Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Coal combustion products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal combustion products (CCPs), also called coal combustion wastes (CCWs) or coal combustion residuals (CCRs), are categorized in four groups, each based on physical and chemical forms derived from coal combustion methods and emission controls...

Settable Building Material Composition Including Landfill Leachate

InactiveUS20110232532A1High compressive strengthReduce Shrinkage ProblemsSolid waste managementCement productionBottom ashLitter

A composition capable of setting to produce a building material is disclosed. The composition can include from 1% to 30% by weight of an activator, from 1% to 55% by weight of a pozzolan, such as fly ash; from 40% to 90% by weight of an aggregate; and liquid landfill leachate in a sufficient amount such that the composition sets to a building material having a compressive strength of at least 2 MPa, wherein all weight percentages are percent by weight of the total composition. The liquid landfill leachate replaces all or part of the tap water in a conventional composition for forming a building material. The liquid landfill leachate can be recovered after a liquid (typically water) percolates through a landfill and contacts at least one landfilled coal combustion product selected from fly ash, bottom ash, boiler slag, and flue gas desulfurization material. The building material can be a concrete, or a masonry unit.

Owner:WISCONSIN ELECTRIC POWER

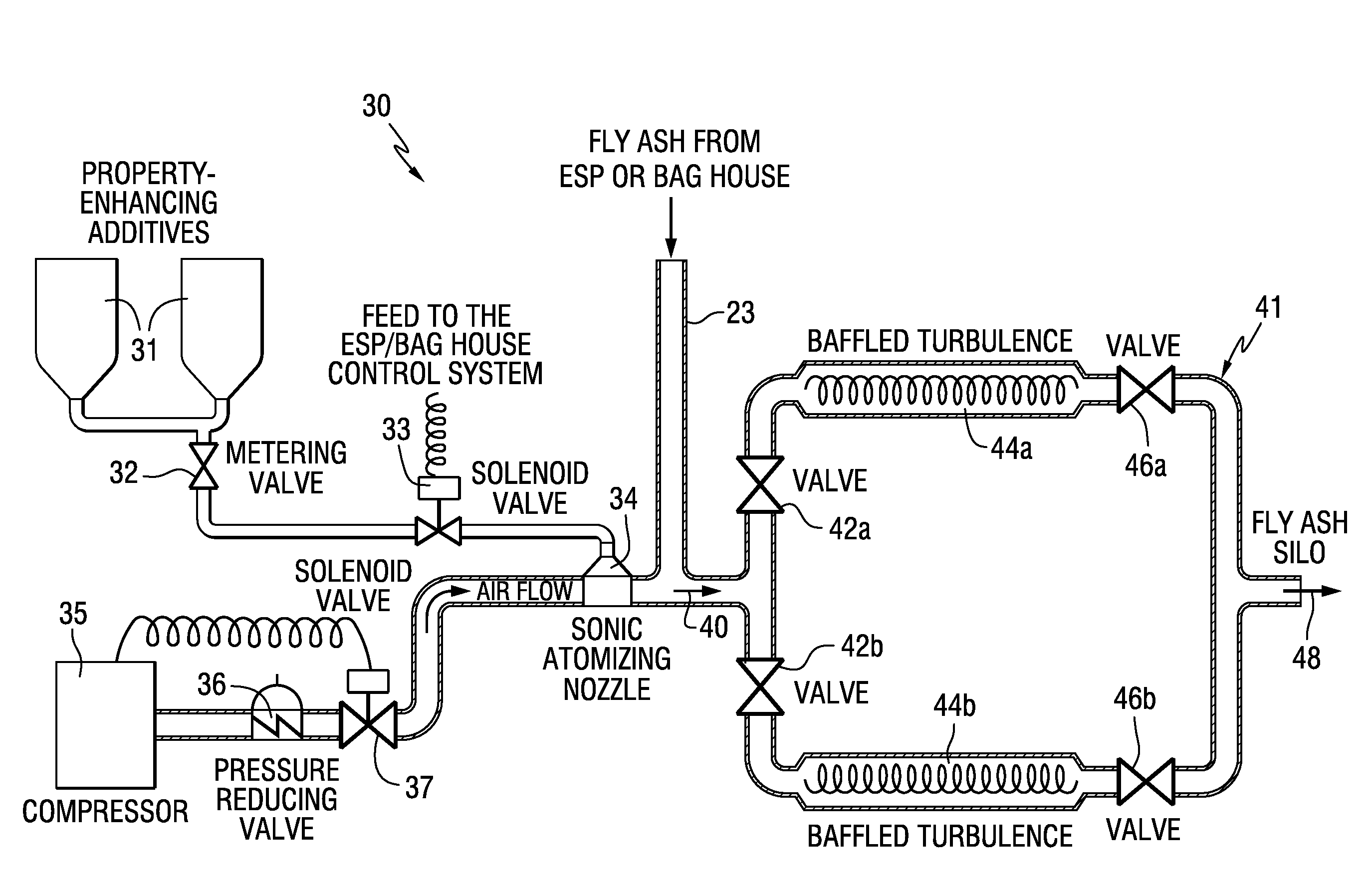

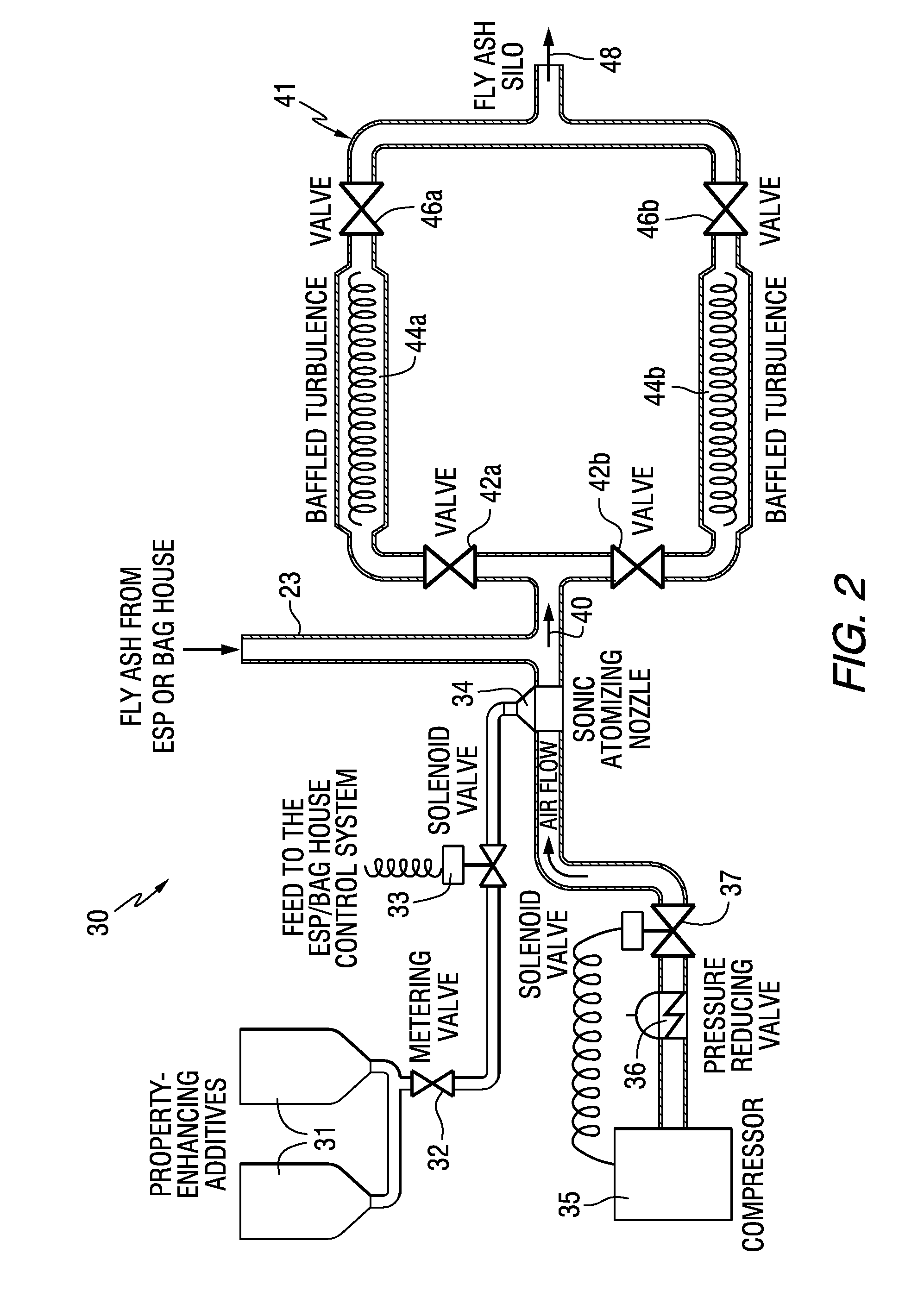

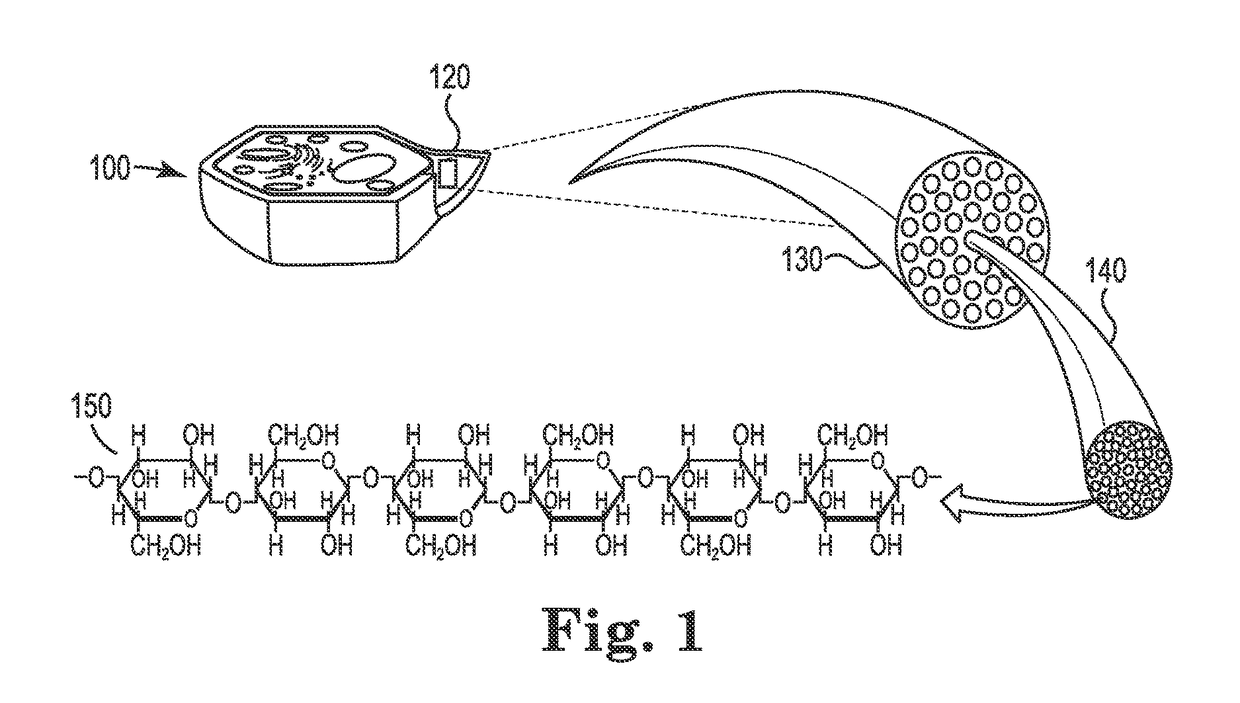

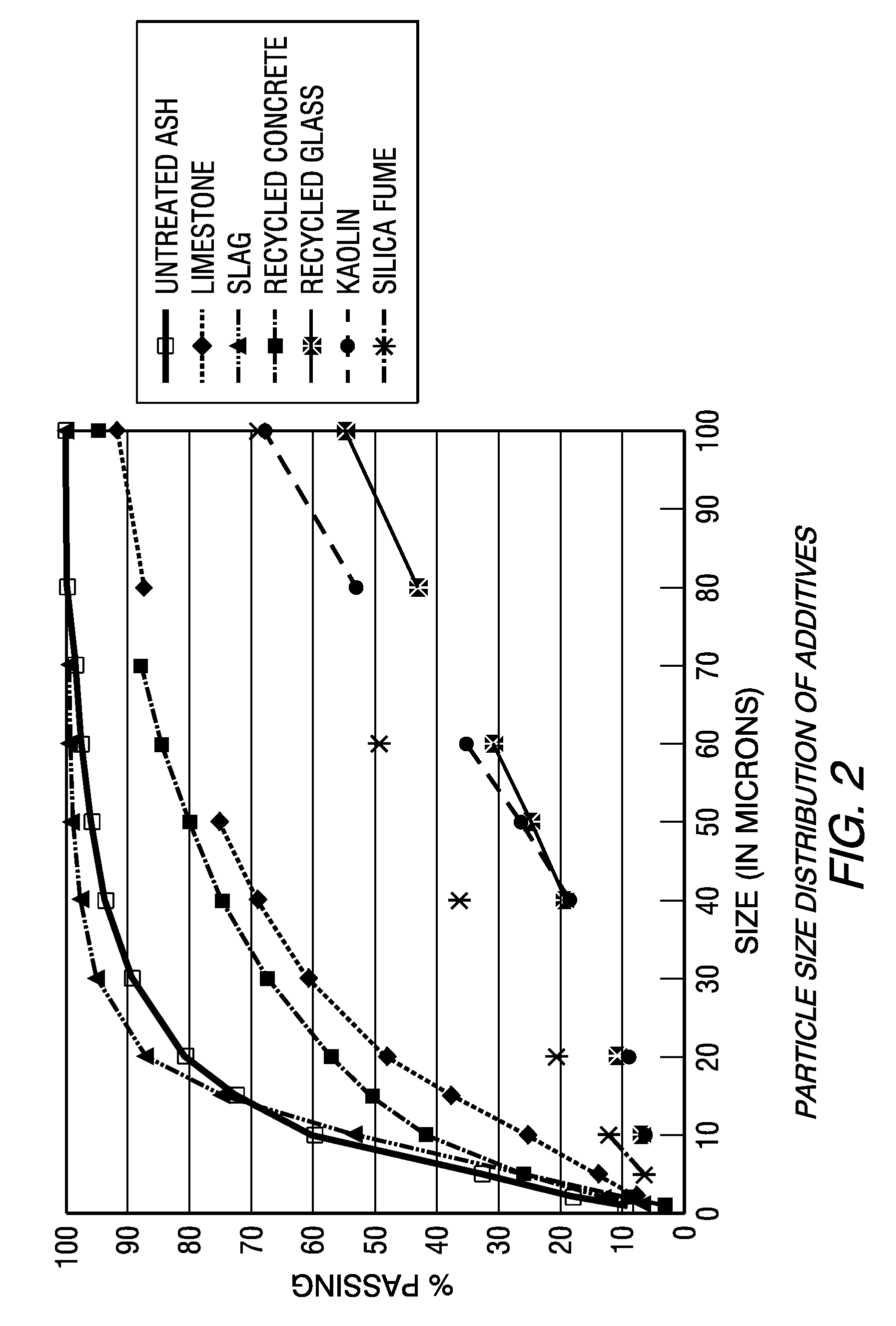

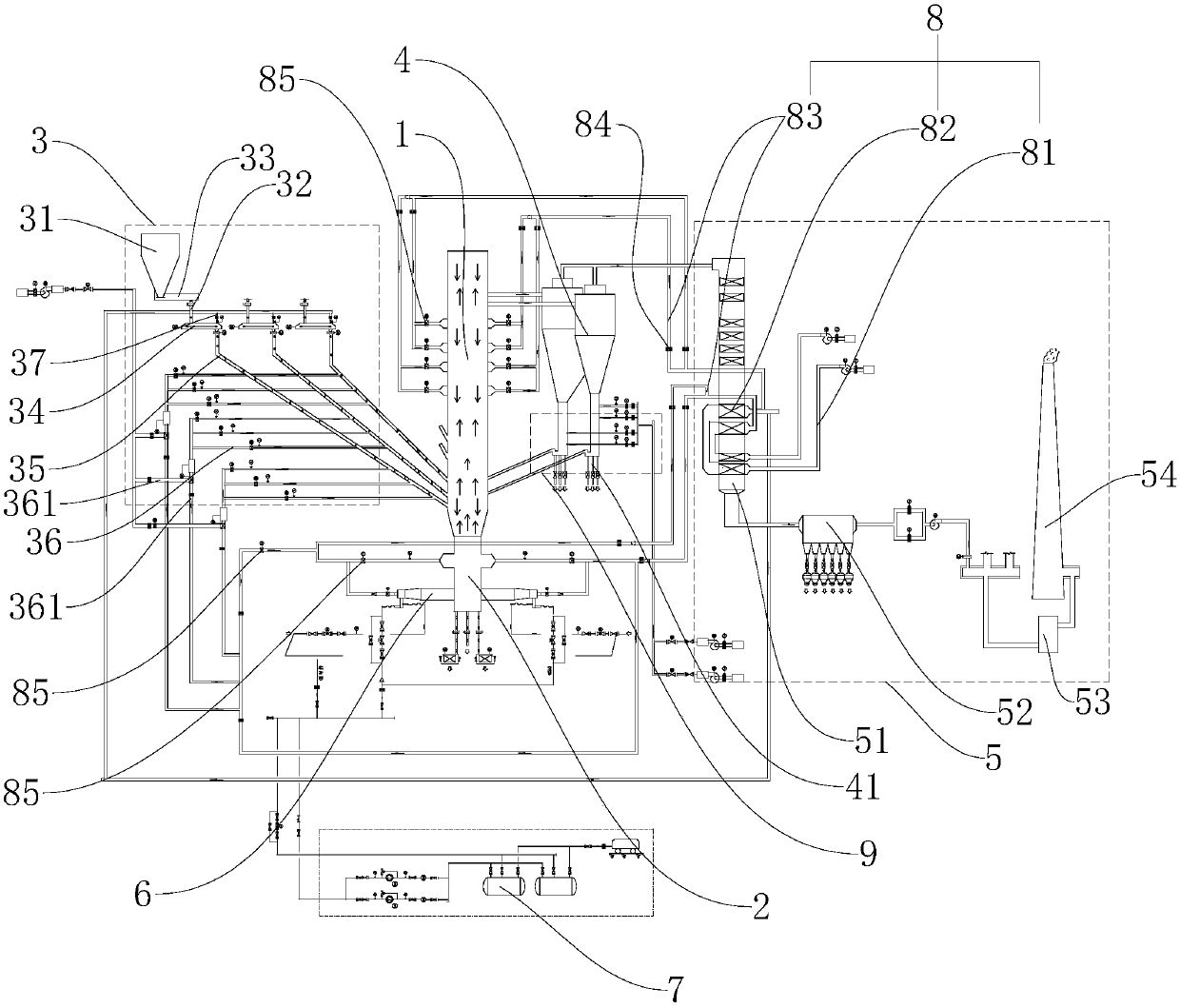

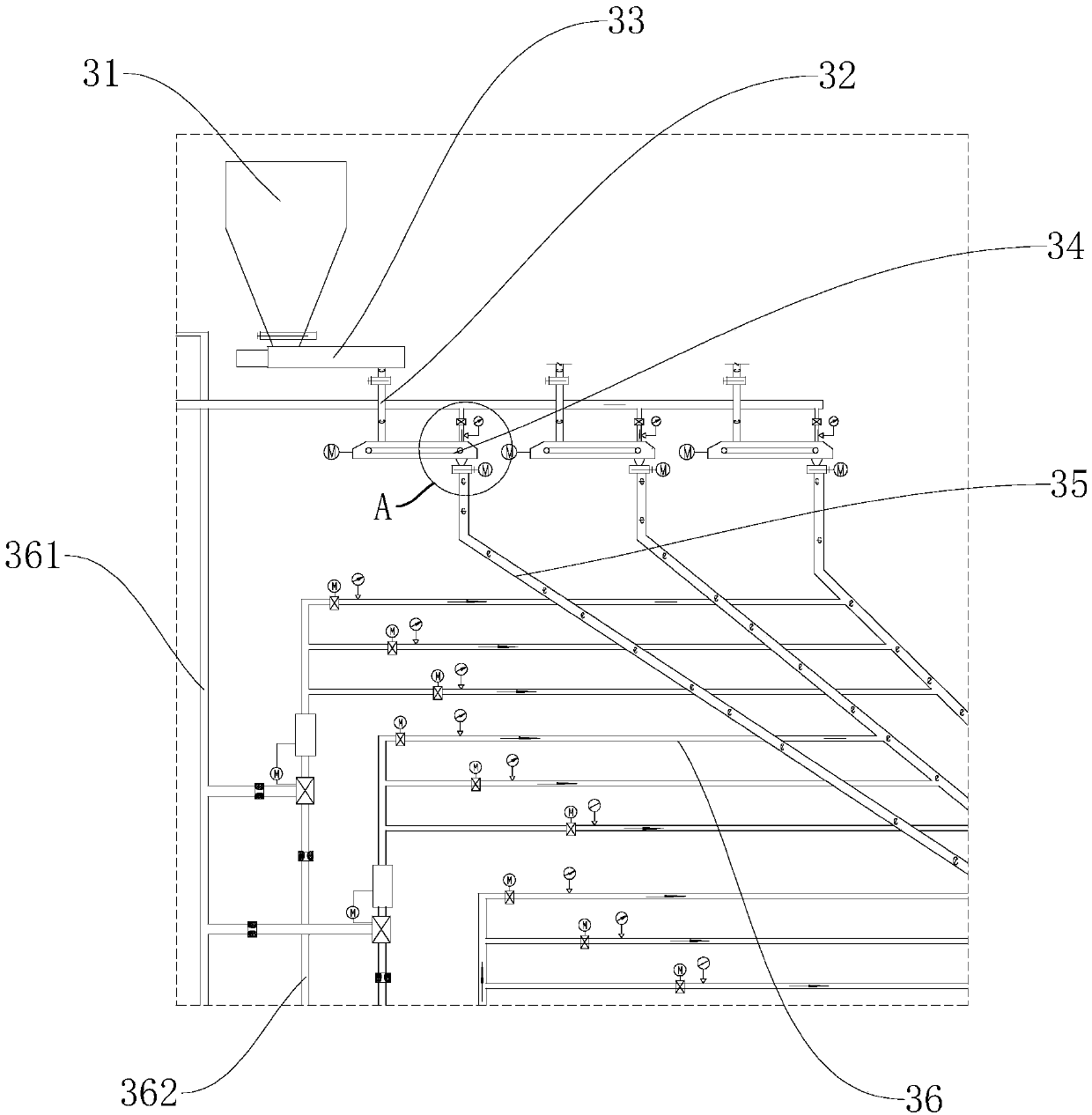

In-process addition of property-enhancing additives to coal combustion products used in cementicious materials

InactiveUS20130125791A1Well formedOptimizing rheologicalFlow mixersSolid waste managementProcess systemsPulverized fuel ash

In-process systems and methods for treating coal combustion products with property-enhancing additives are disclosed. Coal combustion products such as fly ash are collected upon their formation and are contemporaneously treated with additives such as dispersants, rheology modifiers, retarders and accelerators to improve properties of the treated products when they are used in cement, concrete, mortar and other hydraulic mixtures.

Owner:ASH IMPROVEMENT TECH

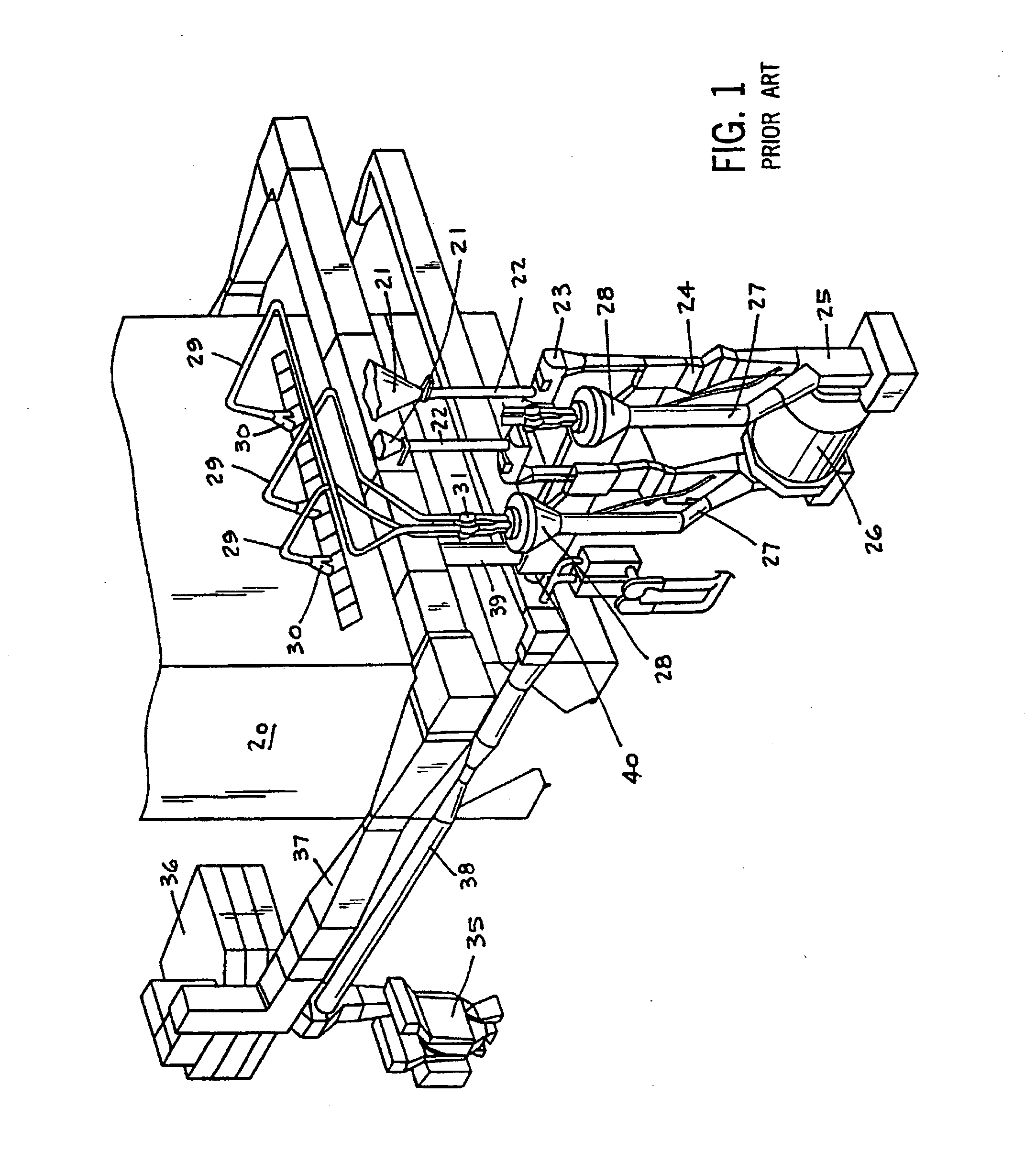

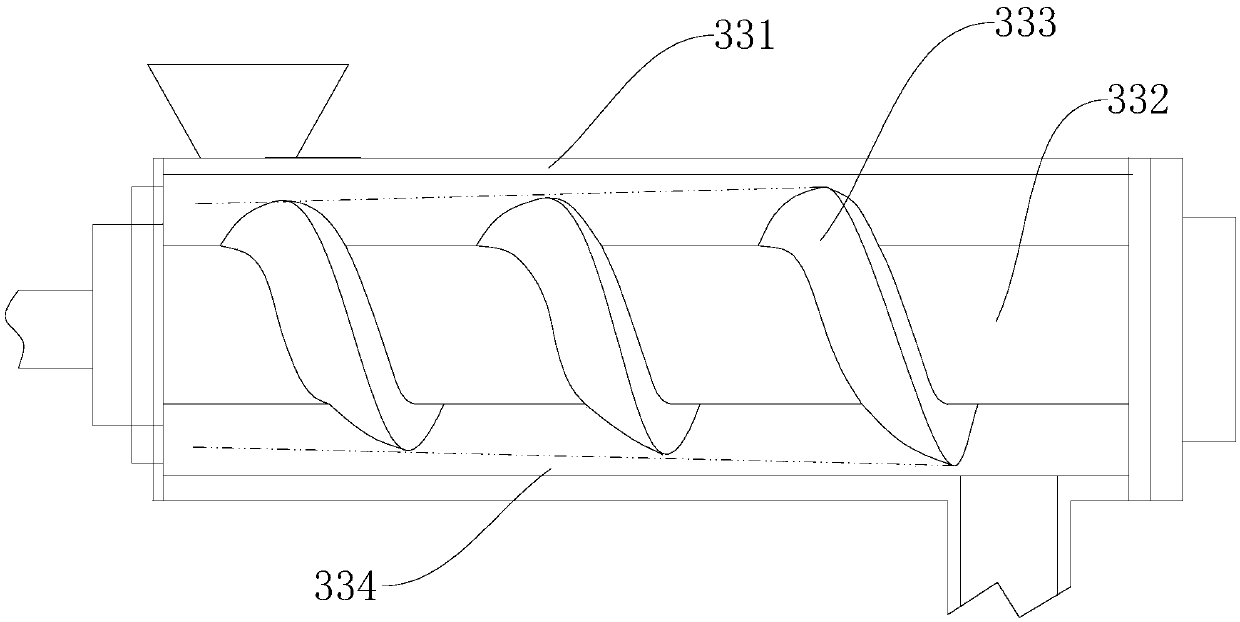

Systems and methods for comminuting and recirculating coal combustion products

InactiveUS20130125799A1Reduce contentSpeed up developmentSolid waste managementCocoaProcess engineeringComminution

A method and system for reducing the un-burned carbon content in coal combustion products are disclosed. A coal combustion product is separated into a coarse particle fraction and a fine particle fraction, and the coarse particles are comminuted by milling, grinding or the like. Additives may be added of the coarse particles prior to comminution. The comminuted particles are then co-combusted with coal to burn at least a portion of the un-burned carbon contained in the original coal combustion product.

Owner:ASH IMPROVEMENT TECH

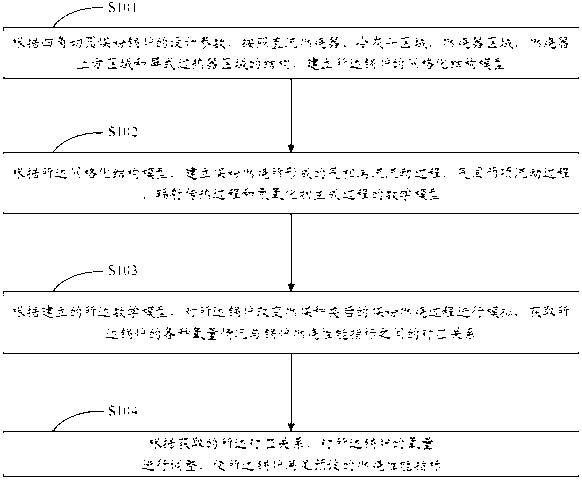

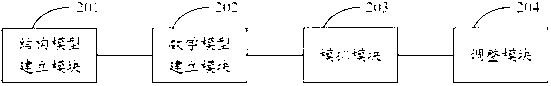

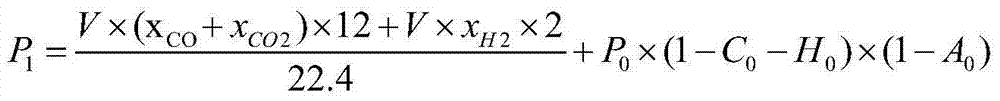

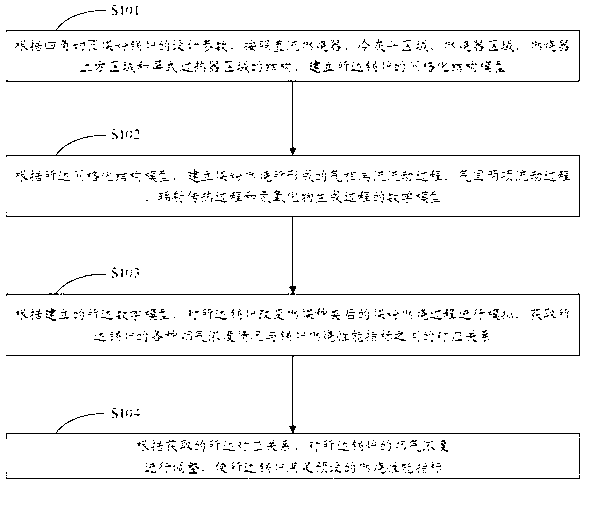

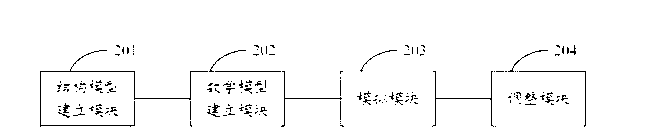

Oxygen volume adjusting method and system for pulverized coal boiler after change of coal type

ActiveCN103225819AImprove visibilityOvercome stabilityAir supply regulationMathematical modelPerformance index

The invention discloses an oxygen volume adjusting method for a pulverized coal boiler after a change of coal type. The method comprises the following steps: a grid structure model of the pulverized coal boiler is built; a mathematical model of various physical and chemical processes generated in pulverized-coal combustion is built; the pulverized-coal combustion process after the change of coal type is simulated to obtain the corresponding relation between various oxygen volumes and the burning performance indexes of the pulverized coal boiler; and the oxygen volume of the pulverized coal boiler is adjusted to allow the pulverized coal boiler to meet preset burning performance indexes. In addition, the invention further discloses an oxygen volume adjusting method for the pulverized coal boiler after the change of coal type. The method and system provided by the invention can improve the accuracy rate and security of pulverized coal boiler oxygen volume control after the change of coal type, solve the problems of unstable furnace combustion and low combustion efficiency easily caused by manual control, and simultaneously greatly reduce pollutants produced during the process of combustion.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

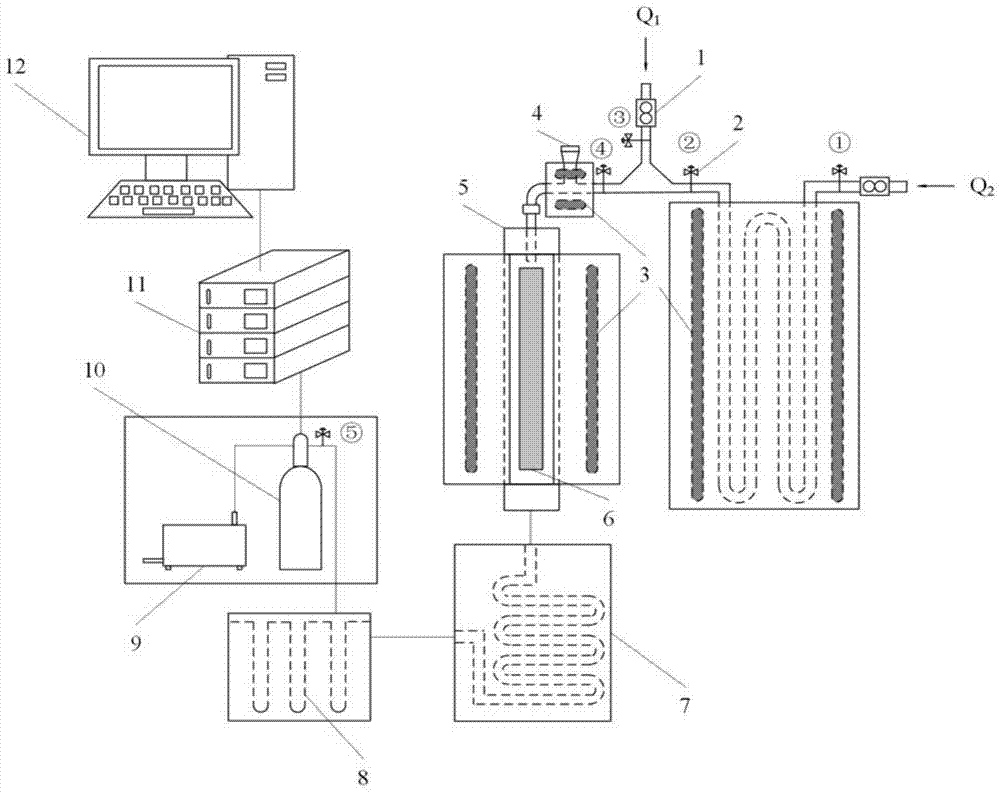

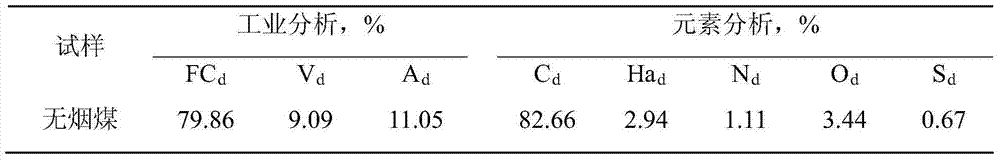

Visual detection method of pulverized coal combustion ratio

InactiveCN104764852ASolve the problem of low burn rateWith visualizationChemical analysis using combustionCombustorFlue gas

The invention discloses a visual pulverized coal combustion performance detection method for monitoring and analyzing pulverized coal combustion condition in real time. The method comprises the following steps: preheating a pulverized coal sample to 50-400 DEG C; preheating pulverized coal carrier gas to 50-400 DEG C; spraying the pulverized coal into a combustor by using gas produced by pressure difference in a pipeline; visualizing the pulverized coal combustion process, recording the pulverized coal combustion process through a camera; cooling flue gas; collecting unburned pulverized coal; collecting the flue gas and computing the pulverized combustion ratio. Through the adoption of the visual pulverized coal combustion performance detection method, the pulverized coal sample and the pulverized coal carrier gas are respectively pre-heated, the pulverized coal combustion process is visual; the combustion ratio of the pulverized coal is computed respectively through a flue gas component analysis method and an ash content quality balance method, the combustion performance of the coal sample is represented by using the average value of the combustion ratios obtained by the two method, and the obtained combustion ratio result is more accurate.

Owner:UNIV OF SCI & TECH LIAONING

Smoke concentration adjustment method and smoke concentration adjustment system after fire coal variety of pulverized coal boiler is changed

ActiveCN103216846AImprove accuracyImprove securitySpecial data processing applicationsCombustion regulationMathematical modelEngineering

The invention discloses a smoke concentration adjustment method after the fire coal variety of a pulverized coal boiler is changed. The smoke concentration adjustment method after the fire coal variety of the pulverized coal boiler is changed comprises the following steps: establishing a meshing structural model of the boiler, establishing a mathematical model of each physical and chemical process formed by combustion of pulverized coal; imitating a pulverized coal combustion process after the fire coal variety of the pulverized coal boiler is changed, and obtaining a corresponding relation between various smoke concentration situations and boiler combustion performance indexes; and adjusting the smoke concentration of the boiler so that the boiler meets preset combustion performance indexes. Besides, the invention further discloses a smoke concentration adjustment system after the fire coal variety of the pulverized coal boiler is changed. The smoke concentration adjustment method and the smoke concentration adjustment system after the fire coal variety of the pulverized coal boiler is changed can improve the accuracy and safety of smoke concentration control after the fire coal variety of the pulverized coal boiler is changed, resolve the problems of unstable combustion in the boiler and low combustion efficiency easily caused by manual control, and largely lower pollutants produced in the combustion process.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

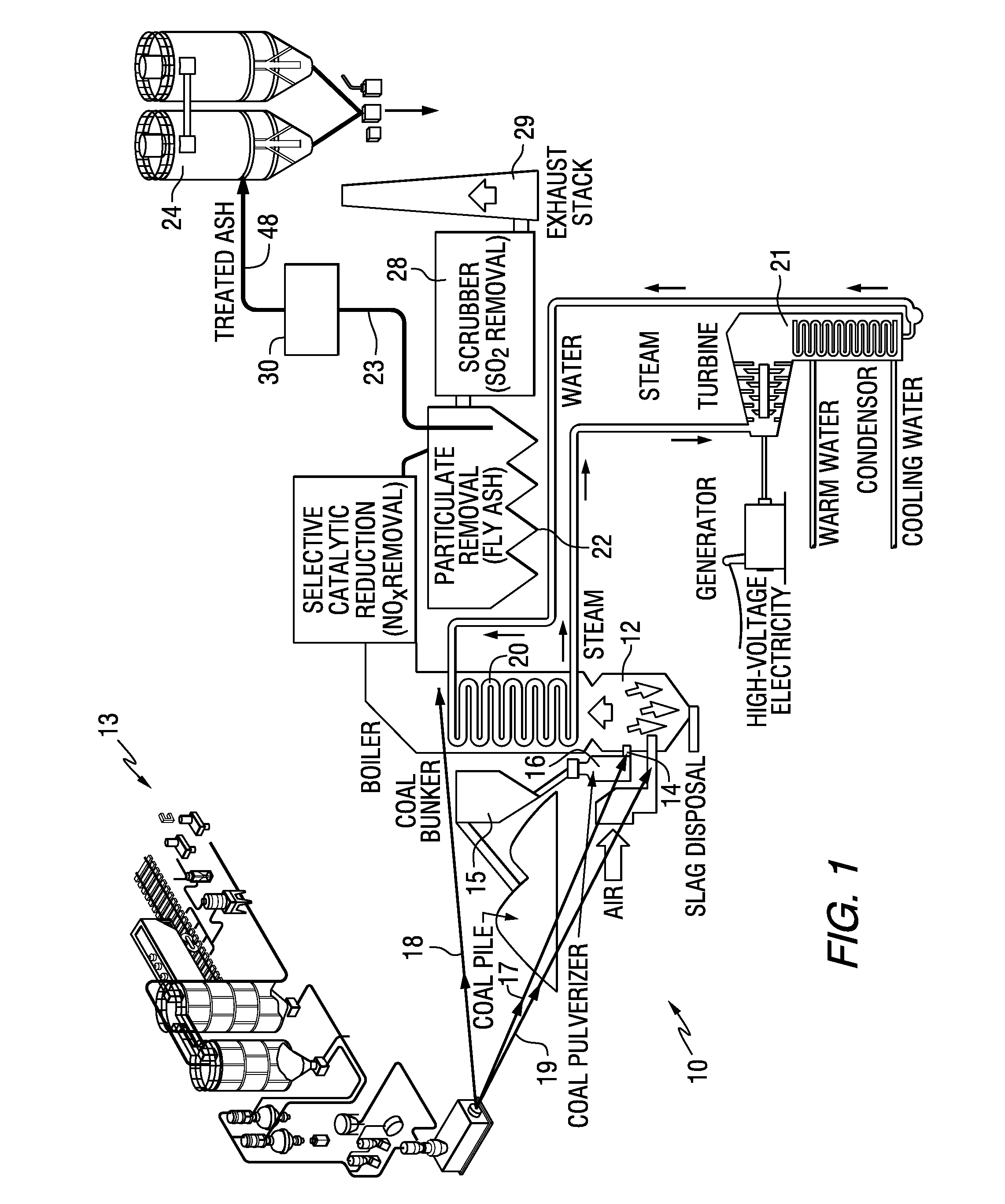

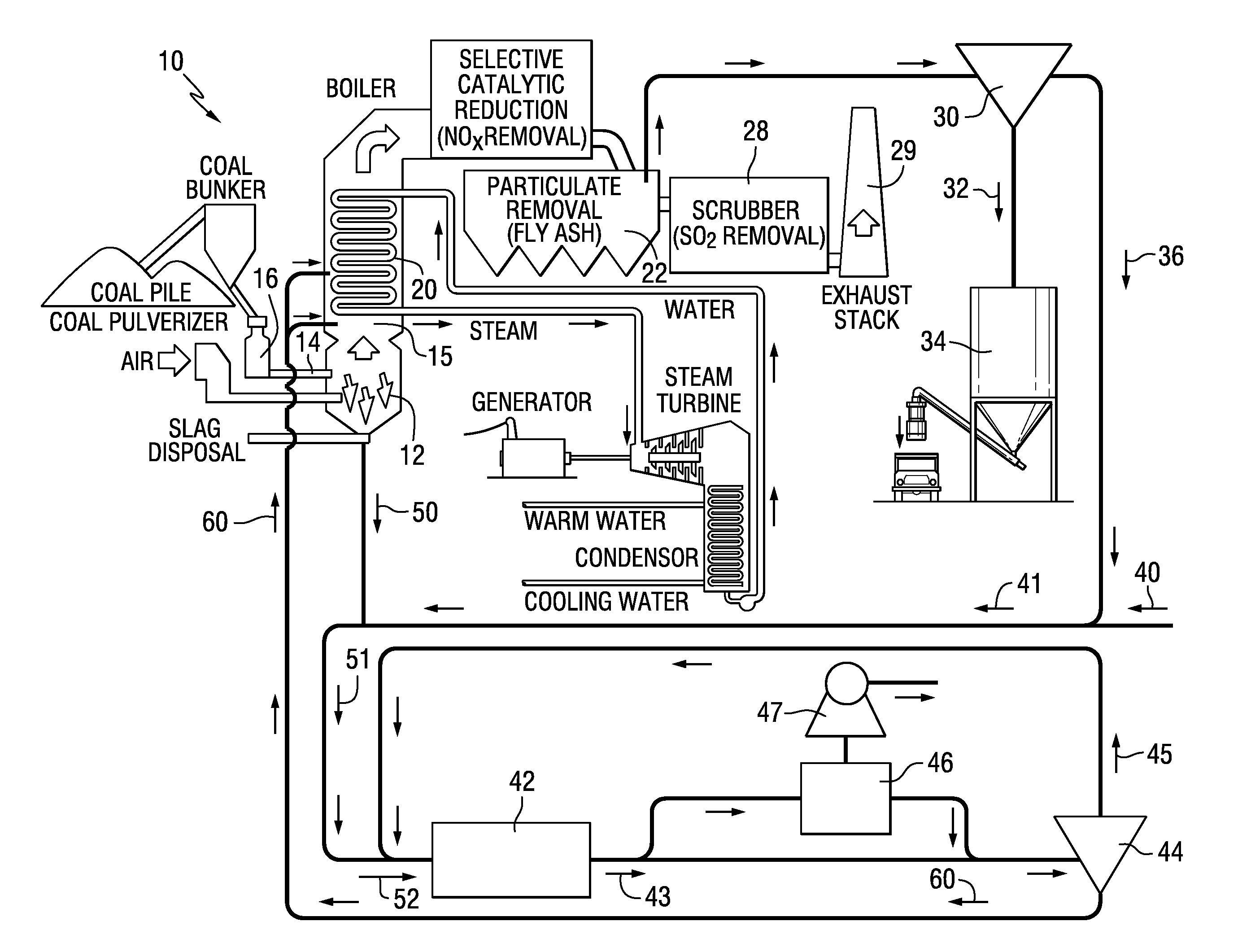

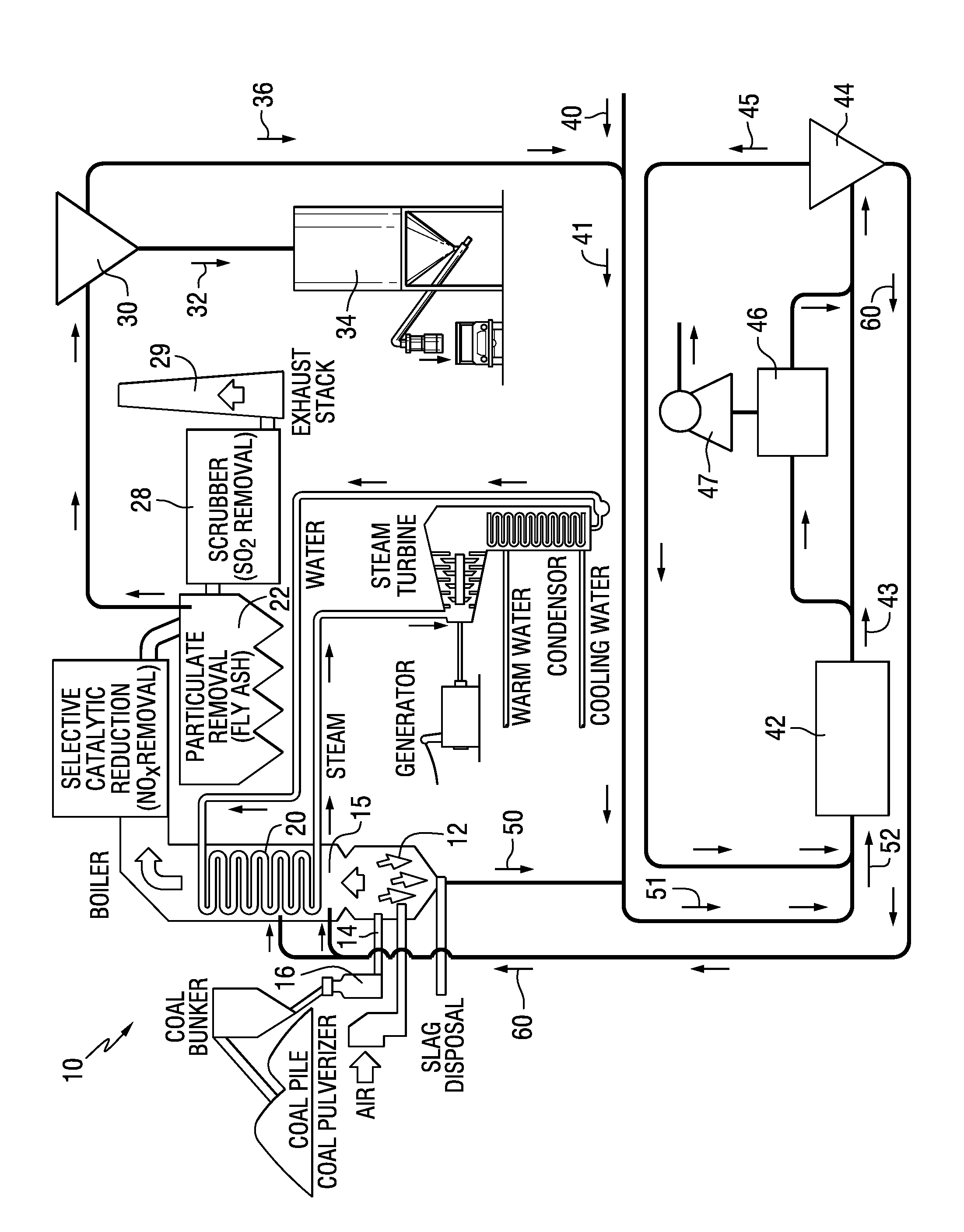

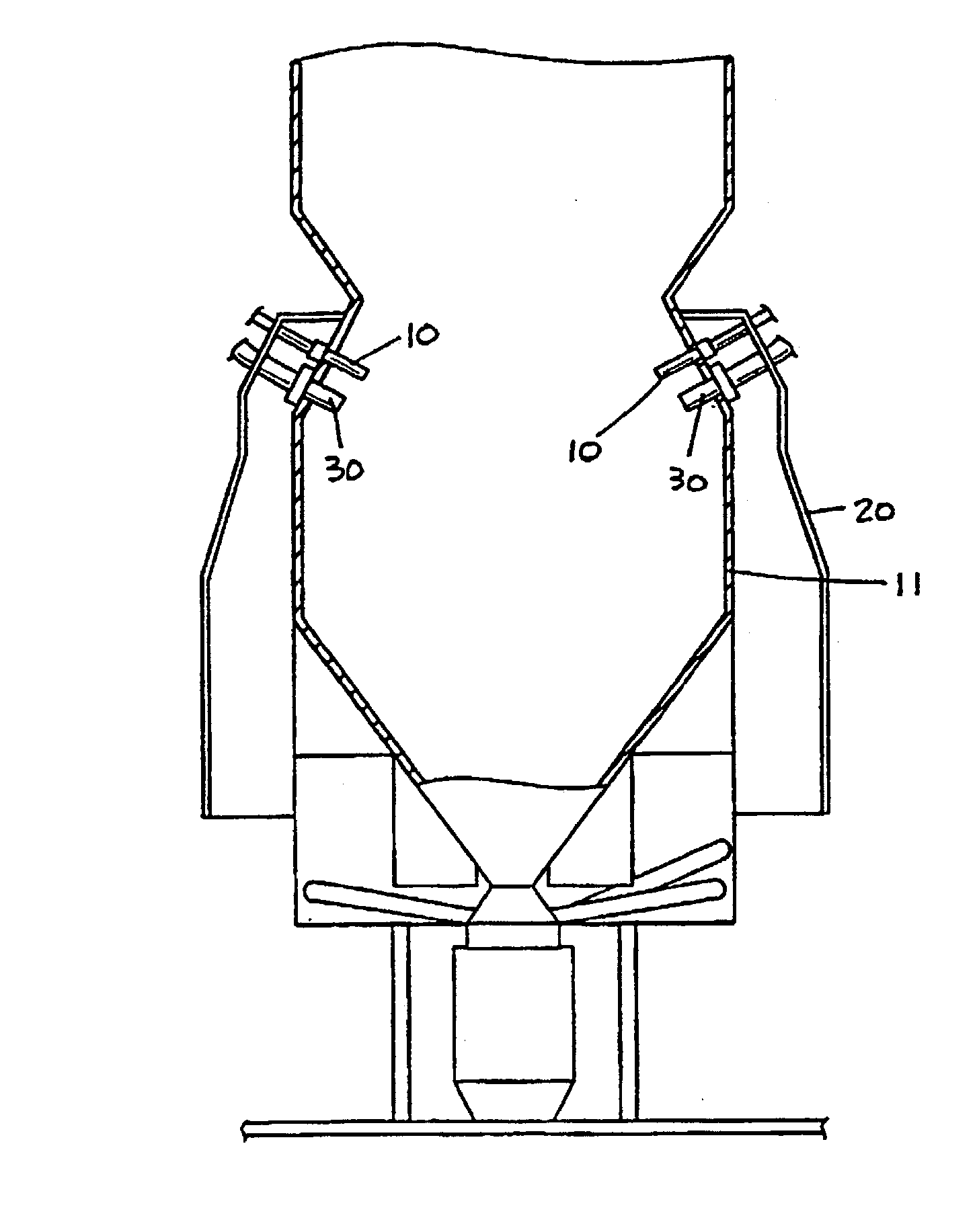

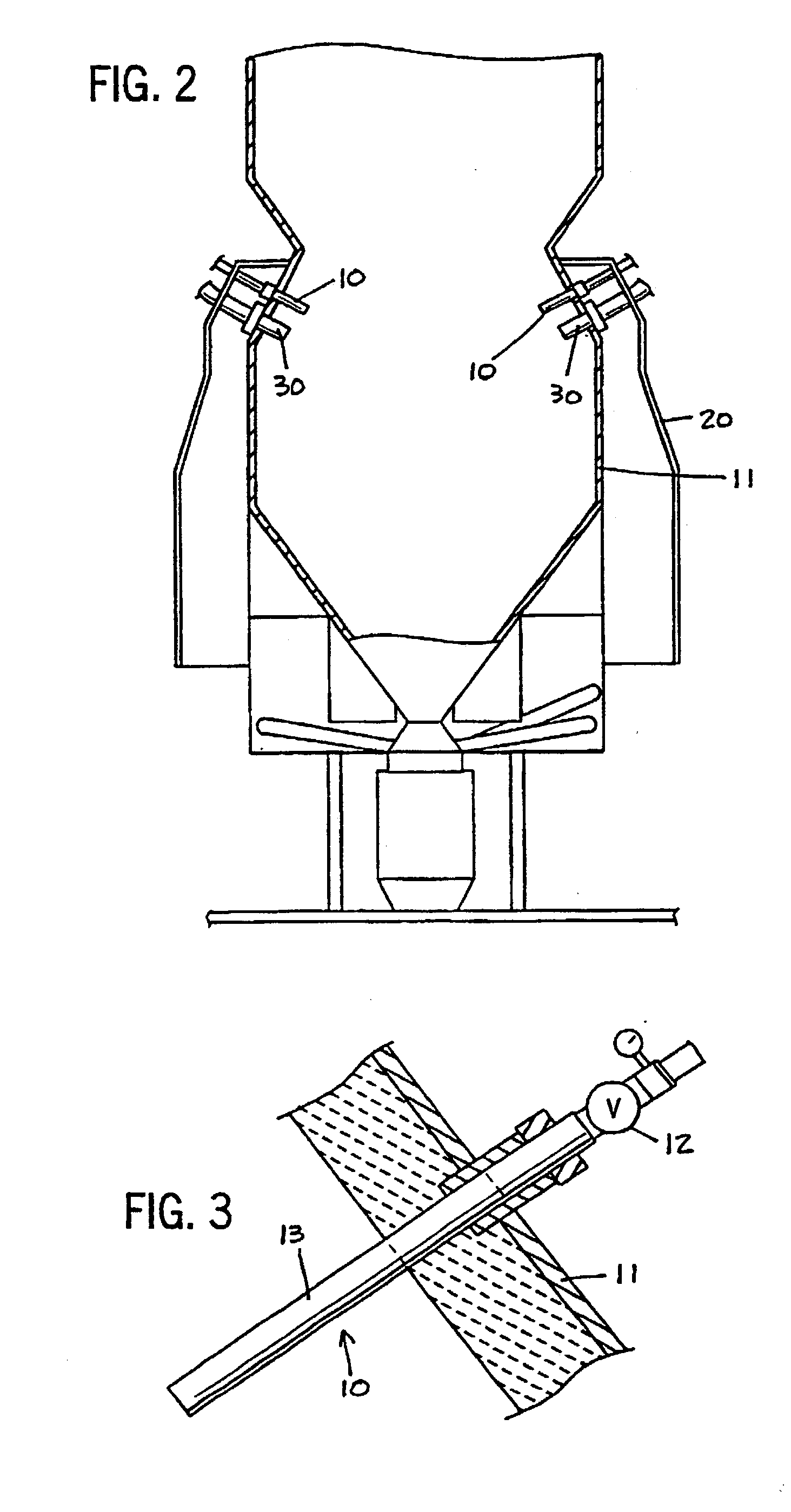

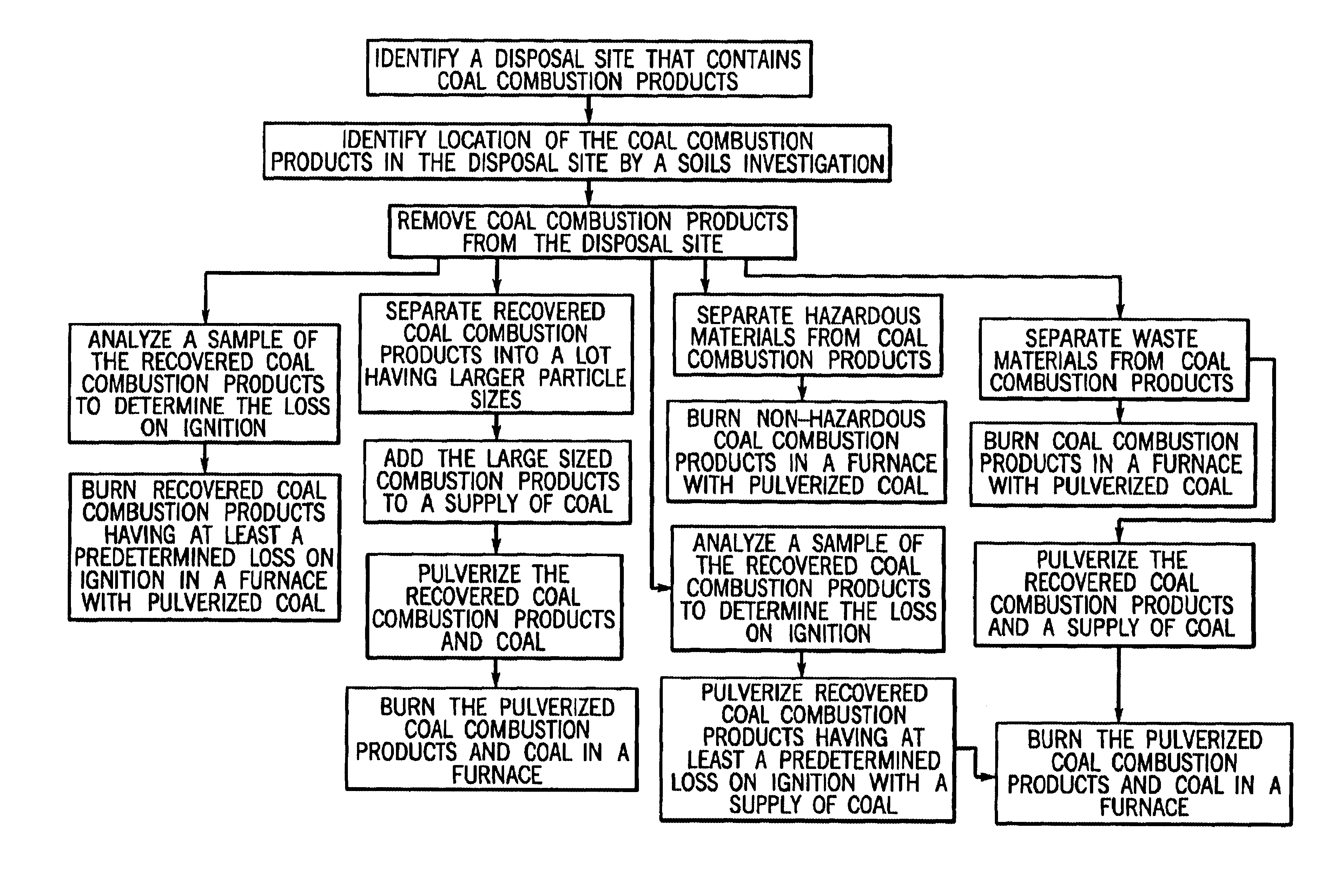

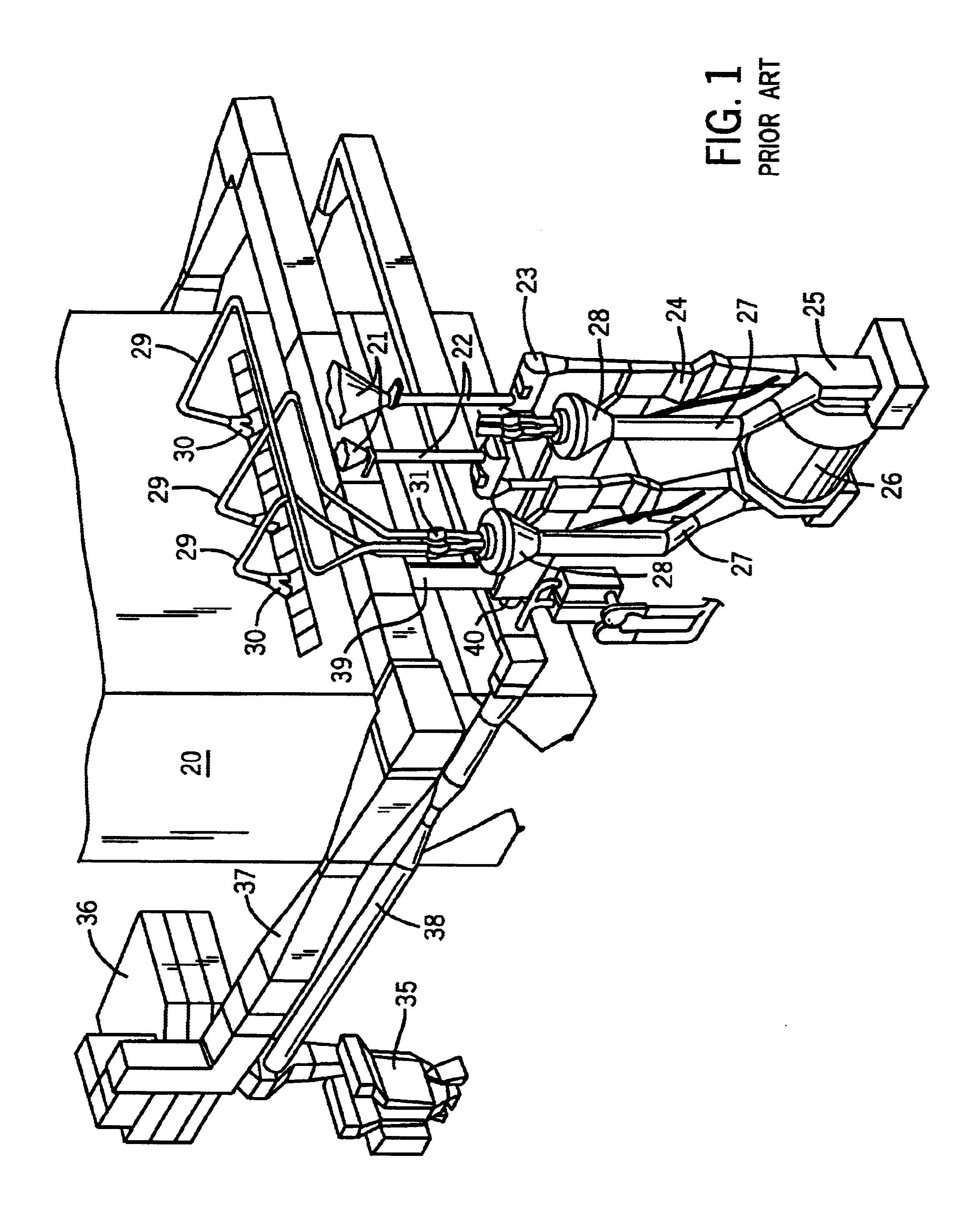

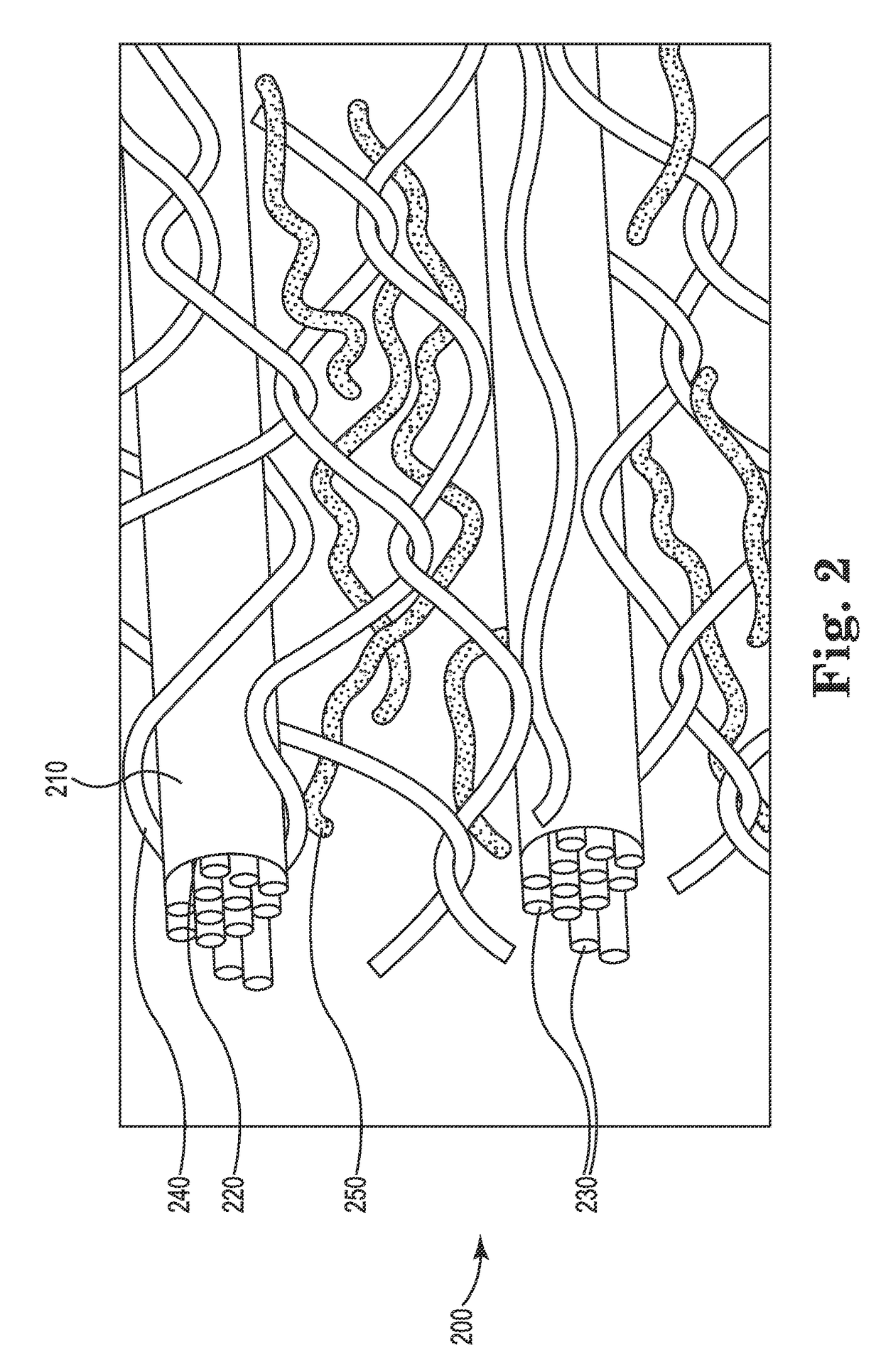

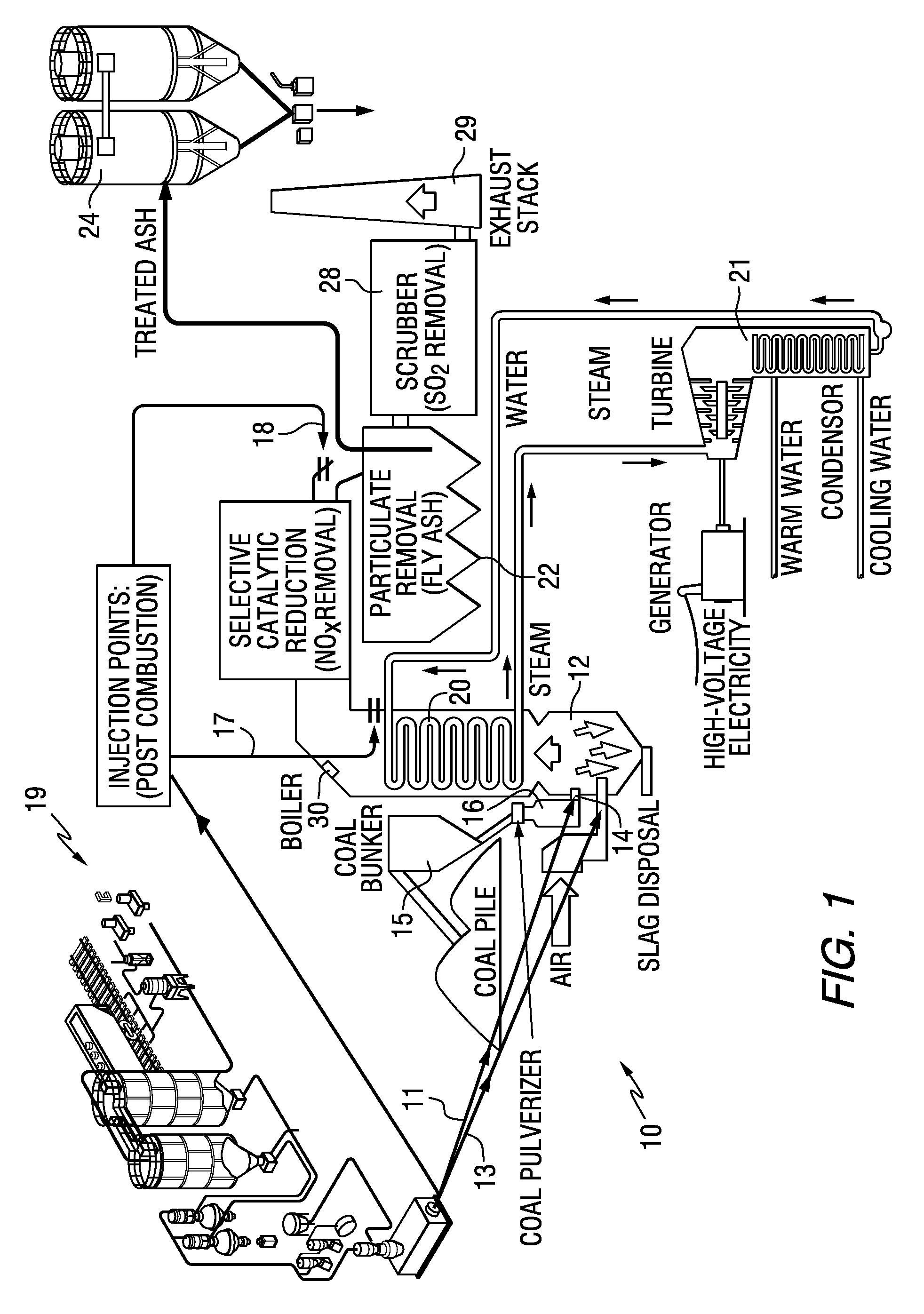

Coal combustion products recovery process

InactiveUS20030097970A1Low ignitionReduce lossSolid fuel pretreatmentCombustion using multiple fuelsBottom ashThermodynamics

A process for recovering the byproducts of a process that burns coal and for reusing the byproducts is disclosed. The process includes the steps of identifying a disposal site that contains the byproducts (typically fly ash and bottom ash), removing at least a portion of the byproducts from the disposal site, analyzing a sample of the portion of the byproducts to determine the loss on ignition of the portion of the byproducts, introducing the portion of the byproducts along with pulverized coal into a pulverized coal furnace if the portion of byproducts have a loss on ignition greater than or equal to a predetermined loss on ignition value (typically greater than or equal to 1 to 5%), and burning the portion of the byproducts in the furnace with the pulverized coal to render the byproducts into a commercially valuable fly ash and bottom ash having very low loss on ignition, typically lower than 3%.

Owner:WISCONSIN ELECTRIC POWER

Coal combustion products recovery process

InactiveUS6637354B2Low ignitionReduce lossSolid fuel pretreatmentCombustion using multiple fuelsBottom ashEnvironmental engineering

A process for recovering the byproducts of a process that burns coal and for reusing the byproducts is disclosed. The process includes the steps of identifying a disposal site that contains the byproducts (typically flyash and bottom ash), removing at least a portion of the byproducts from the disposal site, analyzing a sample of the portion of the byproducts to determine the loss on ignition of the portion of the byproducts, introducing the portion of the byproducts along with pulverized coal into a pulverized coal furnace if the portion of byproducts have a loss on ignition greater than or equal to a predetermined loss on ignition value (typically greater than or equal to 1 to 5%), and burning the portion of the byproducts in the furnace with the pulverized coal to render the byproducts into a commercially valuable fly ash and bottom ash having very low loss on ignition, typically lower than 3%.

Owner:WISCONSIN ELECTRIC POWER

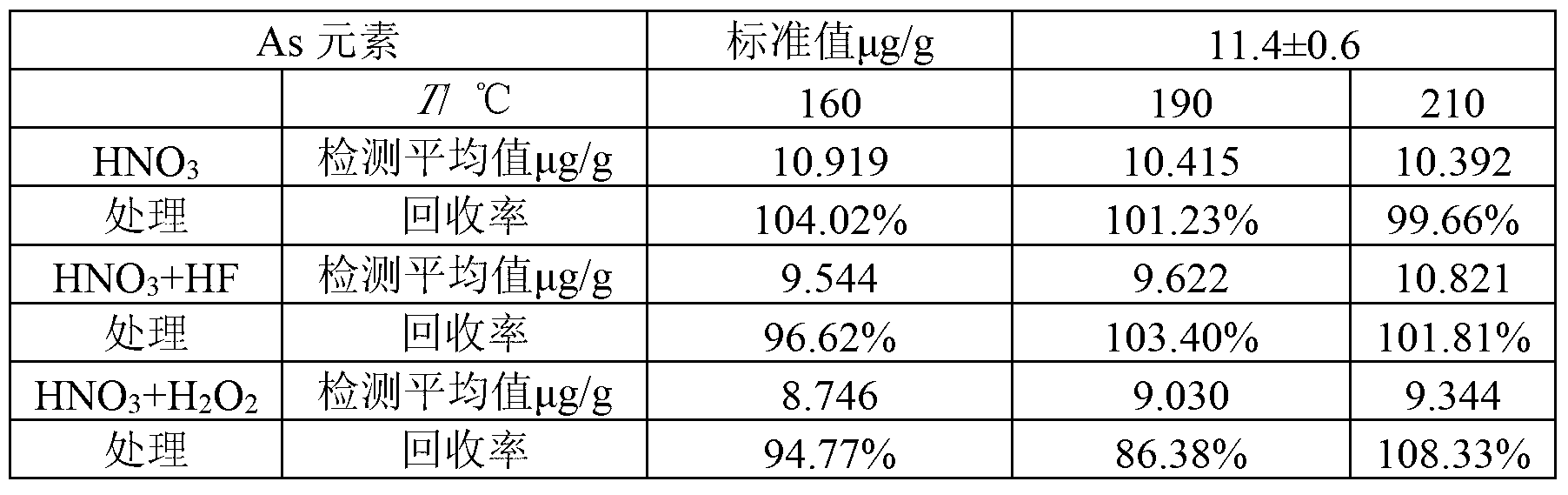

Determination method for volatile element arsenic in coal combustion product

InactiveCN103267796AReduce volatile lossShorten the timePreparing sample for investigationMaterial analysis by electric/magnetic meansQuantitative determinationInductively coupled plasma

The invention discloses a determination method for the volatile element arsenic in a coal combustion product. The method comprises the following steps: mixing a sample with a digestion solution and carrying out microwave digestion; adding deionized water to allow a constant volume of 100 mL to be obtained; and carrying out quantitative determination by using an inductively coupled plasma mass spectrometer. The determination method provided by the invention is a novel method which can overcome the disadvantages that arsenic easily suffers from volatilization loss in the process of pretreatment, time for sample treatment is long, a detection limit of a quantitative analysis instrument is not accurate enough and the like and has the advantages of high selectivity, easy and convenient operation, speed and high precision of determination results.

Owner:TIANJIN UNIV

Settable building material composition including landfill leachate

InactiveUS8236098B2High compressive strengthReduce Shrinkage ProblemsSolid waste managementCement productionBottom ashBoiler slag

A composition capable of setting to produce a building material is disclosed. The composition can include from 1% to 30% by weight of an activator, from 1% to 55% by weight of a pozzolan, such as fly ash; from 40% to 90% by weight of an aggregate; and liquid landfill leachate in a sufficient amount such that the composition sets to a building material having a compressive strength of at least 2 MPa, wherein all weight percentages are percent by weight of the total composition. The liquid landfill leachate replaces all or part of the tap water in a conventional composition for forming a building material. The liquid landfill leachate can be recovered after a liquid (typically water) percolates through a landfill and contacts at least one landfilled coal combustion product selected from fly ash, bottom ash, boiler slag, and flue gas desulfurization material. The building material can be a concrete, or a masonry unit.

Owner:WISCONSIN ELECTRIC POWER

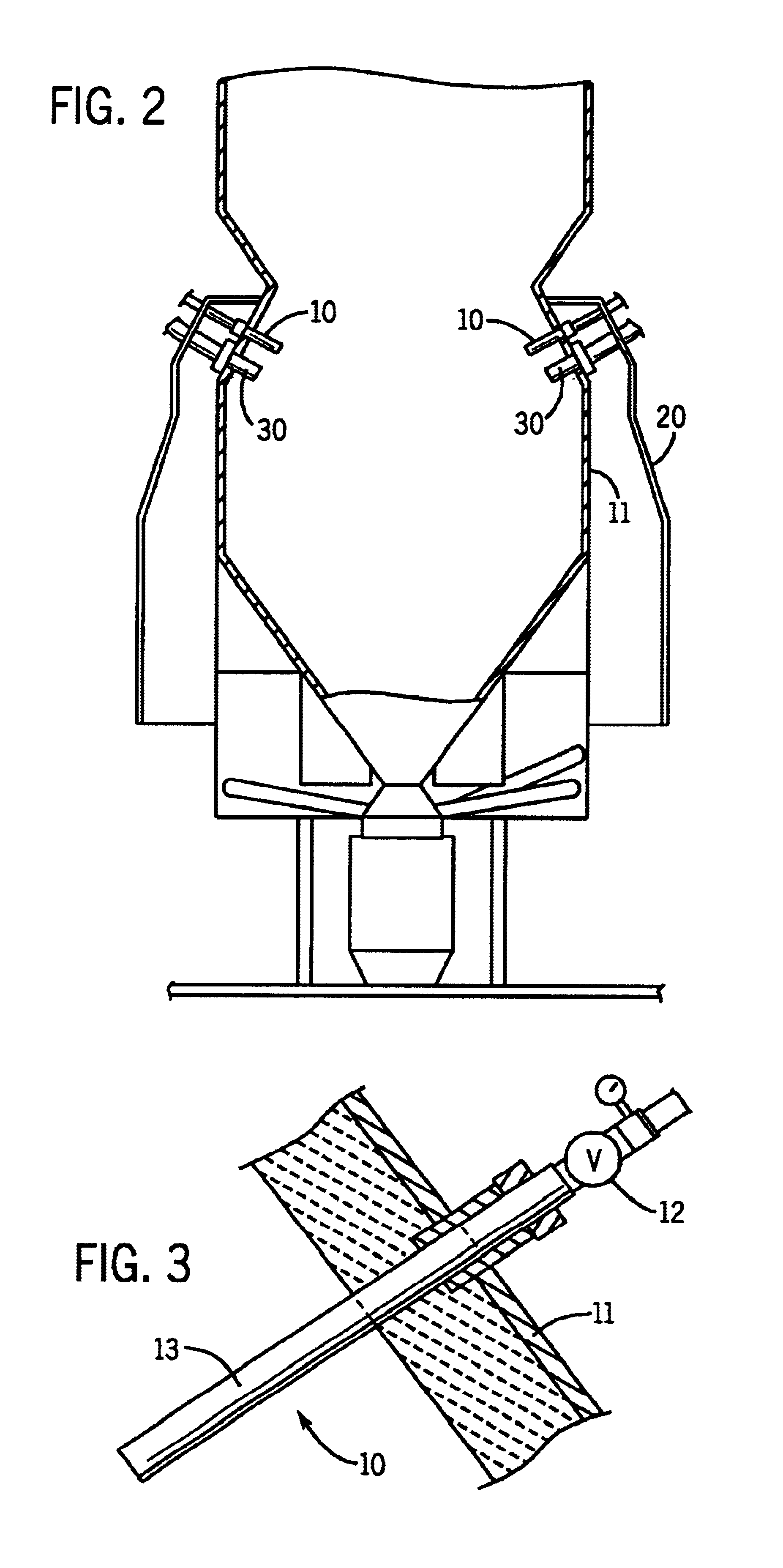

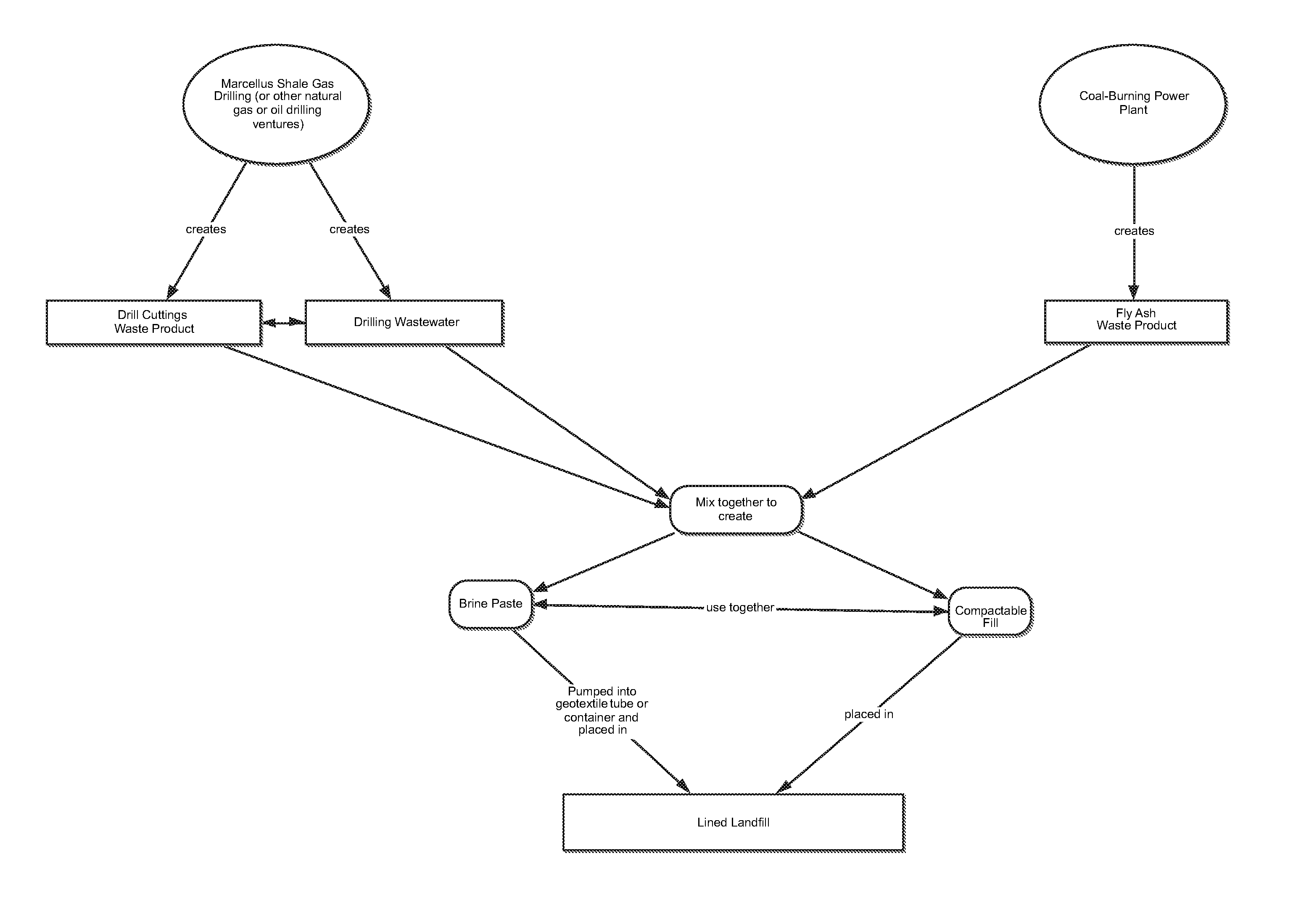

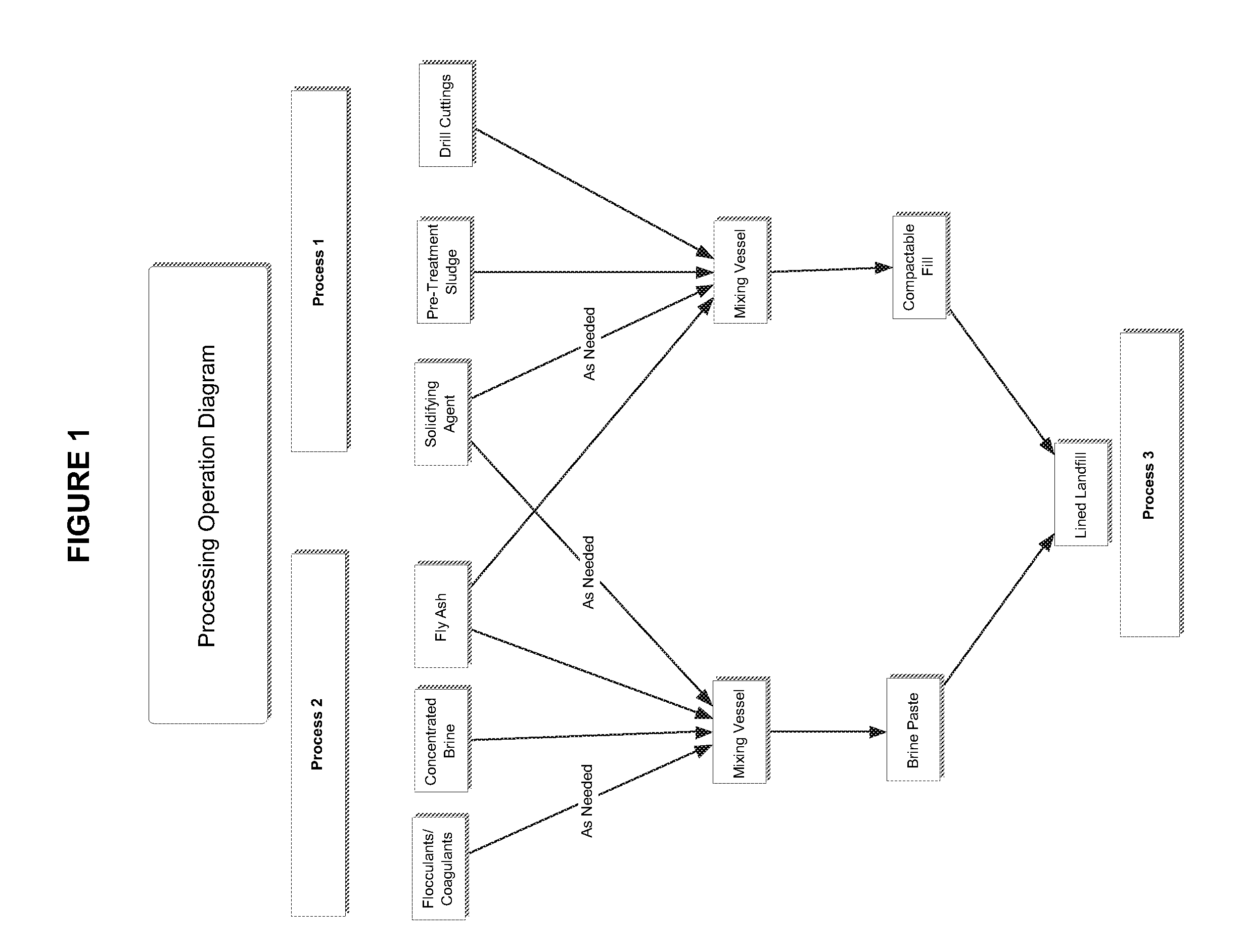

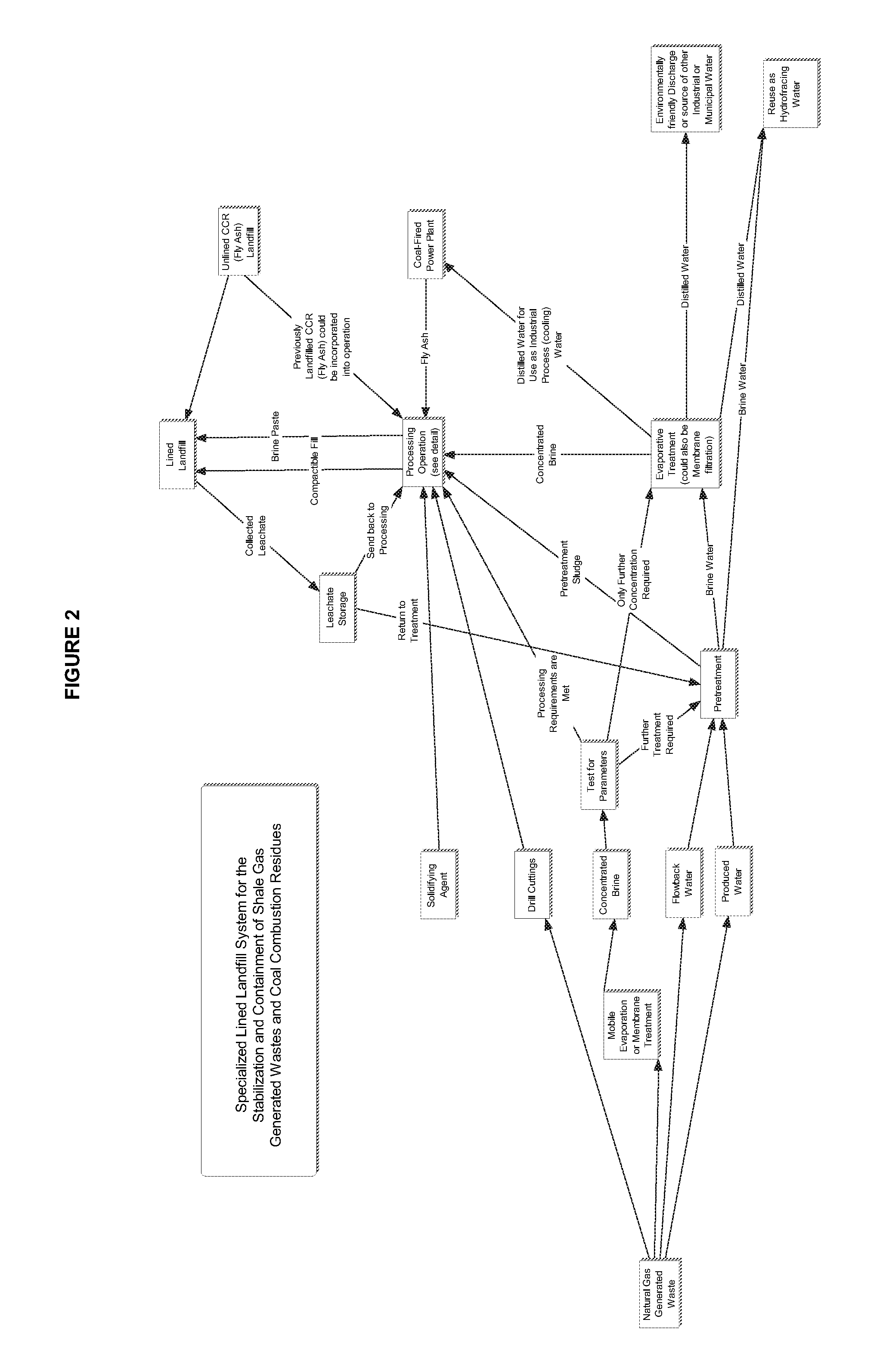

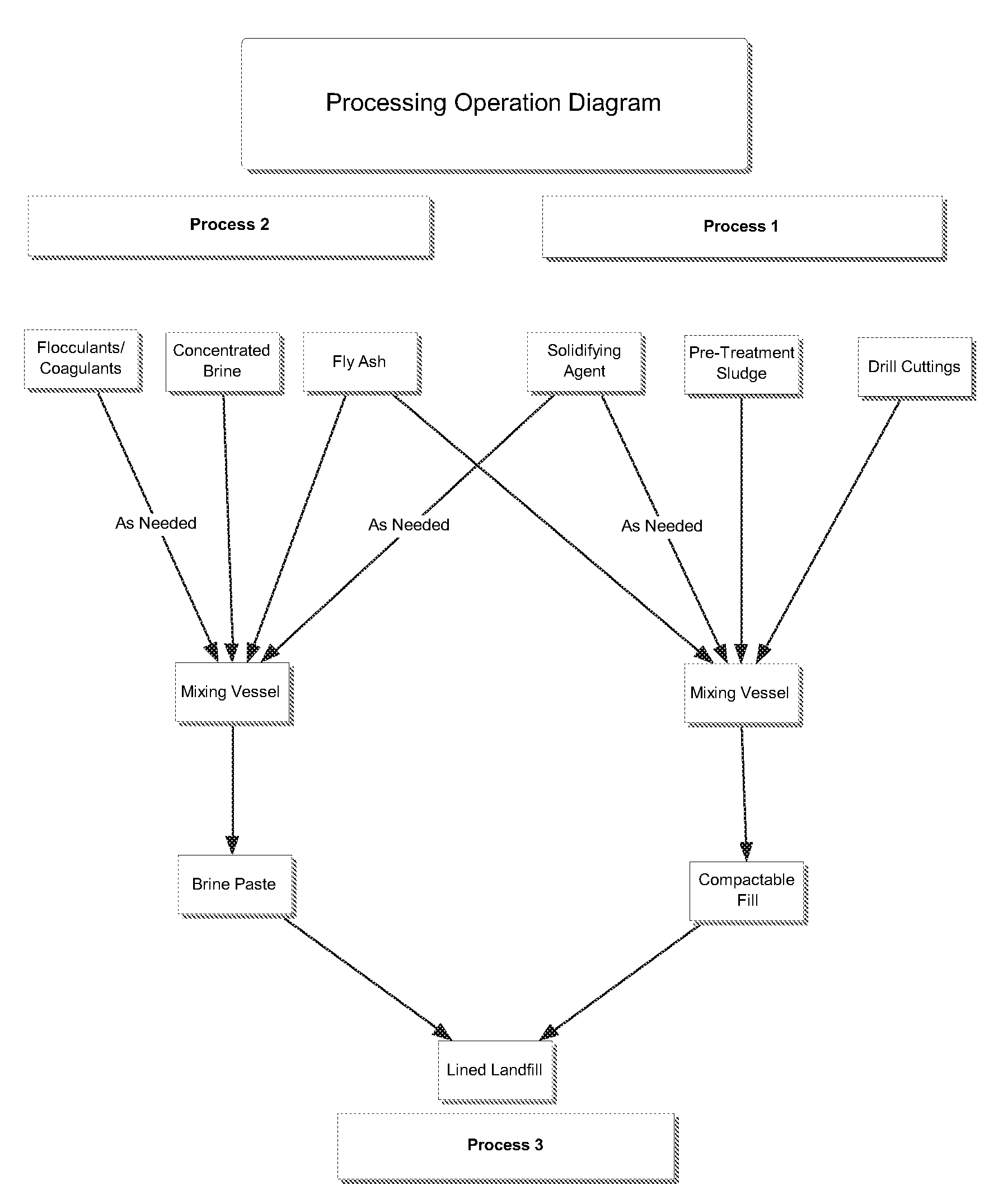

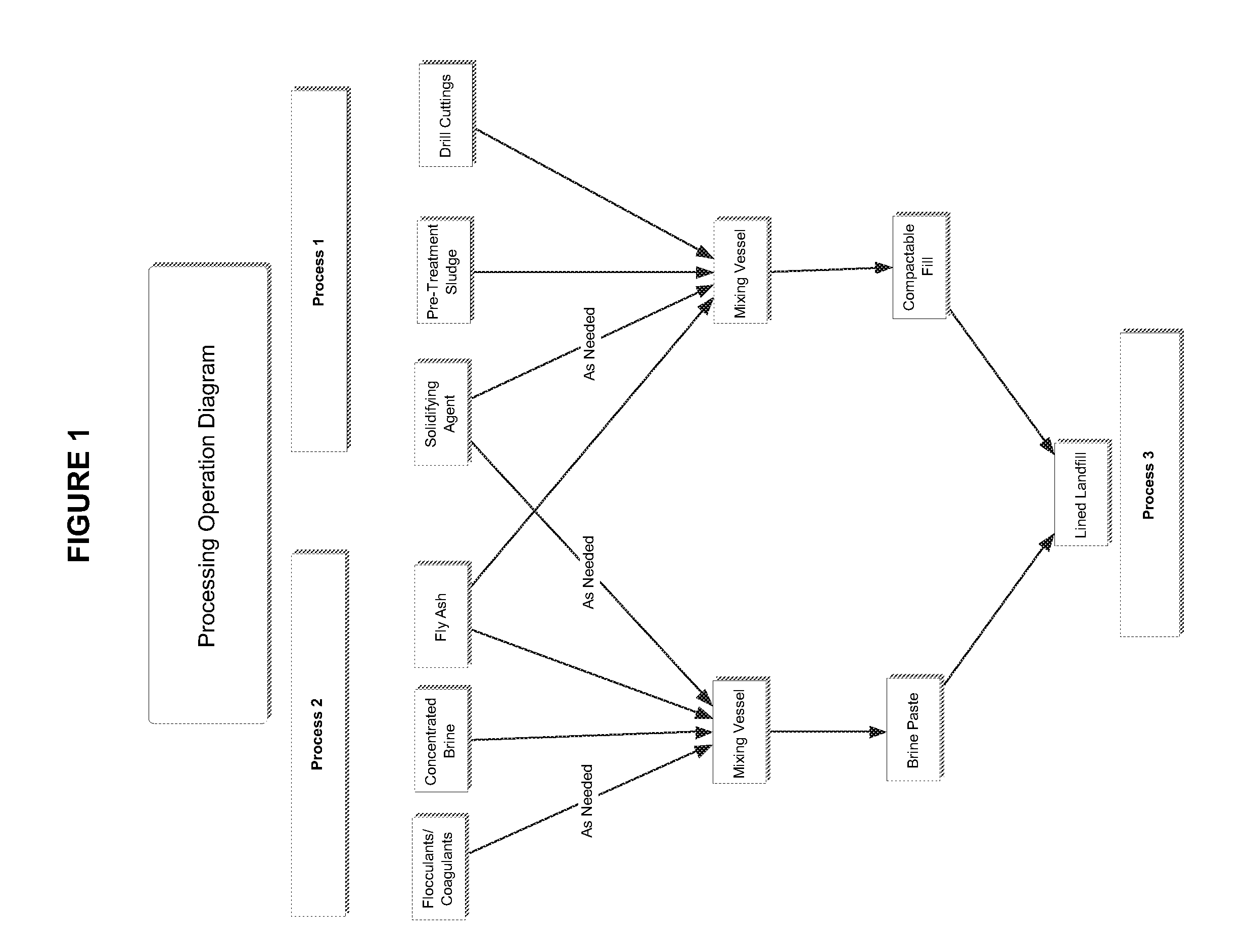

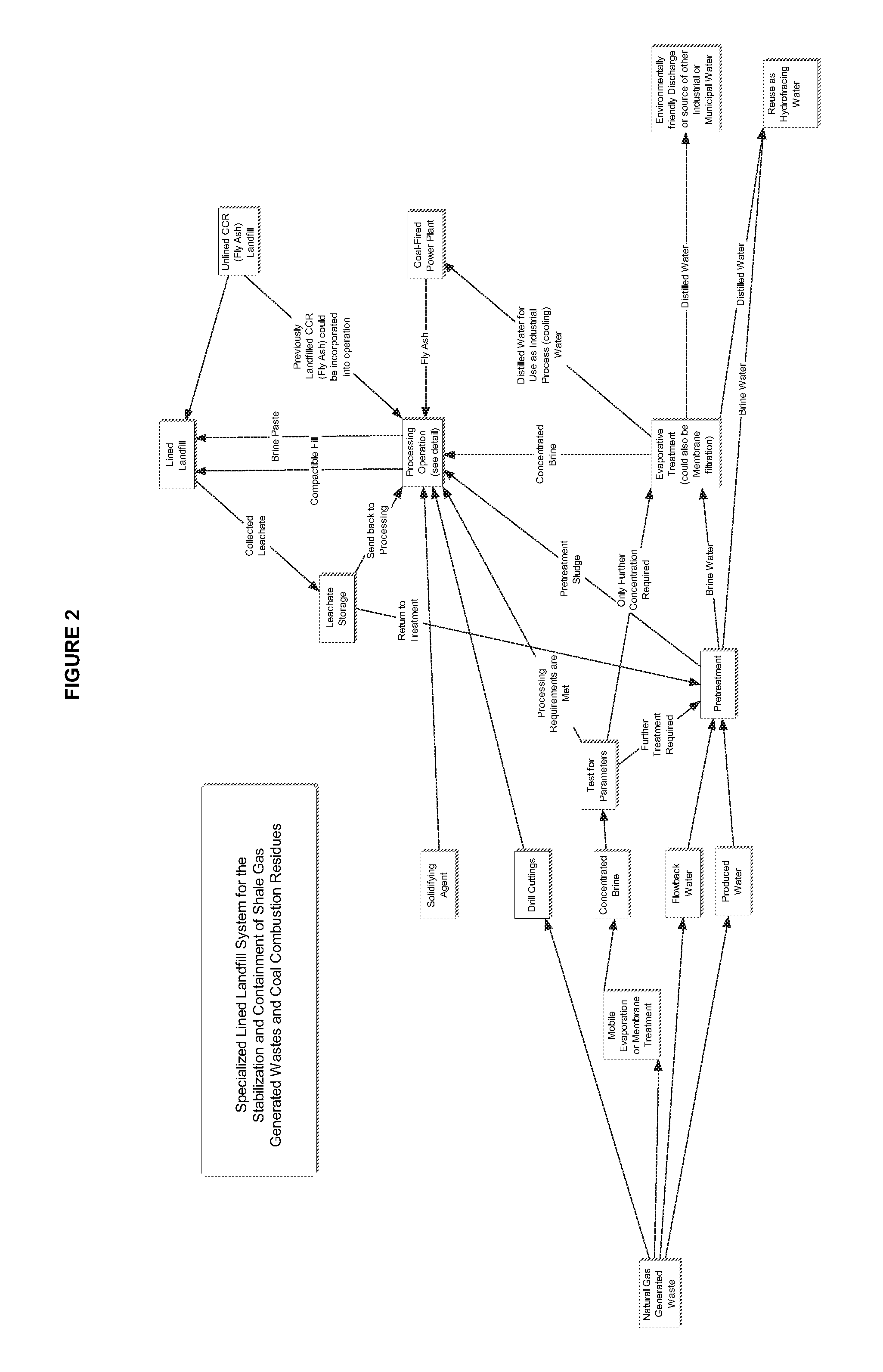

Specialized lined landfill system for the stabilization and containment of drilling wastes and coal combustion residues

ActiveUS20120271091A1Eliminate the effects ofEasy to placeSolid waste managementSolid waste disposalWell drillingLitter

Systems and methods of the present invention include a method for the treatment of drilling wastes and coal combustion residues, comprising combining at least a first drilling waste with coal combustion residues to form a paste, combining at least a second drilling waste with coal combustion residues to form a compactable fill, and placing the paste and the compactable fill in a landfill. Other embodiments include a method of treating drilling wastes and coal combustion residues, comprising combining at least one drilling waste with a coal combustion residue to form a paste. Further embodiments include containing the paste within at least one geotextile container. Still further embodiments include placing the geotextile container in a landfill.

Owner:MANNO JR JAMES JOSEPH +1

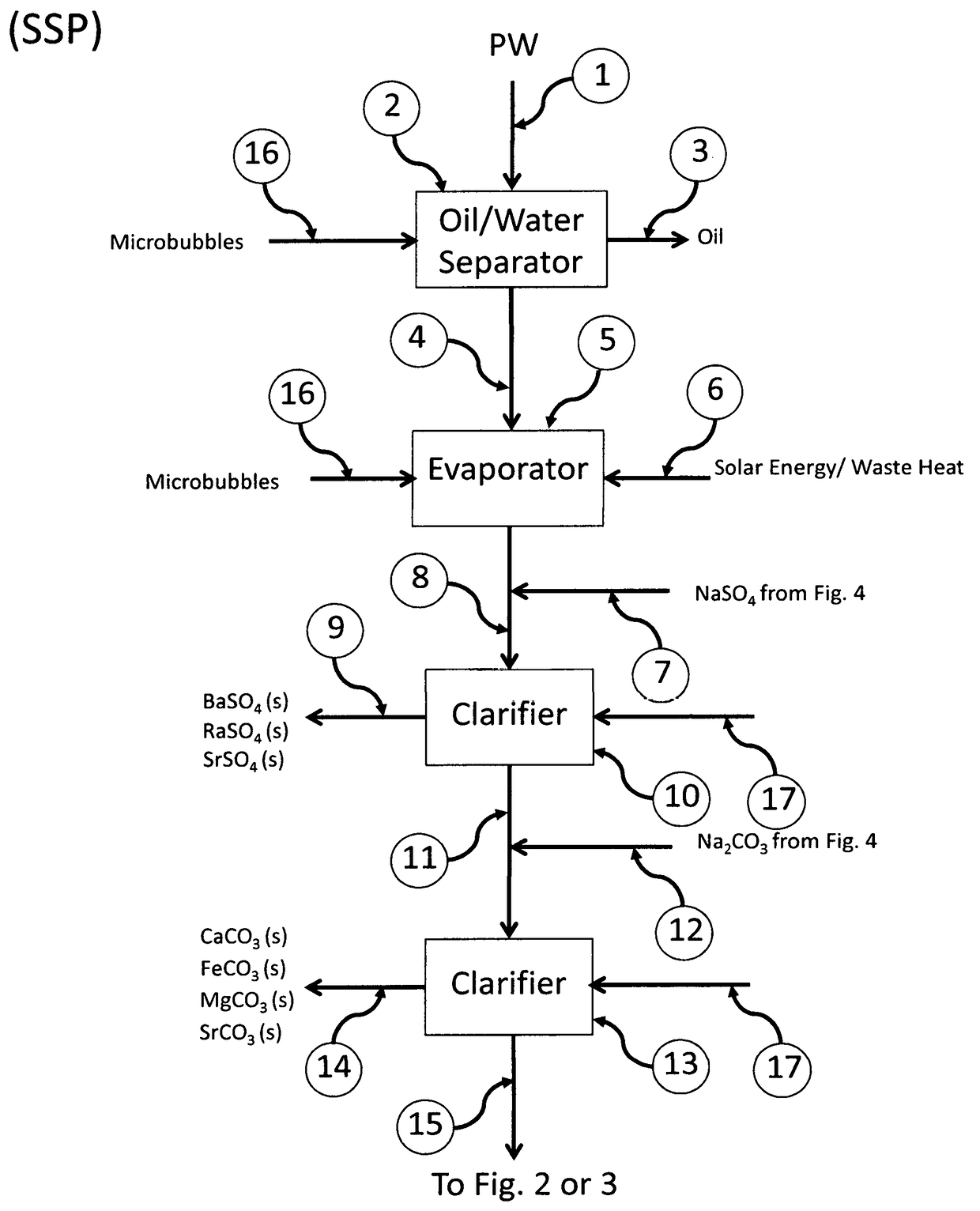

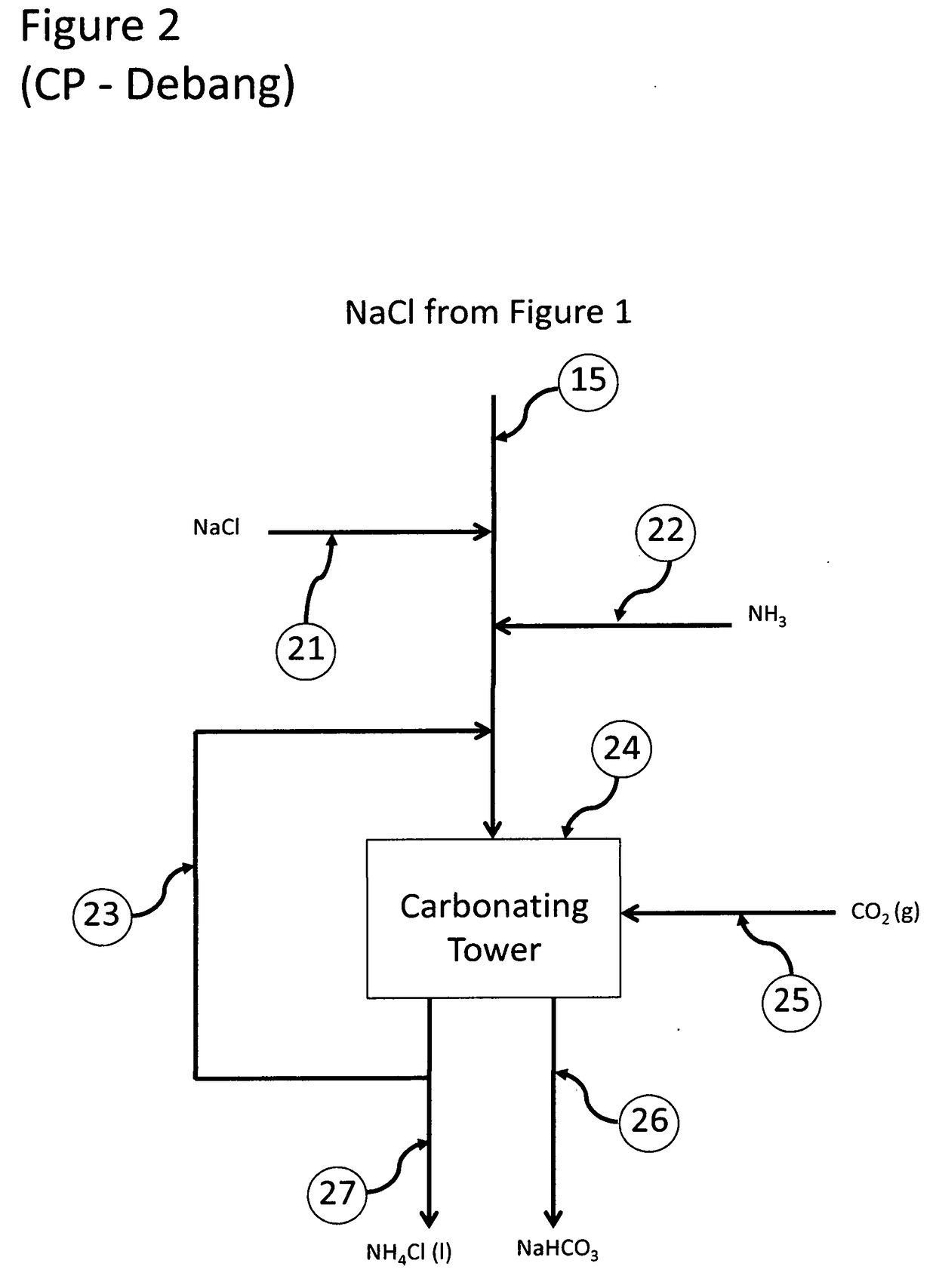

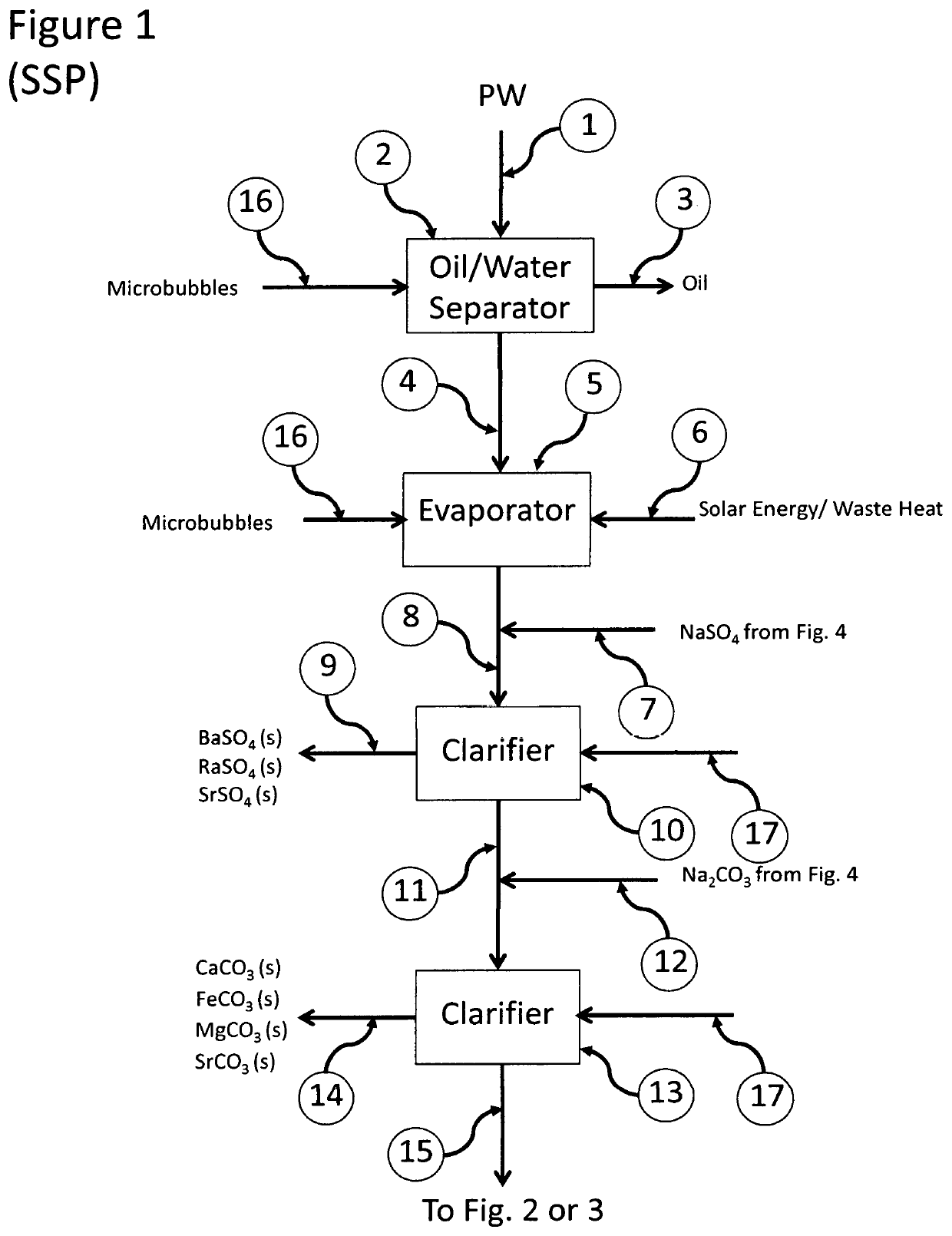

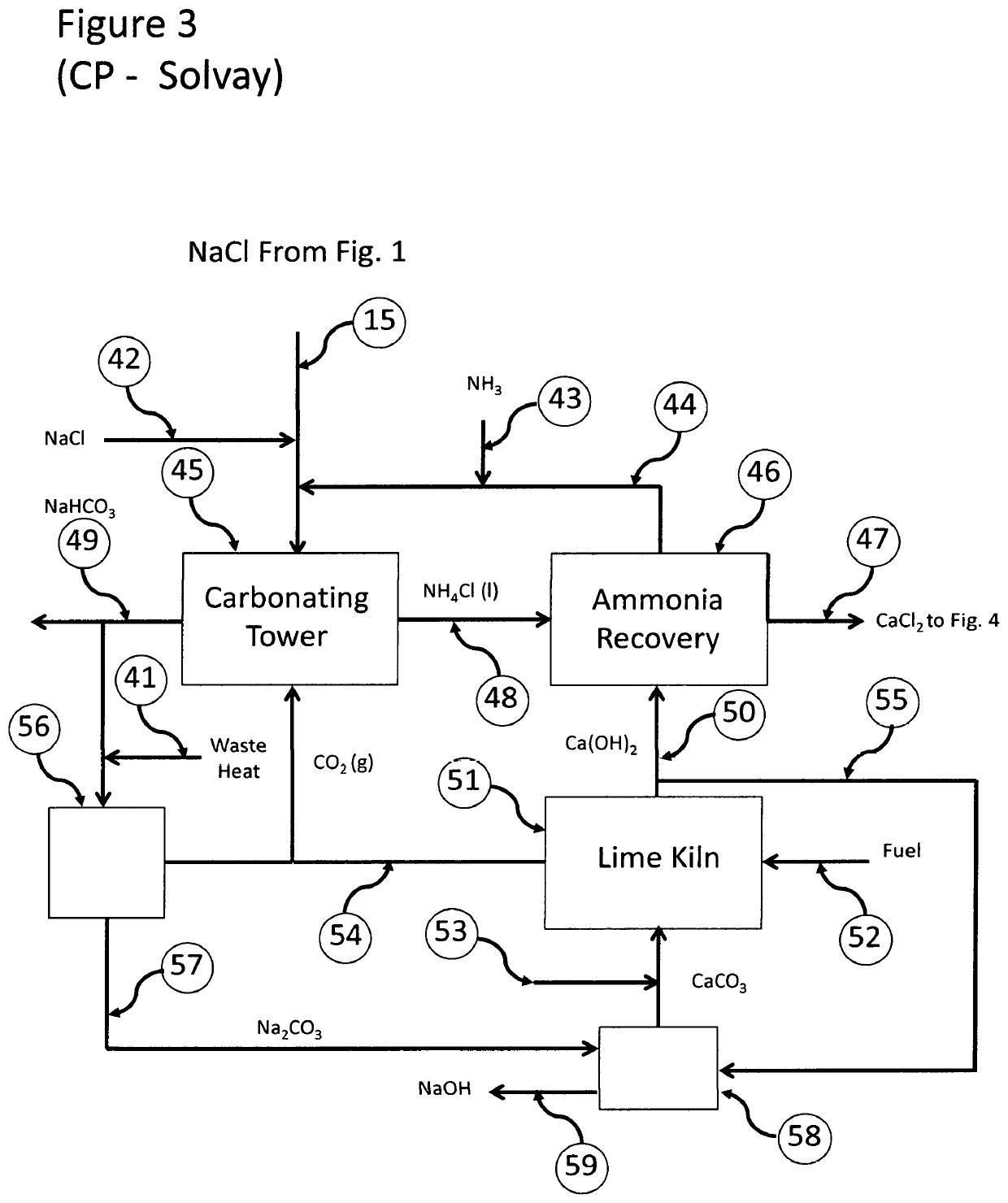

Recovery of Valuable Resources from Produced Water and Coal Combustion Products

ActiveUS20180022617A1Increase valueIncrease wasteWaste water treatment from quariesStrontium carbonatesFlue gasWaste stream

The present invention relates to processes employing water produced from wells that, after suitable purification steps, is processed to recover resources that can be used to treat other waste streams, such as flue gases and ashes from combustion of fossil fuels.

Owner:CORT STEVEN L

Coal combustion product cements and related methods of production

Coal combustion product cement compositions produced using classes of relatively low-cost industrial by-products and low-value minerals. A variety of highly sustainable cements with low-environmental impact can be provided. Coal combustion by-products and other wastes produced on the large scale from the burning of coal or coal and biomass in coal-fired power stations with or without low-value minerals, processed minerals, and / or by-products of the mining, mineral processing, metal refining, petrochemical, fine chemical, pharmaceutical, agrochemical, biotechnology, food, feed and energy industries, as well as agricultural and municipal by-products, can be utilized to provide improved cements and cementitious materials that are more economic and environmentally friendly than traditional cements including Portland cement.

Owner:CALSTAR CEMENT

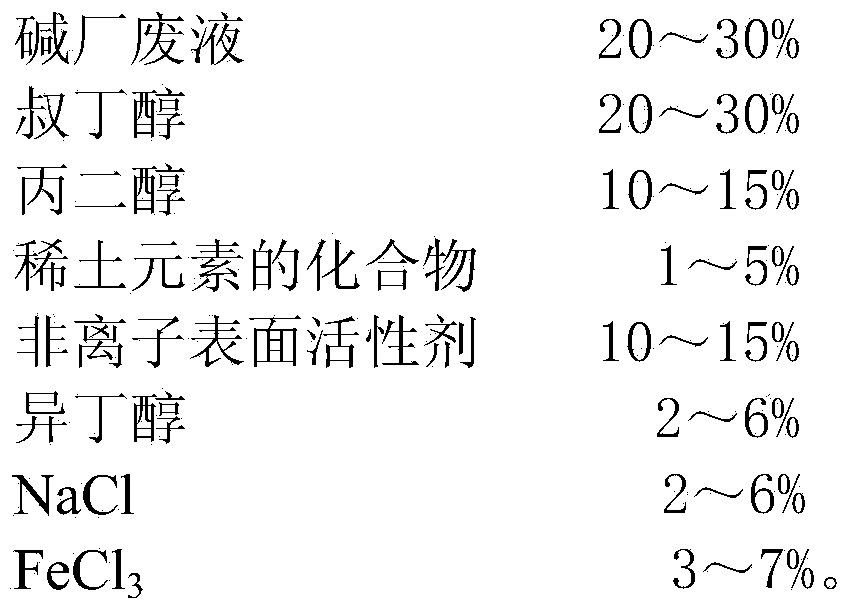

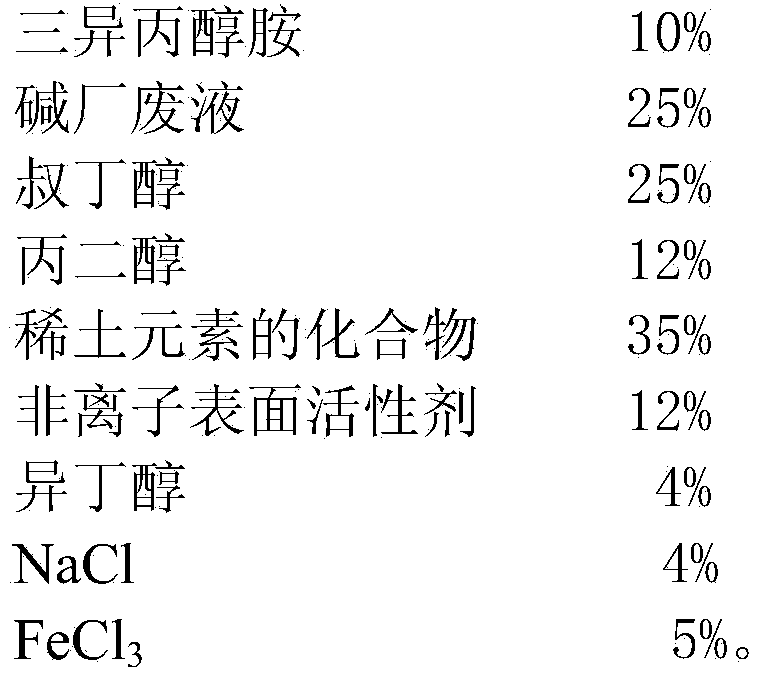

High-efficiency coal combustion catalyst

The invention relates to the technical field of coal combustion additives, particularly a high-efficiency coal combustion catalyst which is prepared from the following raw materials in percentage by weight: 5-15% of triisopropanolamine, 20-30% of alkali plant waste liquid, 20-30% of tert-butyl alcohol, 10-15% of propanediol, 1-5% of rare-earth element compound, 10-15% of nonionic surfactant, 2-6% of isobutanol, 2-6% of NaCl and 3-7% of FeCl3. When being used in the coal combustion process, the coal combustion catalyst can lower the ignition point of the coal and enhance the combustion velocity, thereby enhancing the coal combustion efficiency and lowering the discharge amount of harmful substances. By using the alkali plant waste liquid as the raw material, the coal combustion catalyst changes wastes into valuable substances and lowers the cost.

Owner:SCI RES ACADEMY OF GUANGXI ENVIRONMENTAL PROTECTION

Pulverized coal jet flow midstream and downstream combustion organization method in tangent circle pulverized coal combustion boiler

InactiveCN106287678AIncrease oxygen concentrationIncrease burn rateCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBurning tissueCombustor

The invention discloses a pulverized coal jet flow midstream and downstream combustion organization method in a tangent circle pulverized coal combustion boiler. Corresponding wall air nozzles are distributed in a hearth main combustion area of the pulverized coal combustion boiler in a manner of corresponding to primary air pulverized coal combustors, and are formed in the positions, close to the pulverized coal jet flow midstream and downstream positions of outlets, of a hearth water cooling wall, part of hot air is introduced into the wall air nozzles, and is directly sprayed into the corresponding primary air pulverized coal jet flow midstream and downstream interval in a jet flow manner, pulverized coal jet flow midstream and downstream combustion organization is carried out, the oxygen concentration and the pulverized coal combustion rate of the pulverized coal jet flow midstream and downstream interval are improved, and wall attaching happening of the pulverized coal jet flow midstream and downstream interval is directly obstructed. According to the method, pulverized coal jet flow midstream and downstream interval combustion organization and control can be achieved, happening of water cooling wall coking and high-temperature corrosion is prevented, the pulverized coal combustion efficiency is further improved, NOx generation and emissions are reduced, the proper combustion capacity of the pulverized coal combustion boiler for combustion low-volatile lower-ash-melting-point coal is expanded, and the fuel procurement cost is reduced.

Owner:张泽

Desulfurization, dedusting and coal combustion promoter

The invention discloses a preparation method of a desulfurization, dedusting and coal combustion promoter, and is characterized in that the method comprises the following process steps: according to the mass percentage concentration, adding 20%-30% of potassium nitrate, 10-16% of aluminum nitrate, 12-20% of calcium carbonate, 5-10% of potassium permanganate, 15-25% of soluble starch, 4-10% of ferric chloride and 8-18% of betaine into a reactor, wherein the sum of the percentages of all the components is 100%; and mixing evenly, and thus obtaining the coal desulfurization, dedusting and coal combustion promoter. The preparation method has the advantages of simple preparation process, low production cost and easy industrialized production, is not corrosive to a boiler with long-term use, can also reduce fouling of calcium sulfate in the boiler, improves the service life of the boiler, and improves the combustion efficiency of coal.

Owner:龙祥雨(深圳)科技有限公司

Recovery of valuable resources from produced water and coal combustion products

ActiveUS10875785B2Increase valueIncrease wasteWaste water treatment from quariesStrontium carbonatesWaste streamFlue gas

The present invention relates to processes employing water produced from wells that, after suitable purification steps, is processed to recover resources that can be used to treat other waste streams, such as flue gases and ashes from combustion of fossil fuels.

Owner:CORT STEVEN L

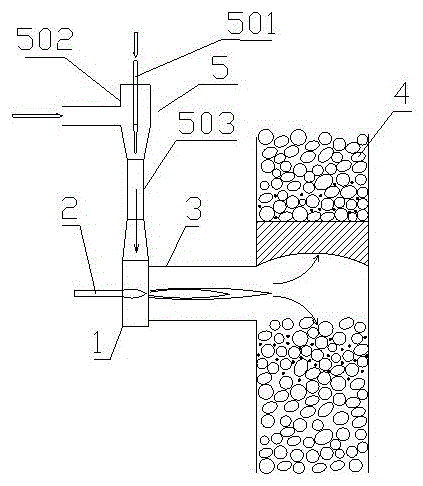

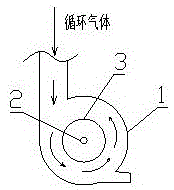

Pulverized coal combustion process in annular lime kiln and application thereof

ActiveCN105036573AReduce the probability of reactionInhibition productionCombustion chamberReaction rate

The invention relates to a pulverized coal combustion process in an annular lime kiln and application thereof. The process comprises the following steps: (1) anoxic ignition combustion of pulverized coal in a volute; (2) combustion of pulverized coal volatile matters in a combustion chamber; and (3) combustion of pulverized coal fixed carbon in a material bed. The process provided by the invention is used for calcining limestone. The process has the advantages that because of oxygen debt, the combustion temperature level and the combustion speed level are low, the combustion process is delayed, the NOx reaction rate is reduced in a reducing atmosphere, and the NOx yield in the area is inhibited; the circulating gas in the step (2) has large overall weight and high flow rate, the heat generated by combustion of volatile matters can be diluted and quickly transferred into a limestone material bed, the decreasing amplitude of the temperature of the combustion chamber is relatively large, and thus coal ash fusion nodulation and refractory material damage caused by accumulation of the heat in the combustion zone are avoided; and the burn-off rate of fixed carbon in the step (3) is improved, the content of CO in the tail gas is reduced to be 100-150mg / Nm<3>, and when the process provided by the invention is used for calcining limestone, the heat loss is reduced to 860kCal / kg from 930kCal / kg.

Owner:包头东盛科技有限公司 +1

System for co-firing cleaned coal and beneficiated organic-carbon-containing feedstock in a coal combustion apparatus

A co-firing process is described using cleaned coal and processed biomass to reduce adverse by-products in a coal combusting apparatus. The coal feedstock comprises an aggregate blend of cleaned coal and processed biomass. The biomass feedstock comprises processed biomass pellets. The total energy density is predetermined and can be similar to the coal component or higher than the coal component. The intracellular salt in the processed biomass is at least 60 wt % less for the processed organic-carbon-containing feedstock used to make the processed biomass pellets than that of the starting un-processed processed organic-carbon-containing feedstock. The cleaned coal has a sulfur content that is 50 wt % less than that of un-cleaned coal before it passed through the coal-cleaning sub-system.

Owner:CTP BIOTECH LLC

System for co-firing coal and beneficiated organic-carbon-containing feedstock in a coal combustion apparatus

Owner:CTP BIOTECH LLC

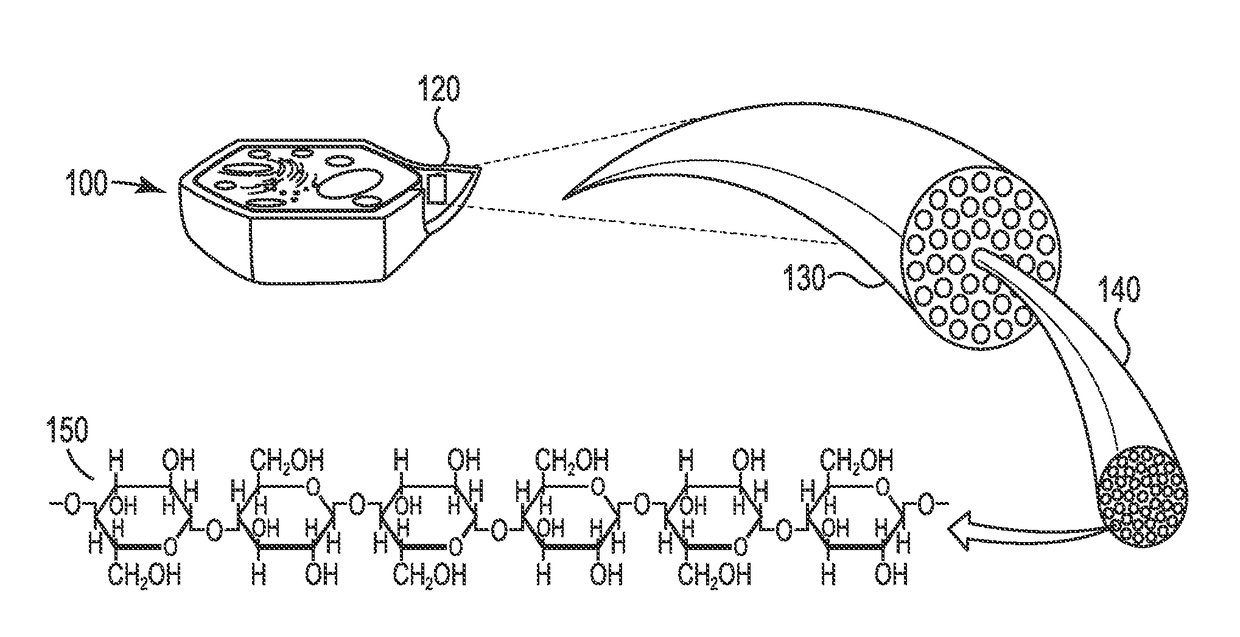

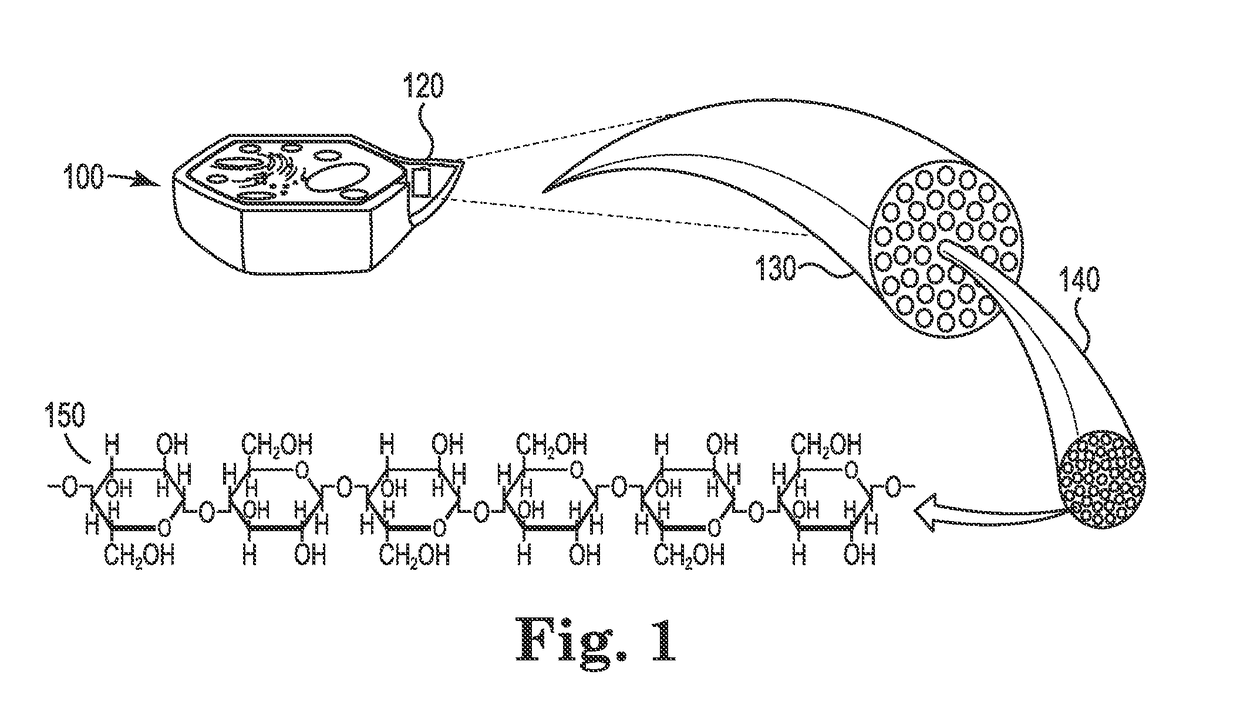

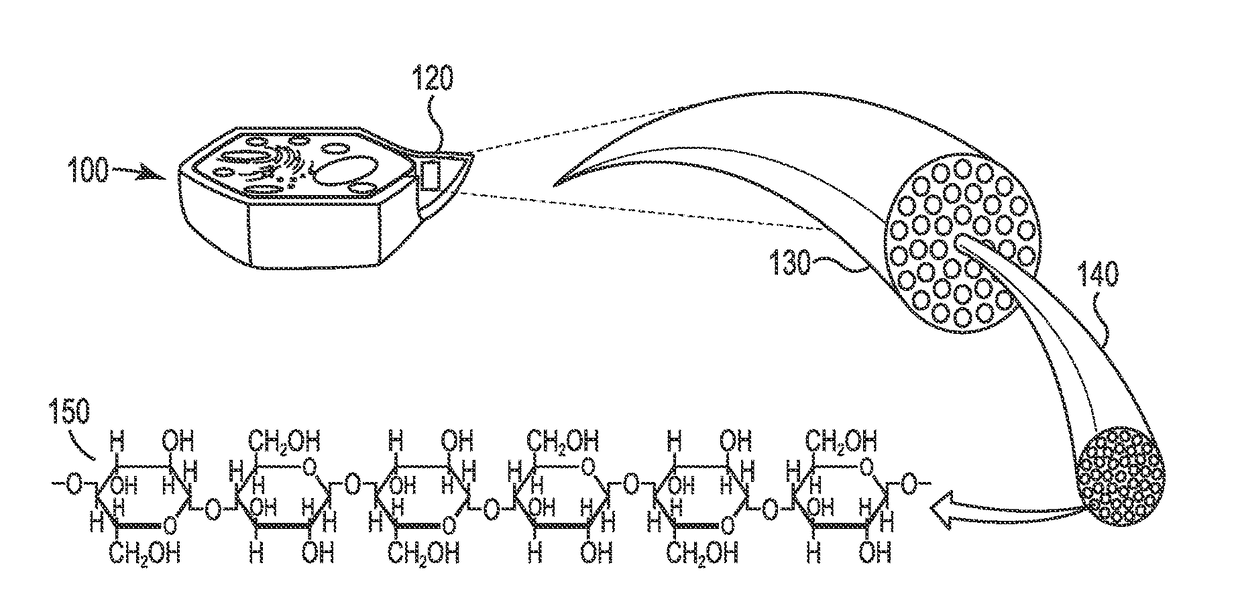

Production of coal combustion products for use in cementitious materials

ActiveUS8961684B2Small particle sizeIncrease surface areaSolid waste managementCoatingsMaterials scienceCoal combustion products

A method and system for producing modified coal combustion products are disclosed. The additives reduce the particle sizes of the coal combustion product and may reduce the amount of un-burned carbon in the coal combustion product, making the modified product useful as an addition to cementitious materials.

Owner:ASH IMPROVEMENT TECH

Specialized lined landfill system for the stabilization and containment of drilling wastes and coal combustion residues

ActiveUS8807871B2Eliminate the effects ofEasy to placeSolid waste managementSolid waste disposalEnvironmental engineeringCoal combustion products

Systems and methods of the present invention include a method for the treatment of drilling wastes and coal combustion residues, comprising combining at least a first drilling waste with coal combustion residues to form a paste, combining at least a second drilling waste with coal combustion residues to form a compactable fill, and placing the paste and the compactable fill in a landfill. Other embodiments include a method of treating drilling wastes and coal combustion residues, comprising combining at least one drilling waste with a coal combustion residue to form a paste. Further embodiments include containing the paste within at least one geotextile container. Still further embodiments include placing the geotextile container in a landfill.

Owner:MANNO JR JAMES JOSEPH +1

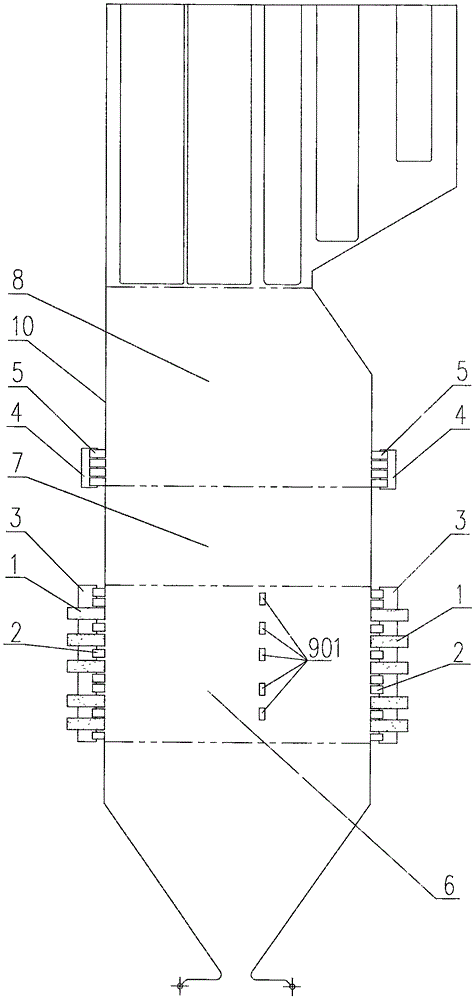

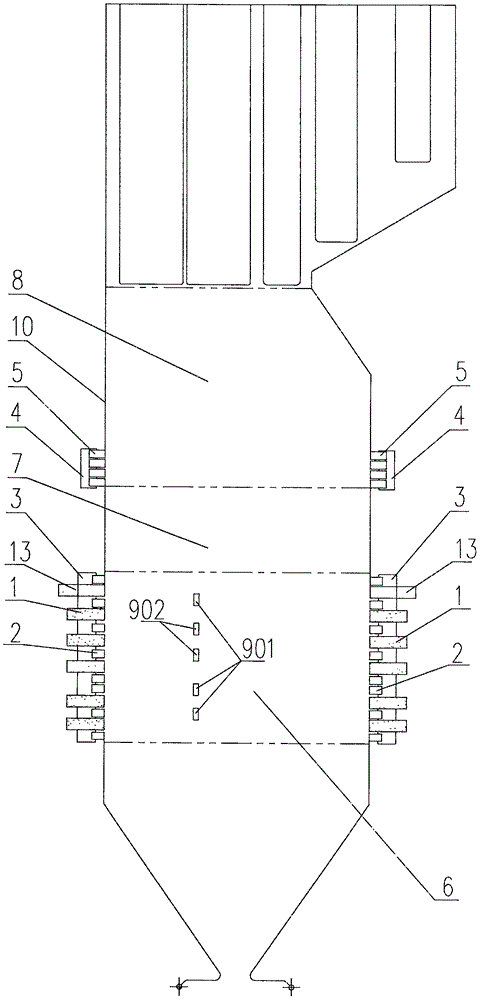

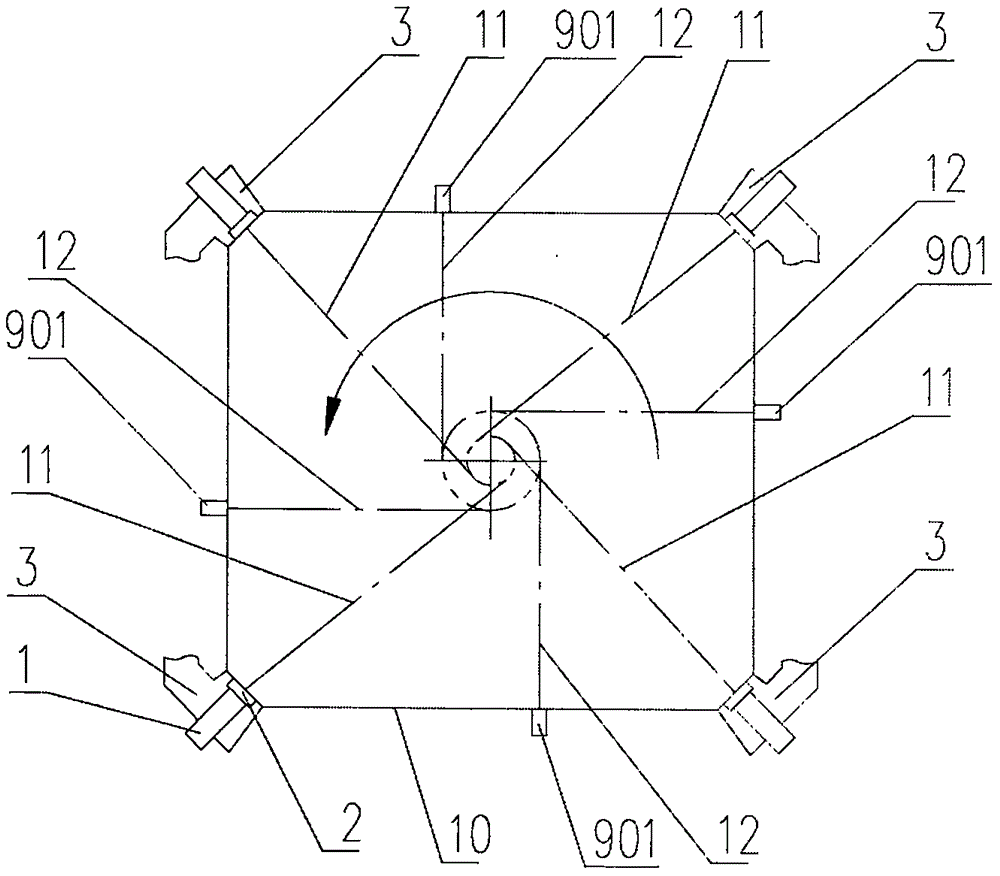

Boiler combustion return device and boiler combustion system with the device

ActiveCN106439800BReduce the temperatureAvoid damageFluidized bed combustionApparatus for fluidised bed combustionCombustion systemProcess engineering

The invention discloses a boiler combustion returning device and a boiler combustion system with the same. The boiler combustion returning device and the boiler combustion system with the same have the advantages that part of coal ash is returned to a boiler through the returning device and combined with coal, so that combustion speed is decreased, and the coal cannot be combusted instantly; since the coal ash derives from coal combustion, introduction of other dust impurities is not required; the coal ash from the boiler is extremely high in heat, and accordingly secondary heat use is achieved to a certain degree when the coal ash is returned, and coal combustion is saved; uneven contact between the large-particle coal ash and the coal is adverse to sufficient combustion of the coal, and accordingly a selecting mechanism is arranged to select relatively even coal ash, control the size of the coal ash and prevent large-particle coal ash from entering the boiler; a flow control mechanism is capable of adjusting a ratio of the coal to the coal ash, so that coal combustion speed is controlled.

Owner:杭州红山热电有限公司

Coal combustion process and combustion furnace thereof

ActiveCN106838861AEmission reductionAvoid energy lossSteam boilersSmall footprintOxy-fuel combustion process

A coal combustion process and its combustion furnace. The equipment of the present invention uses pure oxygen to react with coal as fuel, and uses the micro-negative pressure of the furnace to control the combustion temperature in the furnace to avoid energy loss caused by flue gas circulation and the impact on the furnace due to circulation. The wear of the wall is relatively serious; compared with the current circulating fluidized bed boiler, IGCC and oxygen-enriched combustion process, the equipment investment is small, the floor space is small, the structure is simple, the combustion temperature is high, and the environment and carbon emissions are small.

Owner:云南大为制焦有限公司

Catalyst for catalyzing simultaneous coal char combustion and in-situ denitration and application method thereof

InactiveCN110420638AImprove combustion efficiencyEmission reduction releaseDispersed particle separationSolid fuelsReduction ratePollutant emissions

The invention discloses a catalyst for catalyzing simultaneous coal char combustion and in-situ denitration and an application method thereof, belonging to the technical field of efficient catalytic combustion of coal and coke and pollutant emission reduction. According to the invention, Fe or a Fe and CaO composite or a Fe and CeO2 composite is selected as the catalyst, and under the condition that the addition amount of the catalyst is 1-15% of the mass of coal char and the mass ratio of Fe to CaO or Fe to CeO2 is 0.1-3, the ignition point of the coal char can be reduced, the burning rate ofthe coal char can be improved, and meanwhile, the NOx emission amount in the coal char combustion process can be effectively reduced. The catalyst can reduce the ignition temperature and burnout temperature of coke powder by 15.1 DEG C and 68.8 DEG C respectively, and the NO emission reduction rate can reach 39.6%. The catalyst is cheap and easy to obtain, realizes high-efficiency utilization ofwaste, also has simple operation and easy realization in use process, and has good application prospect.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

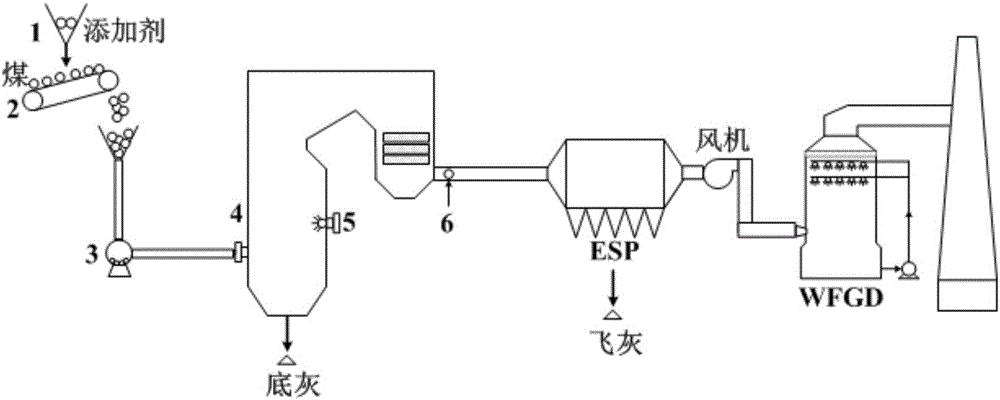

Method for regulating oriented conversion of uranium in coal combustion process

ActiveCN106350146AAdequate responseBoost Targeted ConversionsLighting and heating apparatusSolid fuelsBottom ashBoiler furnace

The invention discloses a method for regulating the oriented conversion of uranium in a coal combustion process. The method comprises the following steps of (1) adopting a sequential chemical extraction method and an inductively coupled plasma mass spectrometry for testing the content m1 of organic combined state uranium in coal; (2) according to the content m1 of the organic combined state uranium in the step (1), confirming the additive amount m2 of an additive to be equal to k1.m1, wherein the k1 is an excess coefficient; (3) adding the additive into a coal handling system through an additive adding system, fully mixing the additive and the coal in a coal mill, combusting in a boiler furnace, and reacting the additive and gas-state uranium in the furnace to generate solid-state uranate, wherein the solid-state urinate is fixed in bottom ash. According to the method provided by the invention, without influencing the normal combustion of a boiler, the oriented conversion from a gas-state uranium product to the solid-state uranate can be effectively promoted, the release of the uranium during the coal combustion process can be effectively reduced as long as adding a little cheap additive, and the method is simple to operate and lower in investment and operation cost.

Owner:HUAZHONG UNIV OF SCI & TECH

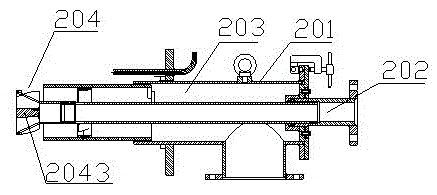

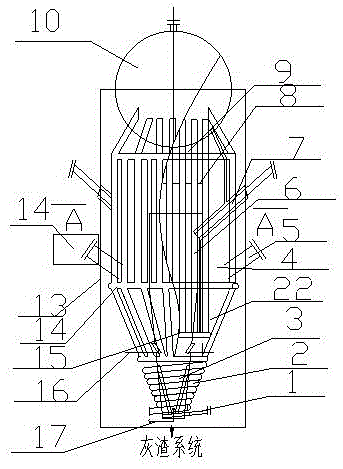

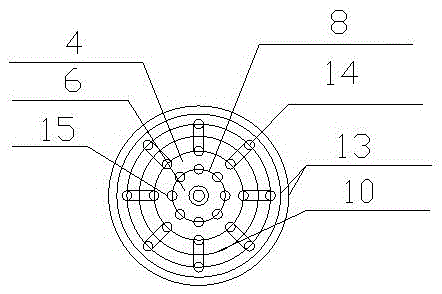

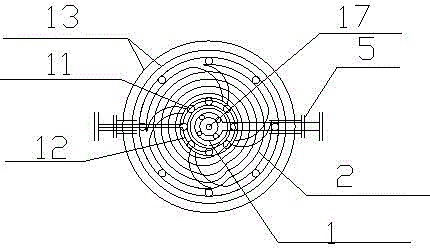

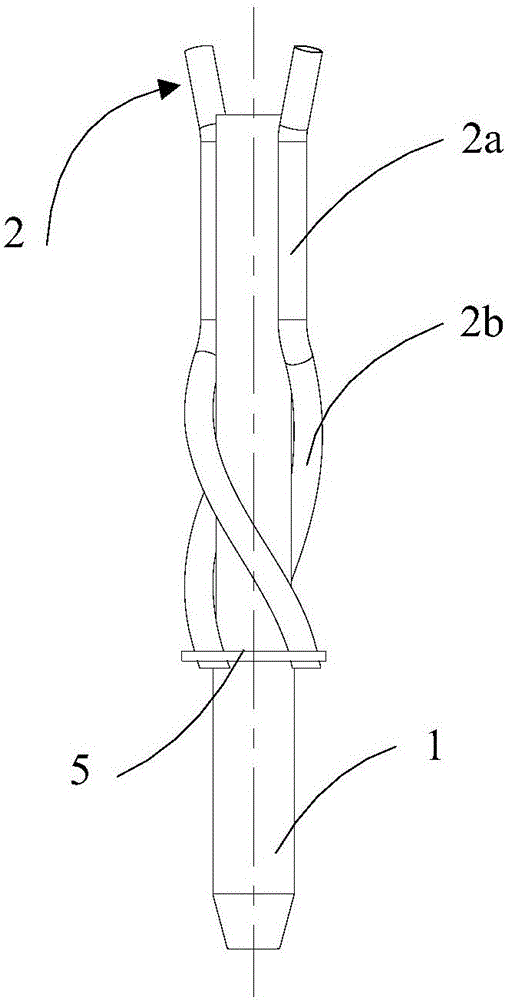

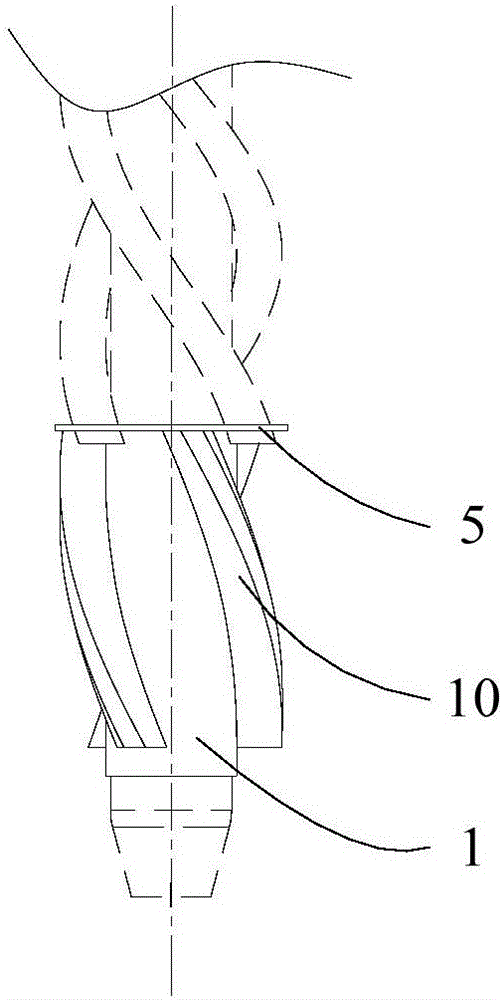

Uniform pulverized-coal distribution device

InactiveCN106047420AImprove distribution uniformityStable combustionGasifier feeding meansGranular/pulverulent flues gasificationEngineeringOxygen delivery

The invention discloses a uniform pulverized-coal distribution device. The uniform pulverized-coal distribution device is arranged at the head portion of a nozzle and comprises an oxygen delivery pipe, multiple pulverized-coal delivery pipes fixed to the outer circumferential surface of the oxygen delivery pipe and a cooling device arranged around the multiple pulverized-coal delivery pipes, wherein a gradually shrunk guide channel is formed in the inner side in the pulverized coal output direction and at the outlet position of the oxygen delivery pipe. The uniform pulverized-coal distribution device further comprises multiple distribution ribs arranged between the pulverized-coal delivery pipes and the guide channel, wherein each distribution rib is of a spiral rib structure and is fixed to the outer circumferential surface of the oxygen delivery pipe, and multiple spiral channels are formed among the multiple distribution ribs. The uniform pulverized-coal distribution device has the advantages that the pulverized-coal distribution uniformity at the outlet position of the nozzle is improved, the pulverized-coal combustion process can be more stable, and accordingly the problem of local deviant combustion is avoided.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP +2

Coal combustion improver

The invention relates to a chemical product and especially relates to a coal combustion improver. The coal combustion improver can improve a coal combustion rate and reduce pollution. The coal combustion improver is characterized by comprising 30 to 35% of calcium oxide, 20 to 25% of iron oxide, 30 to 45% of active carbon and 10 to 15% of a binder. The coal combustion improver has the advantages of low energy consumption, simple formula, simple processes, low cost and good smoke removal effect and can be widely used for industrial and civil soft coal.

Owner:王连义

Method for preparing desulfurizer from coal slag

The invention discloses a method for preparing a desulfurizer from coal cinder, which comprises the following steps: firstly, placing the coal cinder into a soaking pool, and filling soaking water for soaking; and secondly, detecting the pH value of a soak solution after soaking in the soaking water, and generating the desulfurizer which can be directly poured on coal to be combusted when the detected pH value reaches more than 12. By adoption of the method to prepare the fuel coal desulfurizer, not only the coal cinder generated by coal combustion in various coal combustion yards can be fully utilized but also the prepared desulfurizer has strong desulfurization effect on flue gas generated by coal combustion, realizes reutilization of waste coal cinder, saves the desulfurization cost, reduces resource waste, and simultaneously can also simplify the desulfurization technology and reduce the cost of the desulfurizer and equipment.

Owner:蒋利群

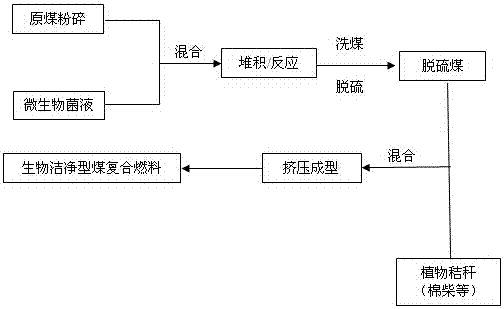

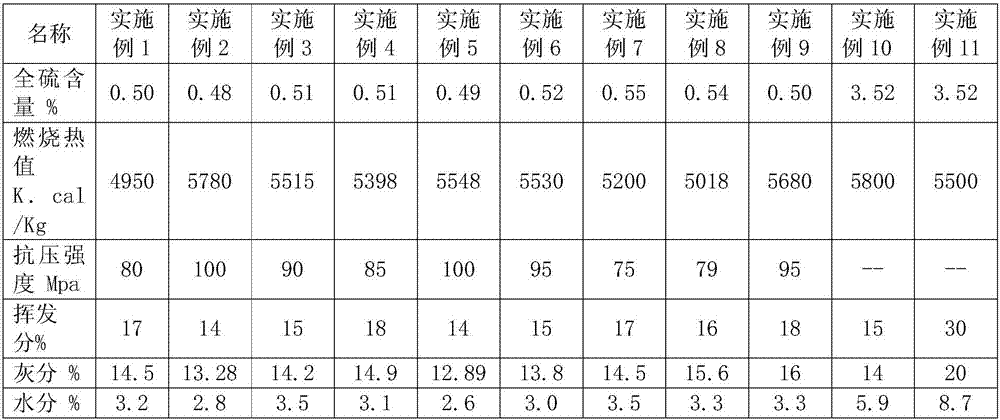

Biological clean type composite fuel and preparation method thereof

InactiveCN106867610AEasy to makeGood repeatabilityBacteriaSolid fuelsManufacturing technologyTemperature and pressure

The invention relates to a biological clean type composite fuel and a preparation method thereof. The fuel is prepared from the following raw materials in parts by weight: 80-150 parts of raw coal, 15-45 parts of plant straws, 5-20 parts of water and 1-2 parts of a microbial bacteria solution. The preparation method specifically comprises the following steps of: treating the raw coal with the microbial bacteria solution; converting sulfur in the raw coal into a salt through an accumulating reaction; removing sulfur in the raw coal through a coal washing process to obtain desulfurized coal with a relatively low sulfur content; and then extruding and forming the desulfurized coal and the plant straws through molded coal forming equipment at a certain temperature and pressure to obtain the biological clean type composite fuel. By combining a biological desulphurization technology with a biomass molded coal manufacturing technology, the obtained product has the advantages of being high in compressive strength, low in full sulfur content and high in heat of combustion. More importantly, the environmental pollution problem in the coal combustion process is solved, and the fuel has a good ecological benefit; and meanwhile, preparation of the biological clean type composite fuel product opens up a novel path for utilization of biomass energy sources such as straws.

Owner:UNIV OF JINAN +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com