Method for producing ethylene oxide

A technology of ethylene oxide and nitric oxide, used in products, organic chemistry, reagents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Preparation of Catalyst A: Add 28 parts of ethylenediamine, 10 parts of ethanolamine and 46 parts of deionized water into a stirred glass flask. While stirring, slowly add 62 parts of silver oxalate with a silver content of 62.6wt% into the mixed solution, keep the solution temperature at 0-15°C, and form a silver amine solution after all the silver oxalate is dissolved, then add 0.10 parts of cesium hydroxide, 0.02 Potassium hydroxide, 0.01 part of ammonium sulfate. Take 10g of the carrier and put it in a vacuumable container, evacuate it to below 10mmHg, immerse the carrier in the silver amine solution configured above for 30 minutes, leach off the excess solution, and then heat it in the air flow at 300°C for 5 minutes. Catalyst A was prepared after cooling.

[0026] Preparation of Catalyst B: Add 28 parts of ethylenediamine, 10 parts of ethanolamine and 46 parts of deionized water into a stirred glass flask. While stirring, slowly add 62 parts of silver oxalate wi...

Embodiment 1~6

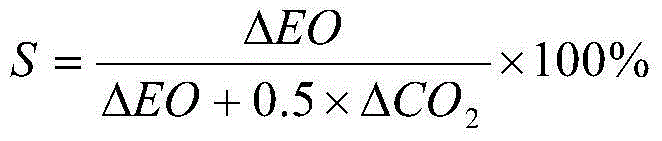

[0033] Feed gas mixture composition: Ethylene (C 2 h 4 ), 30.0±2.5mol%; oxygen (O 2 ), 7.2±0.5mol%; carbon dioxide (CO 2 ), 2 ),margin. The reaction pressure is 1.8MPa; the space velocity is 5000h -1 ; The concentration of ethylene oxide (EO) in the reactor outlet tail gas is 2.5%. Catalysts A-F were selected for micro-reaction evaluation, corresponding to Examples 1-6, and the results are shown in Table 1.

Embodiment 7

[0037] Feed gas mixture composition: Ethylene (C 2 h 4 ), 30.0±2.5mol%; oxygen (O 2 ), 7.2±0.5mol%; carbon dioxide (CO 2 ), 2 ),margin. The reaction pressure is 1.8MPa; the space velocity is 5000h -1 ; The concentration of ethylene oxide (EO) in the reactor outlet tail gas is 2.5%. Catalyst D was selected for micro-reaction evaluation, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com