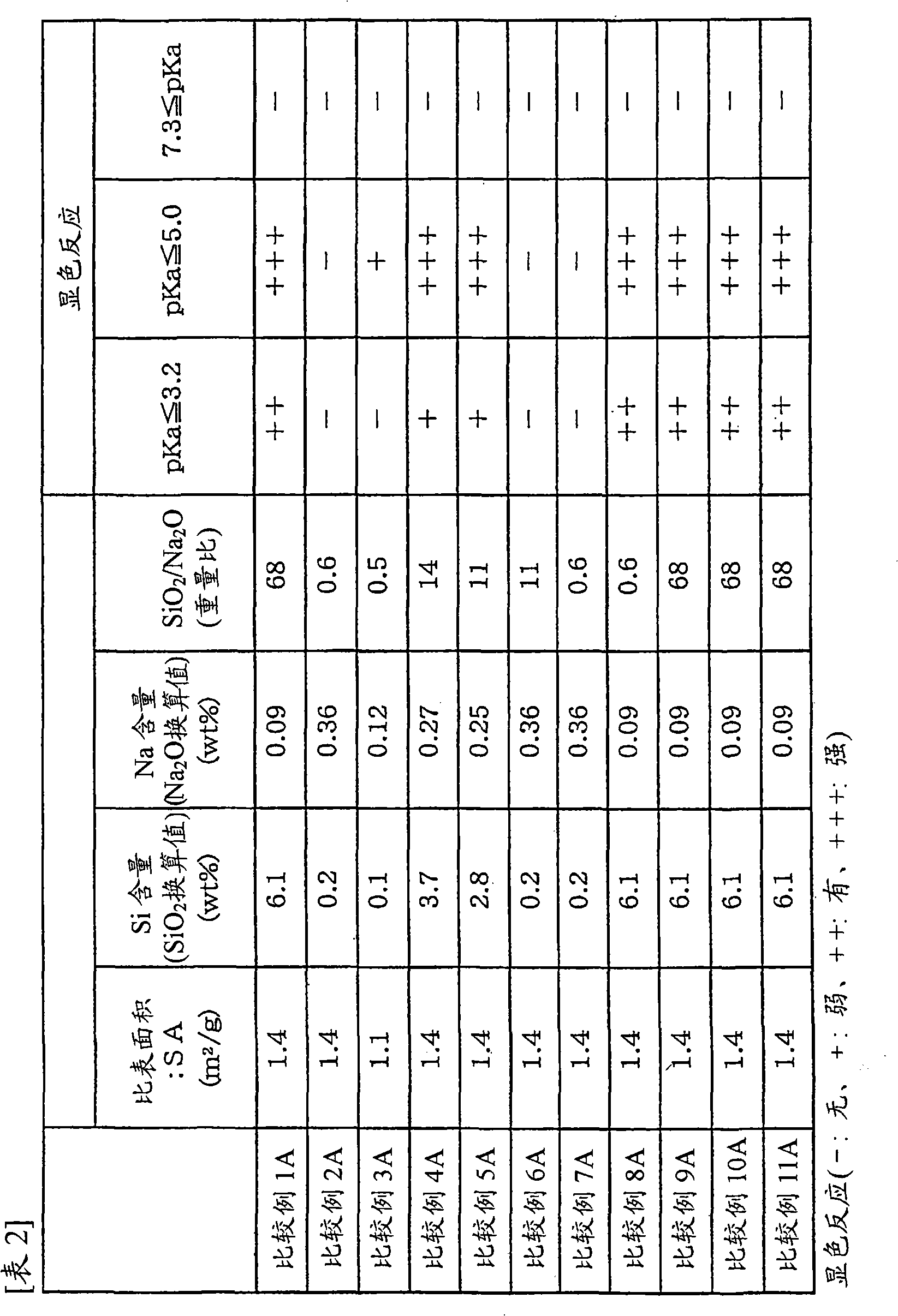

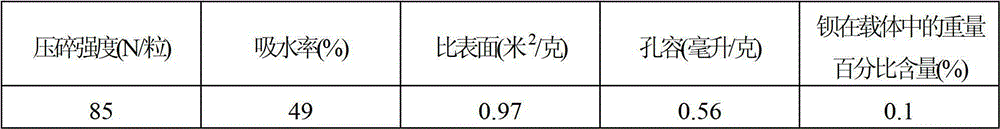

Catalyst for ethylene oxide production, method for producing the same, and method for producing ethylene oxide

ActiveCN101360562AGood choiceImprove overall lifespanOrganic chemistry methodsCatalyst activation/preparationRheniumEthylene oxide

Disclosed is a catalyst for ethylene oxide production which is used for producing ethylene oxide from ethylene. This catalyst is composed of at least silver (Ag), caesium (Cs), rhenium (Re) and a carrier, and improved especially in selectivity. Specifically disclosed is a catalyst for ethylene oxide production, which is used for producing ethylene oxide from ethylene and composed of at least silver (Ag), caesium (Cs), rhenium (Re) and a carrier. If necessary, an alkali metal is loaded onto the carrier as a pretreatment, and then Ag, Cs and Re are loaded onto the carrier, thereby obtaining the catalyst. The carrier has a specific surface area of 0.6-3.0 m2 / g, and a weight ratio between the silicon (Si) content and the sodium (Na) content in terms of SiO2 / Na2O of 2-50. The Re content (based on the carrier) is 170-600 ppm per 1 m2 / g of the specific surface area of the carrier, and the molar ratio Cs / Re is 0.3-19.

Owner:MITSUBISHI RAYON CO LTD

Ethylene oxide purification method

ActiveCN109422708AImprove solubilityImprove thermal stabilityOrganic chemistryPurification methodsHigh energy

Owner:CHINA PETROLEUM & CHEM CORP +1

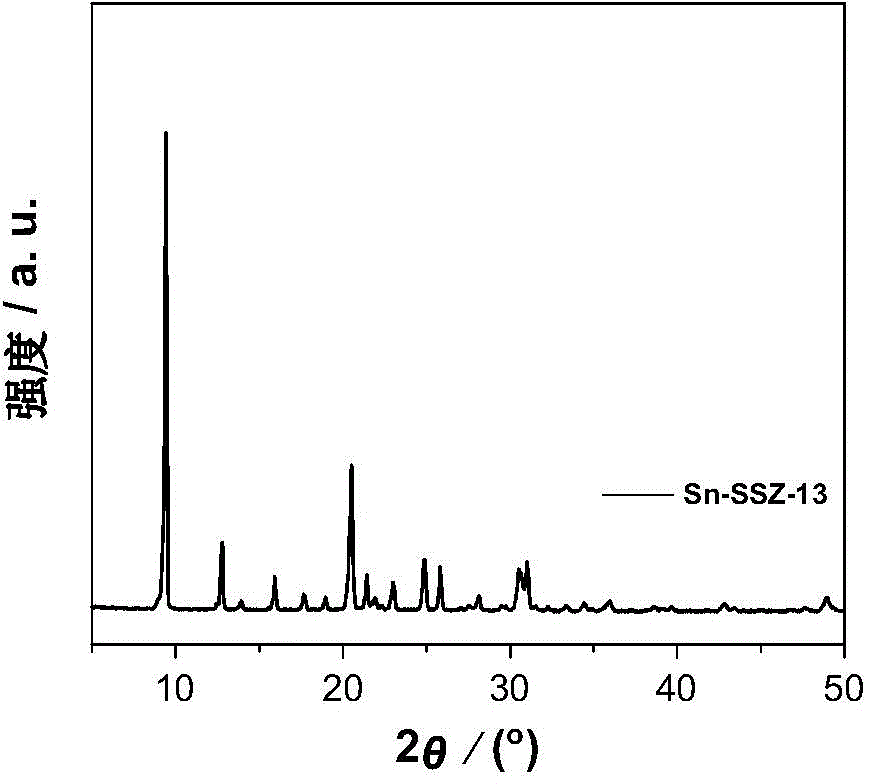

Tin-containing molecular sieve catalyst used for preparing ethylene glycol by hydrating ethylene oxide and application method

ActiveCN104437607AHigh selectivityReduced inactivation rateMolecular sieve catalystsBulk chemical productionHydration reactionWater vapor

The invention relates to a tin-containing molecular sieve catalyst used for preparing ethylene glycol by hydrating ethylene oxide and an application method of the tin-containing molecular sieve catalyst. The tin-containing molecular sieve catalyst is prepared by taking H-SSZ-13 zeolite molecular sieve raw powder as a raw material, carrying out water steam treatment or water steam and acid combined treatment on the raw material, and introducing active central metal in a manner of roasting by a vacuum pipe type furnace. The preparation method comprises the following steps: mixing an H-SSZ-13 zeolite molecular sieve treated by the water steam or acid with an organic metal compound precursor at a ratio and roasting in vacuum. According to the tin-containing molecular sieve catalyst, the problems of high water ratio, high energy consumption, environmental pollution caused in a production process and the like in a traditional process can be solved. According to the catalyst, a carrier is cheap and easy to obtain, a preparation process of the catalyst is simple and the stability of the catalyst is good; and the catalyst has excellent catalyzing activity and selectivity when being applied to a process of preparing ethylene glycol by directly hydrating ethylene oxide under a warm condition, is easy to recycle and can be used for industrial production for preparing ethylene glycol by hydrating ethylene oxide.

Owner:NANKAI UNIV

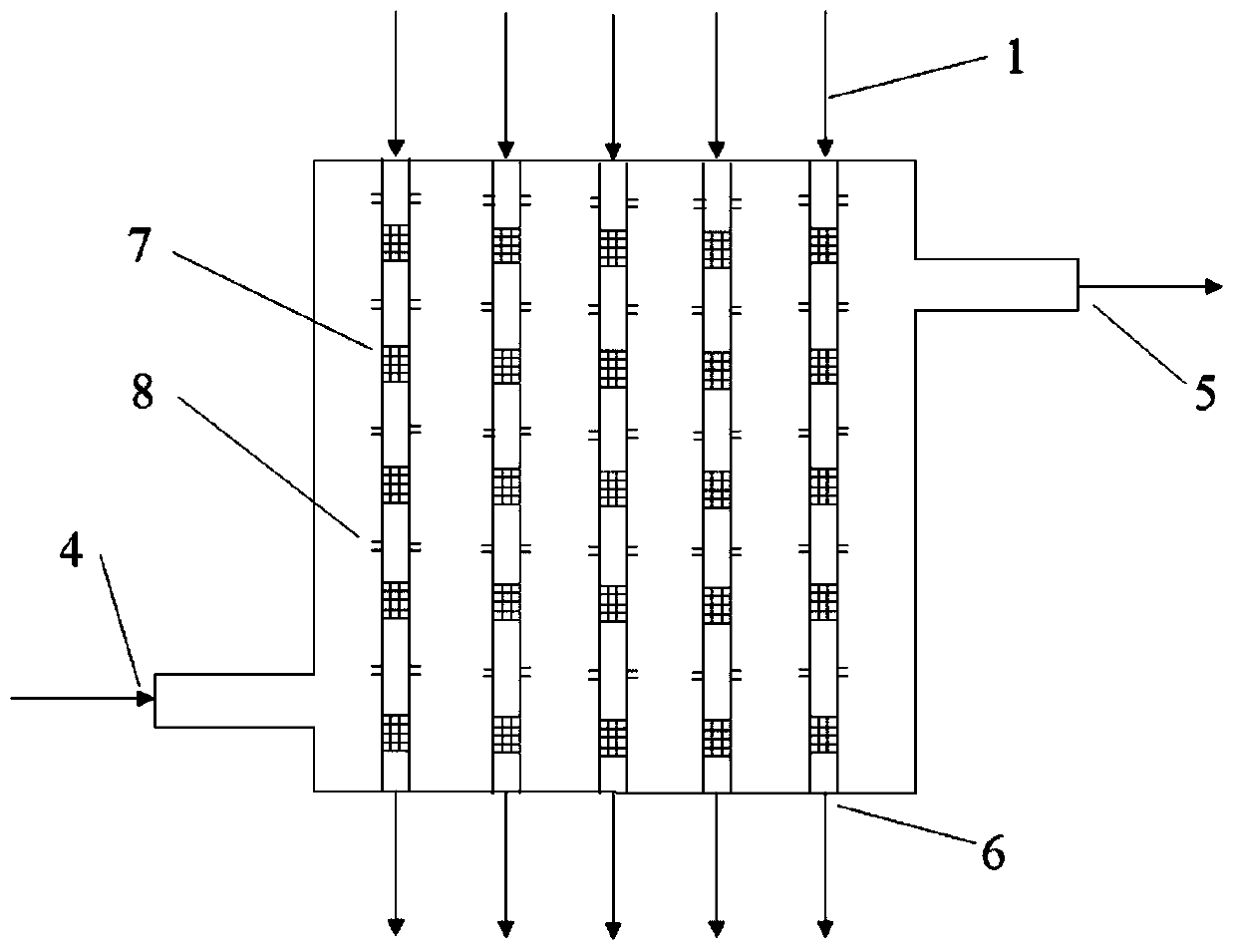

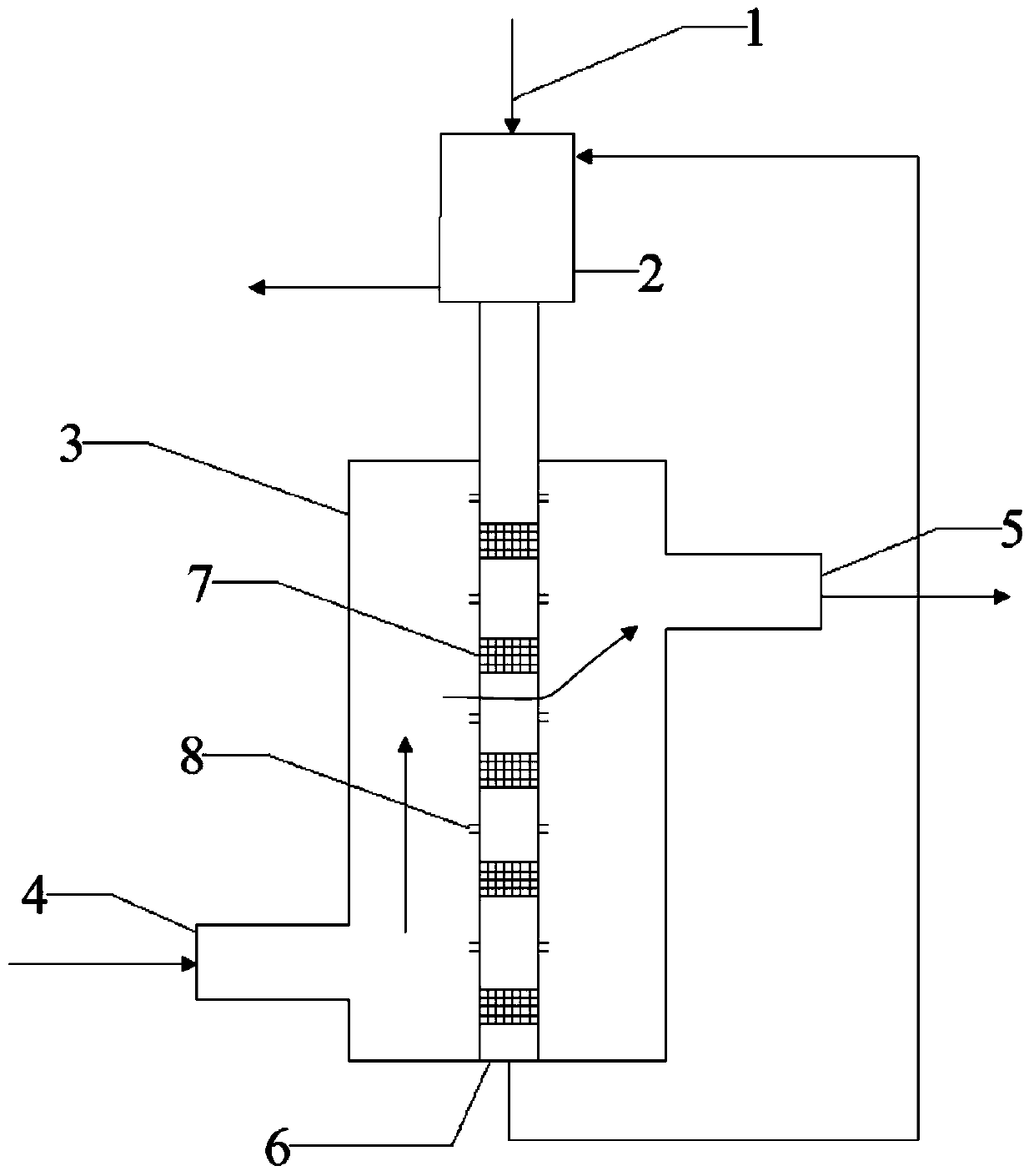

Use of structured catalyst beds for preparing ethylene oxide

The present invention relates to a process for preparing ethylene oxide by reaction of ethylene with oxygen in the presence of at least one silver-comprising catalyst, wherein the reaction takes place in a reactor which has a catalyst packed bed having at least two zones (i) and (ii) and the silver content of the catalyst in zone (i) is lower than the silver content of the catalyst in zone (ii). The catalyst packed bed preferably has a further zone (a) with which the reaction mixture comes into contact before the zones (i) and (ii). According to the invention, the silver content of the catalyst in the zone (a) is higher than the silver content of the catalyst in zone (i).

Owner:BASF AG

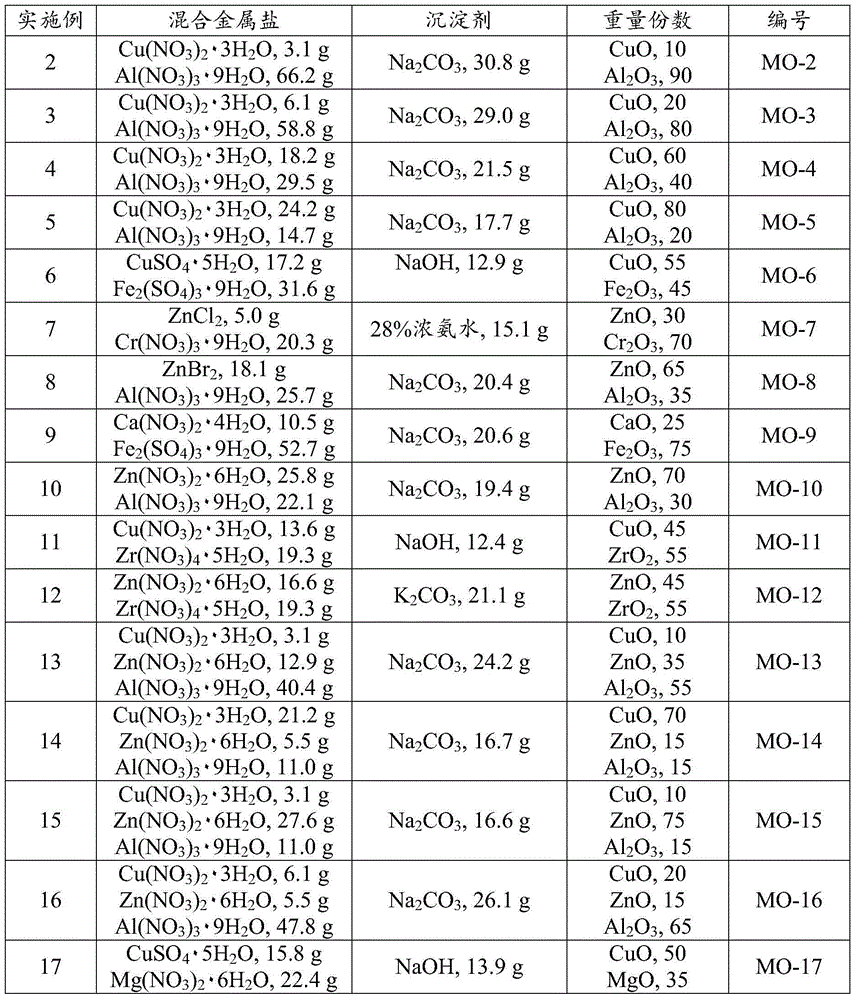

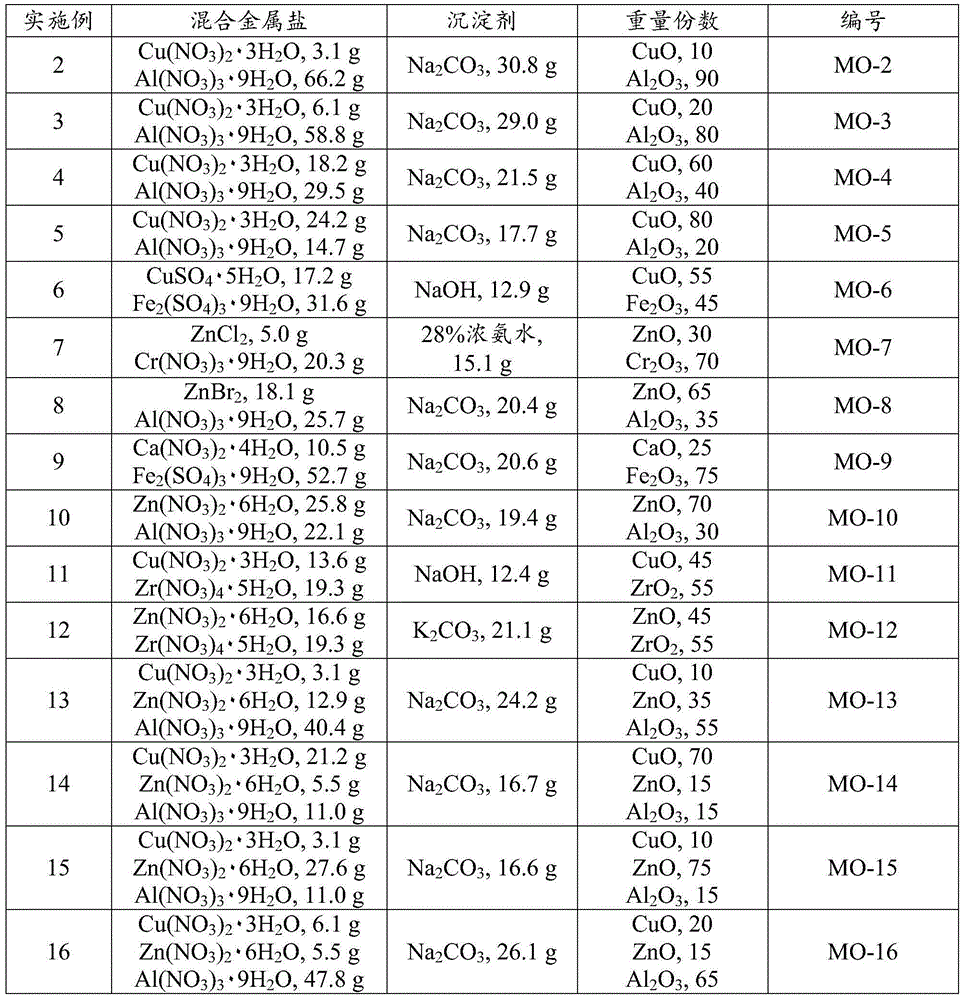

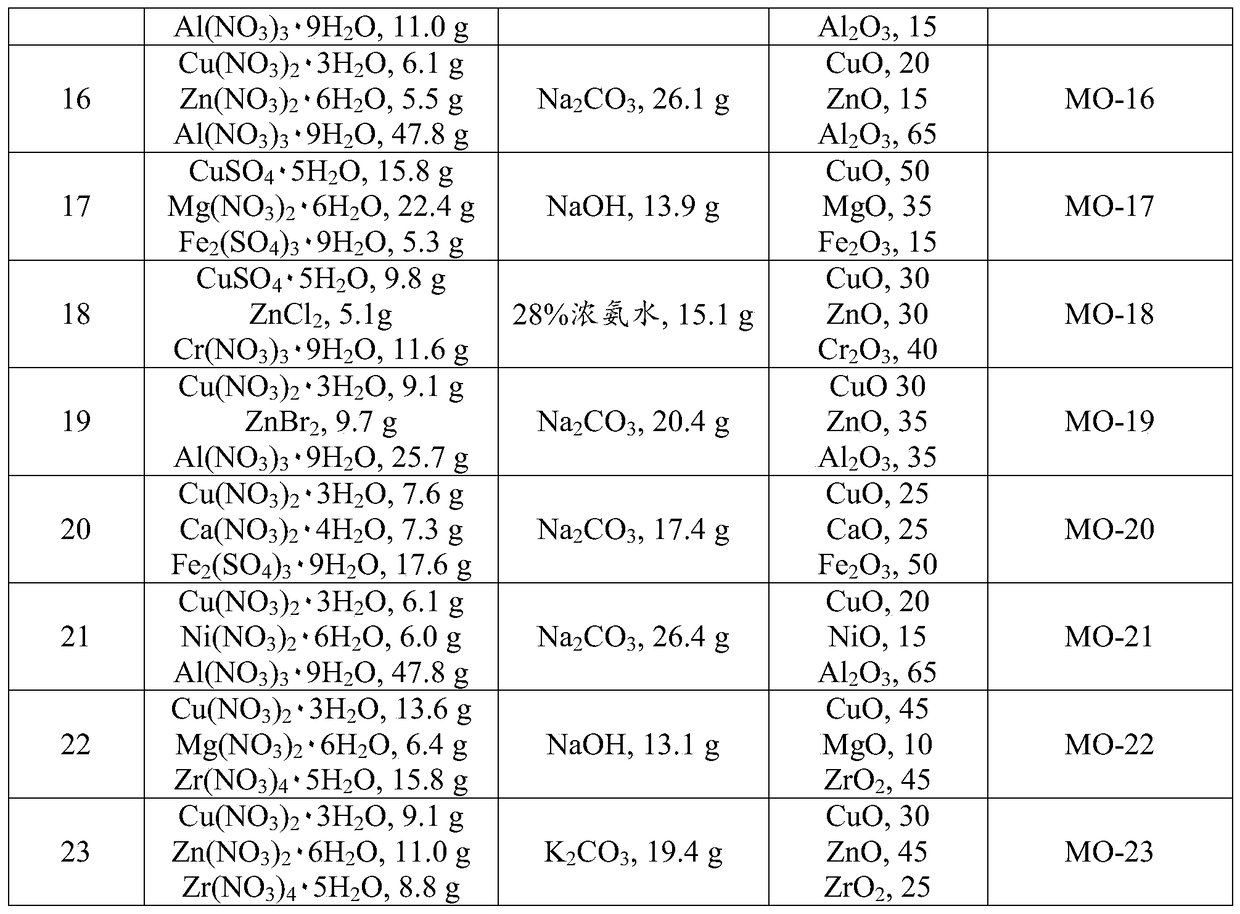

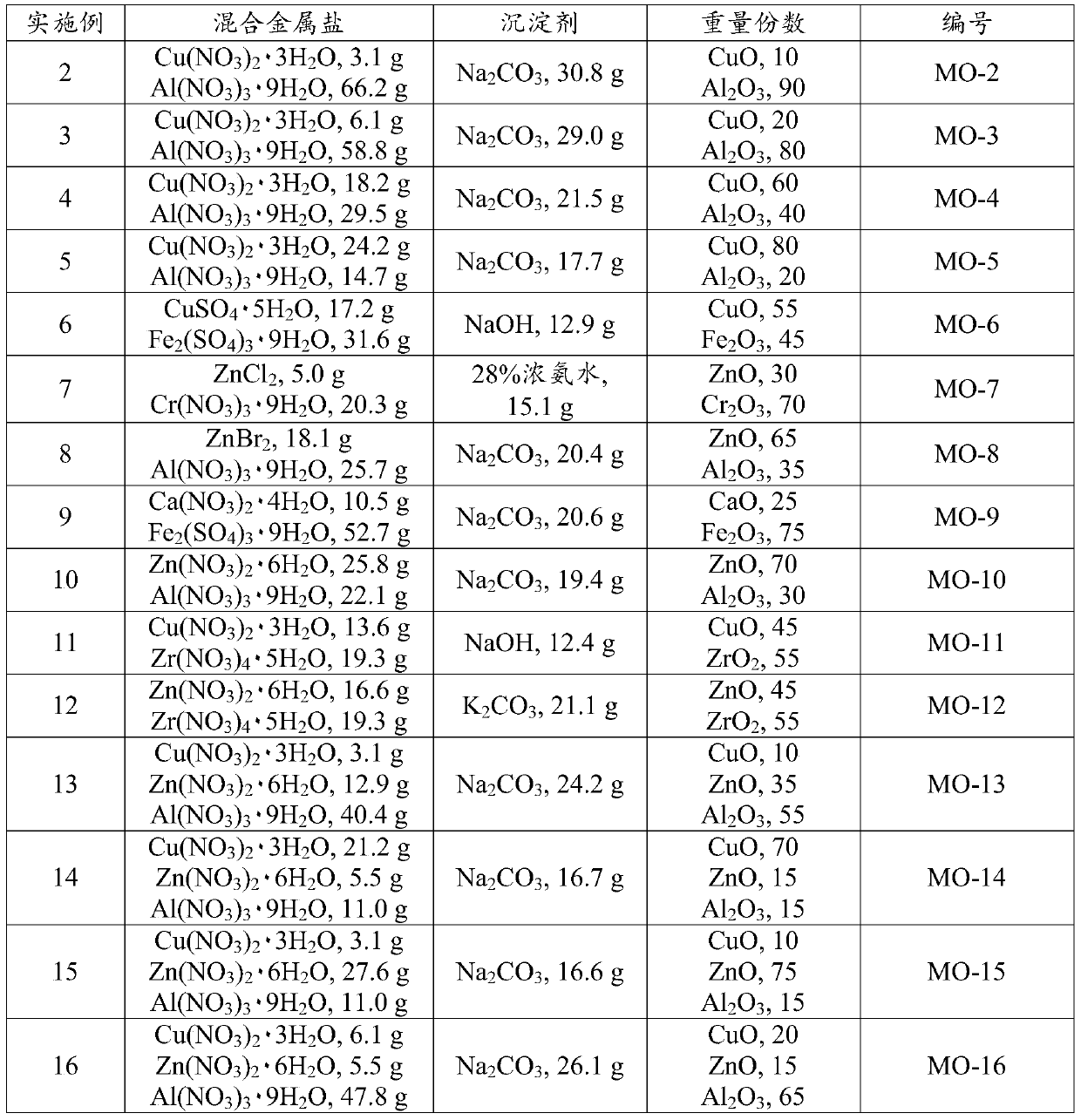

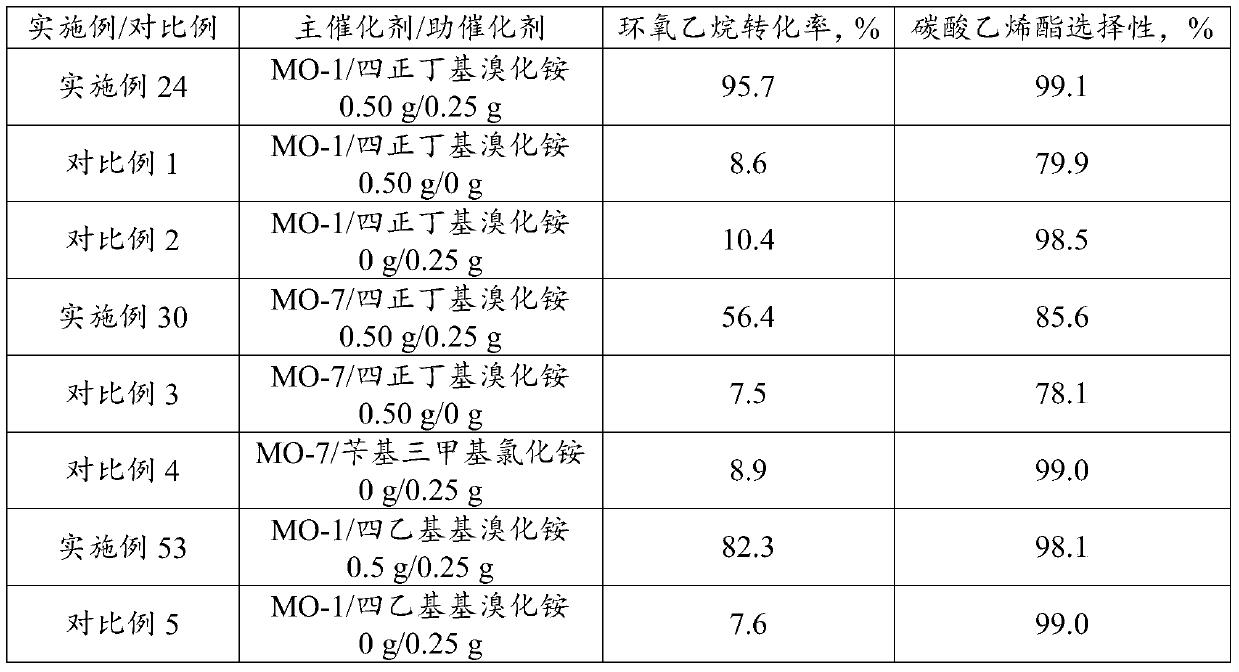

Catalyst for preparing ethylene carbonate from ethylene oxide and carbon dioxide, and preparation method thereof

ActiveCN105214732AOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsLow activityMixed oxide

The invention relates to a catalyst for preparing ethylene carbonate from ethylene oxide and carbon dioxide, and a preparation method thereof to mainly solve the problem of low activity of heterogeneous catalysts in the prior art. The catalyst comprises a main catalyst and a cocatalyst; the main catalyst is a metal mixed oxide AaOb / BcOd, wherein A is selected from at least one of Cu, Mg, Zn, Ca, Co or Ni, and B is selected from at least one of Al, Fe, Cr or Zr; the cocatalyst is an organic amine R1R2R3N; and a weight ratio of the cocatalyst to the main catalyst is 0.1-10. The catalyst adopting the above technical scheme well solves the problem, and can be used in industrial production of ethylene carbonate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silver impregnation liquid and silver catalyst for ethylene oxide production through ethylene epoxidation, and preparation methods thereof

ActiveCN110605116AImprove uniformityHigh selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsEthylene DibromideAmmonia

The invention belongs to the field of catalysts, and provides a silver impregnation liquid for ethylene oxide production through ethylene epoxidation, a silver catalyst and preparation methods thereof. The silver impregnation liquid for ethylene oxide production through ethylene epoxidation comprises the following components: 1) a silver-ammonia complex; 2) polar amino acid; 3) water; 4) an optional auxiliary agent; wherein based on the total weight of the impregnation liquid, the content of the polar amino acid is 0.05-60 wt%. Compared with the prior art, the uniformity of the silver catalystprepared by the method provided by the invention is improved, and the silver catalyst has higher selectivity and higher catalytic activity for the reaction of producing ethylene oxide by ethylene oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano-sensitive material for detecting ethylene oxide

InactiveCN102809556ARapid determinationAccurate measurementChemiluminescene/bioluminescenceEthylene oxideEthylene Dibromide

The invention relates to a nano-sensitive material for detecting ethylene oxide. The nano-sensitive material is characterized by consisting of Ag atom-doped Al2O3, V2O5 and BaO nano-powder, wherein the Ag atom-doped Al2O3, V2O5 and BaO nano-powder comprises the following components: 6 to 9 percent of Ag, 25 to 35 percent of Al2O3, 35 to 45 percent of V2O5 and 10 to 25 percent of BaO; and the particle size range is 35 to 50nm. An ethylene oxide sensor which is prepared from the sensitive material has the advantages of wide linear range, high selectivity and sensitivity and the like, can monitor a trace amount of ethylene oxide on line, and is not affected by coexisting substances.

Owner:BIOCHEM ENG COLLEGE OF BEIJING UNION UNIV

Catalyst for preparing ethylene carbonate from ethylene oxide and carbon dioxide, and preparation method thereof

ActiveCN105214731AOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsLow activityMixed oxide

The invention relates to a catalyst for preparing ethylene carbonate from ethylene oxide and carbon dioxide, and a preparation method thereof to mainly solve the problem of low activity of heterogeneous catalysts in the prior art. The catalyst comprises a main catalyst and a cocatalyst; the main catalyst is a metal mixed oxide AaOb / BcOd, wherein A is selected from at least one of Cu, Mg, Zn, Ca, Co or Ni, and B is selected from at least one of Al, Fe, Cr or Zr; the cocatalyst is a quaternary ammonium salt R1R2R3R4N<+>X<->; and a weight ratio of the cocatalyst to the main catalyst is 0.1-10. The catalyst adopting the above technical scheme well solves the problem, and can be used in industrial production of ethylene carbonate.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of silver catalyst and its application in the production of ethylene oxide by ethylene oxidation

ActiveCN103418380BOrganic chemistryCatalyst activation/preparationEthylenediamineAlkaline earth metal

The invention provides a preparation method of a silver catalyst, and the preparation method comprises the following steps: step A, dissolving ethylenediamine and ethanol in water; step B, under stirring, adding a silver containing compound to the solution, and before, meanwhile and after adding of the silver containing compound, dropping additive dimethylamine and / or diethylamine into the solution; step C, adding assistants containing alkali metals and alkaline earth metals into the silver amine solution to produce a dipping solution; step D, putting an alumina carrier in the dipping solution for dipping; and step E, separating a solid from the dipping solution, and thus obtaining the silver catalyst after thermal activation. In the preparation method, addition of the dimethylamine and the diethylamine can help to improve the activity and stability of the silver catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing ethylene carbonate from ethylene oxide and CO2

ActiveCN107915709AStable in natureNot easy to loseOrganic chemistryMolecular sieve catalystsAlkaline earth metalHomogeneous catalysis

The invention relates to a method for producing ethylene carbonate from ethylene oxide and CO2 and mainly solves the problem that heterogeneous catalysts have low activity in the prior art. The methodcomprises the step of contacting ethylene oxide and CO2 with a catalyst under the reaction condition, wherein the catalyst is a supported compound e metal oxide catalyst MO-TO2 / SP; M is at least oneof alkaline earth metals Mg, Ca, Sr and Ba; T is at least one of Ti and Zr; SP is at least one of porous silicon oxide, SBA-15, MCM-41, MCF, HMS, aluminum oxide and activated carbon; the weight content of MO is 1%-20%, the weight content of TO2 is 5%-30% and the weight content of SP is 50%-94%. With the adoption of the technical scheme, the problem is better solved and the method can be applied toindustrial production of preparation of ethylene carbonate from ethylene oxide and CO2.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing ethylene carbonate or propylene carbonate with carbon dioxide and ethylene oxide or propylene oxide

ActiveCN101824022BHigh activityReduce lossesOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyAlkaline earth metal

The invention relates to a method for synthesizing ethylene carbonate or propylene carbonate with carbon dioxide and ethylene oxide or propylene oxide. The method adopts continuous circulation reaction; 150g / h ethylene oxide or propylene oxide and 2-4Mpa of carbon dioxide are respectively added from the bottom of a reactor; the reaction pressure is 1.0-5.0Mpa, the reaction temperature is 100-200 DEG C, and the reaction time lasts for 1-5 hours; a catalyzer is compositive catalyzer formed by carbonate and alkyl imidazolium or fxanol ionic liquid; the catalyzer is 7.5g / h, and the weight ratio of the carbonate to the alkyl imidazolium or fxanol ionic liquid ammonia is 1: 6.5; and the carbonate is alkali carbonate or aldaline-earth metal carbonate. The invention has simple process, high activity of the catalyzer and less loss of the catalyzer, the percent conversion of epoxy ethane reaches 96-99 percent, and the selectivity is 97-99 percent.

Owner:PETROCHINA CO LTD

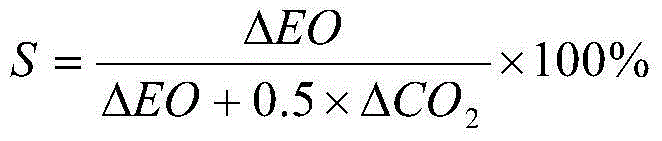

Process for the preparation of ethylene carbonate from ethylene oxide and carbon dioxide

ActiveCN102295632AHigh N contentHigh activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMass ratioMicrosphere

The invention relates to a method for preparing ethylene carbonate from ethylene oxide and carbon dioxide, which mainly solves the problems of low catalyst activity and high probability of loss of active ingredients existing in the prior art. In the method, the ethylene oxide and the carbon dioxide are utilized as raw materials; the reaction raw materials are contacted with a catalyst to generatethe ethylene carbonate under the conditions of reaction temperature of 50-200 DEG C, reaction pressure of 0.1-10.0MPa and mass ratio of the catalyst to the ethylene carbonate of 0.001-1:1; and in thecatalyst, SiO2 microspheres with average diameter of 15-500nm are used as a nuclear phase, and metal salt MYn complexed by polyethyleneimine is used as a shell phase, wherein M is Ni, Zn, Cu, Fe or Co; Y is Cl, Br or I; and n is 2 or 3. The periphery of the nuclear-phase nano SiO2 spheres is wrapped by a metal salt shell layer complexed by the polyethyleneimine; the thickness of the shell layer is 0.5-8nm; and the weight ratio of the nuclear phase to the shell phase is 45 / 55-99.5 / 0.5. Due to the technical scheme, the problem is solved better; and the method can be used for industrial production of the ethylene carbonate from the ethylene oxide and the carbon dioxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing ethylene oxide

The invention provides a method for producing ethylene oxide. The method comprises the following steps that charging gas mixture is reacted under existence of a silver catalyst to generate a reaction product containing ethylene oxide; wherein, the charging gas mixture contains ethane, oxygen and a mixing nitrogen oxide, the mixing nitrogen oxide contains two or more components from nitric oxide, nitrogen dioxide and nitrous oxide; and the content of rhenium element in the silver catalyst is equal to or smaller than 100 ppm. The invention provides the novel industrial method for producing ethylene oxide by using the silver catalyst containing rhenium with low rhenium content or containing no rhenium.

Owner:CHINA PETROLEUM & CHEM CORP +1

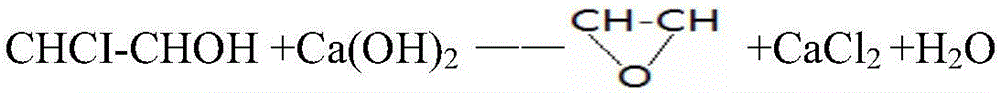

Methods for preparing halogenated ethanol and ethylene oxide by dry gas

ActiveCN106518614AEasily damagedSolve intractablePreparation by OH and halogen introductionBulk chemical productionHydrogen halideLithium hydroxide

A method for preparing halogenated ethanol by a dry gas is disclosed, and the method comprises the following steps: (1) halohydrination, to be more specific, adding hydrogen halide, H2O2 and the dry gas in a reactor for halohydrination to obtain the halogenated ethanol. A method of producing ethylene oxide by the dry gas is also disclosed, and the method comprises the following steps: (1) halohydrination, to be more specific, adding the hydrogen halide, the H2O2 and the dry gas in the reactor for halohydrination to obtain the halogenated ethanol; and (2) saponification, to be more specific, taking the halogenated ethanol obtained by the step (1) and an alkali metal hydroxide (preferably, sodium hydroxide, potassium hydroxide or lithium hydroxide) for saponification, and separating to obtain the ethylene oxide and a halogenated alkali metal salt. By preparation of the halogenated ethanol from the hydrogen halide, the H2O2 and the dry gas and then saponification, the ethylene oxide can be prepared by extremely-high-selectivity and high-yield use of an ethylene component in the dry gas, and waste water and waste residue discharge is greatly reduced.

Owner:JIANGXI SUKEER NEW MATERIAL

Preparation method of high-efficiency silver catalyst for preparing ethylene oxide through ethylene oxidation with polypeptide as three-dimensional guiding agent

InactiveCN108160075AImprove performanceSolution to short lifeOrganic chemistryHeterogenous catalyst chemical elementsRheniumActive component

The invention relates to a preparation method of a high-efficiency silver catalyst for preparing ethylene oxide through ethylene oxidation with polypeptide as a three-dimensional guiding agent. Duringpreparation, a certain amount of the loaded three-dimensional guiding agent is added, the loaded three-dimensional guiding agent takes polypeptide formed by two or more amino acids as a silver activeingredient and takes cesium and / or rhenium as active auxiliary agents, silver and other inorganic active components are selectively precipitated on the surface of alpha-Al2O3 to form a membrane distributed with uniform bulges. The preparation method can realize the membrane-like distribution of the active component silver and the like in the silver catalyst without too complicated change of a conventional preparation process and mode. The method has the advantages of simple operation, low cost, strong controllability and easy preparation. The prepared silver catalyst has the advantages of good activity, high selectivity, good stability and the like.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +4

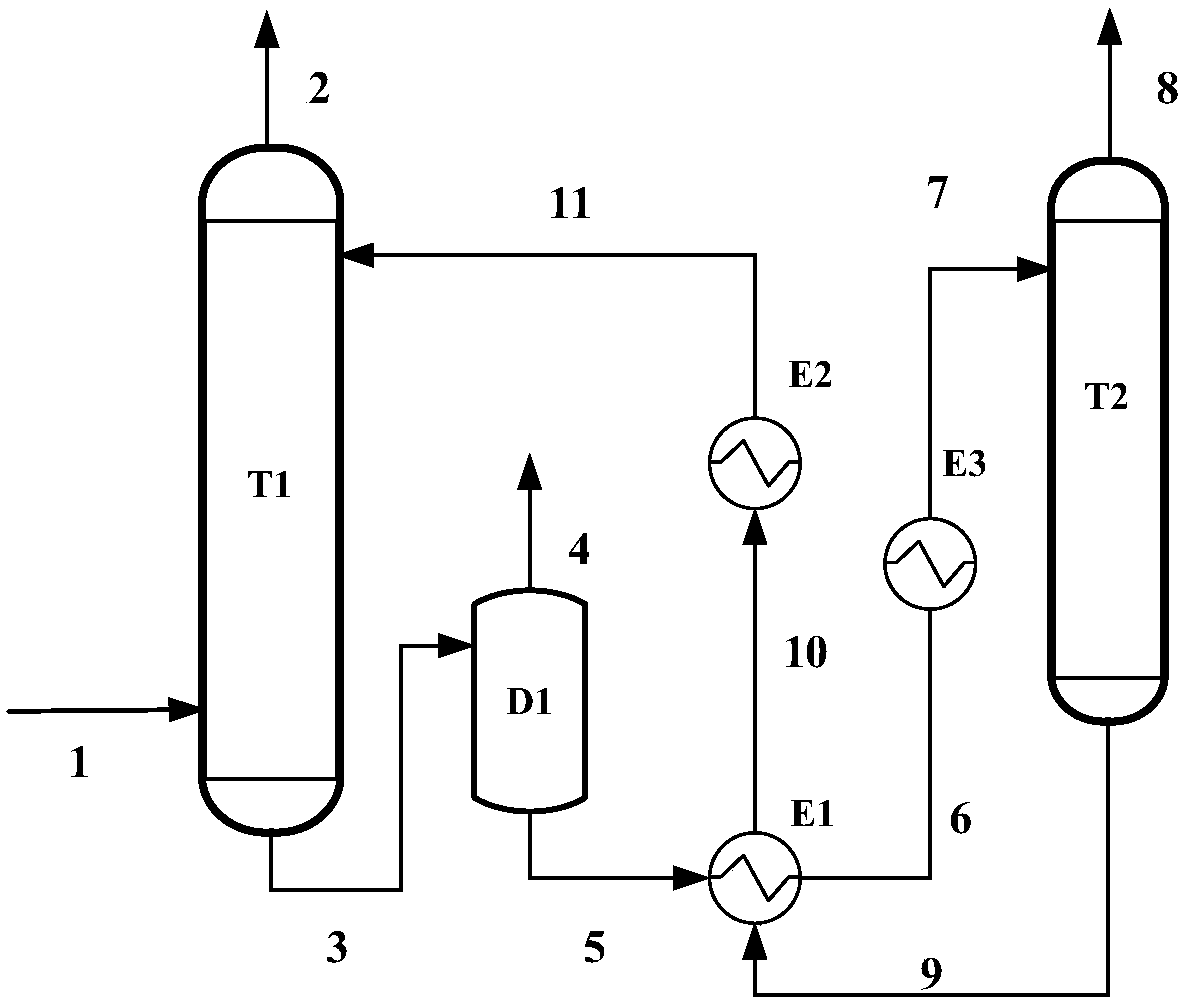

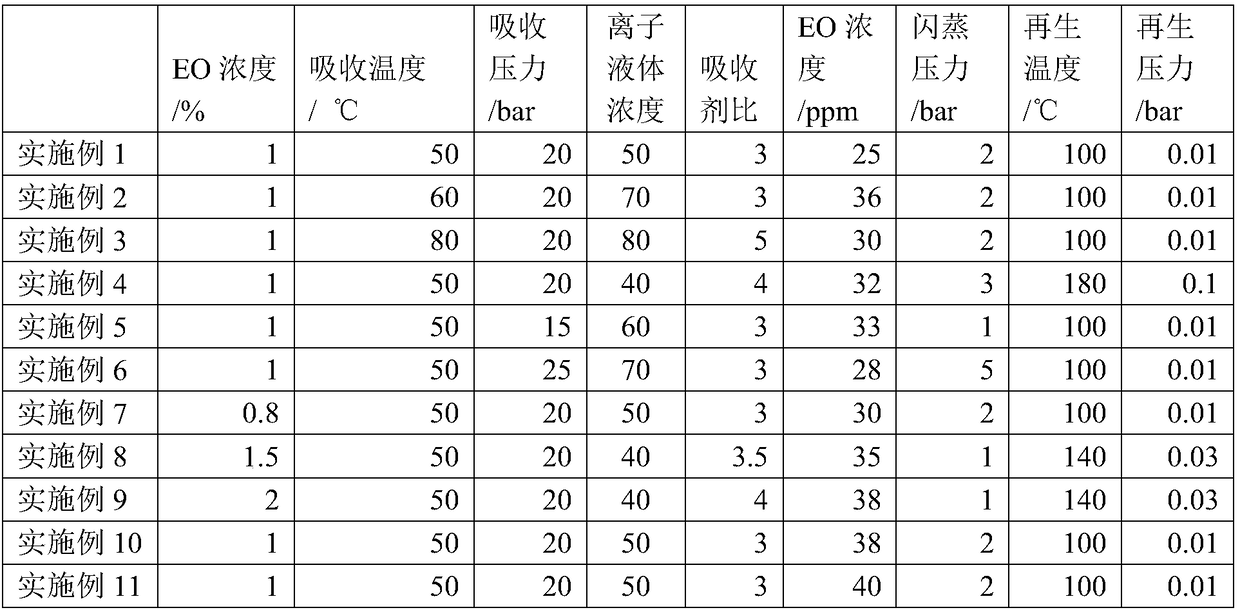

Process for the preparation of ethylene oxide from oxygen and ethylene

ActiveCN107216295BReduce the risk of explosionAvoid flying temperatureOrganic chemistryEthylene oxideDesorption

The invention relates to a method for preparing epoxyethane from oxygen and ethylene. The method is mainly used for solving the problem in the prior art that the safety is relatively poor. According to the method, through adopting the technical scheme that the method for preparing the epoxyethane from the oxygen and the ethylene comprises the steps that reactant ethylene gas is heated by a gas-gas heat exchanger and then enters at least one oxygen-transmission membrane tube in a reactor, the oxygen-transmission membrane tubes are made from mixed-conductor inorganic ceramic membranes and are of calandria arrangement, air enters an area, outside the oxygen-transmission membrane tubes, in the reactor, the oxygen is subjected to adsorption and desorption on surfaces of oxygen-transmission membranes and then enters the oxygen-transmission membrane tubes to be in contact with the ethylene, a reaction is carried out in the presence of a catalyst to produce a product containing the epoxyethane, the product flows out from outlets of the oxygen-transmission membrane tubes, passes through the gas-gas heat exchanger and then enters a downstream separating system, and remaining nitrogen-enriched air is discharged from the reactor, the problem is better solved, so that the method can be applied to the preparation of the epoxyethane.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of reuse method of organic waste gas containing ethylene oxide

InactiveCN104815535BReduce contentReduce environmental disposal costsDispersed particle separationHydration reactionResource utilization

The present invention discloses a recycling method of ethylene oxide-containing organic waste gas. The specific technical scheme comprises that: ethylene oxide in ethylene oxide-containing organic waste gas is subjected to circulation absorbing in a hydrolysis tower by using dilute sulfuric acid with a certain concentration as an absorbent so as to produce a hydration reaction to generate ethylene glycol, the ethylene glycol is conveyed into an ethylene glycol solution storage tank after the ethylene glycol in the solution achieves a certain concentration, a sodium hydroxide solution is added to neutralize, one part of the neutralized ethylene glycol solution is used for the acid gas washing process, the other part is conveyed to the product separation and recovery, the tail gas discharged from the hydrolysis tower enters a reactor to carry out deep oxidation, an acid gas washing treatment is performed, the treated standard tail gas is discharged into the atmosphere, and the absorbing liquid is recycled to the ethylene glycol solution storage tank. According to the present invention, the method has characteristics of short process and simple operation, and with the treatment of the present invention, the ethylene oxide content in the organic waste gas tail gas does not exceed 1 ppm, and a certain amount of the ethylene glycol solution is recovered so as to achieve the resource utilization of the waste gas.

Owner:SHANXI DATONG UNIV

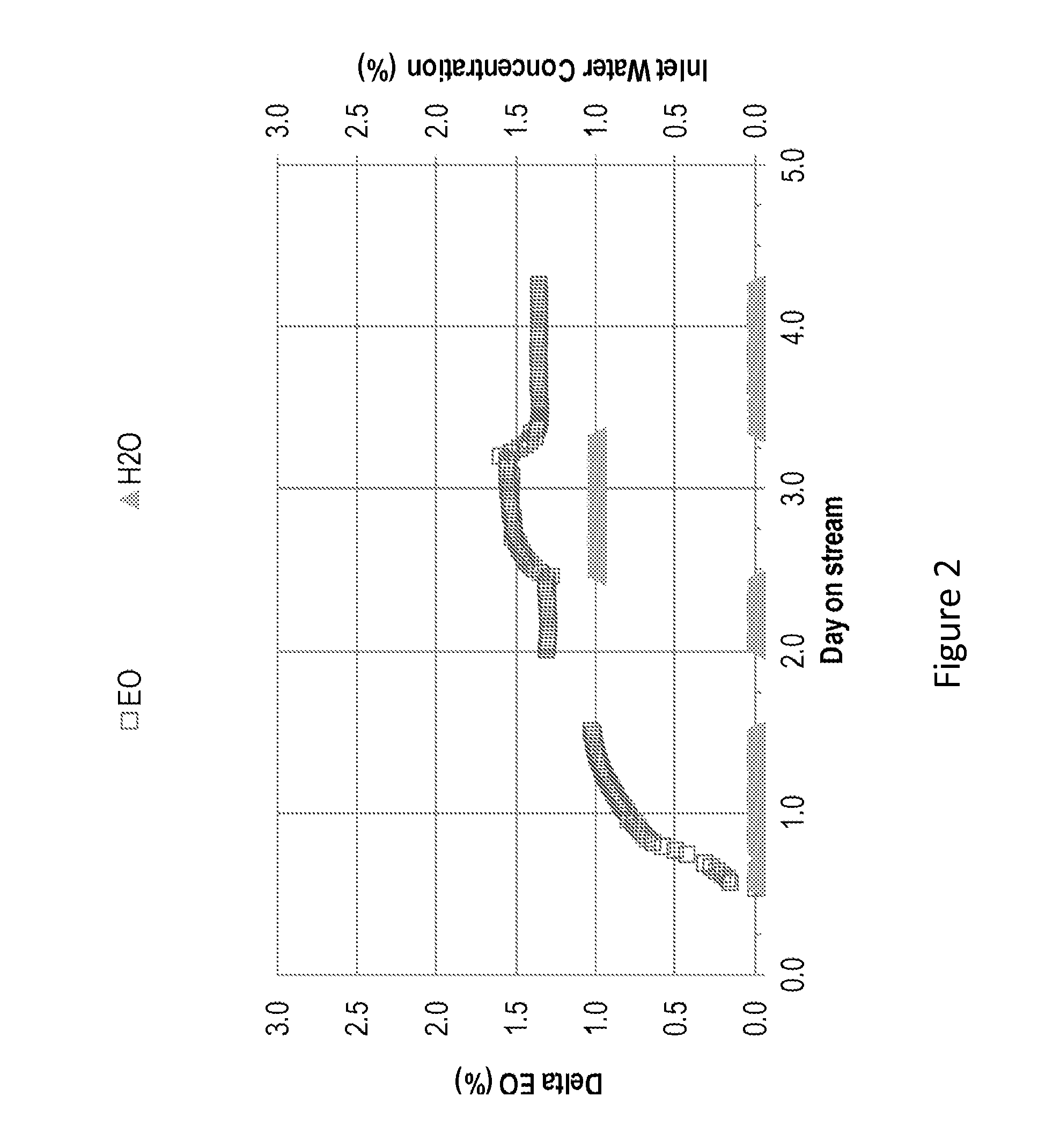

Method for the production of ethylene oxide

ActiveUS20160016924A1Maintain rateOxygen-containing compound preparationOrganic compound preparationRheniumEthylene oxide

A method for the production of ethylene oxide wherein the partial pressure of water vapor at the inlet of the reactor is at least about 8 kPa using a high purity carrier comprising alpha-alumina, a promoting amount of at least one Group IA metal, and a promoting amount of rhenium.

Owner:DOW TECH INVESTMENTS

Alkylene oxide catalyst and use thereof

ActiveUS20160082423A9Improve catalytic stabilityHigh activityOrganic compound preparationCatalyst activation/preparationEthylene DibromideOxygen

A supported silver catalyst and use thereof in a process for producing an alkylene oxide, such as ethylene oxide, by the direct oxidation of an alkylene with oxygen or an oxygen-containing gas, wherein the catalyst provides improved stability and improved resilience to reactor upsets and timely recovery to substantially pre-upset levels of catalyst activity and / or efficiency. In some embodiments, the catalyst also exhibits improved activity. A catalyst capable of producing ethylene oxide at a selectivity of at least 87 percent while achieving a work rate of at least 184 kg / h / m3 at a temperature of no greater than 235° C. when operated in a process where the inlet feed to a reactor containing the catalyst comprises ethylene, oxygen, and carbon dioxide, wherein the concentration of carbon dioxide in the inlet feed is greater than or equal to 2 mole percent.

Owner:DOW GLOBAL TECH LLC

Catalyst and method for preparing ethylene carbonate from ethylene oxide and carbon dioxide

ActiveCN105294643BOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPhosphonium saltMixed oxide

The invention relates to a catalyst and a method for preparing ethylene carbonate from ethylene oxide and carbon dioxide, and mainly solves the problem of low activity of heterogeneous catalysts in the prior art. The present invention comprises a main catalyst and a cocatalyst by using the catalyst; the main catalyst is a metal mixed oxide AaOb / BcOd; wherein, A is selected from at least one of Cu, Mg, Zn, Ca, Co or Ni; B At least one selected from Al, Fe, Cr or Zr; the cocatalyst is a quaternary phosphonium salt R1R2R3R4P+X-; the technical scheme that the weight ratio of the cocatalyst to the main catalyst is 0.1 to 10 solves this problem well , can be used in the industrial production of ethylene carbonate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst and method for preparing ethylene carbonate from ethylene oxide and carbon dioxide

ActiveCN105214731BOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsLow activityMixed oxide

The invention relates to a catalyst for preparing ethylene carbonate from ethylene oxide and carbon dioxide and a method thereof, which mainly solves the problem of low activity of heterogeneous catalysts in the prior art. The present invention comprises a main catalyst and a cocatalyst by using the catalyst; the main catalyst is a metal mixed oxide AaOb / BcOd; wherein, A is selected from at least one of Cu, Mg, Zn, Ca, Co or Ni; B At least one selected from Al, Fe, Cr or Zr; the cocatalyst is a quaternary ammonium salt R1R2R3R4N+X-; the technical scheme that the weight ratio of the cocatalyst to the main catalyst is 0.1 to 10 solves this problem well , can be used in the industrial production of ethylene carbonate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com