Halogen-free scaling powder used for lead-free solder paste and preparation method thereof

A technology of lead-free solder paste and flux, applied in the direction of welding equipment, welding medium, manufacturing tools, etc., can solve the problems of reliability and safety hazards, short circuit of electronic component pins, and many halogen residues, etc., to achieve solderability Good performance, high surface insulation resistance, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

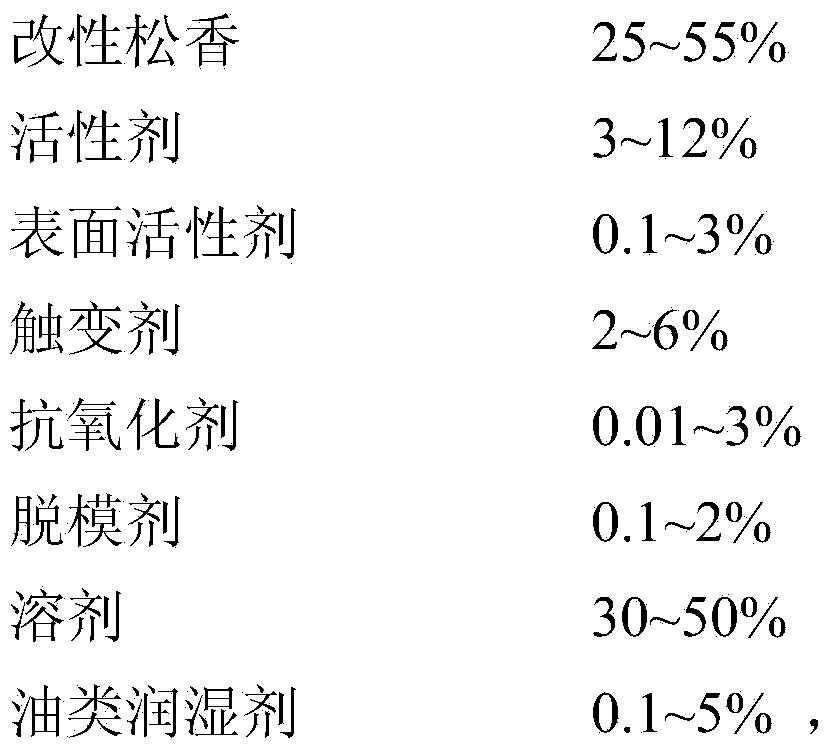

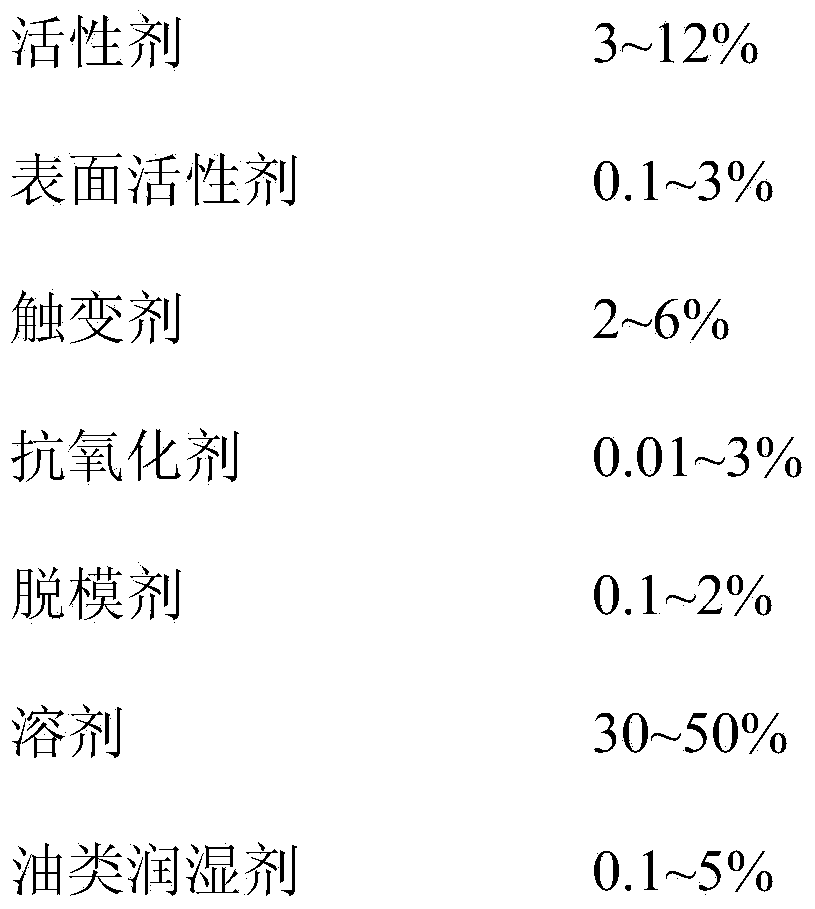

[0031] raw material:

[0032] Water white rosin 10g, polymerized rosin 20g, hydrogenated rosin 25g, succinic acid 1g, glutaric acid 1g, glycolic acid 1g, dodecyl dimethyl amine oxide 0.1g, hydrogenated castor oil 2g, imidazole 0.01g, paraffin 0.1 g, dipropylene glycol 34.79g, castor oil 2g, soybean oil 3g;

[0033] Add 10g of water-white rosin, 20g of polymerized rosin, 25g of hydrogenated rosin, 1g of succinic acid, 1g of glutaric acid, 1g of glycolic acid, 0.1g of dodecyldimethylamine oxide and 34.79g of dipropylene glycol into the vessel after mixing Heat up to 145°C, stir until completely dissolved to obtain a mixture; then cool the above mixture to 80°C, add 2g of hydrogenated castor oil, 0.01g of imidazole and 0.1g of paraffin, stir until complete dissolution to obtain a secondary mixture; The temperature of the secondary mixture was lowered to 35° C., 2 g of castor oil and 3 g of soybean oil were added, and stirred evenly to obtain a halogen-free flux for lead-free sol...

Embodiment 2

[0035] raw material:

[0036] Polymerized rosin 10g, hydrogenated rosin 30g, suberic acid 6g, glycolic acid 6g, dimethyl alkyl betaine 1g, cocamidopropyl betaine 2g, modified hydrogenated castor oil 2g, 6500 thixotropic agent 4g, p-benzene Diphenol 1g, 2,6-di-tert-butyl-4-methylphenol 2g, paraffin 2g, diethylene glycol 20g, diethylene glycol monohexyl ether 13.9g, castor oil 0.1g;

[0037] 10 g of polymerized rosin, 30 g of hydrogenated rosin, 6 g of suberic acid, 6 g of glycolic acid, 1 g of dimethyl alkyl betaine, 2 g of cocamidopropyl betaine, 20 g of diethylene glycol and 13.9 g of diethylene glycol monohexyl ether were added After mixing in a container, heat up to 140°C, stir until completely dissolved to obtain a mixture; then lower the temperature of the above mixture to 80°C, add 2g of modified hydrogenated castor oil, 4g of 6500 thixotropic agent, 1g of hydroquinone, 2g of 2,6-di-tert-butyl-4-methylphenol and 2g of paraffin, stirred until complete dissolution to obta...

Embodiment 3

[0039] raw material:

[0040]Disproportionated rosin 25g, sebacic acid 4g, dodecanoic acid 4g, glycolic acid 4g, octylphenol polyoxyethylene ether 2g, alkylphenol polyoxyethylene ether 1g, 6650 thixotropic agent 2g, 7000 thixotropic agent 3g, hard Fatty acid amide 1g, 2,6-di-tert-butyl-4-methylphenol 1.5g, paraffin 0.5g, glycerin 35g, triethylene glycol monobutyl ether 15g, sesame oil 2g;

[0041] 25g disproportionated rosin, 4g sebacic acid, 4g dodecanoic acid, 4g glycolic acid, 2g octylphenol ethoxylate, 1g alkylphenol ethoxylate, 35g glycerin and 15g triethylene glycol monobutyl ether Add it into the container and mix it, heat it up to 140°C, stir until it is completely dissolved to obtain the mixture; then lower the temperature of the above mixture to 90°C, add 2g of 6650 thixotropic agent, 3g of 7000 thixotropic agent, and 1g of stearic acid amide , 1.5g of 2,6-di-tert-butyl-4-methylphenol and 0.5g of paraffin, stirred until complete dissolution to obtain a secondary mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com