Catalyst for preparing ethylene carbonate by using ethylene oxide and carbon dioxide

A technology of ethylene carbonate and carbon dioxide, which is applied in the preparation of carbon dioxide or inorganic carbonate, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of easy loss of active components and catalyst activity Low problems, to achieve the effect of good stability and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

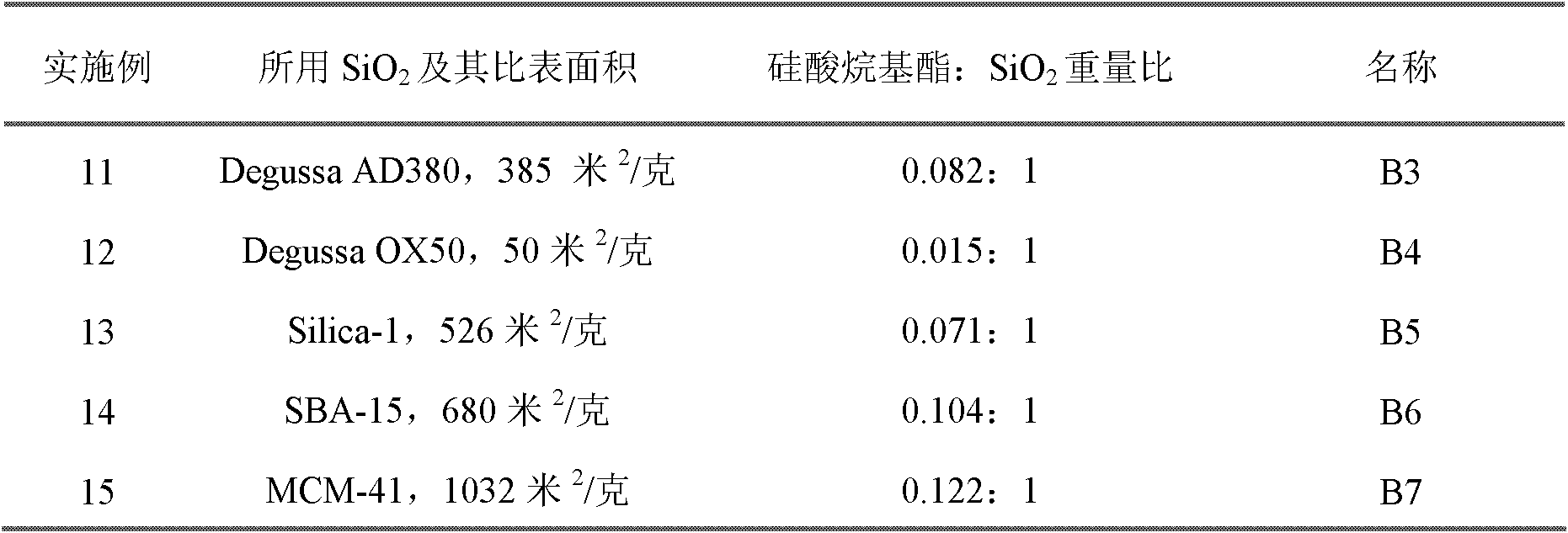

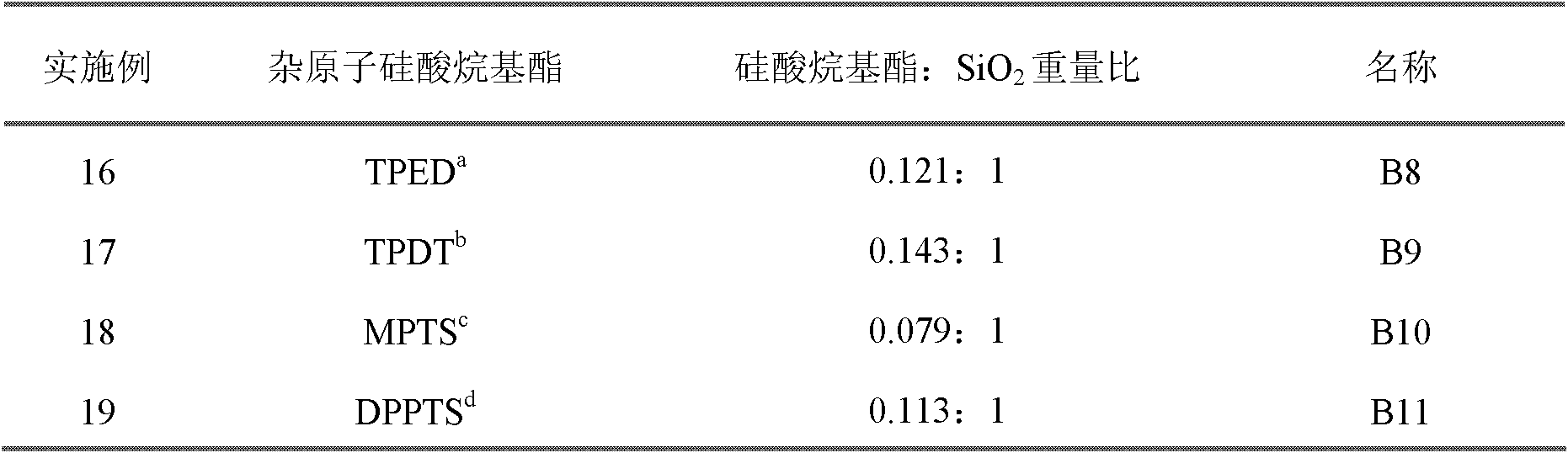

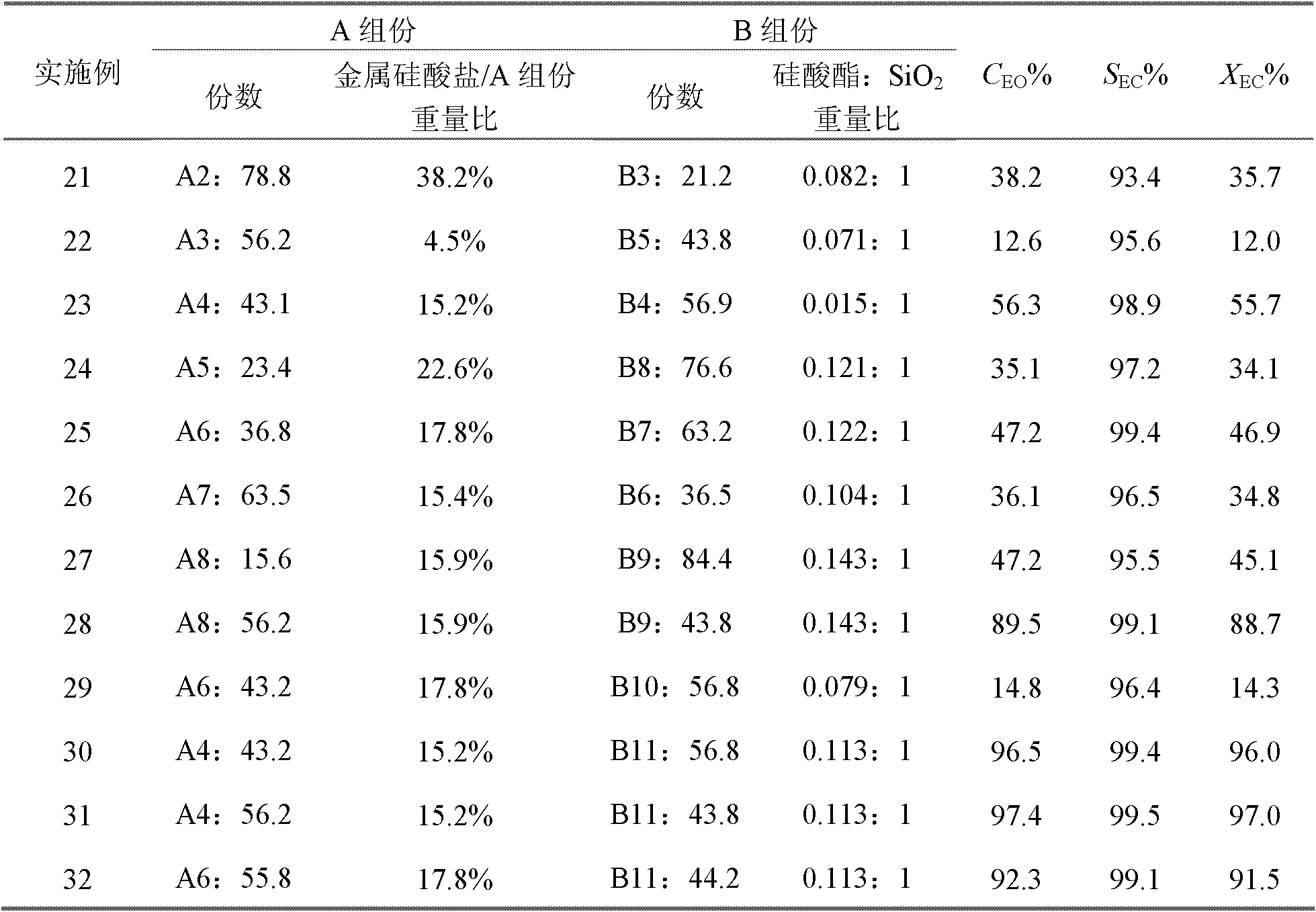

Examples

Embodiment 1

[0018] In a 1000ml beaker, add 24.3g Cu(NO 3 ) 2 300 ml of aqueous solution, then add SiO 2 Carrier 100.0 g (Degussa, Aerisol 200, specific surface area 194 m 2 / gram) and 34.2 grams of urea, under stirring, be warming up to 90 DEG C, and keep 2 hours, filter then, after washing 3 times with deionized water, spend the night in 120 DEG C of oven, the solid of gained is called A1. Determined by ICP-AES, where Cu is CuSiO 3 The weight ratio accounting for A1 is 15.8%.

Embodiment 2

[0020] With [Example 1], only Cu(NO 3 ) 2 The dosage is 58.5 g, SiO 2 The carrier is Degussa OX50 with a specific surface area of 50 meters 2 / gram, the consumption of urea is 82.7 grams, be heated up to 80 ℃ and keep 9 hours, the solid obtained is called A2. Determined by ICP-AES, where Cu is CuSiO 3 The weight ratio accounting for A2 is 38.2%.

Embodiment 3

[0022] With [Example 1], only Cu(NO 3 ) 2 The dosage is 6.72 g, SiO 2 The carrier is Silica-1 with a specific surface area of 526 meters 2 / gram, the consumption of urea is 9.5 grams, and the solid of gained is called A3. Determined by ICP-AES, where Cu is CuSiO 3 Accounting for the weight ratio of A3 is 4.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com