Low-solid content water based clean-free welding flux without volatile organic substance and halogen

A technology with volatile organic compounds and low solid content, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve problems such as operator hazard, fire, surface ozone destruction, etc., and achieve good solder spreadability and transparent tin good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

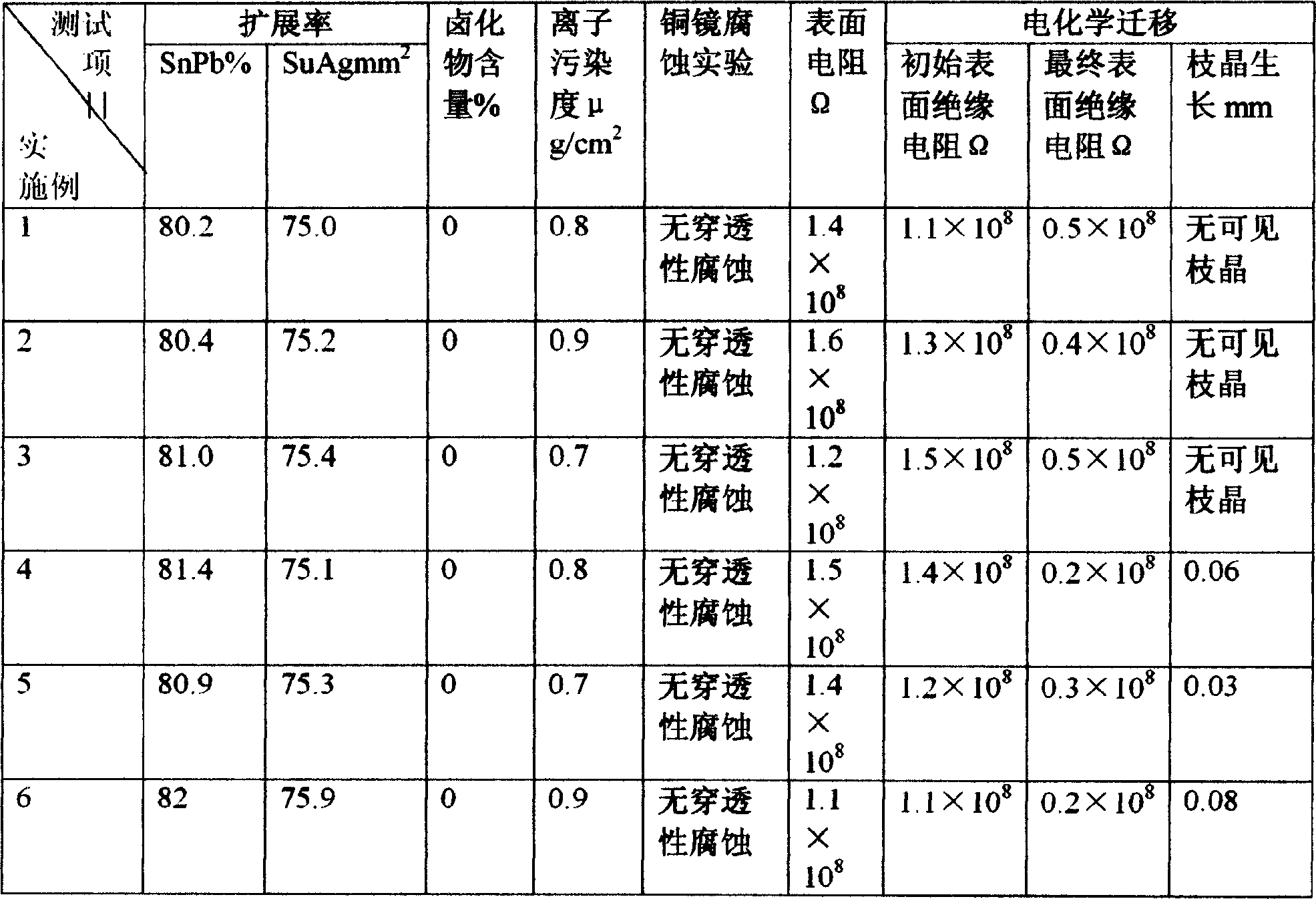

Examples

Embodiment 1

[0023] This is a medium-active, VOC-free, halogen-free, low-solid content water-based no-clean flux, suitable for spraying the flux on the soldering surface of the PCB.

[0024] The raw materials (KG) are: succinic acid 0.5, glutaric acid 1.8, polyethylene oxide 0.5, Ld-1340.05, ethylene glycol 2.5, benzotriazole 0.04, deionized water 94.61.

[0025] Preparation method: first inject a small amount of deionized water into a clean stainless steel kettle with a stirring device, add the film-forming agent into the kettle, soak for half an hour to 1 hour, then pour the remaining deionized water into the kettle, Stir under low temperature to completely dissolve the film-forming agent, then add wetting agent, cosolvent, corrosion inhibitor in turn, when the material is completely dissolved, add the activator, stir until completely dissolved, mix evenly, stop stirring, After filtration is the product.

Embodiment 2

[0027] This is a medium-active, VOC-free, halogen-free, low-solid-content water-based no-clean flux, which is suitable for coating the flux on the soldering surface of the PCB by foaming.

[0028] Raw materials (KG) are: 0.8 malic acid, 0.5 glycolic acid, 1.2 ammonium succinate, 0.2 polyethylacrylamide, 0.3 poly-N-vinylpyrrolidone, 0.1 Ld-134, 2.5 propylene glycol, 0.05 benzotriazole, laurel Amide 0.04, ethylene glycol phenyl ether 0.04, water 94.27.

[0029] The preparation method is the same as in Example 1. The difference is that the blowing agent is also added in sequence.

Embodiment 3

[0031] This is a medium-active, VOC-free, halogen-free, low-solid content water-based no-clean flux, suitable for dipping and coating the flux on the soldering surface of the PCB.

[0032] The raw materials (KG) are: salicylic acid 1.5, triethanolamine 1.5, sorbitol 0.6, Ld-1540.04, glycerol 3, benzotriazole 0.04, water 93.32.

[0033] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com