Molybdenum vanadium tellurium niobium oxygen catalyst for ethane to ethylene, preparation method and application thereof

A catalyst and ethane production technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of reducing ethylene selectivity, increasing the difficulty of product separation, and low ethane conversion rate, etc., to achieve reaction The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

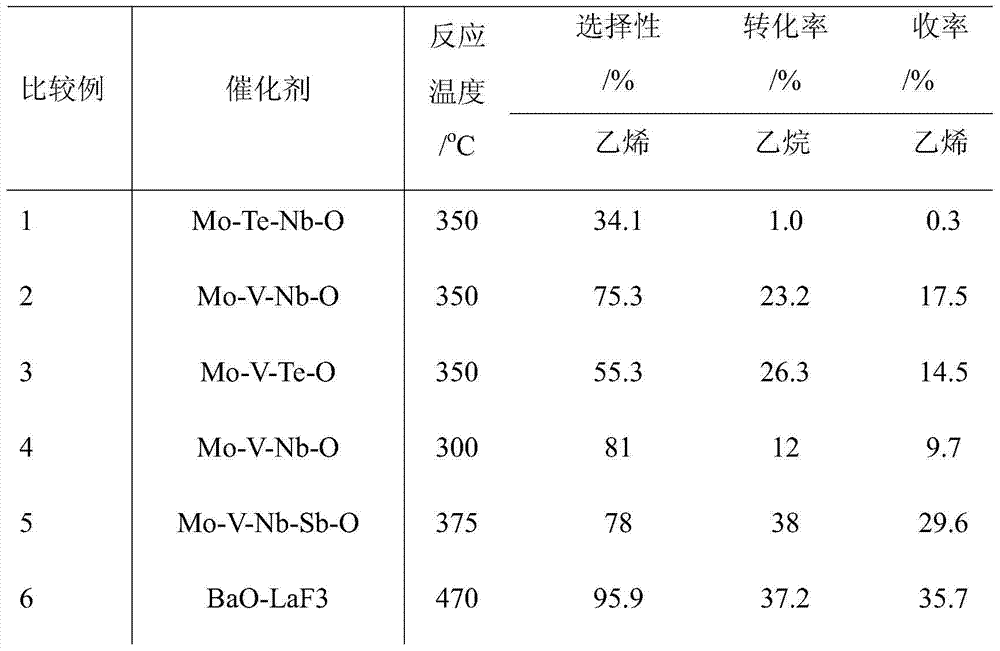

Examples

Embodiment 1

[0034] The Mo-V-Te-Nb-O catalyst was prepared by the temperature-programmed hydrothermal synthesis method. First, weigh the proportions of ammonium molybdate, vanadyl sulfate, telluric acid and niobium oxalate and dissolve them in hot deionized water. After heating each for 30-60 minutes, slowly mix the solutions together and continue stirring for 10-30 minutes. Minutes later, add a certain amount of surfactant CTAB (the ratio of substance is CTAB / Mo=0.04), continue to stir for 3-10 minutes, then transfer it to the special stainless steel tube synthesis kettle described in patent CN101612564 to The temperature rise rate of 10°C / min was increased from room temperature to 180°C, and after keeping it for 20 hours, it was naturally cooled to room temperature, and then taken out, filtered and dried. Grind the obtained black solid and place it in a roasting vessel, raise it from room temperature to 300°C at a heating rate of 3°C / min and keep it for 2 hours (atmosphere is air), then r...

Embodiment 2

[0036] The catalyst preparation procedure in this example is as described in Example 1, except that no surfactant is added during synthesis.

[0037] Take 1g of 20-30 mesh catalyst for the selective oxidation reaction of ethane, and the reaction conditions are the same as in Example 1. The result of the reaction is: the conversion of ethane is 40.5%, and the selectivity of ethylene is 95.0%. The results of the reaction are listed in Table 1.

Embodiment 3

[0039] The catalyst preparation procedure in this example is as described in Example 1, except that the reaction temperature in the reactor during synthesis is 160° C., and the holding time is 2 h.

[0040] Take 1g of 20-30 mesh catalyst for the selective oxidation reaction of ethane, and the reaction conditions are the same as in Example 1. The result of the reaction is: the conversion rate of ethane is 20.8%, and the selectivity of ethylene is 89.0%. The reaction results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com