Catalyst and method for preparing ethylene carbonate from ethylene oxide and carbon dioxide

A technology of ethylene carbonate and ethylene oxide, which is applied in the field of catalysts, can solve the problems of low activity of heterogeneous catalysts, and achieve the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 12.1g Cu(NO 3 ) 2 ·3H 2 O and 44.2g Al(NO 3 ) 3 9H 2 O was dissolved in 300 mL of water, and 200 mL of an aqueous solution containing 25.2 g of anhydrous sodium carbonate was added thereto, the resulting precipitate was collected, washed with deionized water 3 times, 500 mL each time, and the obtained precipitate was dried in an oven at 120°C for 24 hours Afterwards, calcined at 500°C for 5 hours to obtain CuO / Al 2 o 3 Mixed oxide catalyst MO-1, in which CuO and Al 2 o 3 The parts by weight are respectively 40 and 60.

Embodiment 2~23

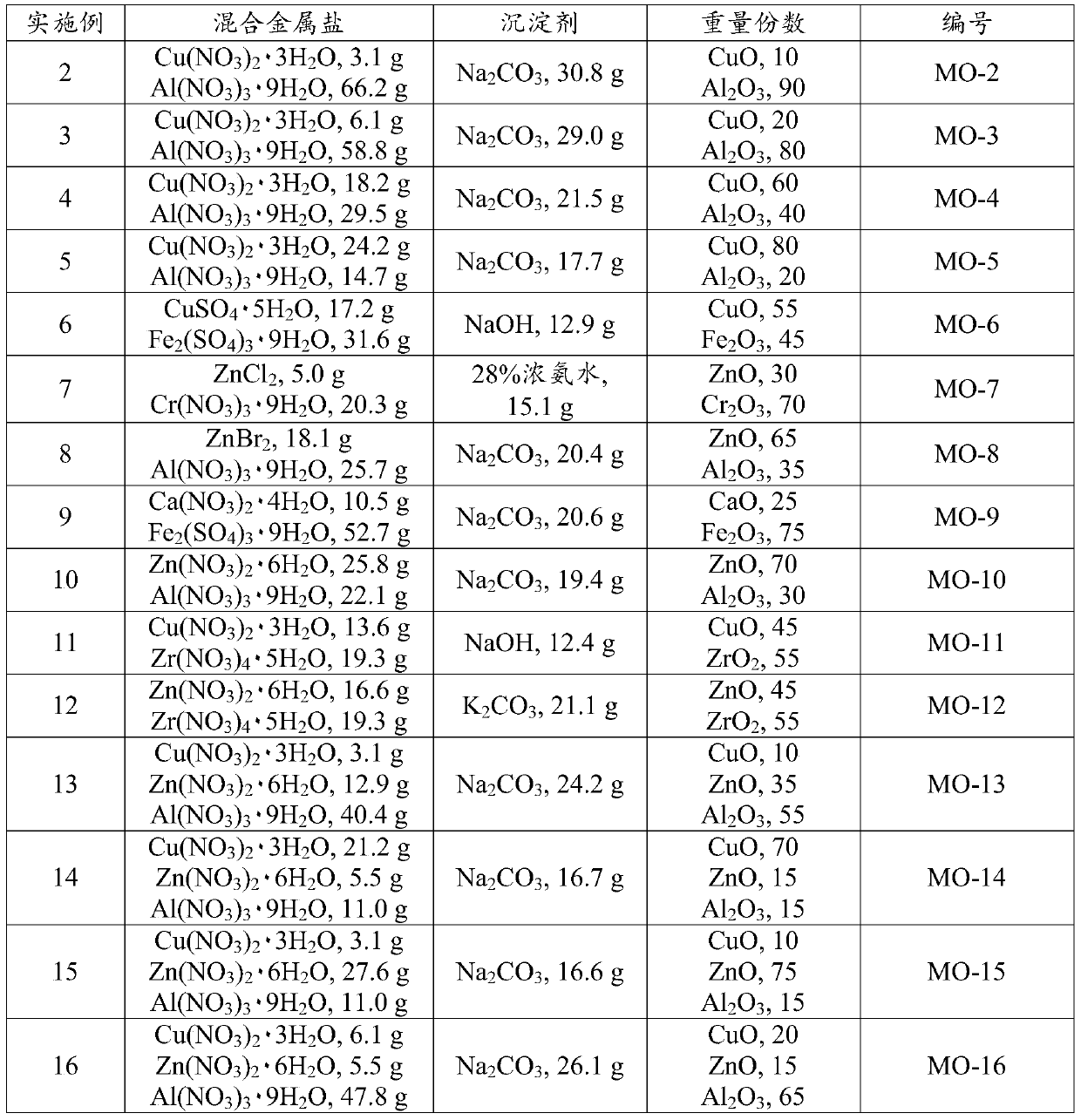

[0039] The mixed metal oxide catalyst obtained is shown in Table 1 by changing the type and amount of mixed metal salts and precipitants used, and keeping the rest of the conditions unchanged.

[0040] Table 1

[0041]

[0042]

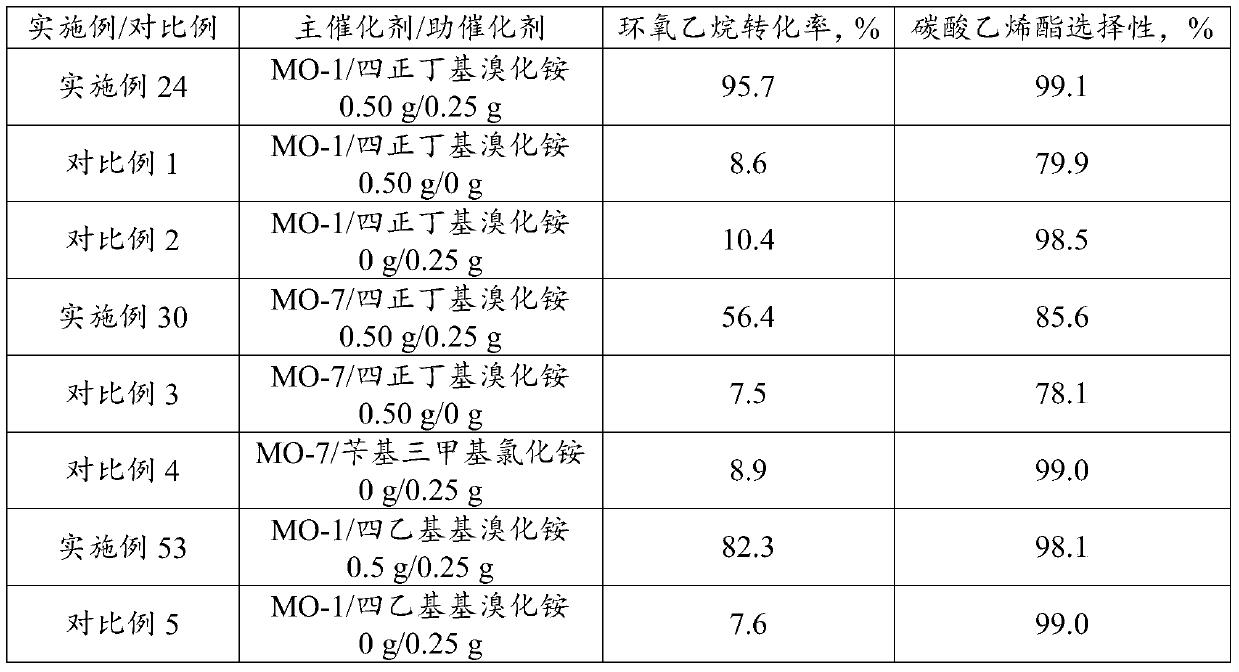

Embodiment 24

[0044] Take by weighing 0.50g MO-1 catalyst prepared by the above [Example 1] and 0.25g tetra-n-butylammonium bromide and place it in a 100mL stainless steel reactor, and use N 2 Replace the air in the reactor, then fill with 50.0g ethylene oxide, pass into CO 2 , keep the system pressure at 1.0MPa, stir for 1 hour and then raise the temperature to 120°C, add CO 2 , keep system pressure 5.0MPa, cool after reacting for 4 hours, carry out chromatographic analysis to reaction product, obtain the conversion rate of ethylene oxide 95.7%, the selectivity of ethylene carbonate is 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com