A kind of solder paste with low dielectric loss and high reliability and preparation method thereof

A reliable, low-dielectric technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve the problem of high dielectric loss of solder paste, reduce dielectric loss, reduce post-soldering residue, and reduce signal interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

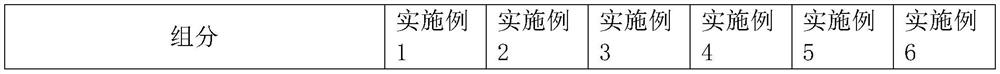

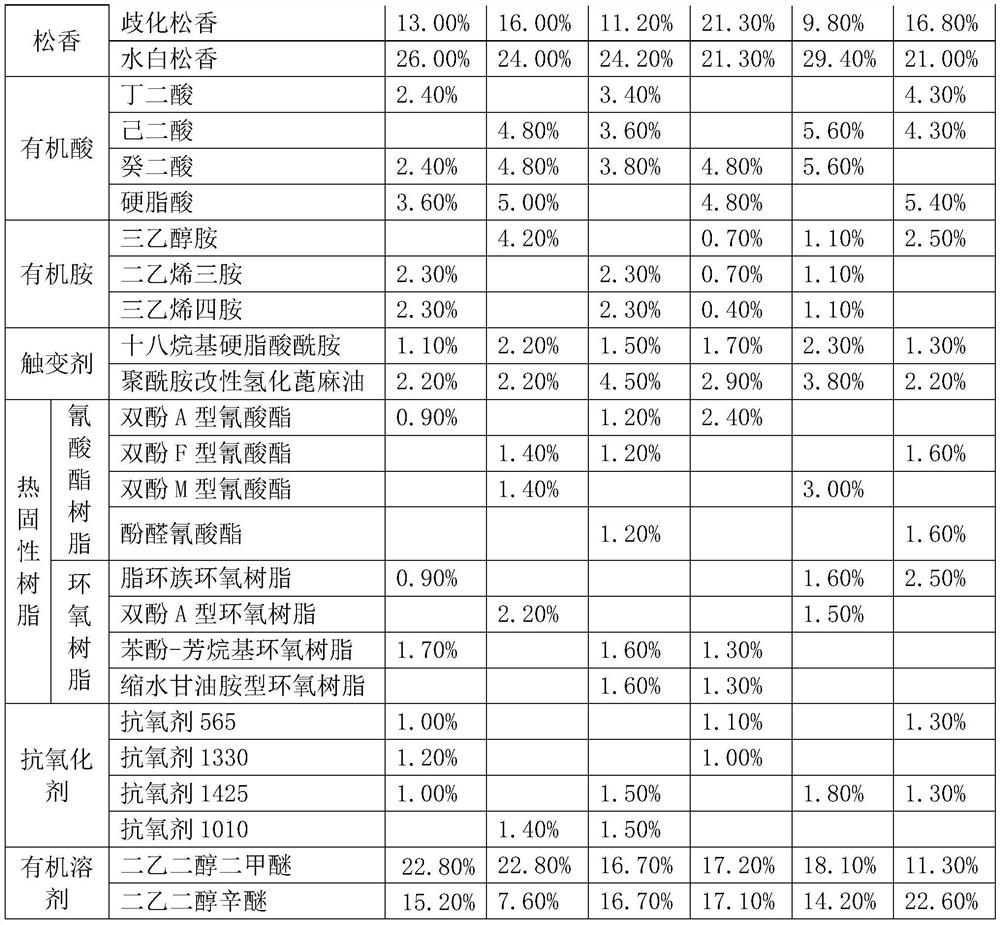

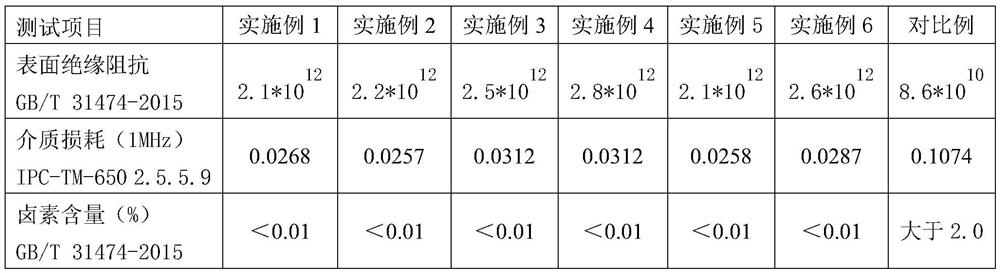

[0032] A low dielectric loss high reliability solder paste, including the following weight component composition, 88.9 wt% solder alloy powder, 11.1% by weight of flux, wherein the group dispensing of tie alloy powder is shown in Table 2, the help The group distribution of the flux is described, for example, the preparation method thereof, comprising the steps of:

[0033] According to Table 2, the weight percentage of Table 3 refers to each component, backup; first add solvent to the container, heated to 120 ° C, then add rosin, stir well to rosin completely dissolve, add thermal resin, maintain temperature at 120 ° C Next, the thixotropic agent is added to the container, maintain the temperature and stir until completely dissolve; the temperature drops to 70 ° C, adding an antioxidant, organic acid and an organic amine, and stirring the temperature and stirring for 45 minutes; The rotational speed of MIN is ground to a particle diameter of less than 20 microns to obtain flux; ad...

Embodiment 2

[0035] A low dielectric loss high reliability solder paste, including the following weight components, 90.1% by weight solder alloy powder, 9.9 wt% flux, wherein the group dispensing of the tie alloy powder is shown in Table 2, the help The group distribution of the flux is described, for example, the preparation method thereof, comprising the steps of:

[0036] According to Table 2, the weight percentage of Table 3 refers to each component, backup; first add solvent to the container, heating to 125 ° C, then add rosin, stir well to rosin completely dissolve, add thermal resin, maintain temperature at 125 ° C Next, the thixotropic agent is added to the container, maintain the temperature and stir until completely dissolve; the temperature drops to 65 ° C, adding an antioxidant, organic acid and an organic amine, and stirring the temperature and stirring for 30 minutes; The rotational speed of MIN is ground to a particle diameter of less than 20 microns to obtain flux; add flux and...

Embodiment 3

[0038] A low dielectric loss high reliability solder paste, including the following weight components, 85.4 wt% solder alloy powder, 14.6 wt% flux, wherein the group dispensing of the tie alloy powder is shown in Table 2, the help The group distribution of the flux is described, for example, the preparation method thereof, comprising the steps of:

[0039] According to Table 2, the weight percentage of Table 3 refers to each component, backup; first add the solvent to the container, heated to 130 ° C, then add rosin, stir until the rosin is completely dissolved, add the thermosetting resin, maintain the temperature at 130 ° C Next, the thixotropic is added to the container, keeps the temperature and stir until completely dissolve; the temperature drops to 80 ° C, the antioxidant, organic acid and the organic amine are added, and the temperature is maintained and stirred for 50 minutes; The rotation of MIN is ground to a particle diameter of less than 20 microns to obtain flux; add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com