Process for the preparation of ethylene oxide from oxygen and ethylene

A technology of ethylene oxide and ethylene, applied in the direction of organic chemistry, etc., can solve problems such as poor safety, reduce the risk of explosion, improve the conversion rate and selectivity, and avoid the effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

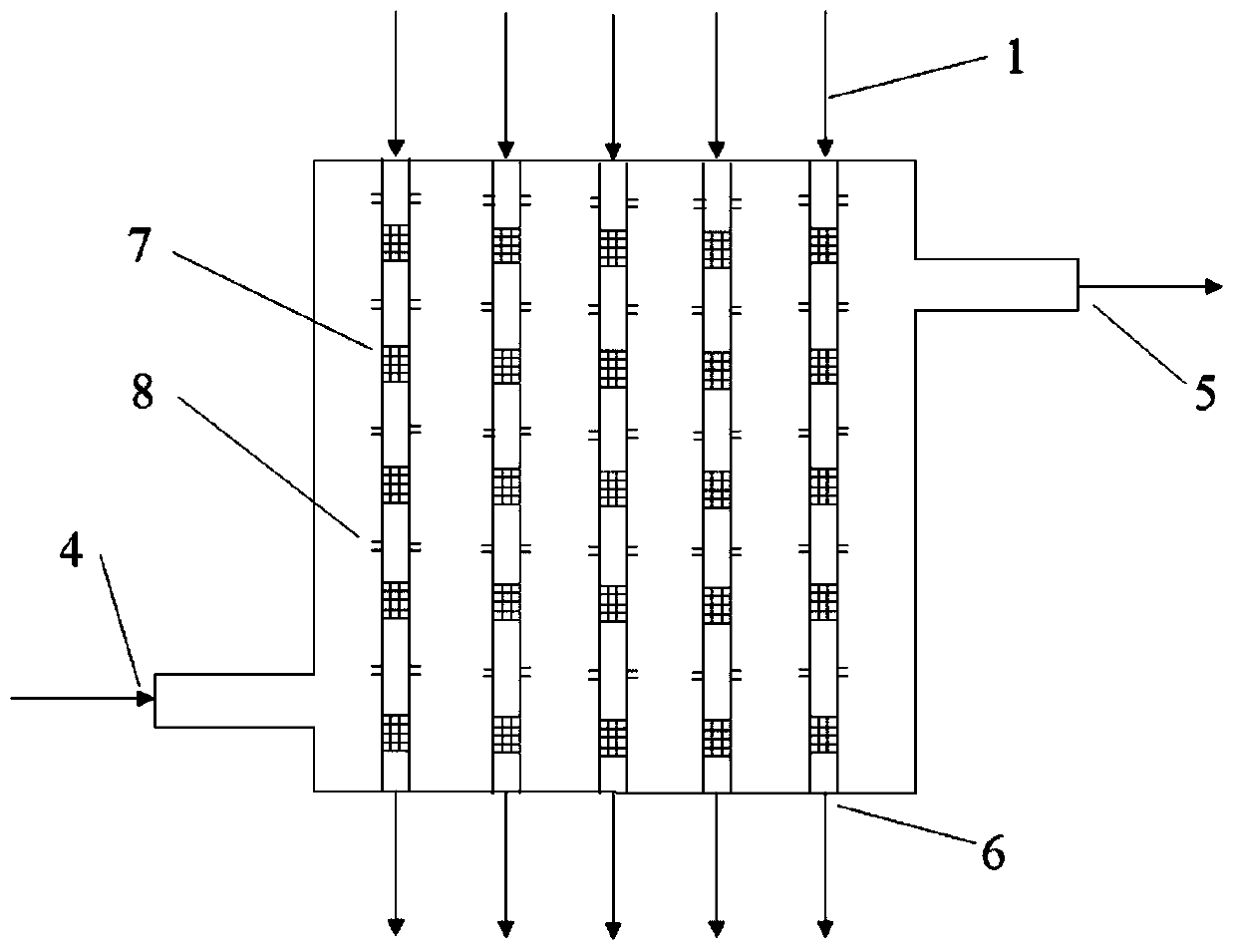

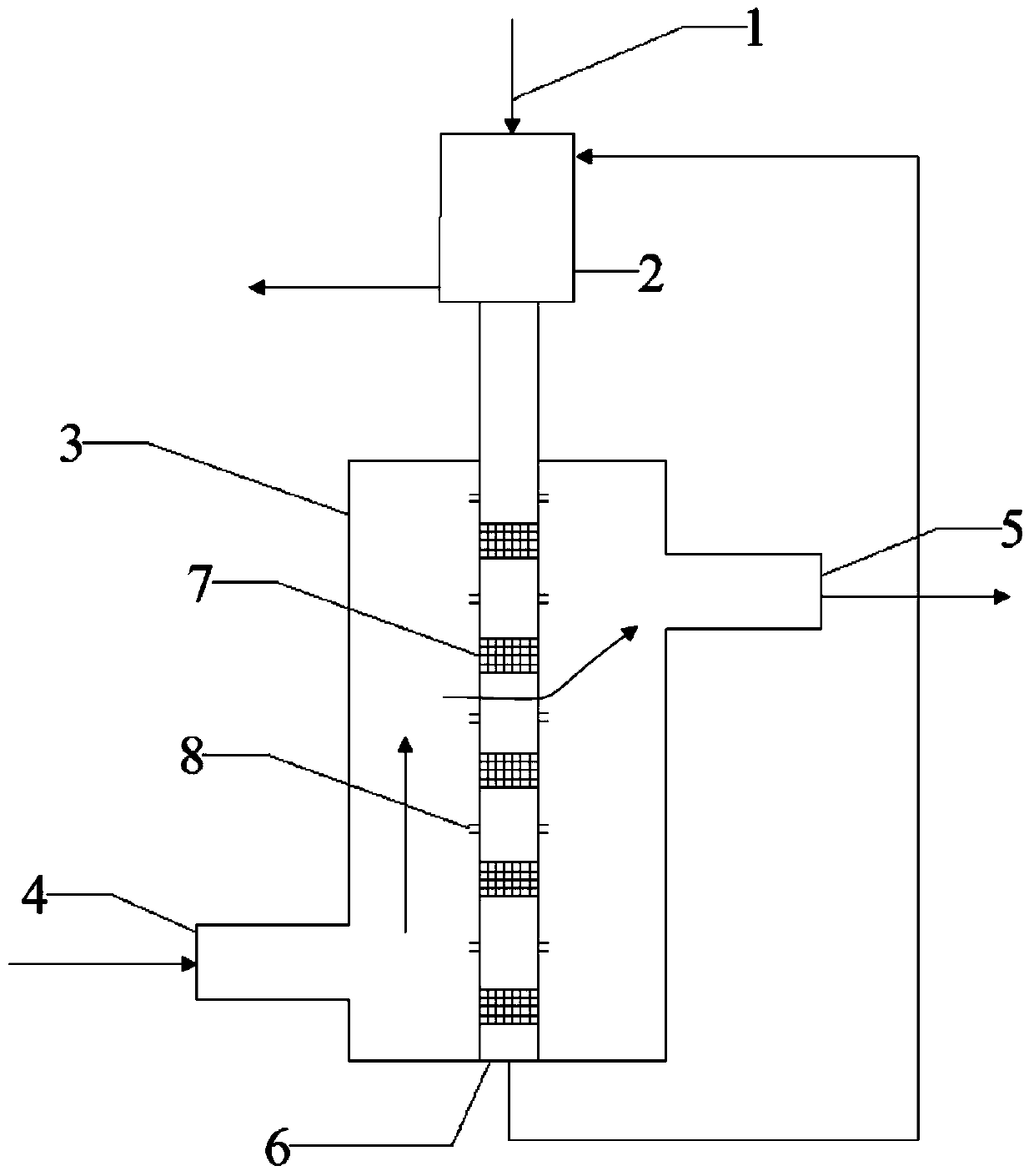

[0020] A process for the preparation of ethylene oxide from oxygen and ethylene, such as figure 1 or figure 2 shown. The reaction raw material ethylene gas is heated to 180°C by a gas-gas heat exchanger and then enters the oxygen-permeable membrane tube in the reactor. The material of the oxygen-permeable membrane tube is a mixed conductor inorganic ceramic membrane. In the area outside the oxygen-permeable membrane tube in the reactor, oxygen is adsorbed and desorbed on the surface of the oxygen-permeable membrane, and then enters the oxygen-permeable membrane tube to contact with ethylene, and reacts under the silver catalyst to produce products including ethylene oxide. The outlet of the membrane tube flows out and enters the downstream separation system after passing through the gas-gas heat exchanger, and the remaining nitrogen-enriched air is discharged from the reactor.

[0021] The operating conditions of the reactor are a temperature of 180° C. and a pressure of 2....

Embodiment 2

[0024] According to the conditions and steps described in Example 1, only the ethylene gas is heated to 185°C by the gas-gas heat exchanger and then enters the oxygen-permeable membrane tubes in the reactor. The operating conditions of the reactor are a temperature of 185° C. and a pressure of 2.05 MPaG. The volume ratio of the ethylene to air is 1:9.2. The oxygen content in the nitrogen-enriched air is 15.4%. The results show that the single-pass conversion of ethylene is 13.6%, and the selectivity of ethylene oxide is 95.2%.

Embodiment 3

[0026] According to the conditions and steps described in Example 1, only the ethylene gas is heated to 192°C by the gas-gas heat exchanger and then enters the oxygen-permeable membrane tubes in the reactor. The operating conditions of the reactor are a temperature of 192° C. and a pressure of 2.06 MPaG. The volume ratio of ethylene to air is 1; 9.5. The oxygen content in the nitrogen-enriched air is 13.6%. The results show that the single-pass conversion of ethylene is 14.8%, and the selectivity of ethylene oxide is 95.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com