A kind of preparation method of silver catalyst and its application in the production of ethylene oxide by ethylene oxidation

A technology of silver catalyst and silver compound, which is applied in the direction of catalyst activation/preparation, bulk chemical production, chemical instruments and methods, etc., can solve the problems of catalyst silver shedding, catalyst activity, low selectivity, etc., achieve high selectivity, improve active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

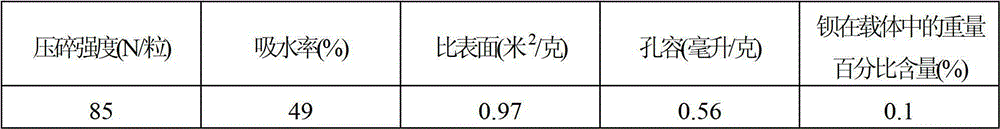

Image

Examples

Embodiment 1

[0029]Dissolve 435g of ethylenediamine and 147g of ethanolamine in 750g of deionized water, stir evenly, then add dimethylamine, the molar ratio of silver to dimethylamine is 1:0.06, slowly add silver oxalate into the mixed solution while stirring, and keep the temperature Below 15 ℃, silver oxalate is completely dissolved, and the addition of silver oxalate makes the impregnating liquid that finally makes contains silver 24% (weight). After the silver amine solution is prepared, keep the current temperature, add 300ppm alkali metal (cesium) additives, 500ppm alkaline earth metal (strontium) additives and 800ppm Re additives to prepare an impregnating solution. Take 1250g of the carrier sample and put it into a container, vacuumize it, introduce the impregnating solution to soak the carrier, then leach it, and heat activate it in the air at 300°C for 5 minutes to obtain the finished silver catalyst.

Embodiment 2

[0033] Dissolve 405g of ethylenediamine and 120g of ethanolamine in 730g of deionized water, stir evenly, then add diethylamine, the molar ratio of silver to diethylamine is 1:0.3, slowly add silver oxalate into the mixture while stirring, and keep the temperature Below 15 ℃, silver oxalate is completely dissolved, and the addition of silver oxalate makes the impregnating liquid that finally makes contains silver 24% (weight). After the silver amine solution is prepared, keep the current temperature, add 500ppm of alkali metal (cesium) additives, 200ppm of alkaline earth metal (strontium) additives and 200ppm of Re additives to prepare an impregnating solution. Take 1150g of the carrier sample and put it into a container, vacuumize it, introduce the impregnation solution to soak the carrier, then leach it, and heat activate it in the air at 290°C for 5 minutes to obtain the finished silver catalyst.

Embodiment 3

[0037] Dissolve 430g of ethylenediamine and 132g of ethanolamine in 745g of deionized water, stir evenly, then add dimethylamine and diethylamine, the molar ratio of silver to dimethylamine and diethylamine is 1:0.05, and mix the oxalic acid with stirring Silver is slowly added in the mixed solution, and the temperature is kept below 15° C. to completely dissolve the silver oxalate. The amount of silver oxalate added makes the final impregnating solution contain 24% silver by weight. After the silver amine solution is prepared, keep the current temperature, add 100ppm alkali metal (cesium) additives, 100ppm alkaline earth metal (strontium) additives and 50ppm Re additives to prepare an impregnating solution. Take 1200g of the carrier sample and put it into a container, vacuumize it, introduce the impregnating solution to soak the carrier, then leach it, and heat activate it in the air at 300°C for 5 minutes to obtain the finished silver catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com