A kind of high-performance halogen-free lead-free solder paste and preparation method thereof

A halogen-free lead-free solder paste, high-performance technology, applied in the field of high-performance halogen-free lead-free solder paste and its preparation, can solve the problems of blackening of the periphery after soldering, a large number of tin beads, and a large number of residues, and achieve solder joints Bright and full, less residue, low corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

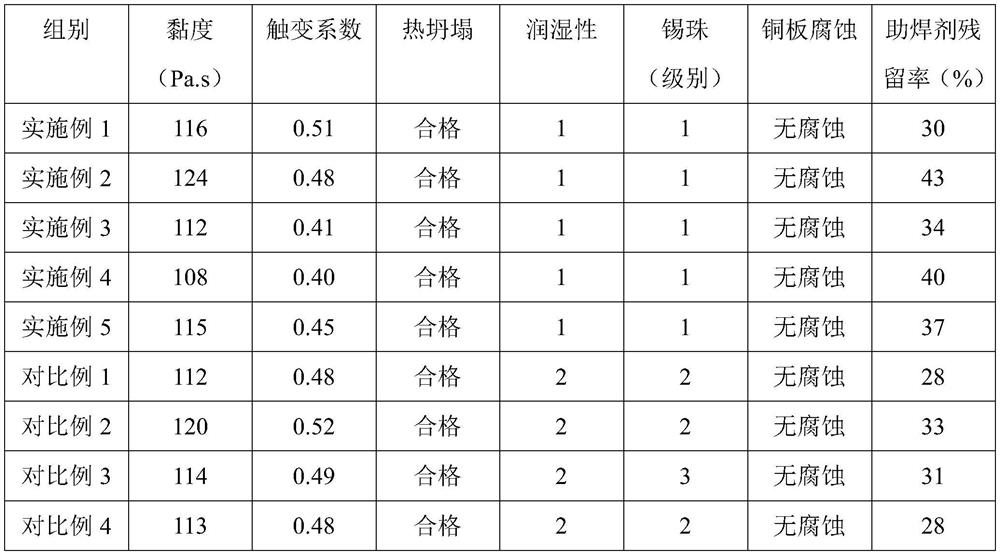

Examples

Embodiment 1

[0031] A high-performance halogen-free lead-free solder paste, including the following components in terms of mass percentage: 80% of Sn58Bi42 alloy powder, 4% of tin lactate, 1% of dioctanoic acid phosphate, 0.5% of hydroxyethylene diphosphonic acid, polyaniline 1%, 0.5% diisooctyl diphenylamine, 2% polyamide-modified hydrogenated castor oil, 3% hydrogenated rosin resin, 8% co-solvent.

[0032] The auxiliary solvent is composed of ethyl borate, N,N-dimethylacetamide, and diethylene glycol butyl ether in a mass ratio of 2:1.5:4.

[0033] Preparation steps:

[0034] S1: Add hydrogenated rosin resin, polyamide-modified hydrogenated castor oil, polyaniline, dicaprylic acid phosphate, ethyl borate, N,N-dimethylacetamide, diethylene glycol butyl ether into the reaction kettle, Fully stir and dissolve at 100°C, add diisooctyl diphenylamine and hydroxyethylene diphosphonic acid when the solution is cooled to 80°C, stir evenly, continue to cool to room temperature, add tin lactate an...

Embodiment 2

[0038] A high-performance halogen-free lead-free solder paste, including the following components in terms of mass percentage: 85% of Sn58Bi0.3Ag41.7 alloy powder, 5% of zinc salicylate, 2% of dicapric acid phosphate, hydroxyethylene di Phosphonic acid 0.2%, polyaniline 0.5%, dialkyl diphenylamine 0.5%, ethylene bis stearic acid amide 1.8%, disproportionated rosin resin 2%, cosolvent 3%.

[0039] The auxiliary solvent is composed of ethyl borate, N,N-dimethylacetamide, and diethylene glycol butyl ether in a mass ratio of 4:3:5.

[0040] Preparation steps:

[0041] S1: Add disproportionated rosin resin, ethylene bis stearic acid amide, polyaniline, dicapric acid phosphate, ethyl borate, N,N-dimethylacetamide, diethylene glycol butyl ether to the reaction kettle , fully stirred and dissolved at 120°C, when the solution was cooled to 70°C, added dialkyl diphenylamine and hydroxyethylene diphosphonic acid, stirred evenly, continued to cool to room temperature, added zinc salicyla...

Embodiment 3

[0045] A high-performance halogen-free lead-free solder paste, including the following components in terms of mass percentage: Sn64.5Bi35Cu0.5 alloy powder 82.5%, zinc citrate 2%, monoisodecanoic acid phosphate 2%, hydroxyethylene di Phosphonic acid 1%, polyaniline 1.5%, butyloctyldiphenylamine 0.5%, hydrogenated castor oil 0.5%, polymerized rosin 4%, cosolvent 6%.

[0046] The auxiliary solvent is composed of ethyl borate, N,N-dimethylacetamide, and diethylene glycol butyl ether in a mass ratio of 3:2:3.

[0047] Refer to Example 1 for the preparation steps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com