Method for regulating oriented conversion of uranium in coal combustion process

A directional conversion, coal combustion technology, applied in the direction of fuel, solid fuel, lighting and heating equipment, etc., can solve problems such as human health hazards, achieve low investment and operating costs, simple operation, and reduce the release of uranium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

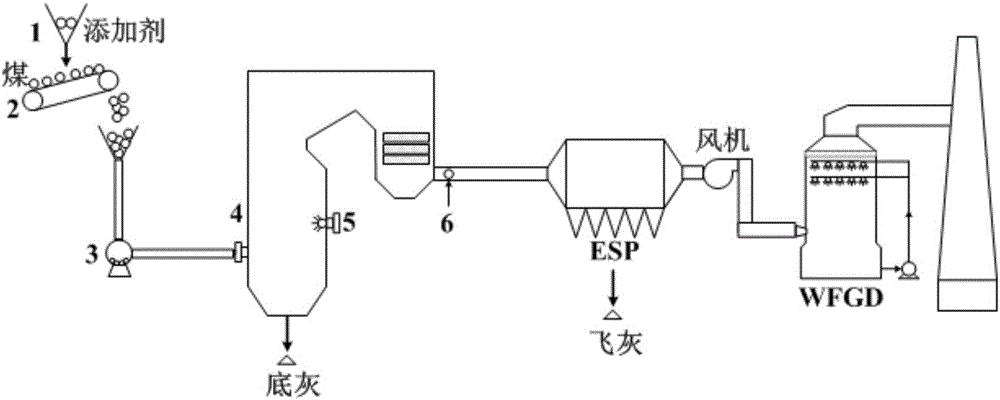

[0027] An embodiment of a method for regulating the directional transformation of uranium in a coal combustion process of the present invention is carried out by the above-mentioned device, and the specific steps of the method are as follows:

[0028] (1) The content m of organically bound uranium in coal was measured by step-by-step chemical extraction method and inductively coupled plasma mass spectrometry (ICP-MS). 1 =6mg / kg coal;

[0029] (2) according to the content m of organically bound uranium in step (1) 1 , determine the amount of CaO added as m 2 =k 1 m 1 , where k is 1 =1.1, that is, 6.6 mg CaO is added per kg of coal;

[0030] (3) Pass figure 1 Medium additive adding system 1 adds additives to coal conveying system 2, the additives and coal are fully mixed in coal mill 3 and then enter the boiler hearth 4 for combustion, the temperature in the boiler hearth is 800 ℃, and the additives react with gaseous uranium in the boiler hearth The formation of solid ur...

Embodiment 2

[0034] An embodiment of a method for regulating the directional transformation of uranium in a coal combustion process of the present invention is carried out by the above-mentioned device, and the specific steps of the method are as follows:

[0035] (1) The content m of organically bound uranium in coal was measured by step-by-step chemical extraction method and inductively coupled plasma mass spectrometry (ICP-MS). 1 =6.9mg / kg coal;

[0036] (2) according to the content m of organically bound uranium in step (1) 1, determine the amount of CaO added as m 2 =k 1 m 1 , where k is 1 = 1.3, that is, 8.97 mg CaO is added per kg of coal;

[0037] (3) Pass figure 1 The medium additive injection device 5 injects the additive into the boiler hearth 4, the temperature in the boiler hearth is 1000 ℃, and the additive reacts with gaseous uranium in the boiler hearth to generate solid uranium salt, which is fixed in the bottom ash;

[0038] (4) Test the concentration of gaseous ur...

Embodiment 3

[0041] An embodiment of a method for regulating the directional transformation of uranium in a coal combustion process of the present invention is carried out by the above-mentioned device, and the specific steps of the method are as follows:

[0042] (1) The content m of organically bound uranium in coal was measured by step-by-step chemical extraction method and inductively coupled plasma mass spectrometry (ICP-MS). 1 =7.7mg / kg coal;

[0043] (2) according to the content m of organically bound uranium in step (1) 1 , determine the amount of CaO added as m 2 =k 1 m 1 , where k is 1 = 1.5, that is, 11.55 mg CaO is added per kg of coal;

[0044] (3) Pass figure 1 The medium additive adding system 1 adds the additive to the coal conveying system 2, and at the same time, injects the additive into the boiler hearth 4 through the additive injection device 5, the temperature in the boiler hearth is 1200 ℃, and the additive reacts with the gaseous uranium product in the boiler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com