Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

273 results about "Boron nitride nanotube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

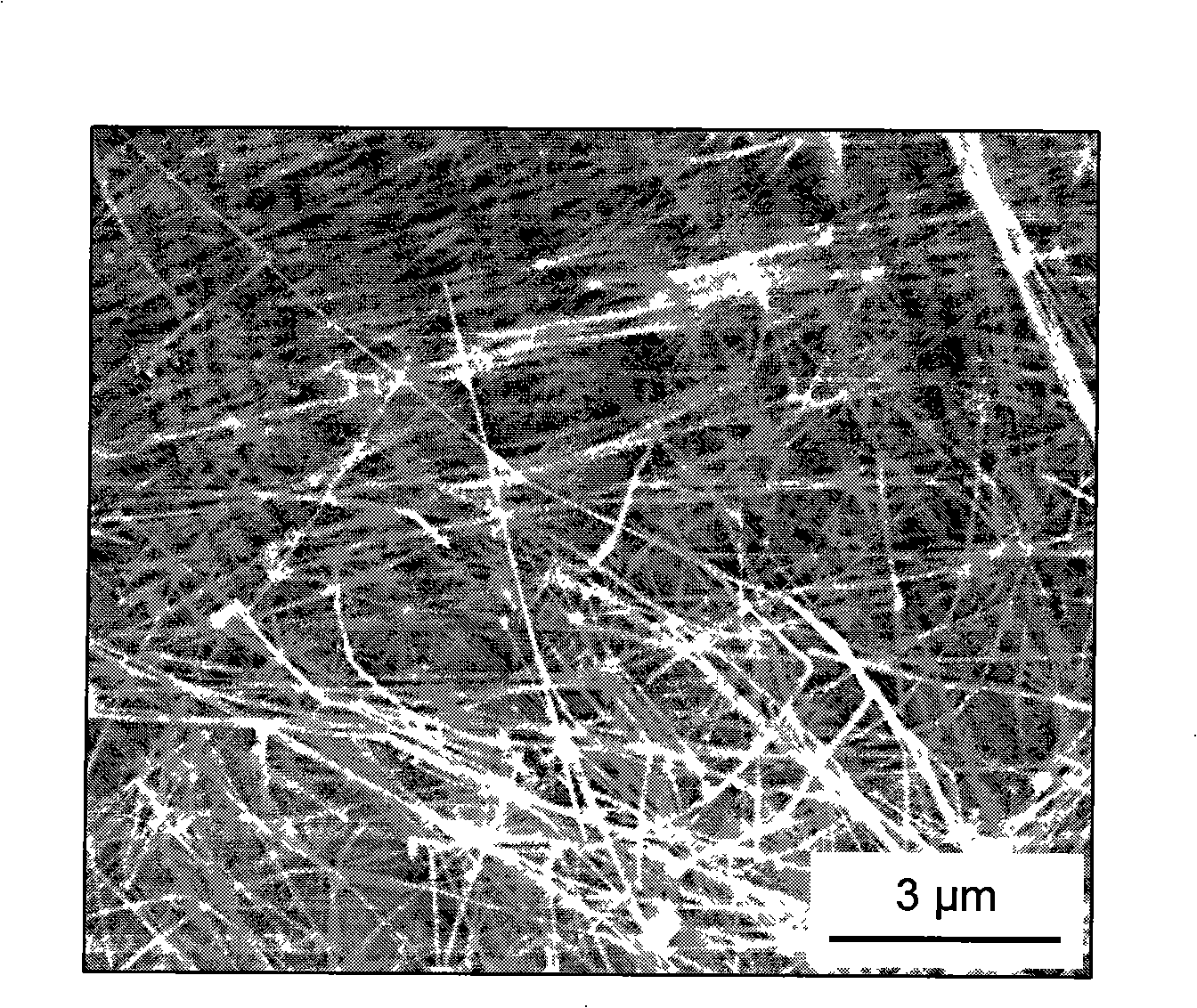

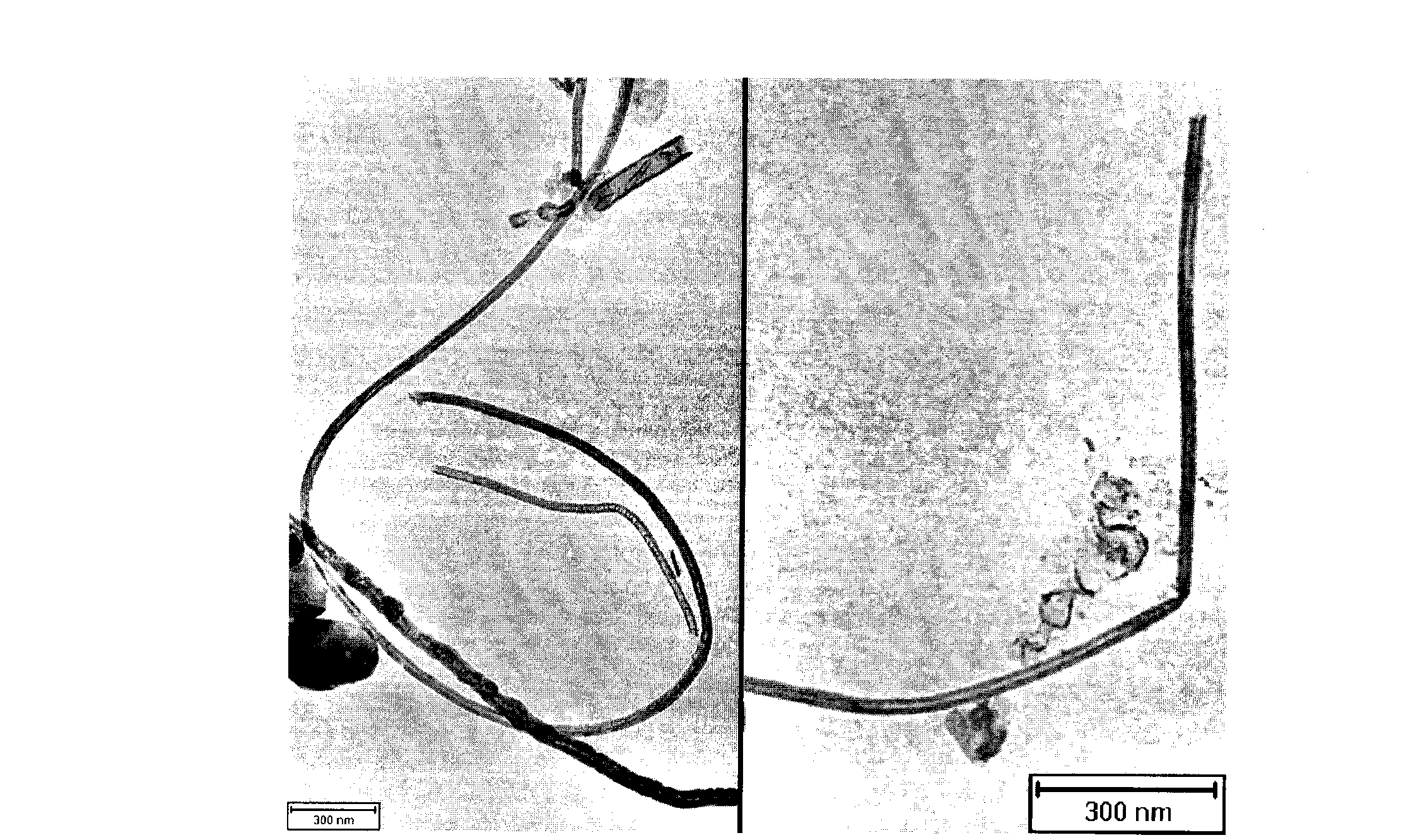

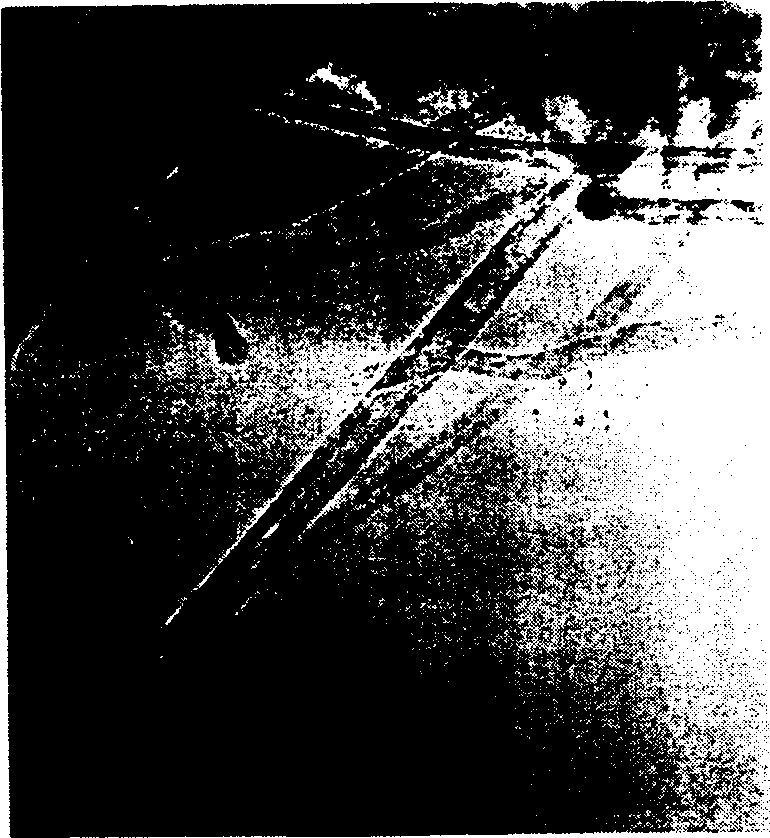

Boron nitride nanotubes (BNNTs) are a polymorph of boron nitride. They were predicted in 1994 and experimentally discovered in 1995. Structurally they are similar to carbon nanotubes, which are cylinders with sub-micrometer diameters and micrometer lengths, except that carbon atoms are alternately substituted by nitrogen and boron atoms. However, the properties of BN nanotubes are very different: whereas carbon nanotubes can be metallic or semiconducting depending on the rolling direction and radius, a BN nanotube is an electrical insulator with a bandgap of ~5.5 eV, basically independent of tube chirality and morphology. In addition, a layered BN structure is much more thermally and chemically stable than a graphitic carbon structure.

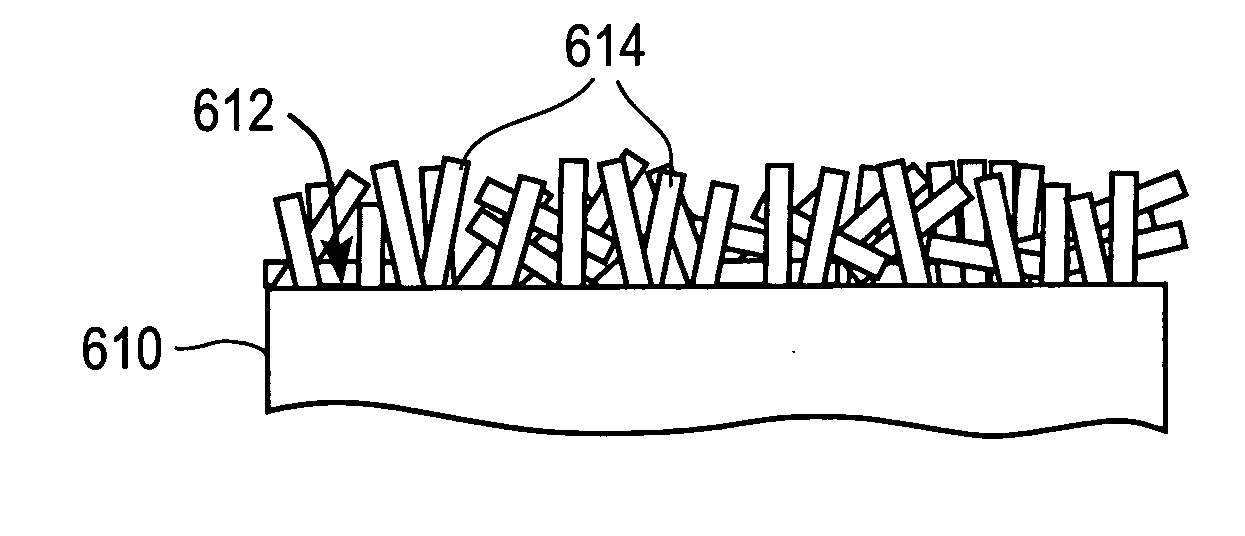

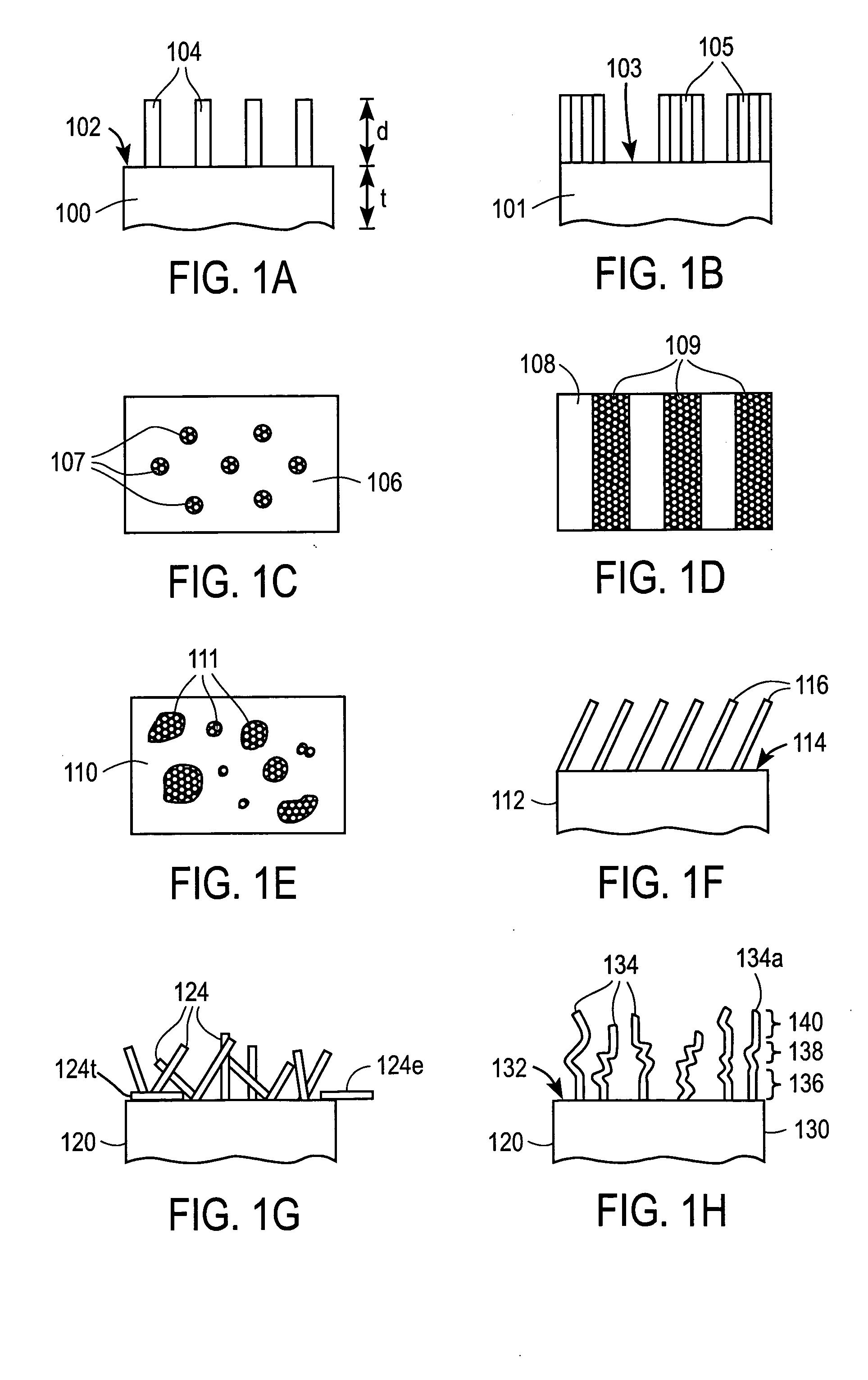

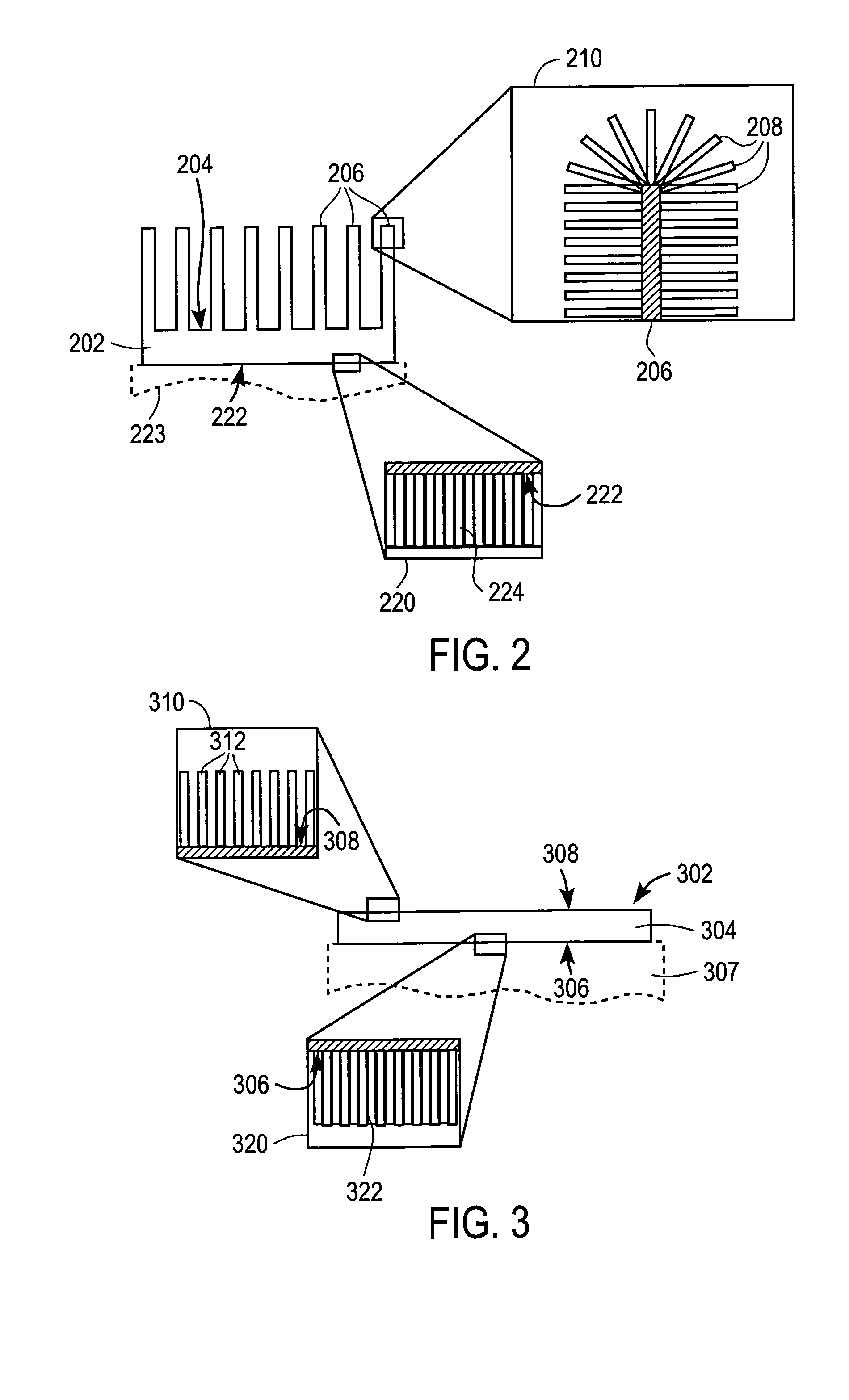

Nanostructure augmentation of surfaces for enhanced thermal transfer with improved contact

InactiveUS20050126766A1Increase surface areaGood thermal contactSemiconductor/solid-state device detailsNanoinformaticsBoron nitrideNanostructure

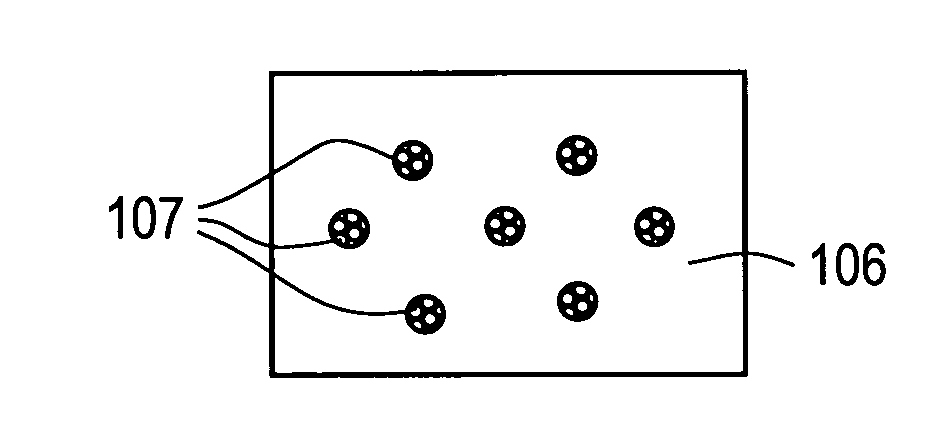

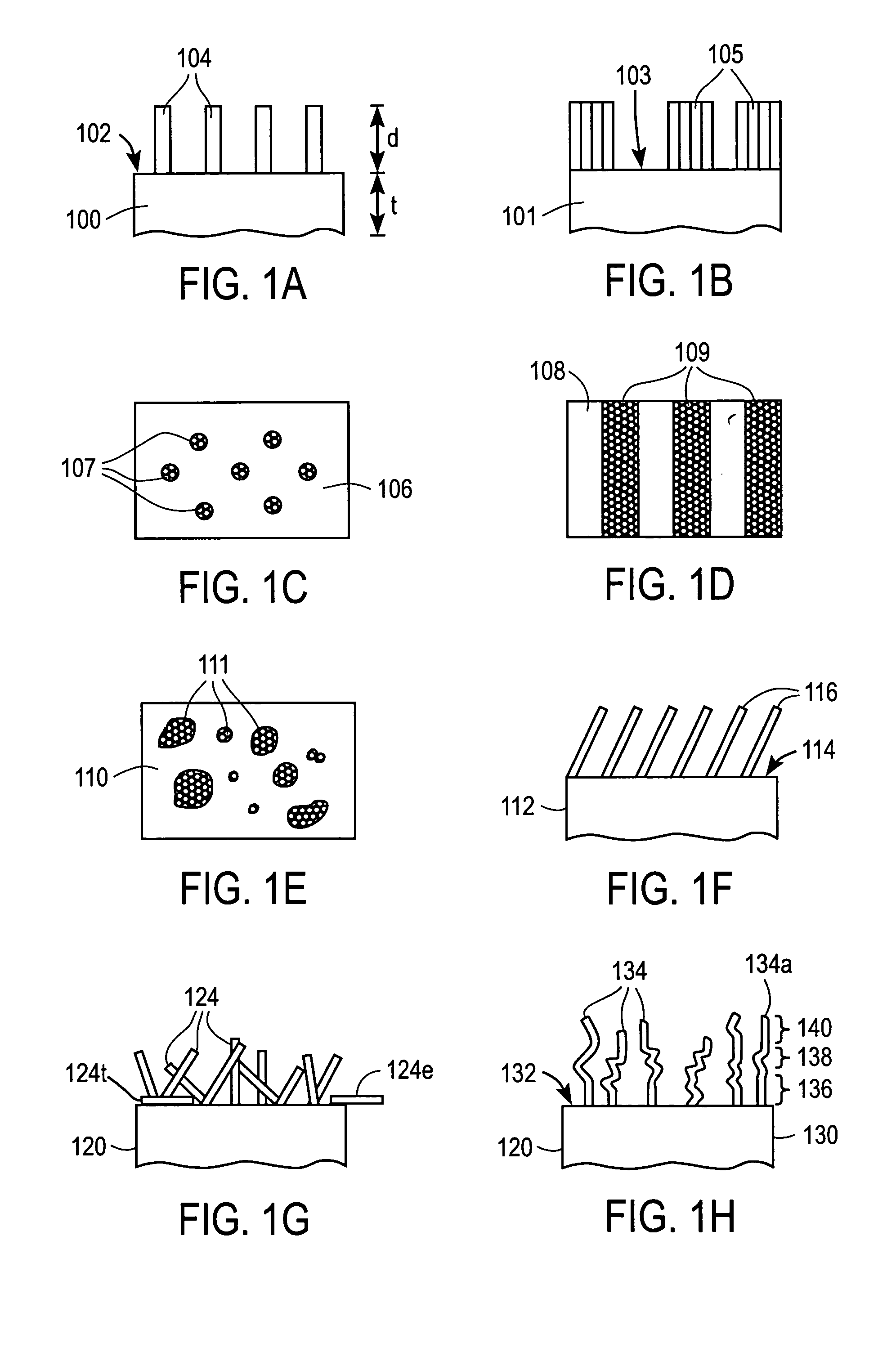

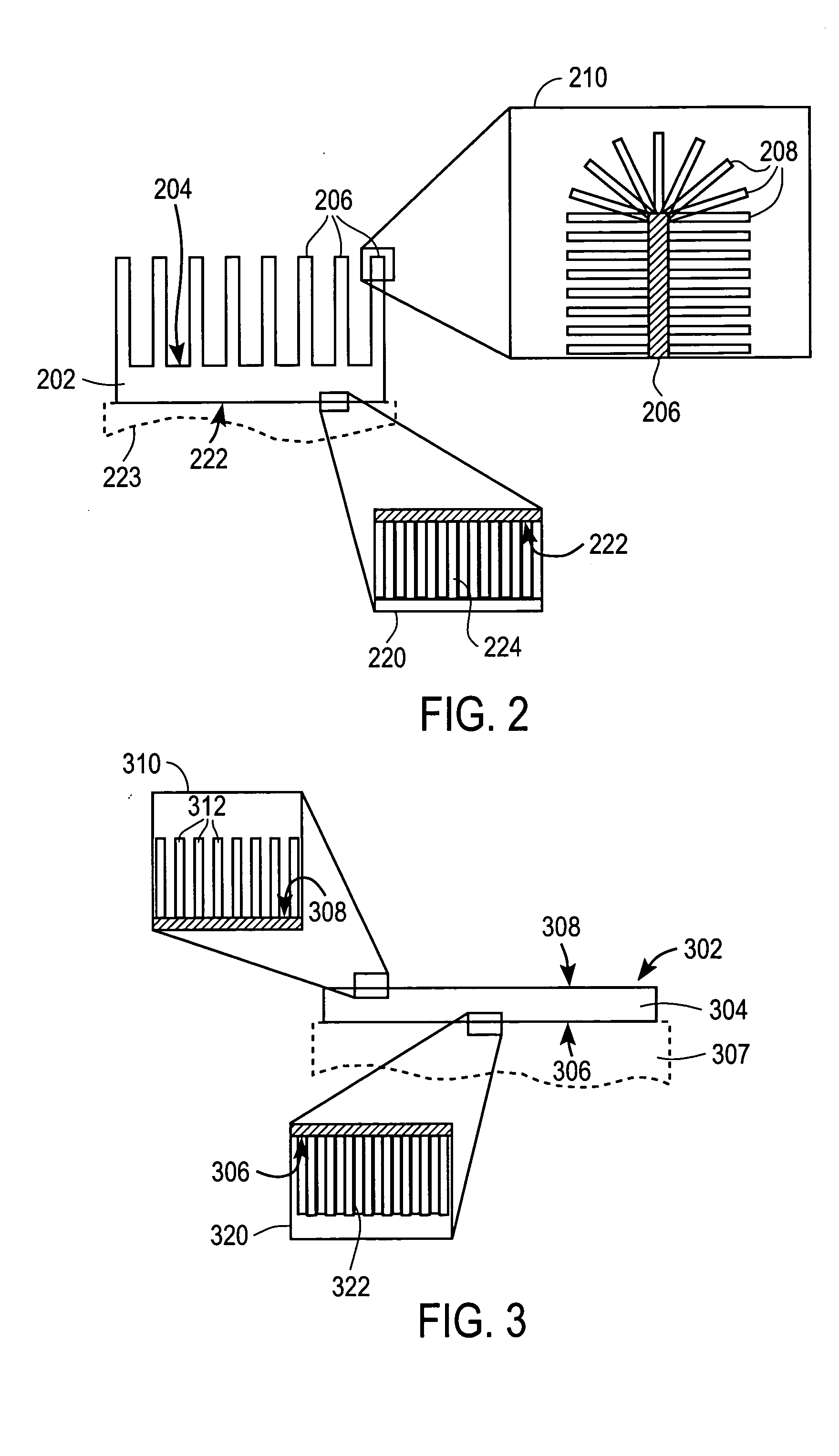

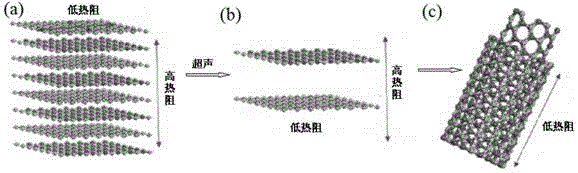

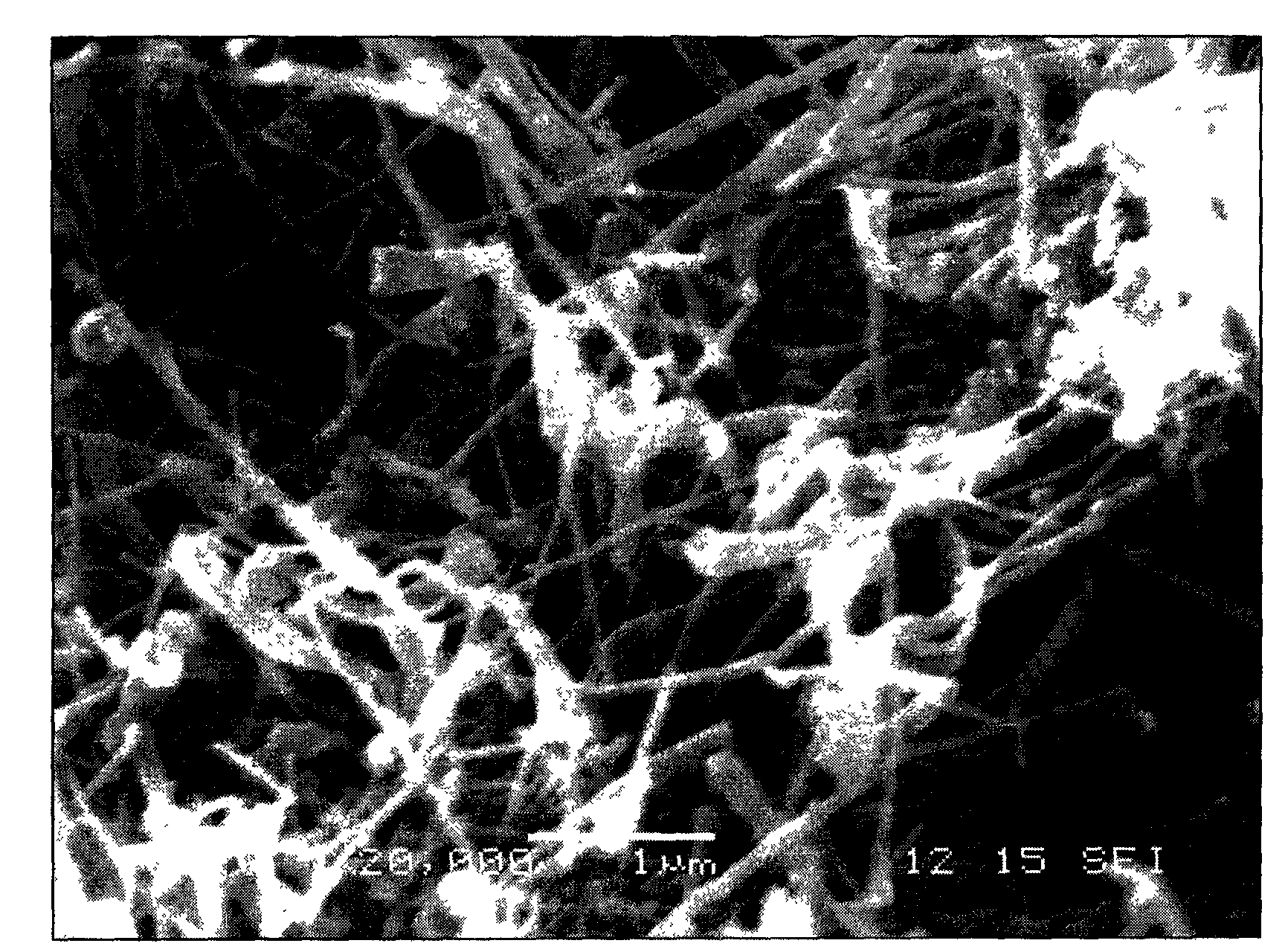

Nanostructures provide improved contact to augment heat-exchange surfaces of various devices or structures. In one embodiment, an article of manufacture has a body having a heat-exchanging surface and nanostructures disposed on the heat-exchanging surface. The nanostructures are arranged to enhance thermal transfer between said body and an object distinct from said body and may be arranged to form a substantially continuous film. Examples of suitable nanostructures include carbon and / or boron nitride nanotubes, which may be grown on the heat-exchanging surface.

Owner:NASREEN CHOPRA

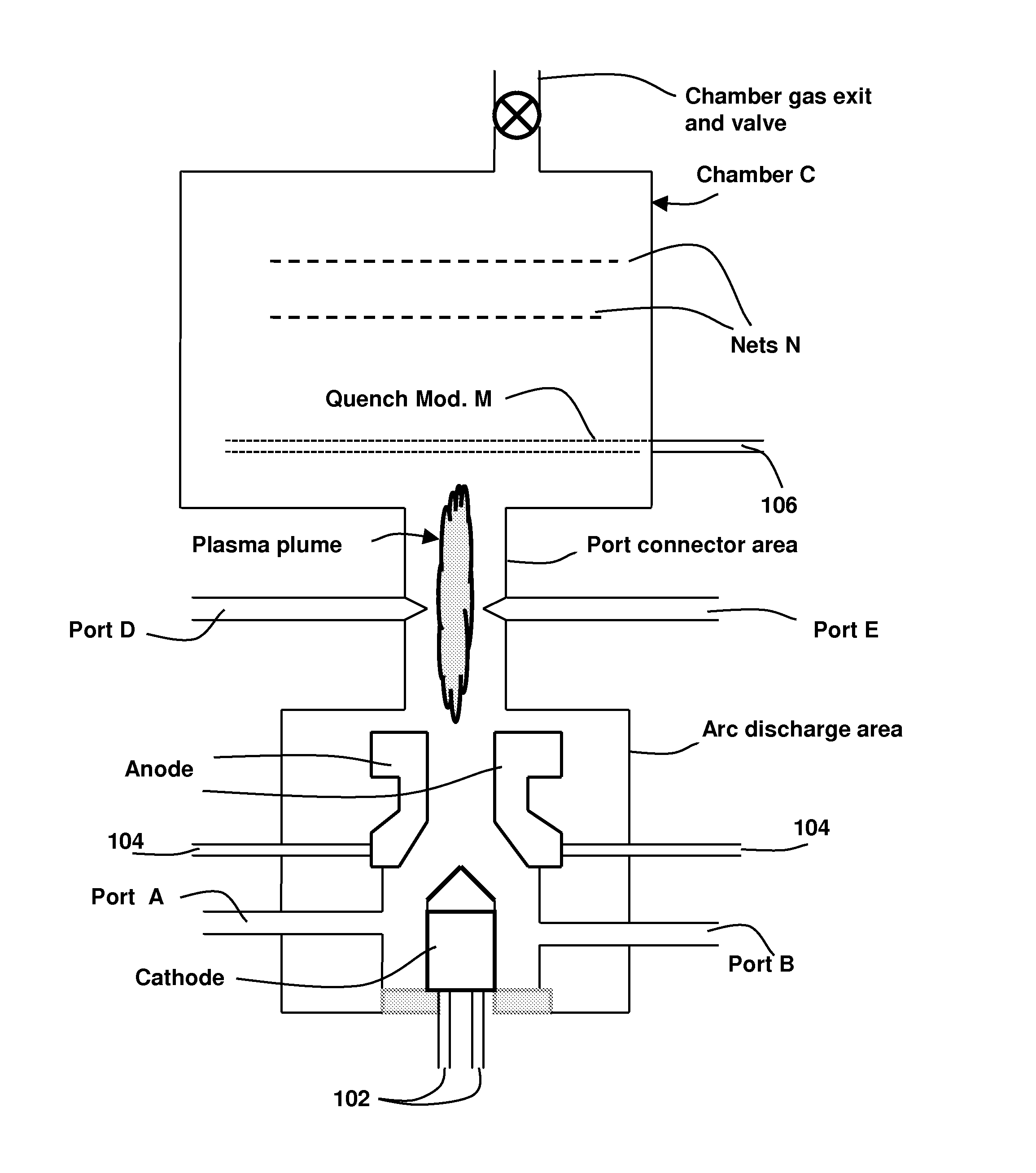

Method and device to synthesize boron nitride nanotubes and related nanoparticles

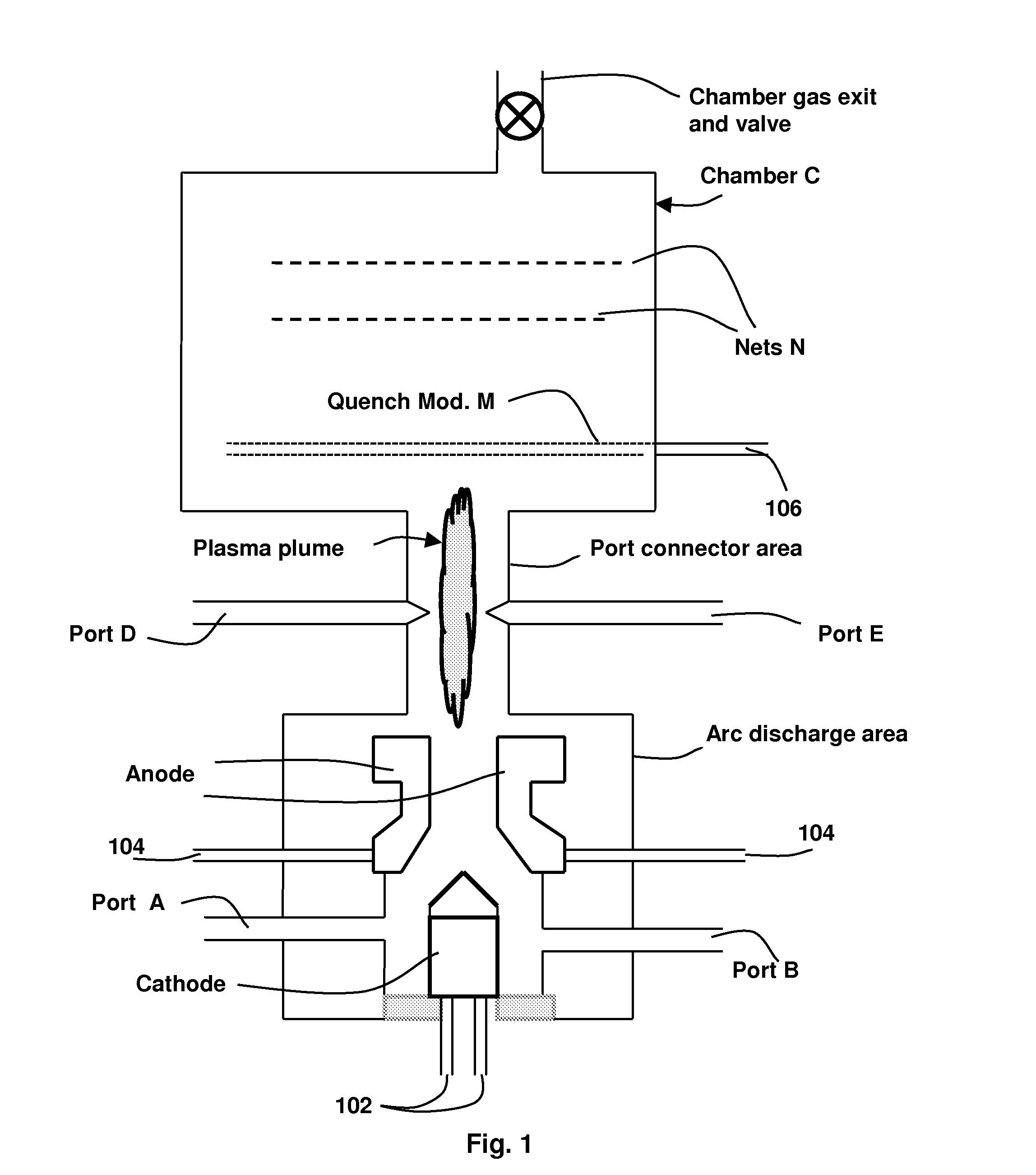

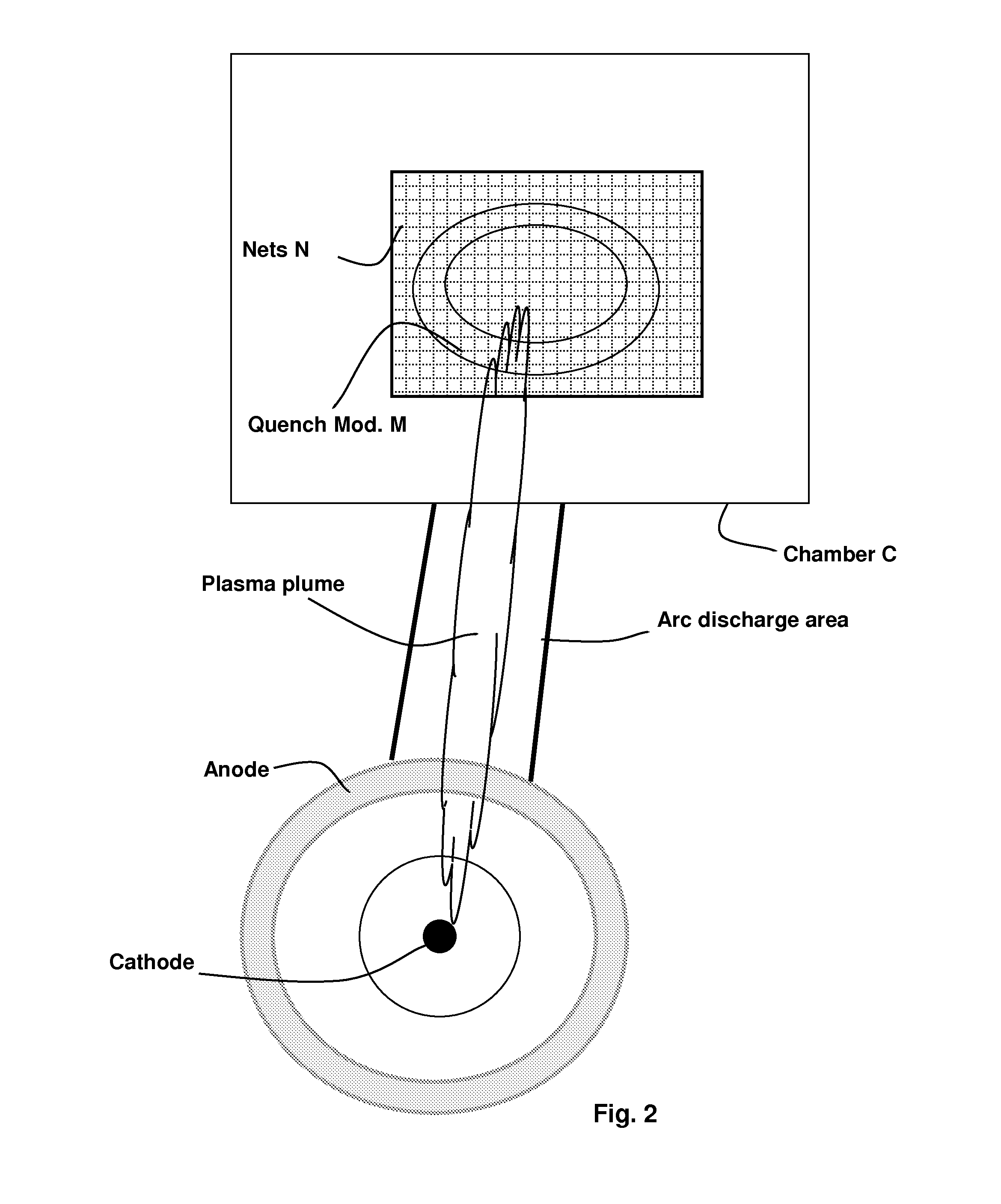

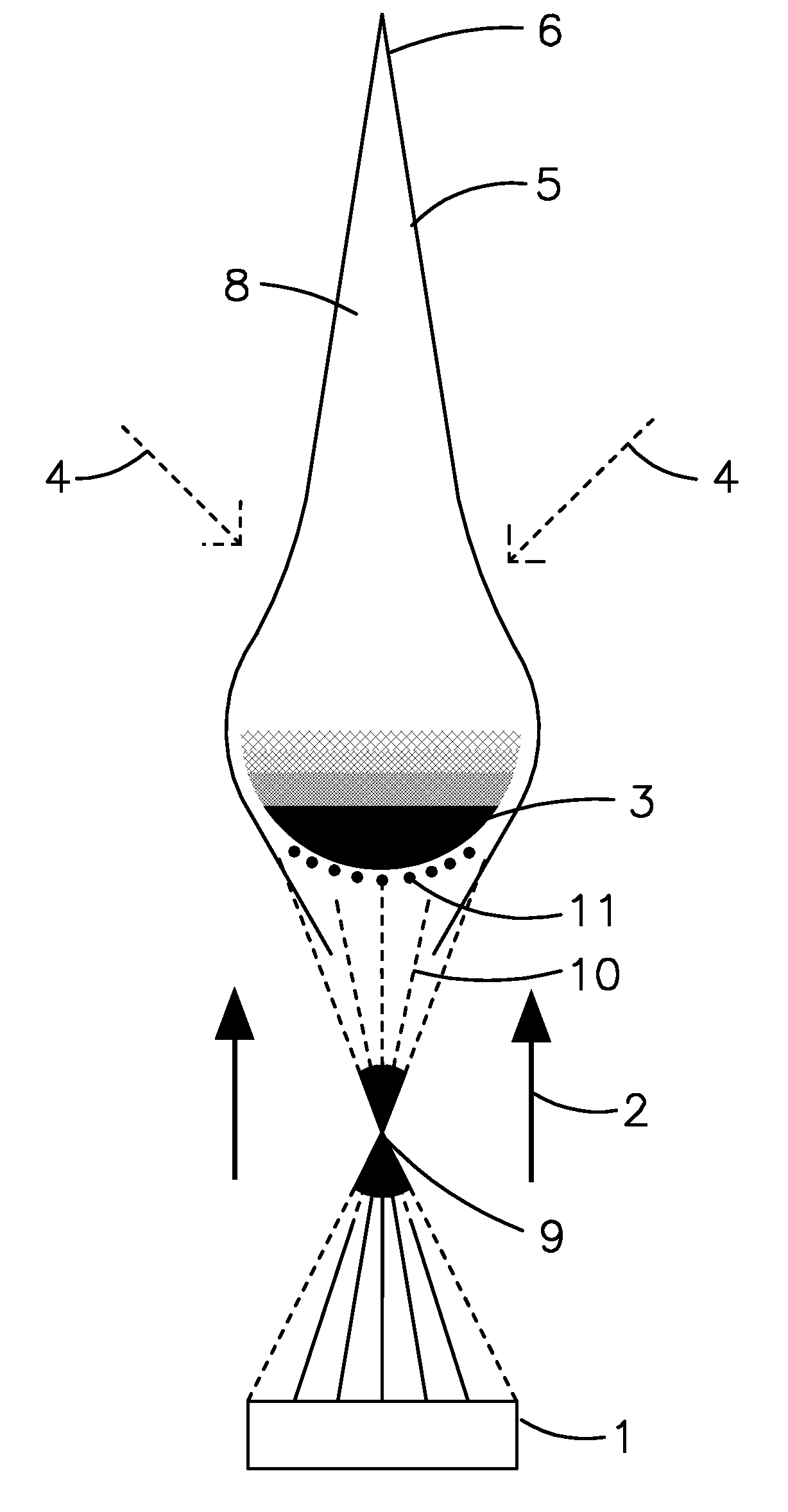

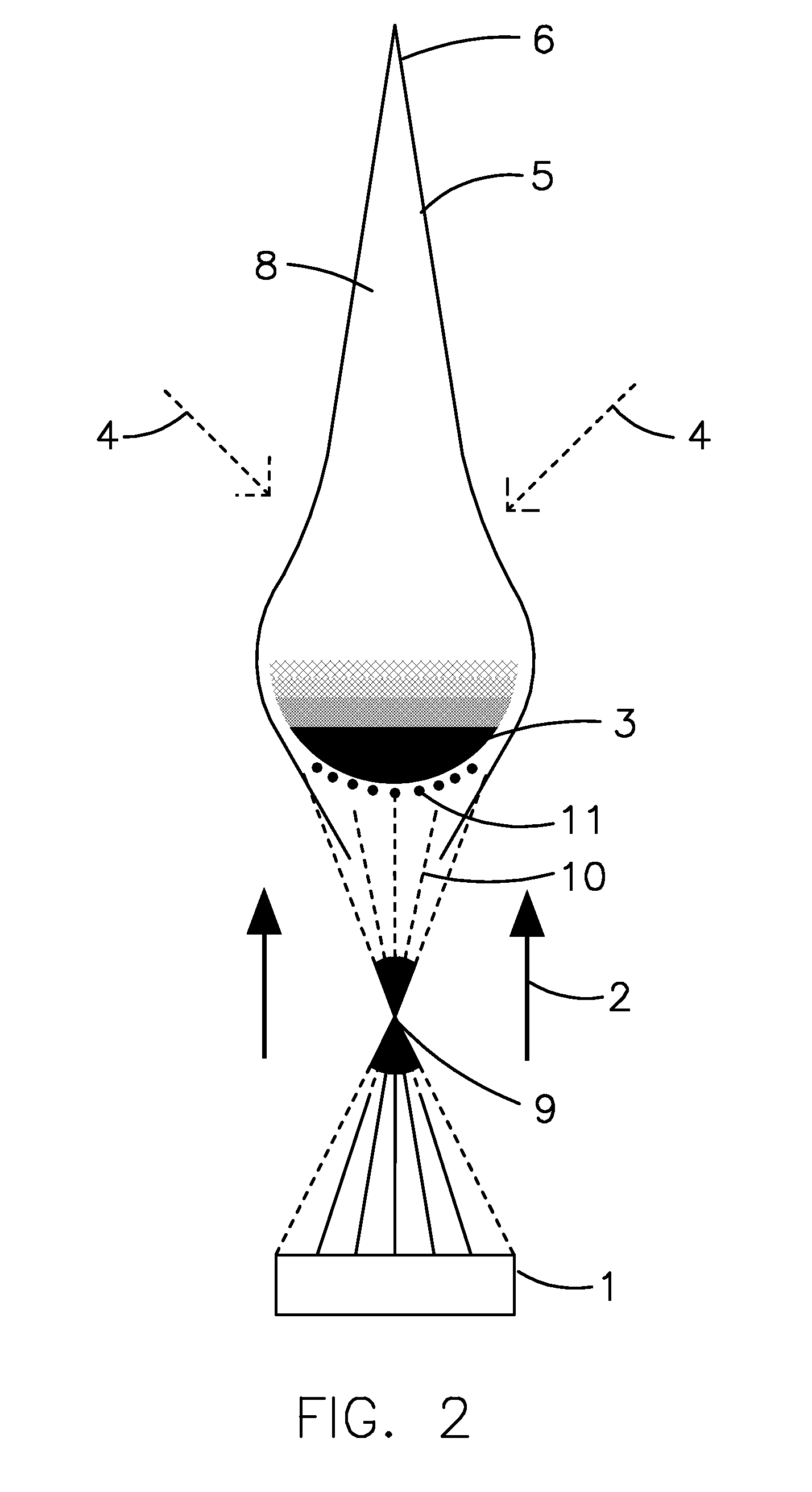

Methods and apparatus for producing chemical nanostructures having multiple elements, such as boron and nitride, e.g. boron nitride nanotubes, are disclosed. The method comprises creating a plasma jet, or plume, such as by an arc discharge. The plasma plume is elongated and has a temperature gradient along its length. It extends along its length into a port connector area having ports for introduction of feed materials. The feed materials include the multiple elements, which are introduced separately as fluids or powders at multiple ports along the length of the plasma plume, said ports entering the plasma plume at different temperatures. The method further comprises modifying a temperature at a distal portion of or immediately downstream of said plasma plume; and collecting said chemical nanostructures after said modifying.

Owner:RGT UNIV OF CALIFORNIA

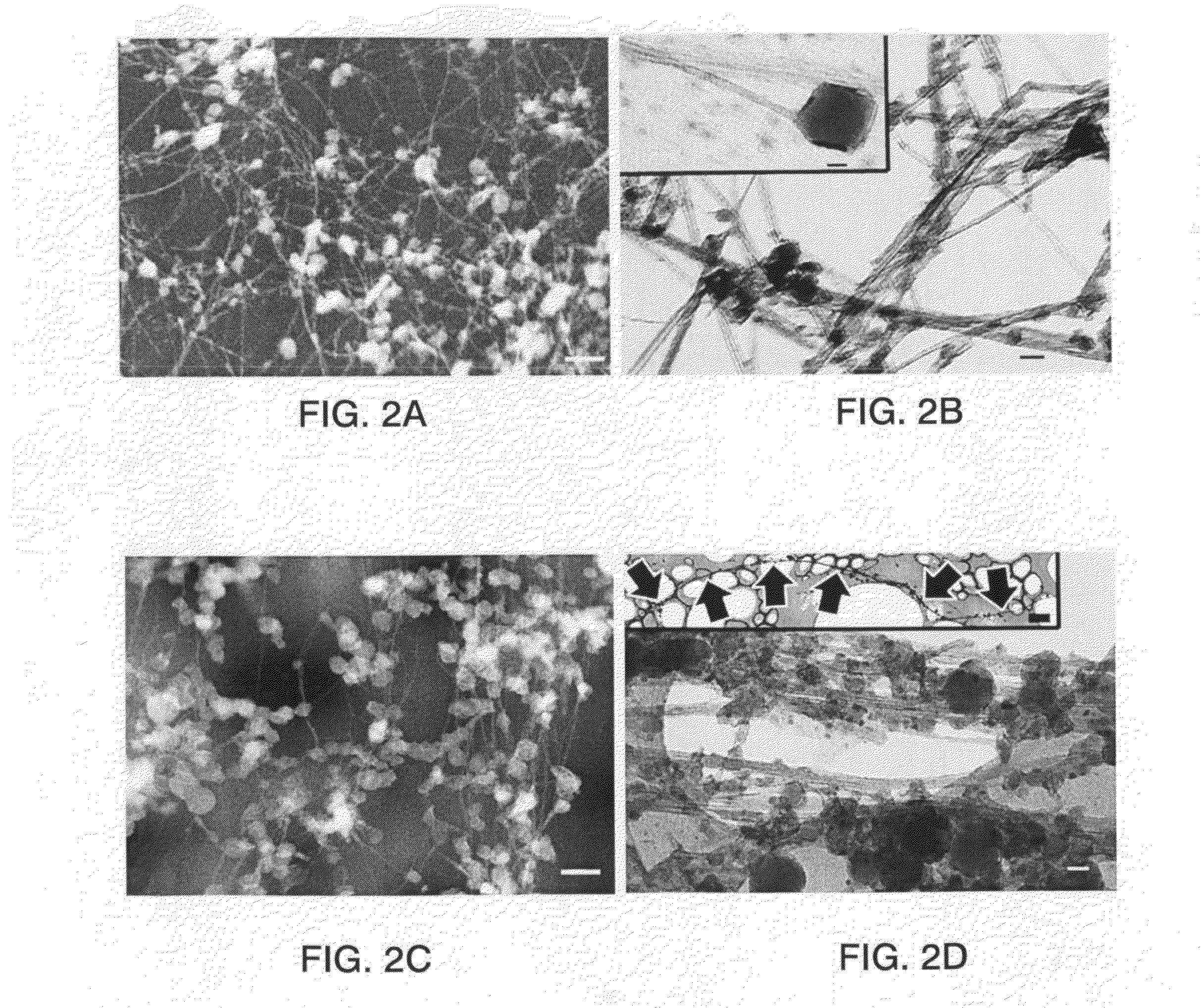

Boron nitride nanotubes

ActiveUS8206674B2Promote resultsMaterial nanotechnologyPolycrystalline material growthMetallurgyCarbon nitride

Owner:NASA +2

Boron Nitride Nanotubes

ActiveUS20090117021A1Promote resultsMaterial nanotechnologyPolycrystalline material growthMetallurgyBoron nitride

Boron nitride nanotubes are prepared by a process which includes:(a) creating a source of boron vapor;(b) mixing the boron vapor with nitrogen gas so that a mixture of boron vapor and nitrogen gas is present at a nucleation site, which is a surface, the nitrogen gas being provided at a pressure elevated above atmospheric, e.g., from greater than about 2 atmospheres up to about 250 atmospheres; and(c) harvesting boron nitride nanotubes, which are formed at the nucleation site.

Owner:NASA +2

Nanostructure augmentation of surfaces for enhanced thermal transfer with increased surface area

InactiveUS20050129928A1Increase surface areaGood thermal contactMaterial nanotechnologyLayered productsBoron nitrideNanostructure

Nanostructures provide increased surface area to augment heat-exchange surfaces of various devices or structures. In one embodiment, an article of manufacture has a body having a heat-exchanging surface and nanostructures disposed on the heat-exchanging surface. The nanostructures are arranged to enhance thermal transfer between the body and a region of fluid and may be spaced apart from each other to permit flow of a fluid between the nanostructures. Examples of suitable nanostructures include carbon and / or boron nitride nanotubes, which may be grown on the heat-exchanging surface.

Owner:CHOPRA NASREEN

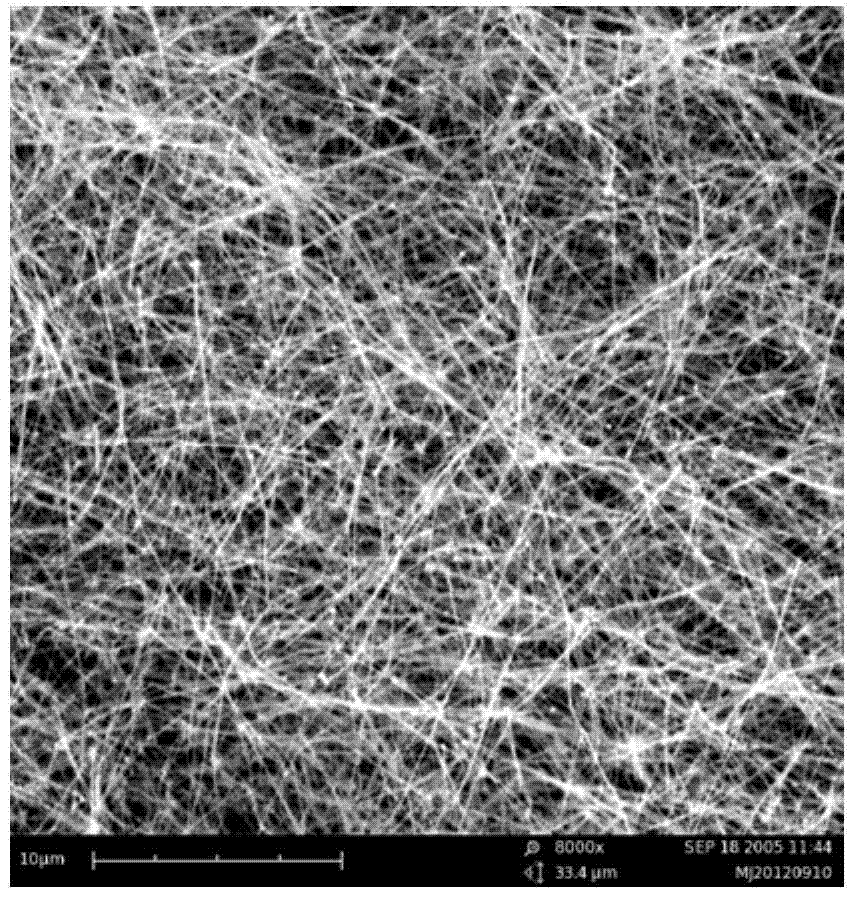

Boron nitride nanotube fibrils and yarns

InactiveUS20100192535A1Easily spun or otherwise processedMaterial nanotechnologyNitrogen compoundsYarnFiber

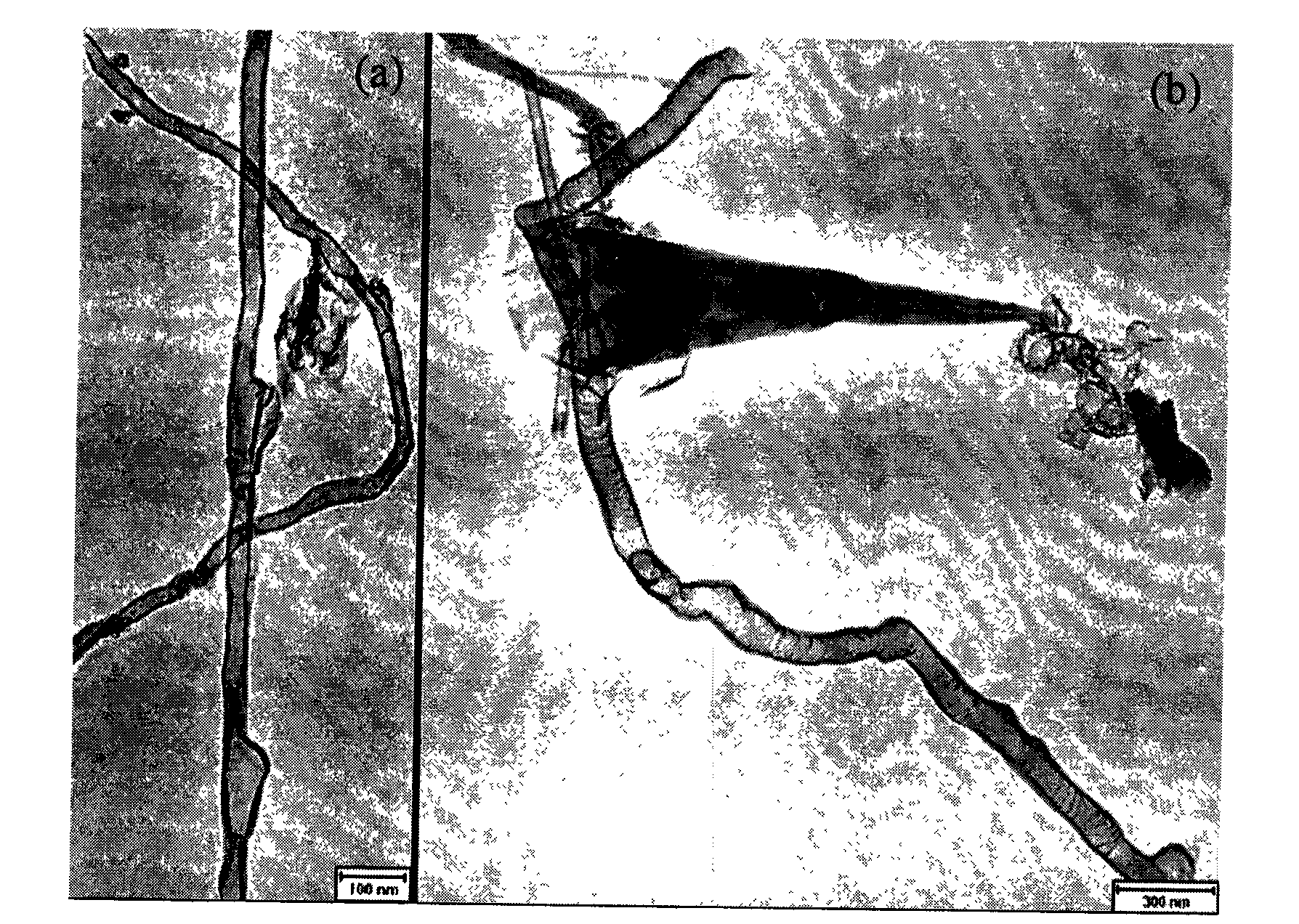

A method for the production of long, high aspect ratio boron nitride nanotubes and boron nitride nanotube fibrils composed of single or few walled boron nitride nanotubes aligned in bundles of nanotubes 20 μm and longer at a rate of above about 1 meter per second. Nanotube yarns comprised of twisted bundles of such nanotube fibrils are also described.

Owner:NASA

Method for preparing functional nanomaterials utilizing endothermic reaction

InactiveUS20050002849A1High yieldIncrease productionMaterial nanotechnologyNanostructure manufactureGas phaseSilicon carbide nanotubes

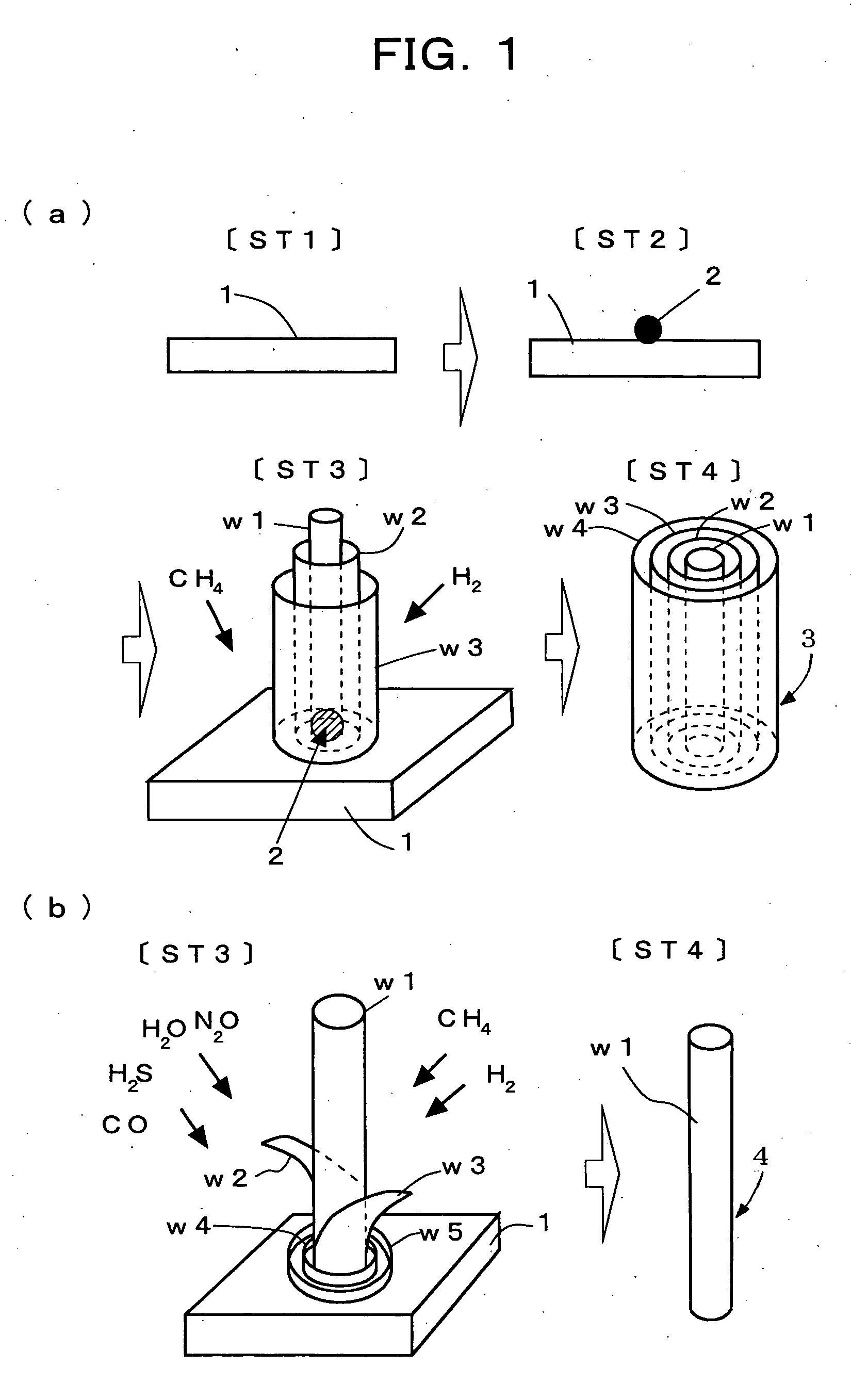

A method is disclosed whereby a functional nanomaterial such as a monolayer carbon nanotube, a monolayer boron nitride nanotube, a monolayer silicon carbide nanotube, a multilayer carbon nanotube with the number of layers controlled, a multilayer boron nitride nanotube with the number of layers controlled, a multilayer silicon carbide nanotube with the number of layers controlled, a metal containing fullerene, and a metal containing fullerene with the number of layers controlled is produced at a high yield. According to the method, when a multilayer carbon nanotube (3) is formed by a chemical vapor deposition or a liquid phase growth process, an endothermic reaction aid (H2S) is introduced in addition to a primary reactant (CH4, H2) in the process to form a monolayer carbon nanotube (4).

Owner:JAPAN SCI & TECH CORP

Induction-coupled plasma synthesis of boron nitride nanotubes

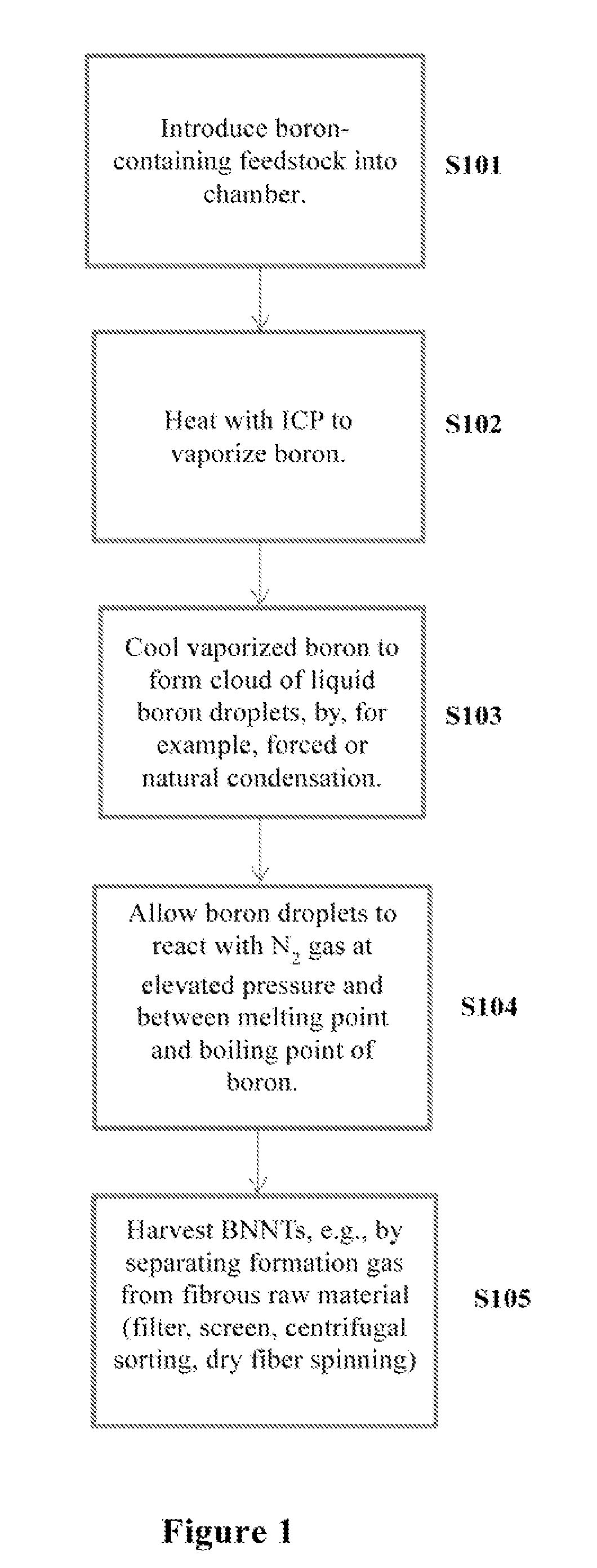

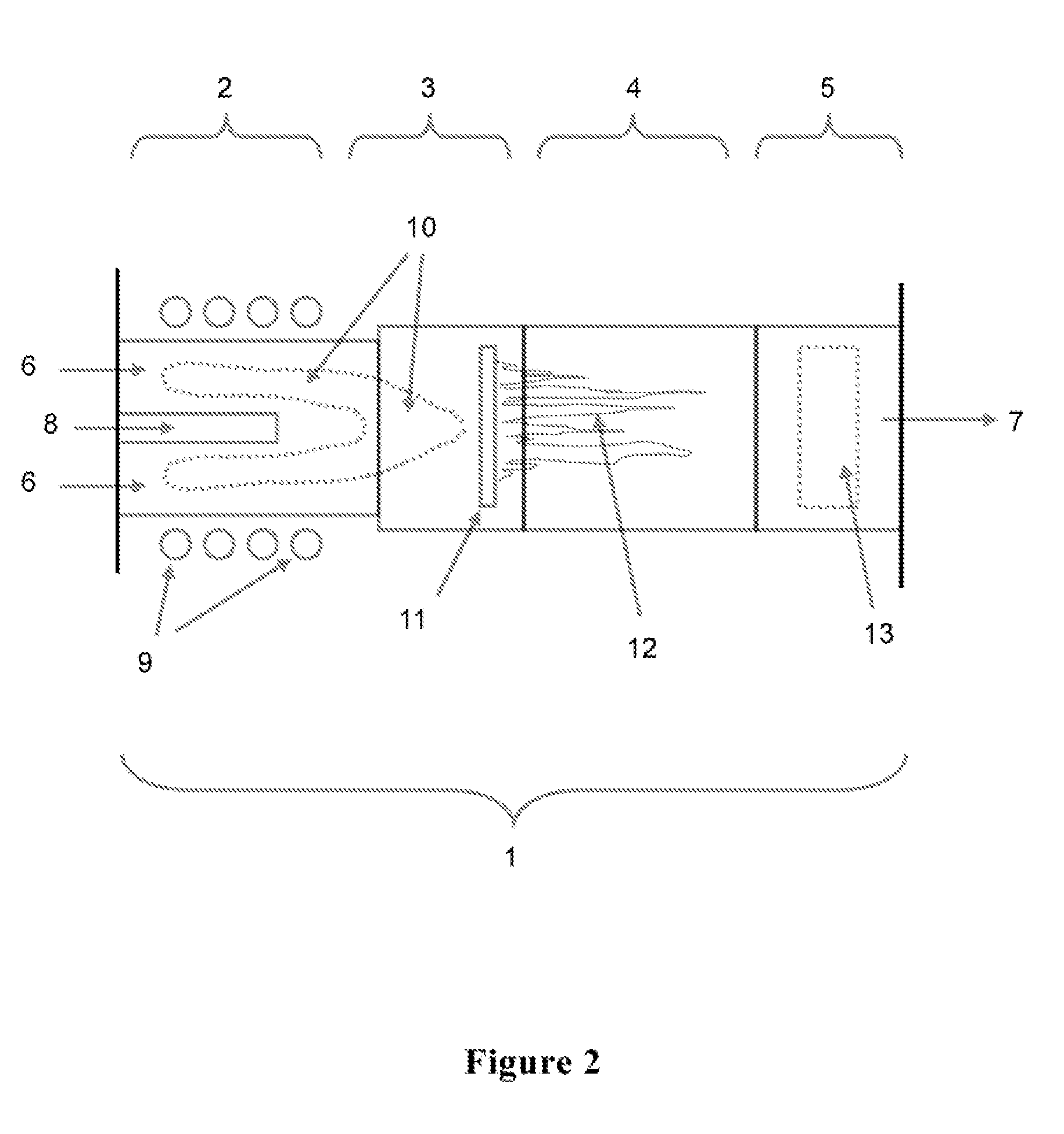

ActiveUS20150125374A1Few crystalline structure defectHigh yieldNitrogen compoundsHigh temperature liquid-gas reactionBoron nitrideNitrogen gas

Described herein are processes and apparatus for the large-scale synthesis of boron nitride nanotubes (BNNTs) by induction-coupled plasma (ICP). A boron-containing feedstock may be heated by ICP in the presence of nitrogen gas at an elevated pressure, to form vaporized boron. The vaporized boron may be cooled to form boron droplets, such as nanodroplets. Cooling may take place using a condenser, for example. BNNTs may then form downstream and can be harvested.

Owner:BNNT

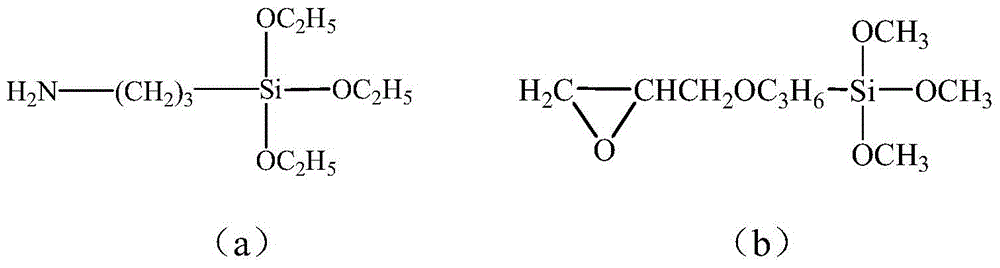

Polymer dielectric medium with low dielectric constant and low loss and preparation method of polymer dielectric medium

InactiveCN103980664AGood dispersionImprove thermal conductivitySynthetic resin layered productsEpoxyHeat conducting

The invention discloses a polymer dielectric medium with low dielectric constant and low loss and a preparation method of the polymer dielectric medium. The polymer dielectric medium comprises the following raw materials: 50-60% of epoxy resin system, and 40-50% of mixed boron nitride nanoparticles, wherein the mixed boron nitride nanoparticle is a mixture of a boron nitride nanotube and a boron nitride nanotube; the epoxy resin system is formed by 100phr of epoxy resin E-51, 85phr of methyl hexahydrophthalic anhydride and 1phr of benzyl dimethylamine in a mixing manner. The thermal breakdown voltage of the polymer dielectric medium is significantly improved by the polymer dielectric material with high heat conductivity and high electric breakdown, the service life is prolonged, the dielectric constant and loss and the heat expansion coefficient are reduced, the mechanical strength and the tenacity are improved, the highest heat conductivity can be up to 5.26W / mK, the volume resistivity is about 1014ohm.cm, the thermal breakdown voltage is about 2-3kV / mm higher than that of the similar heat-conducting polymer dielectric medium, and the dielectric constant and the loss are a little lower than those of pure resin.

Owner:XIAN UNIV OF SCI & TECH

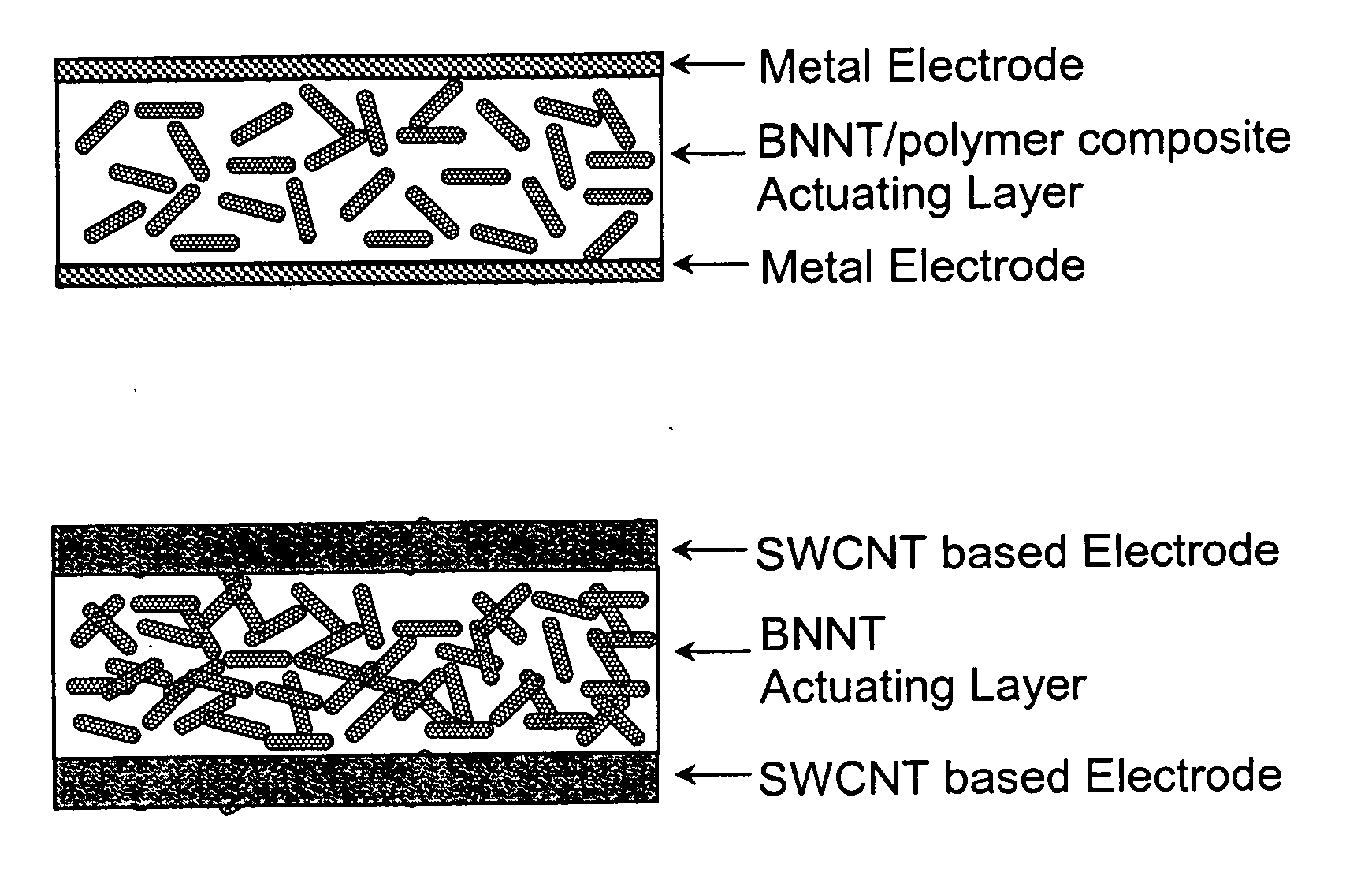

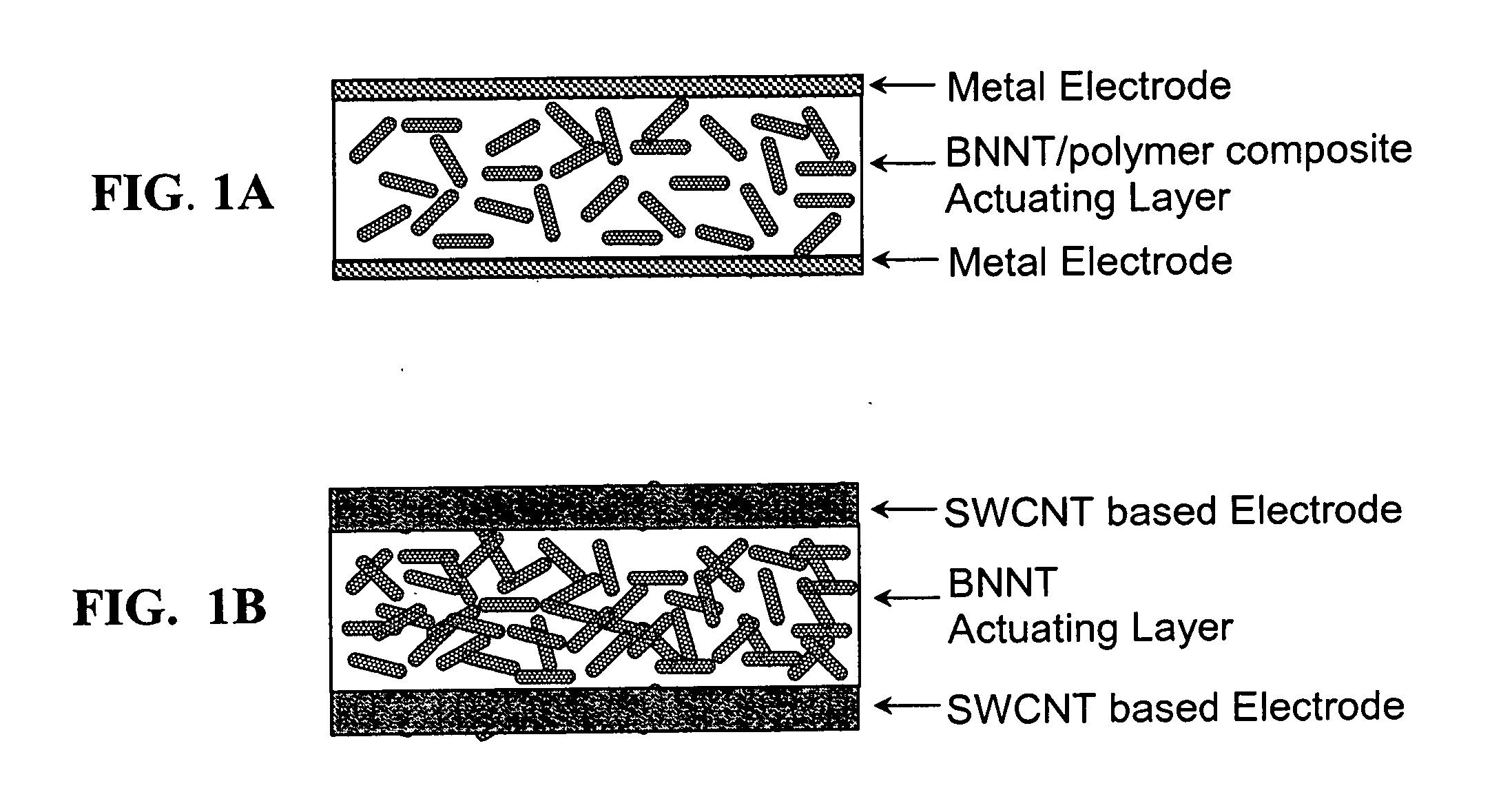

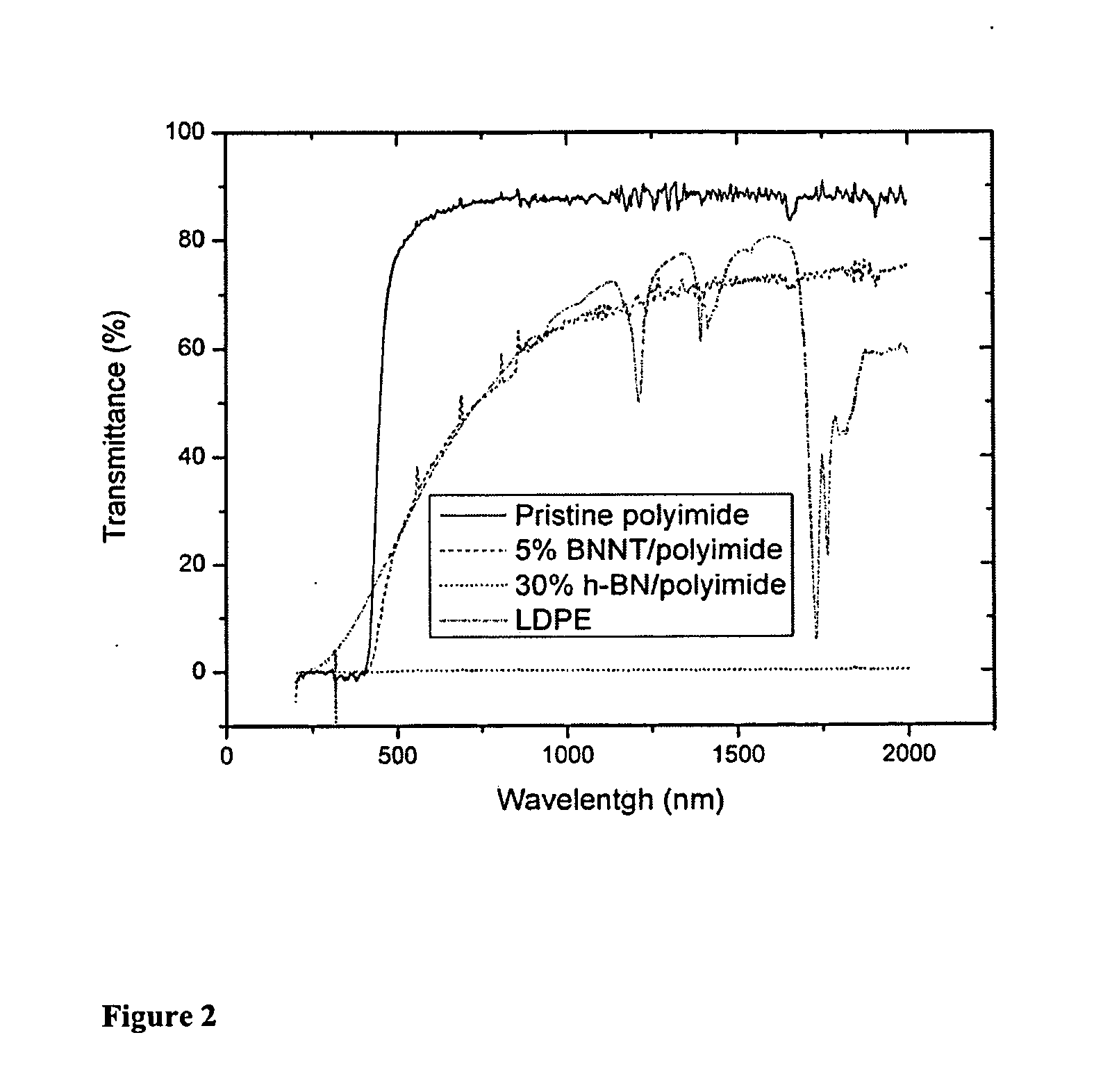

Energy conversion materials fabricated with boron nitride nanotubes (BNNTs) and BNNT polymer composites

ActiveUS20110192016A1Material nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyBoron nitridePolymer composites

Electroactive actuation characteristics of novel BNNT based materials are described. Several series of BNNT based electroactive materials including BNNT / polyimide composites and BNNT films are prepared. The BNNT based electroactive materials show high piezoelectric coefficients, d13, about 14.80 pm / V as well as high electrostrictive coefficients, M13, 3.21×10−16 pm2N2. The BNNT based electroactive materials will be used for novel electromechanical energy conversion devices.

Owner:NASA +1

Method for preparing boron nitride nanotube by magnesium reduction

InactiveCN101348242AEasy to purifyReduce manufacturing costNitrogen compoundsImpurityTemperature drop

The invention provides a method for preparing a borazon nano pipe by the magnesium-thermic reduction, belonging to the inorganic nano material field. In the prior method for preparing the borazon nano pipe, the problems of low yield and high cost exist. The method of the invention comprises the following steps that : (1) under argon shield, according to the mol ratio of 1:1-3:0.01-0.1, borazon, magnesium and ferrous salt are ground, mixed and screened; (2) under argon shield, the screened mixture is heated, and at a temperature of between 900 and 1,200 DEG C, argon gas is closed and the ammonia gas is filled, and when the temperature reaches between 1,200 and 1,600 DEG C, the temperature is maintained for 1 to 5h; (3) after the temperature decreases to the room temperature, the mixture is immersed in nitric acid, the product obtained has impurities removed, and the borazon nano pipe is obtained. The method of the invention has the advantages of simple process, easy control and amplification of reaction, low cost, high yield and uniform size and high purity of the prepared borazon nano pipe.

Owner:BEIJING UNIV OF TECH

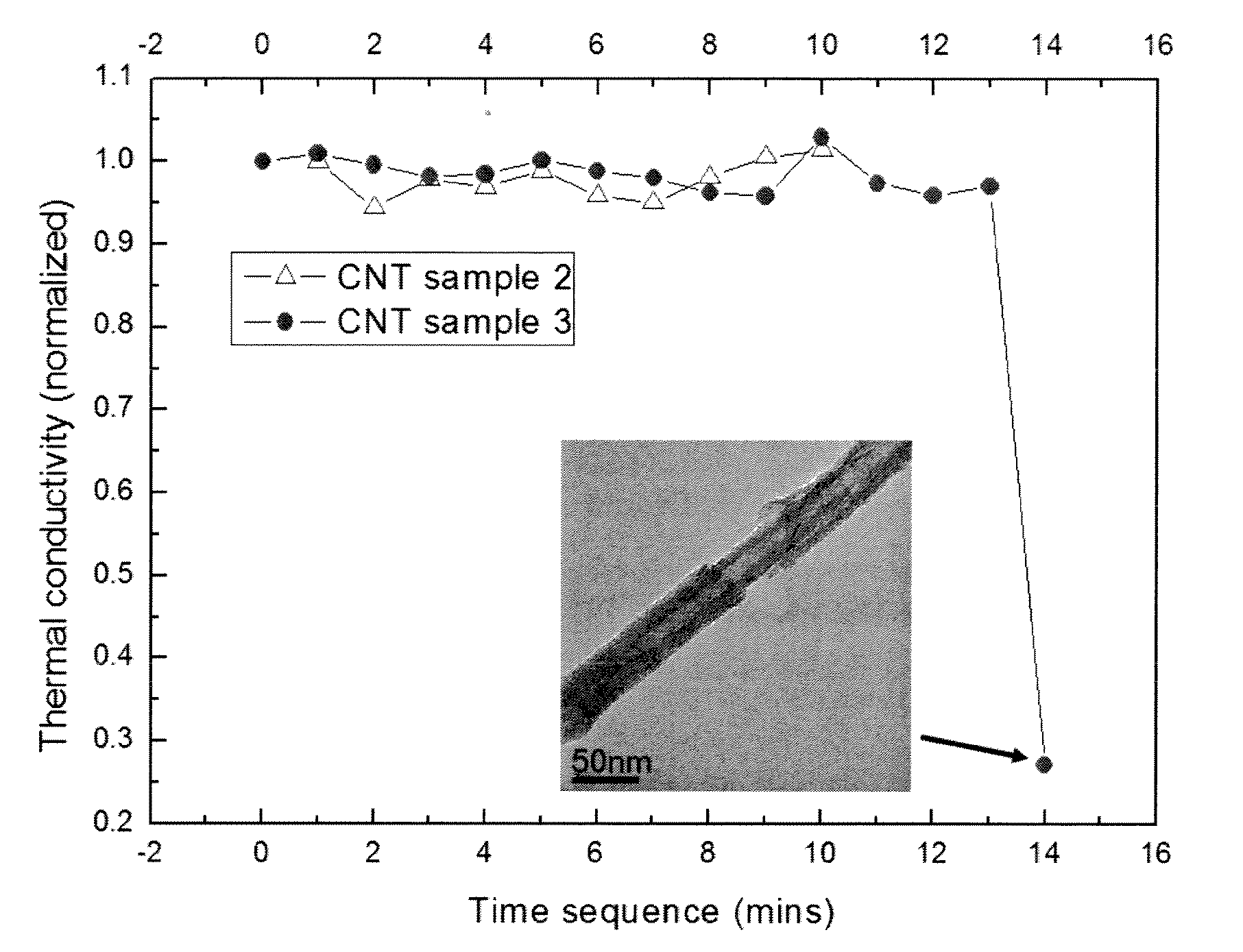

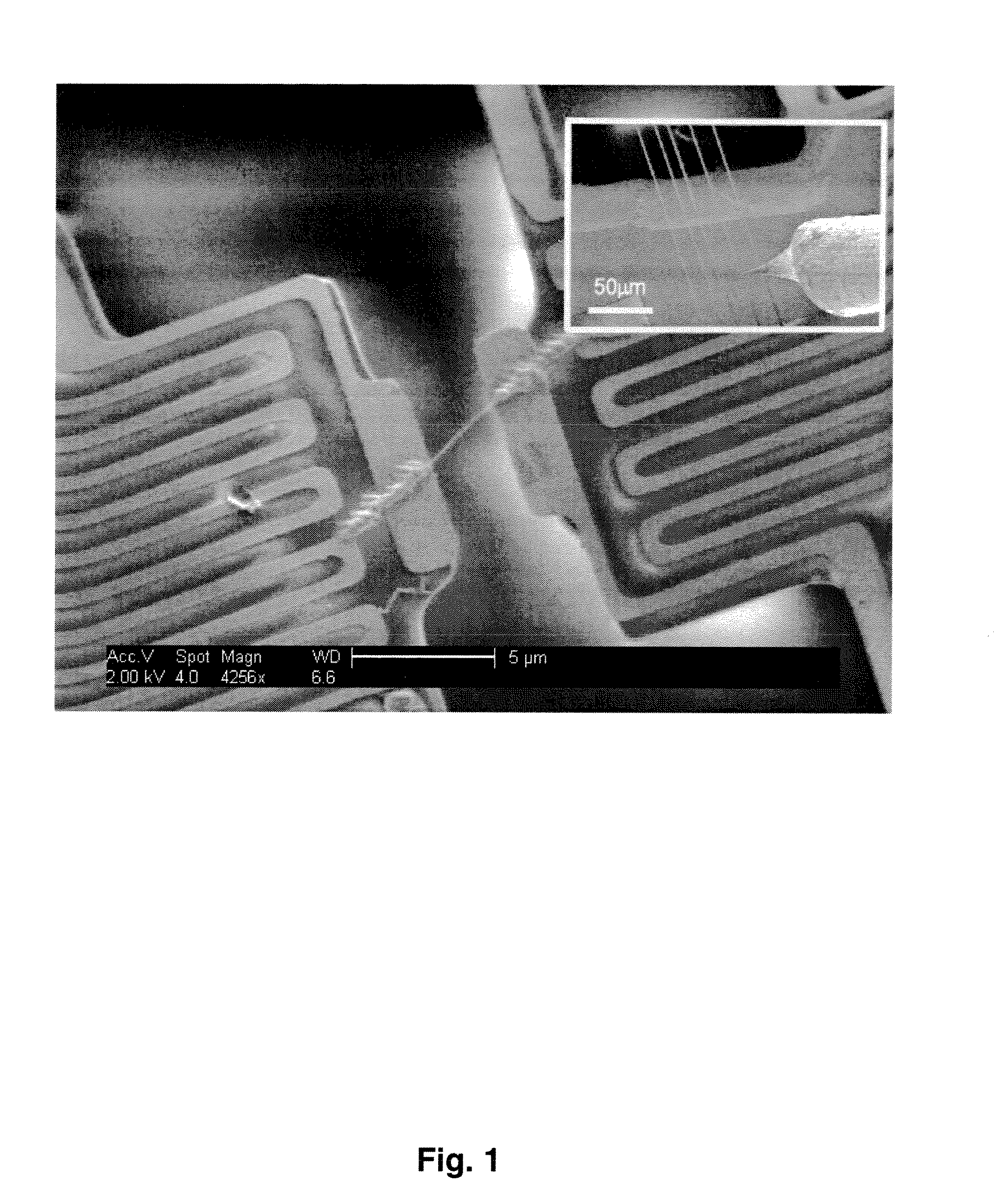

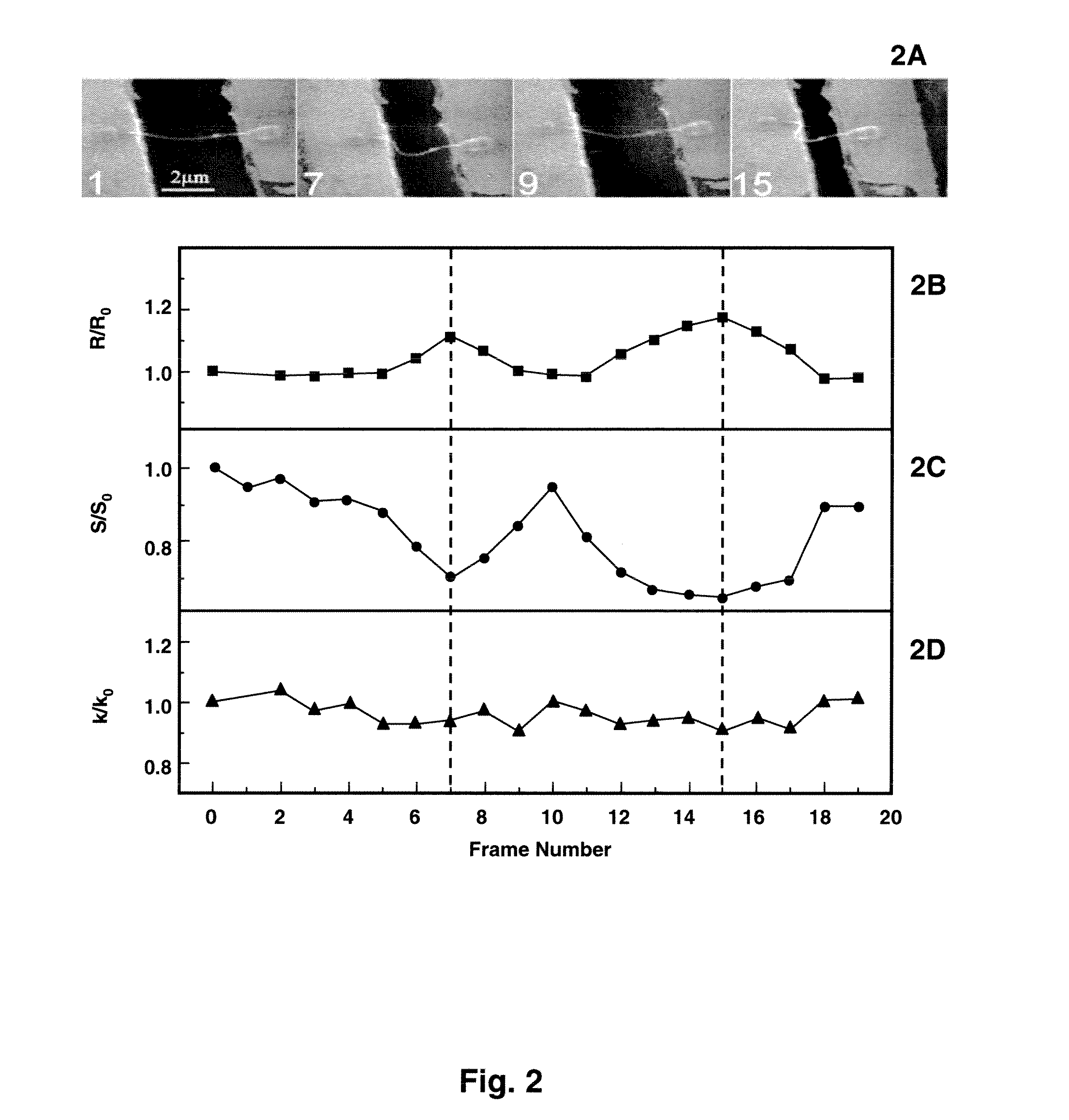

Nanotube phonon waveguide

ActiveUS20130255906A1Improve the immunityImprove thermal conductivityMaterial nanotechnologyAir-treating devicesBoron nitride nanotubePhonon

Owner:RGT UNIV OF CALIFORNIA

Silicon nitride ceramics enhanced by boron nitride nanotube and preparation method thereof

The invention relates to silicon nitride ceramics enhanced by a boron nitride nanotube, which consists of the following components in portion by mass: 0.25 to 5 portions of the boron nitride nanotube, 89.75 to 85 portions of silicon nitride, 10 portions of a sintering assistant and 700 portions of agate milling ball, wherein the mass ratio of mixed powder consisting of the boron nitride nanotube, the silicon nitride and the sintering assistant to the agate milling ball is 1 to 7 all along. The invention simultaneously discloses a preparation process for the silicon nitride ceramics, which comprises the following steps: A, weighing the components according to the requirements; B, ball-milling the weighed materials; C, putting the ball-milled mixed powder into a graphite die, and putting the graphite die into a multi-functional sintering furnace for sintering; D, preserving heat, and then naturally cooling the graphite die to room temperature; and E, preparing a finished product. The bending strength of the product prepared by the process reaches 773.1 MPa, and is 2.1 times of the bending strength of the pure silicon nitride ceramics; and the fracture toughness reaches 11.37 MPa.m, and is improved by 46 percent compared with the pure silicon nitride ceramics.

Owner:LINSHUSNTIAN ABRASIVE

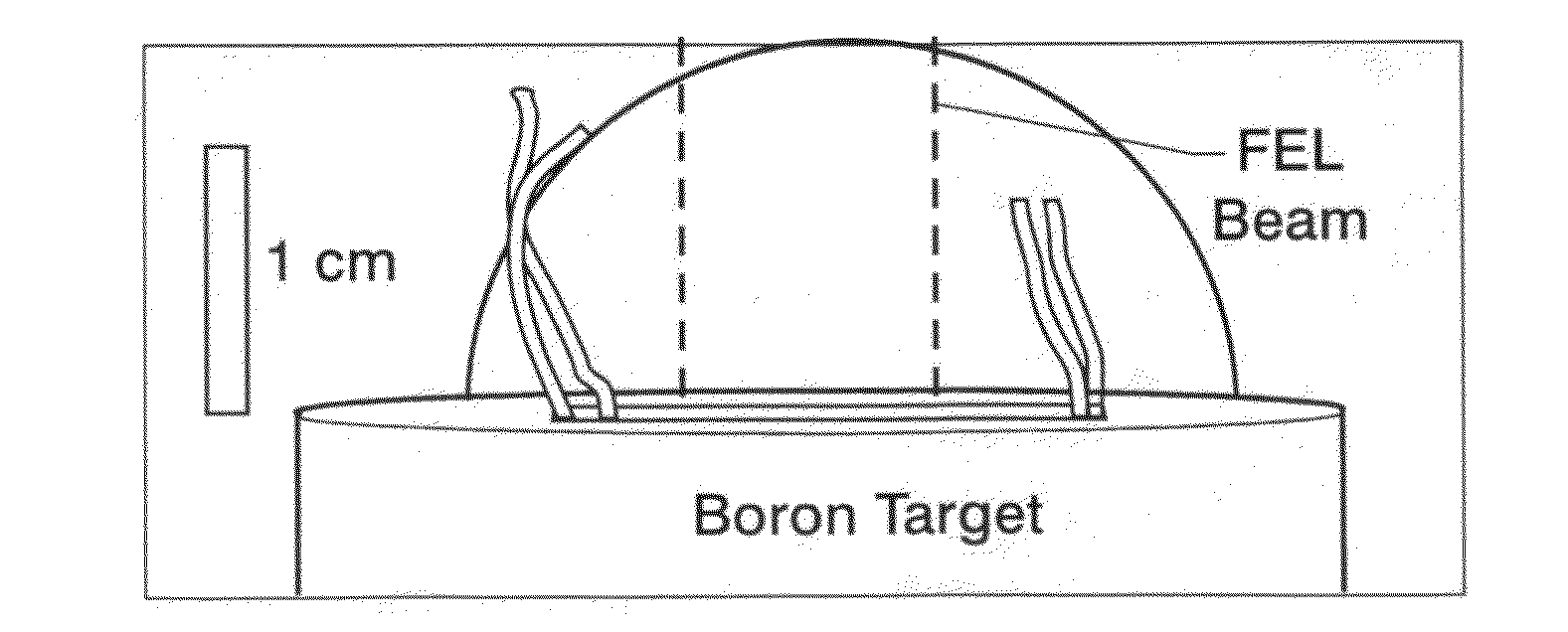

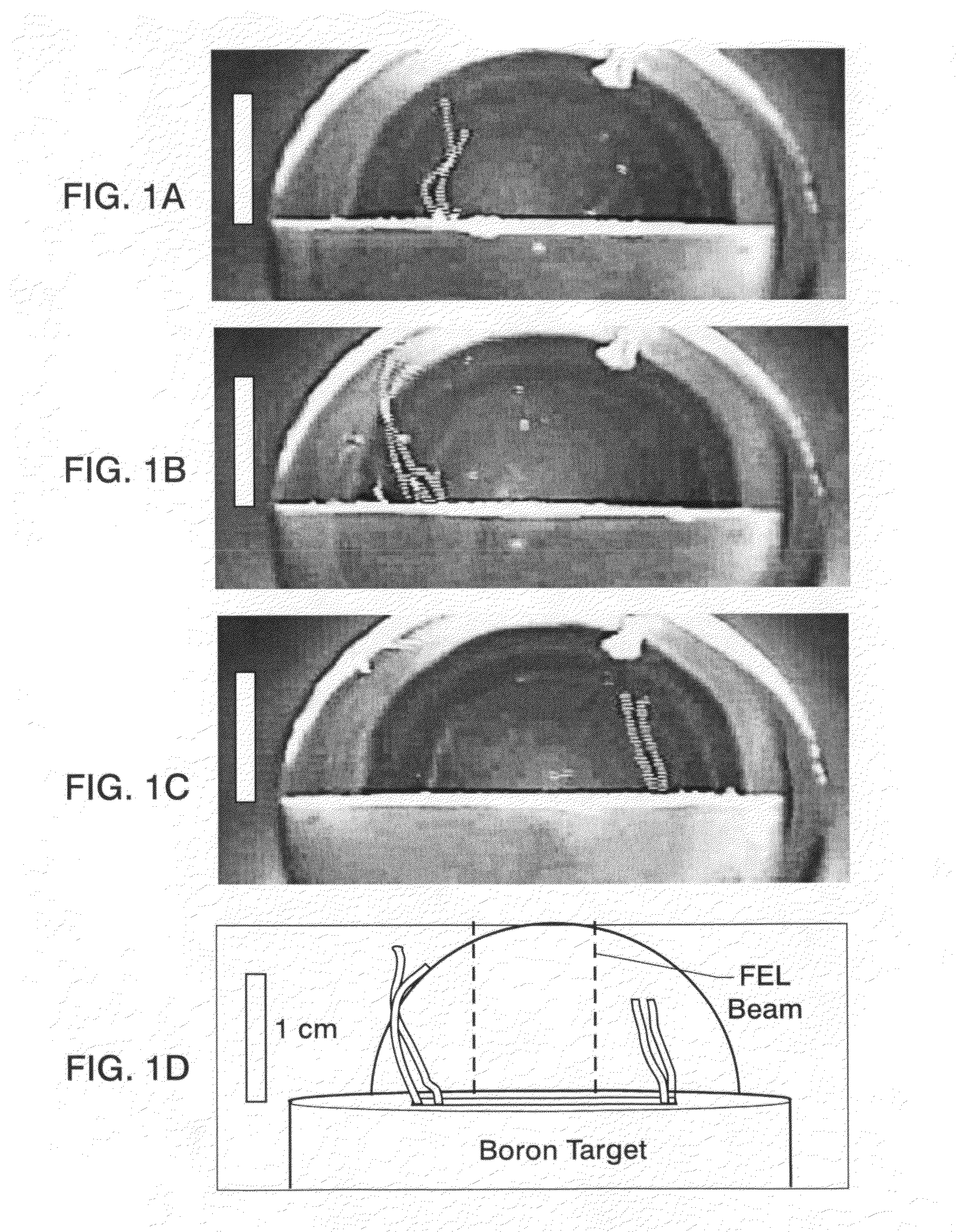

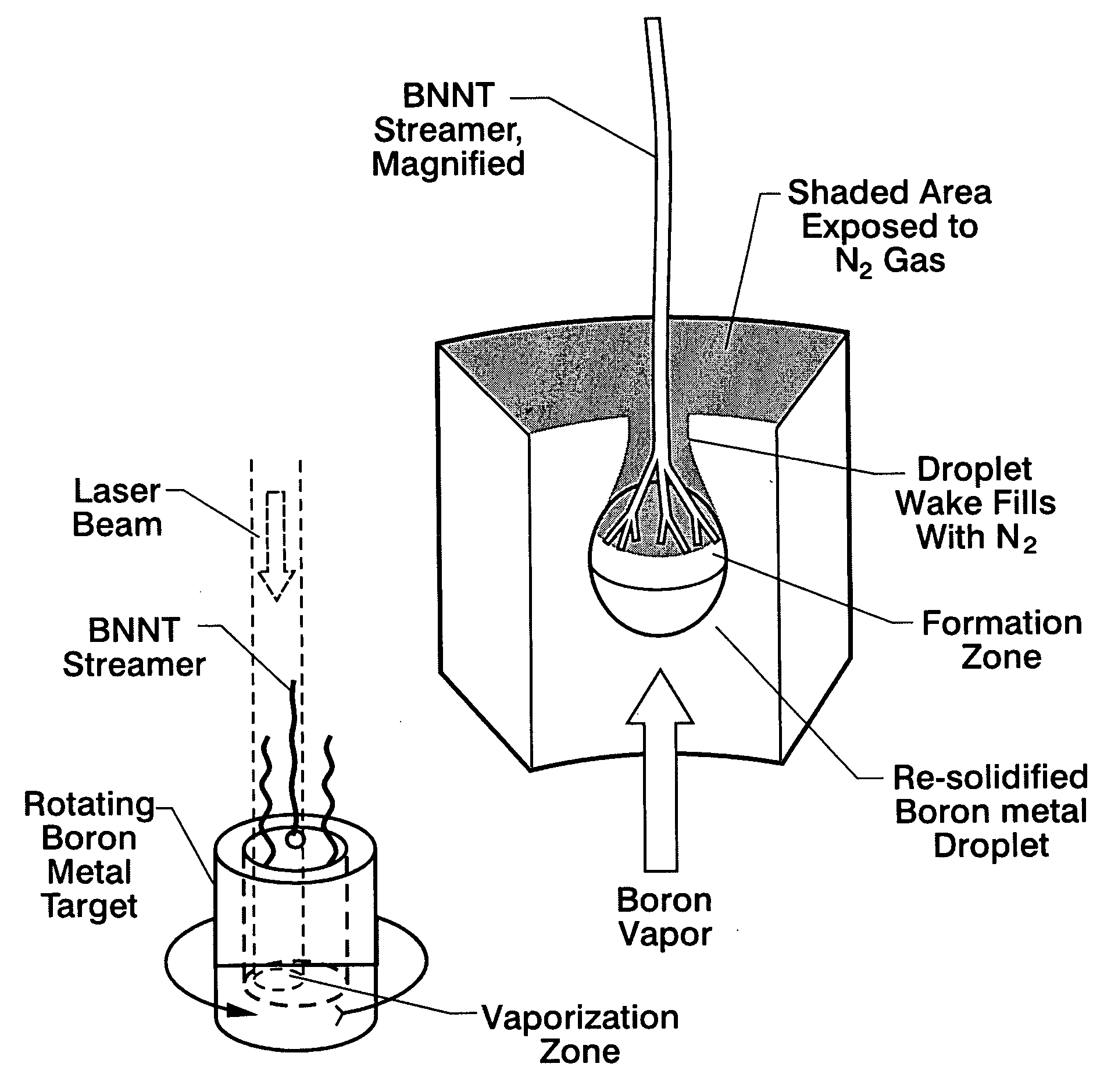

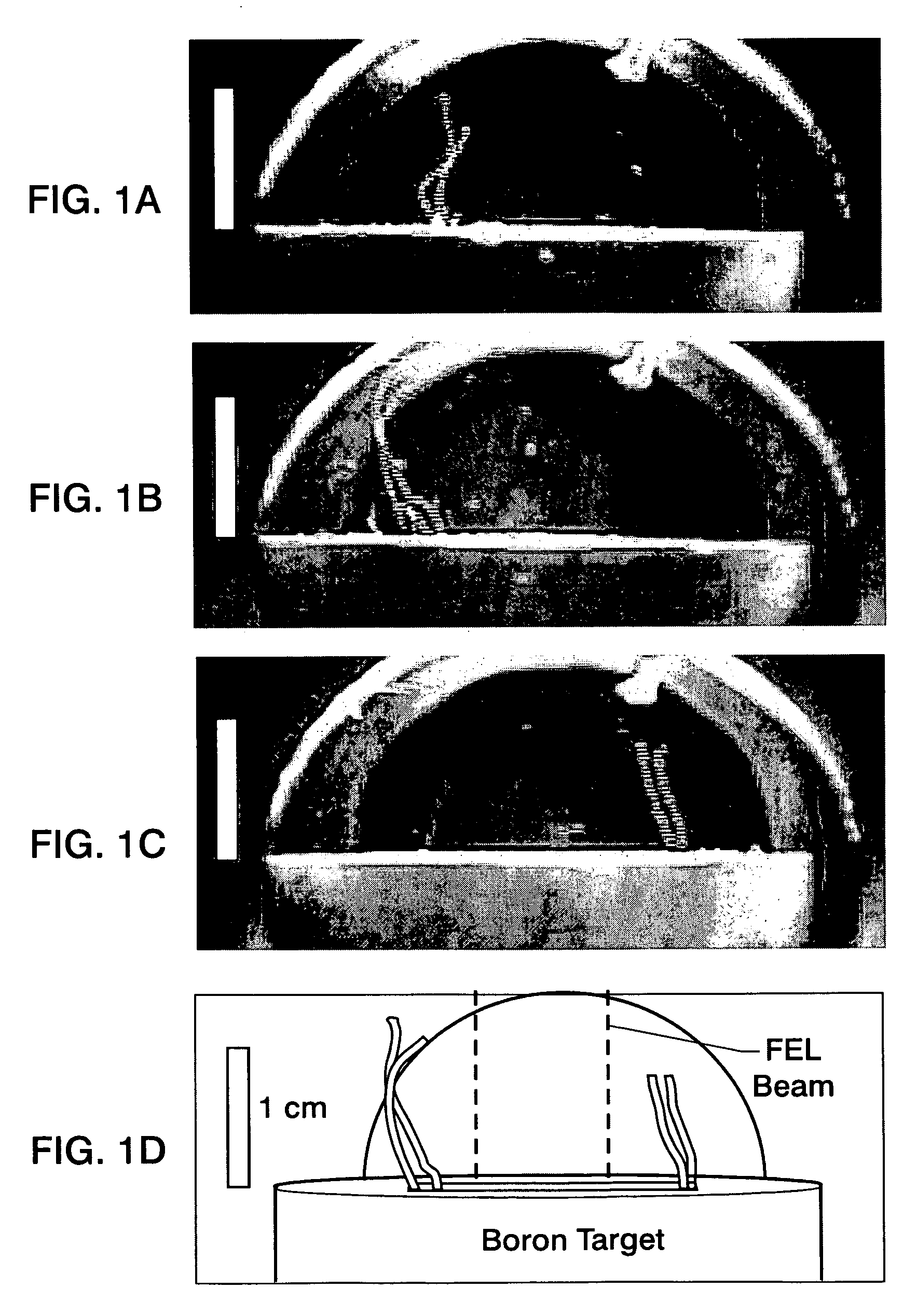

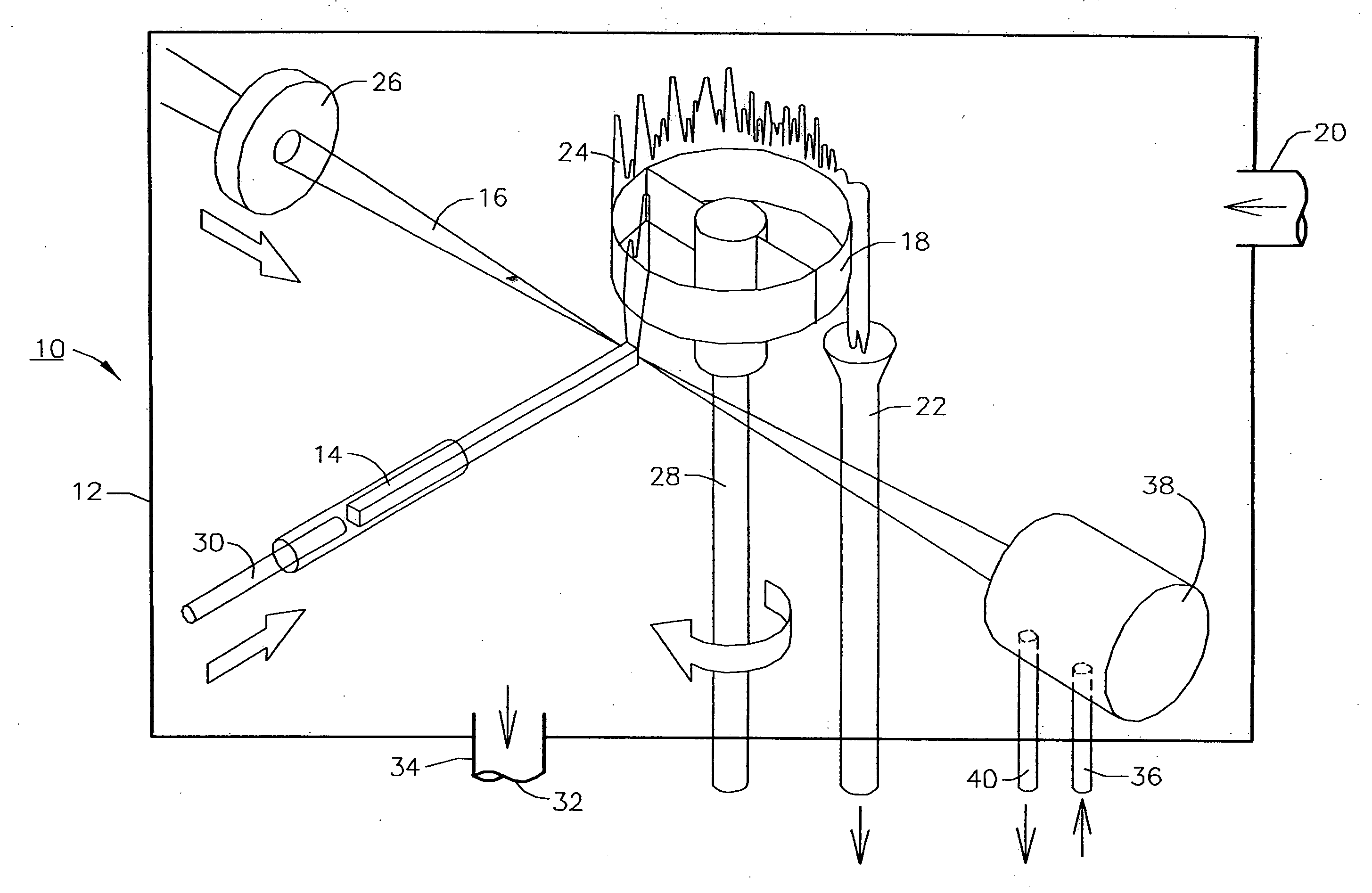

Efficient boron nitride nanotube formation via combined laser-gas flow levitation

A process for producing boron nitride nanotubes and / or boron-carbon-nitrogen nanotubes of the general formula BxCyNz. The process utilizes a combination of laser light and nitrogen gas flow to support a boron ball target during heating of the boron ball target and production of a boron vapor plume which reacts with nitrogen or nitrogen and carbon to produce boron nitride nanotubes and / or boron-carbon-nitrogen nanotubes of the general formula BxCyNz.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION UNITED STATES GOVERNMENT AS REPRESENTED BY THE ADMINISTATION OF +2

Method for preparing boron nitride coating carbon nano-tube/nano-wire and boron nitride nano-tube

Owner:SHANDONG UNIV

Method for preparing boron nitride nano-tube

InactiveCN101513995AMild reaction conditionsEasy to makeNitrogen compoundsAlkaline earth metalBoron nitride

The invention relates to a method for preparing boron nitride nano-tube. Boron-source catalyst precursor reacts in nitrogen, ammonia gas or mixed gas of ammonia gas and hydrogen, and crude products are separated and purified; the boron-source catalyst precursor is formed by the mixture of boron-containing compound, magnesium powder, alkaline-earth metal compound and transition-metal catalyst; the element mol ratio of B: Mg: M1: M2 is 1: 1.65-1.70: 0.165- 0.182: 0.01- 0.06, wherein, the M1 is alkaline earth metal element in the alkaline-earth metal compound, and the M2 is transition-metal element in the transition-metal catalyst. The invention has the advantage that as the boron-source catalyst precursor is adopted, mild reaction condition can be realized, and the preparation process is simpler; the prepared boron nitride nano-tube has even thickness as well as more than 85% of yield coefficient and more than 80wt.% of purity of the boron nitride nano-tube compared with raw material boron element.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

High-strength high-toughness magnesium-base alloy and preparation method thereof

The invention relates to a high-strength high-toughness magnesium-base alloy which is characterized by containing the following components in percentage by weight: 4.5-5.5% of Zn, 0.7-0.8% of Sn, 0.28-0.30% of Gd, 1-1.5% of Ti, 0.5-1% of Al, 0.7-0.8% of Ca, 0.9-1.1% of Sr, 0.3-0.4% of La, 0.4-0.45% of Sm, 0.45-0.55% of Nd, 0.4-0.45% of Y, 0.4-0.5% of Zr, 1-1.1% of Mn, 0.3-0.4% of Cu, 0.3-0.35% of Ce, 1-1.2% of Nb, 4-6% of boron nitride nanotube particle, 5-6% of graphene, 3-4% of tungsten carbide crystal whisker and the balance of Mg. The strength, toughness, heat resistance and tensile property of the alloy are greatly enhanced as compared with the prior art.

Owner:YANCHENG XINYANG ELECTROTHERMAL MATERIAL CO LTD

Preparation of boron nitride nano tube

A process for preparing nanotubes of boron nitride (BN-NTs) includes such steps as dissolving H3BO3, CO(NH2)2 and Fe(NO3)3.9H2O or Co(NO3)2.6H2O, or Ni(NO3)2.6H2O) in deionized water, vacuum drying to obtain mixture powder, loading in open quartz tube, heating to 1000-1300 deg.C, holding the temp for 60-90 min, cooling, and immersing the powder in diluted nitric acid for removing catalyst. Its advantages are simple process and low cost.

Owner:ZHEJIANG UNIV

Method for preparing boron nitride nanotubes by annealing of inorganic boracic precursor

InactiveCN101580236ASimple preparation processChemically stableNanostructure manufactureNitrogen compoundsBoron nitrideBoron

The invention relates to a novel method for preparing boron nitride nanotubes by annealing of an inorganic boracic precursor, comprising annealing the inorganic boracic precursor for 5-50h at the temperature of 800-1200 DEG C to obtain boron nitride nanotubes. The beneficial effects of the invention comprise that 1) annealing reaction of the boracic precursor is adopted to prepare boron nitride nanotubes, boron element is sintered with catalyst to form porous solid, the problem that the yield and the purity of boron nitride nanotubes are low is solved, the preparation yield limit of boron nitride nanotubes is surmounted, the preparation process is simple, the product yield of boron nitride nanotubes is above 80% and the purity is above 85%; 2) the chemical property of the prepared inorganic boracic precursor is stable which is applicable to batch manufacturing boron nitride nanotubes with low cost and high purity; the reaction condition of preparing precursor is mild, the process is simple, and the energy consumption and the cost are low, which is applicable to industrialized production and the precursor can be directly used to prepare boron nitride nanotubes.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

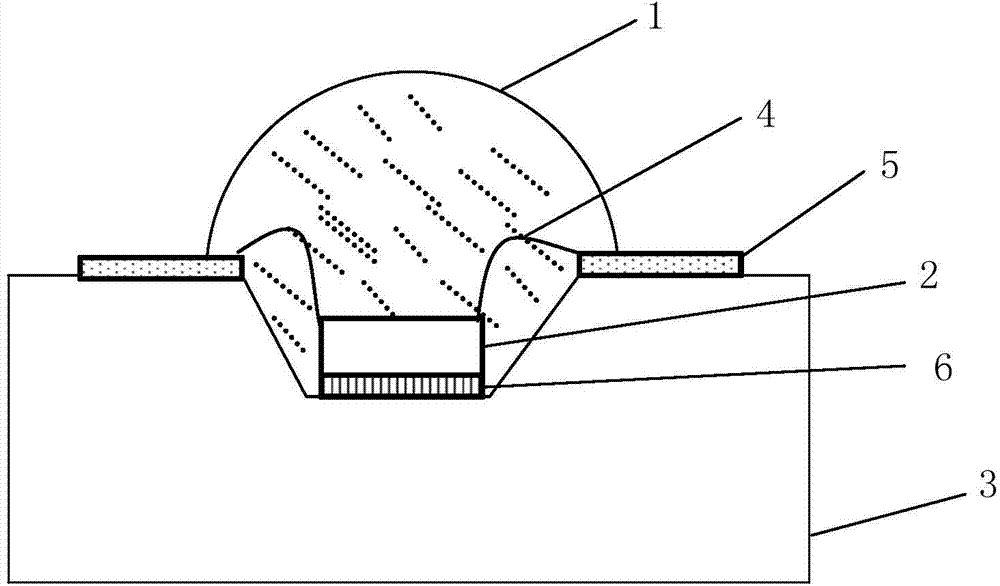

Sealant for large power LED, and large power LED

ActiveCN104774470AImprove job stabilityImprove stabilitySolid-state devicesSemiconductor devicesEpoxyCarbon nanotube

The invention discloses a sealant for a large power LED, and the large power LED. The sealant comprises a composite material composed of a high heat conduction filler and a matrix, the heat conductivity of the high heat conduction filler is 30-5300W / mK, the filler is one or a combination of more of graphene, a boron nitride sheet, a carbon nanotube, a boron nitride nanotube and a nanometer silver wire, and the matrix is silica gel or epoxy resin; and the mass percent of the high heat conduction filler in the composite material is 1-20%, and the mass percent of the matrix in the composite material is 80-99%. The inside and the outside of the reflection cup of the large power LED are filled with the sealant, and the sealant completely covers the LED chip and a pair of weld lines of the large power LED to obtain improved large power LED. The large power LED has good heat radiation effect and good work stability, and the sealant ensures that the light transmittance of the LED meets application requirements.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

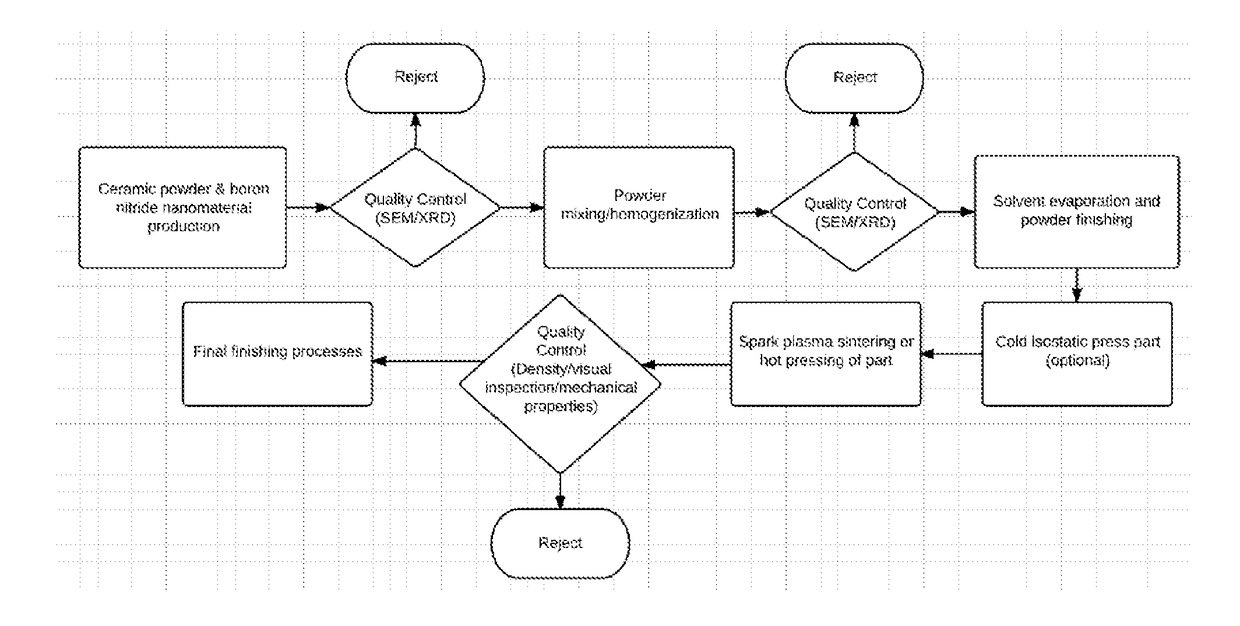

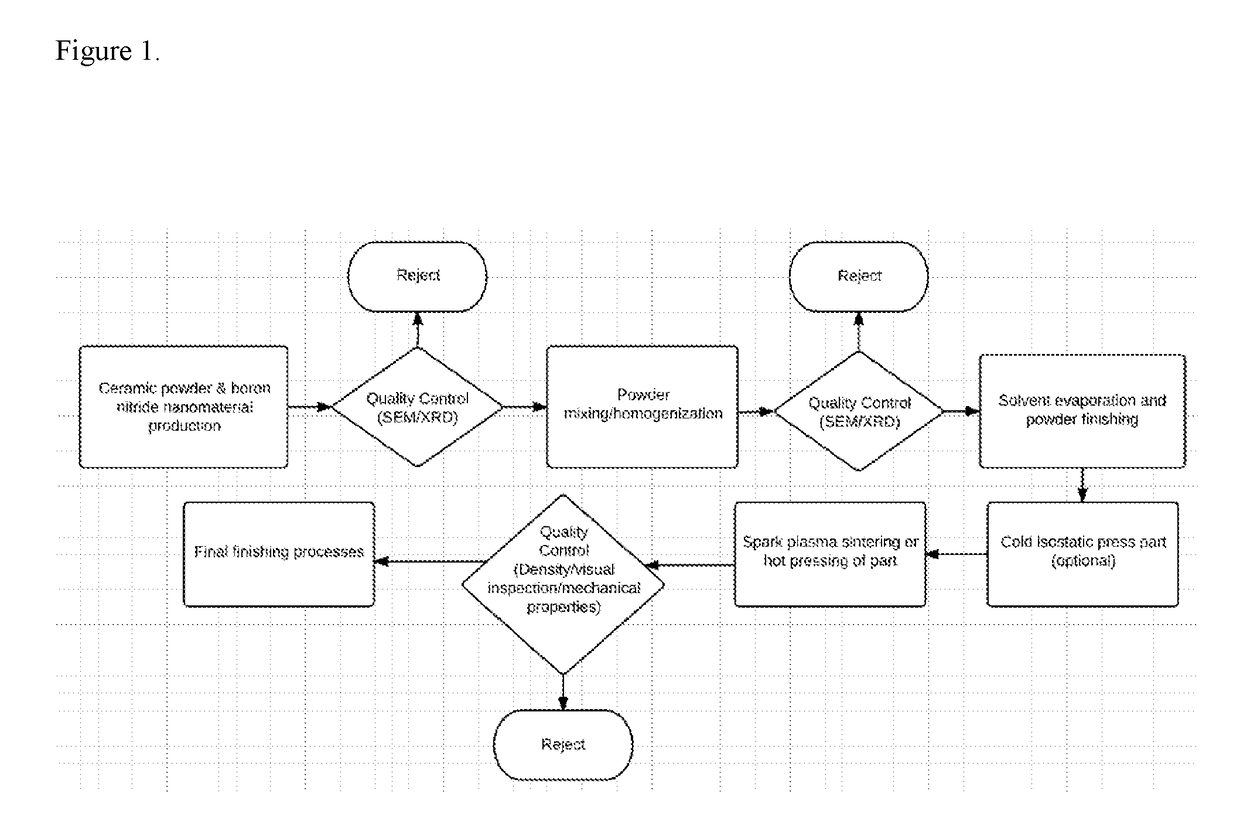

Ceramic and metal boron nitride nanotube composites

InactiveUS20170275742A1High chemical and thermal stabilityImprove thermal conductivityFlexural strengthBoron nitride

The present invention provides for materials and methods of making metal and ceramic matrix composites reinforced with boron nitride nanomaterials for improved physical properties such as hardness, fracture toughness, and bend strength.

Owner:GANOR A JACOB

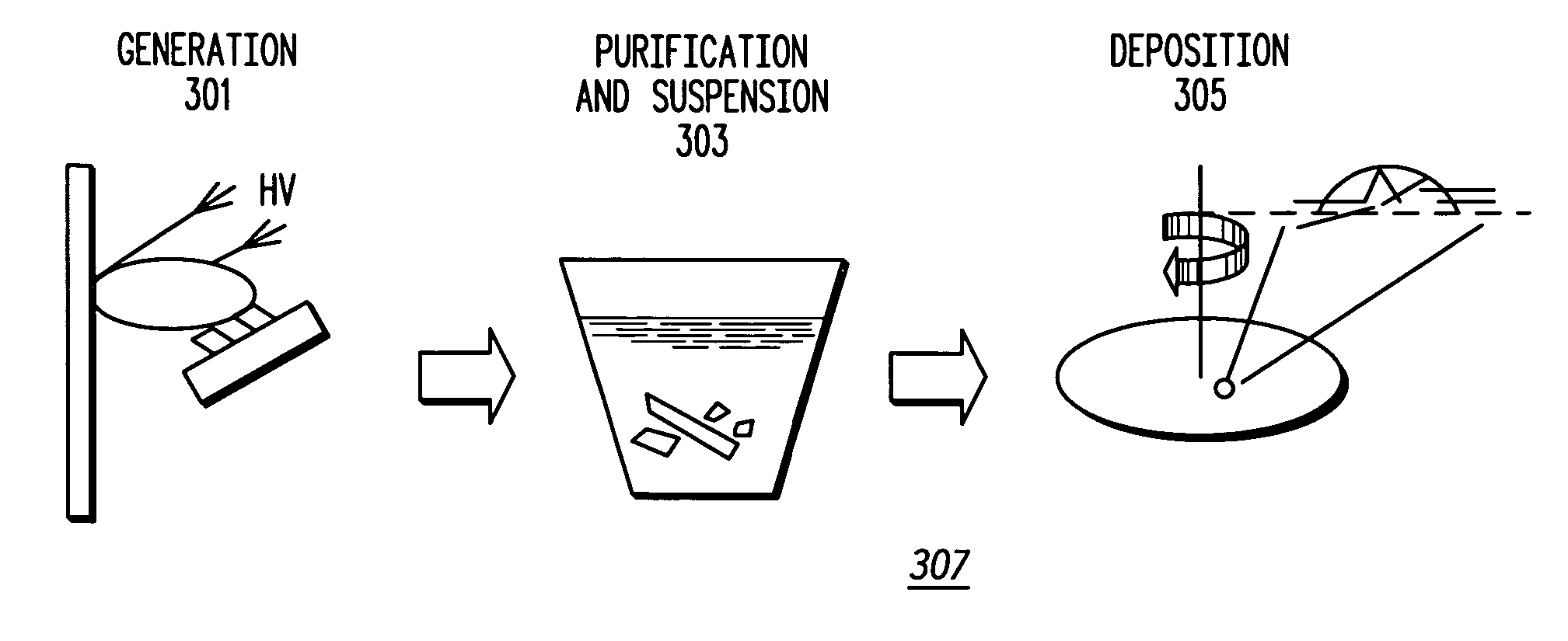

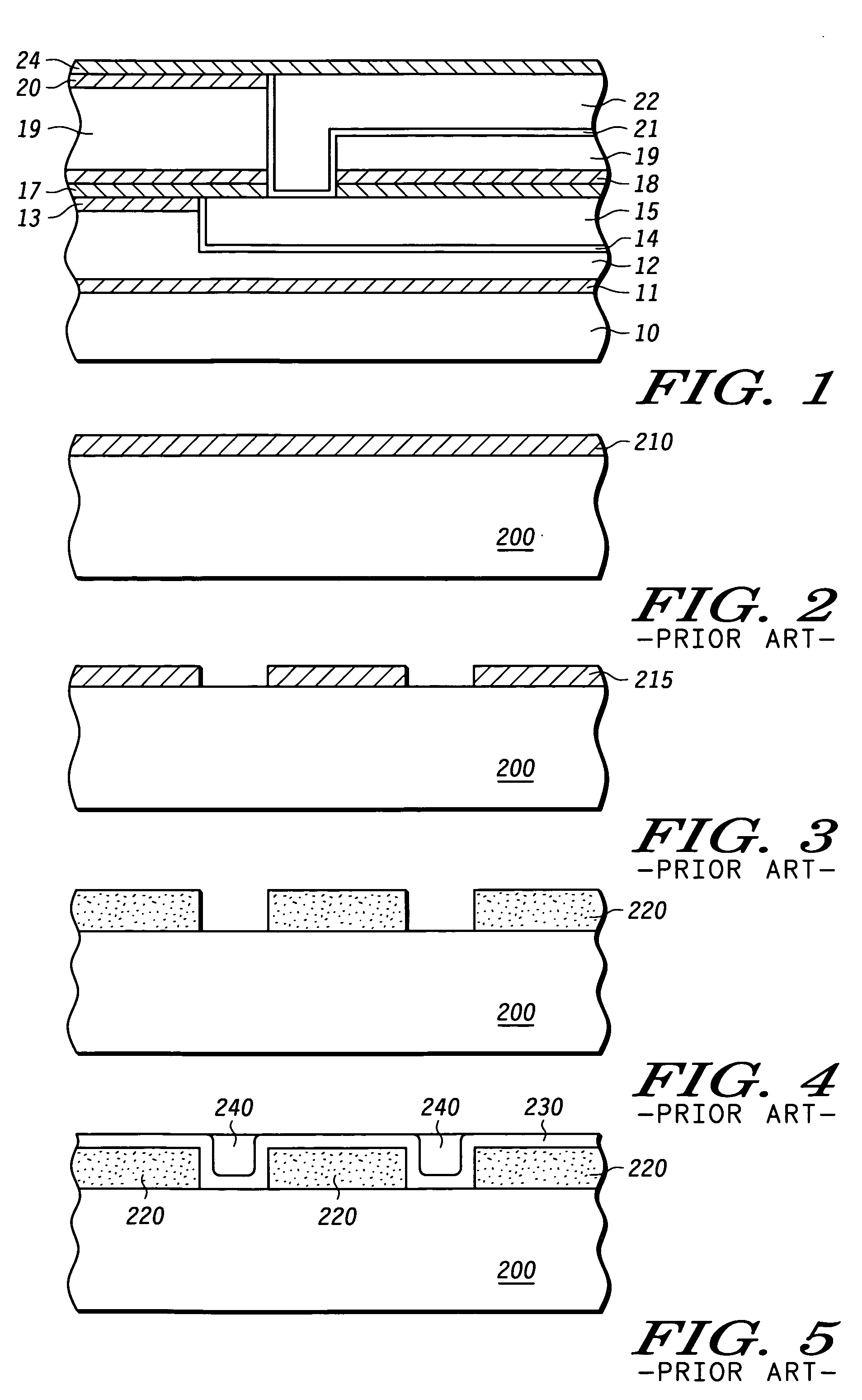

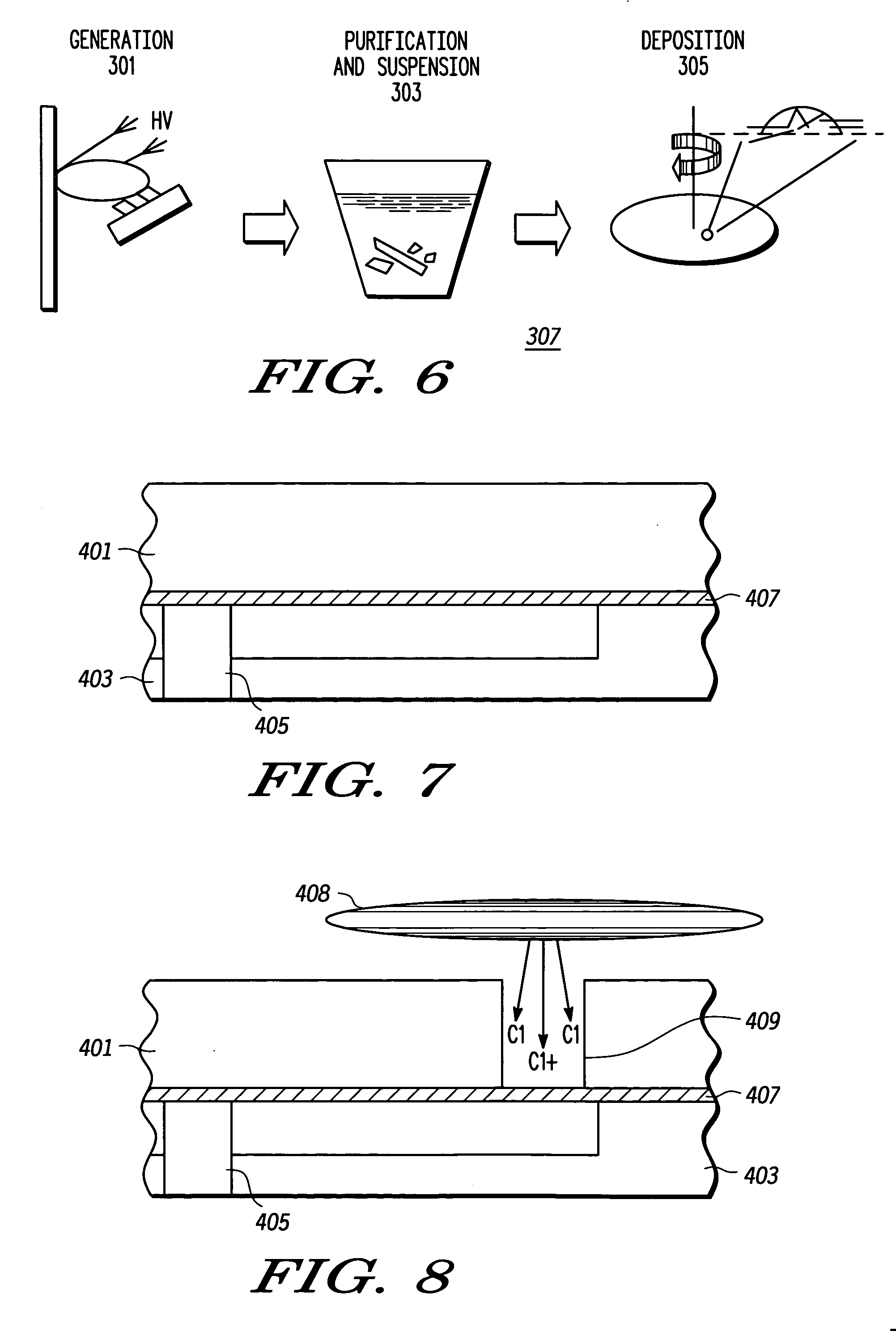

Deposition and patterning of boron nitride nanotube ILD

InactiveUS20060063392A1Semiconductor/solid-state device detailsNanoinformaticsLiquid mediumNanoparticle

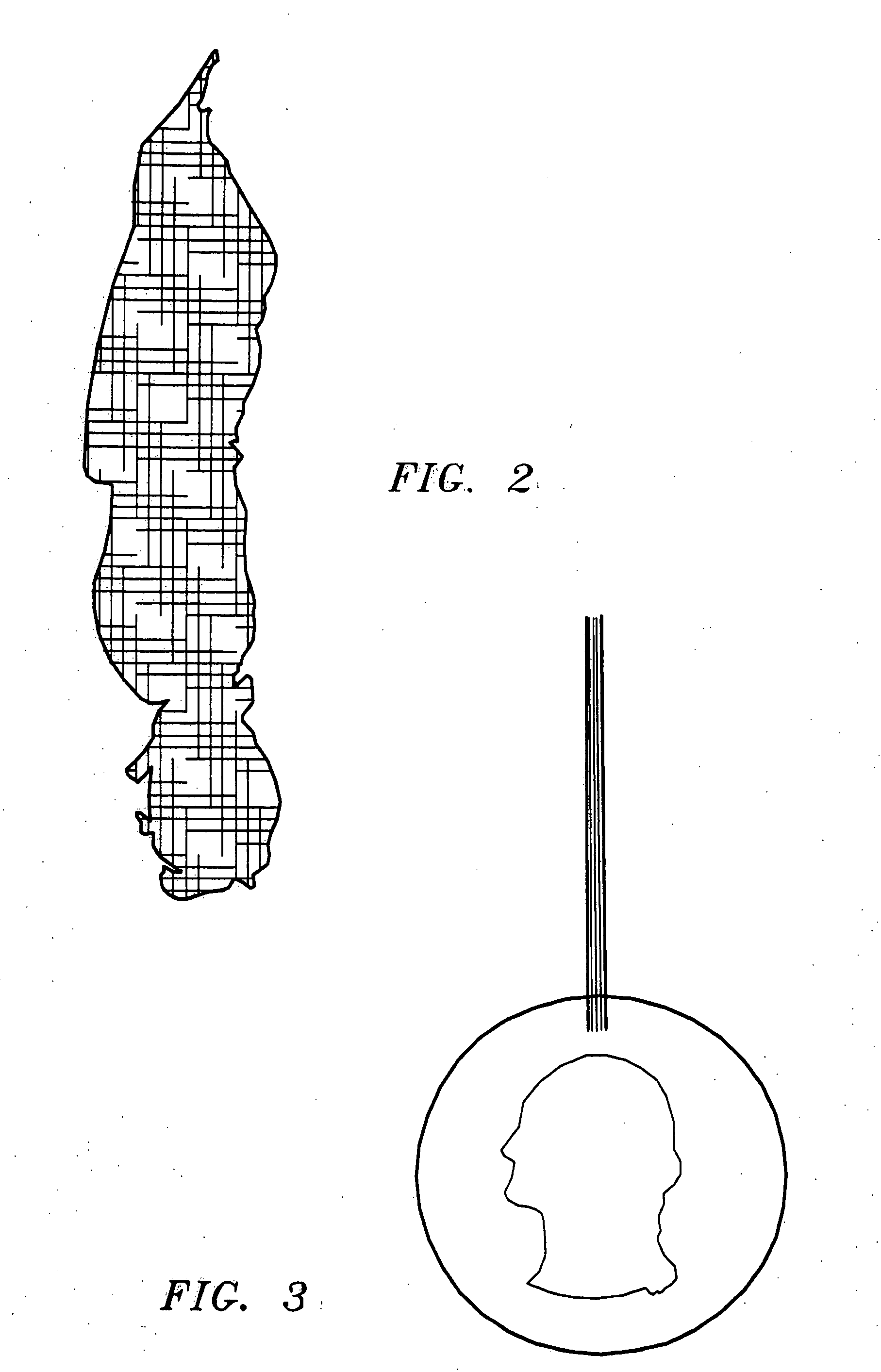

A method for forming a dielectric layer is disclosed herein. In accordance with the method, a first material is provided (303) which comprises a suspension of nanoparticles in a liquid medium. A dielectric layer is then formed (305) on the substrate from the suspension through an evaporative process.

Owner:NXP USA INC

Efficient boron nitride nanotube formation via combined laser-gas flow levitation

A process for producing boron nitride nanotubes and / or boron-carbon-nitrogen nanotubes of the general formula BxCyNz. The process utilizes a combination of laser light and nitrogen gas flow to support a boron ball target during heating of the boron ball target and production of a boron vapor plume which reacts with nitrogen or nitrogen and carbon to produce boron nitride nanotubes and / or boron-carbon-nitrogen nanotubes of the general formula BxCyNz.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION UNITED STATES GOVERNMENT AS REPRESENTED BY THE ADMINISTATION OF +2

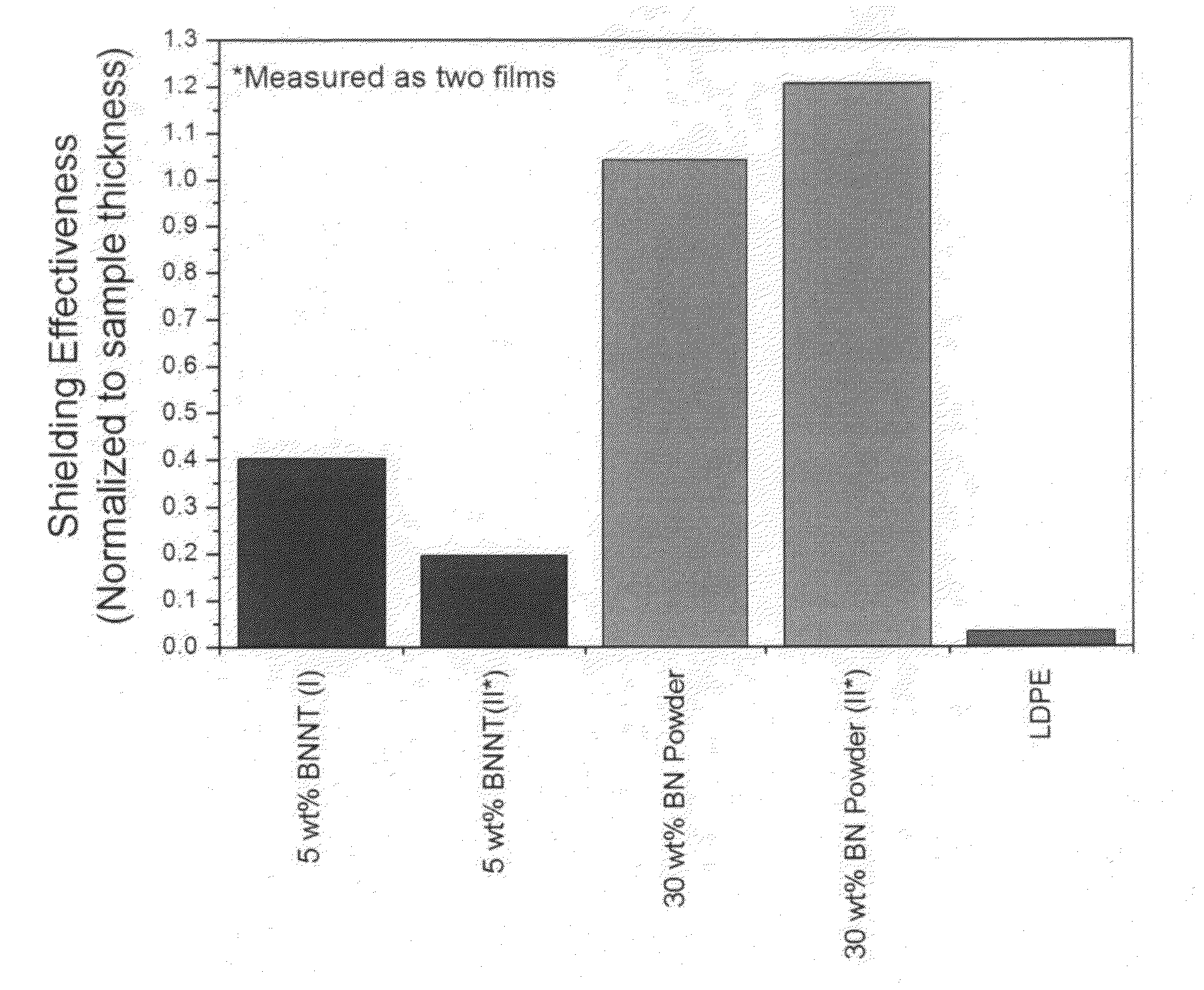

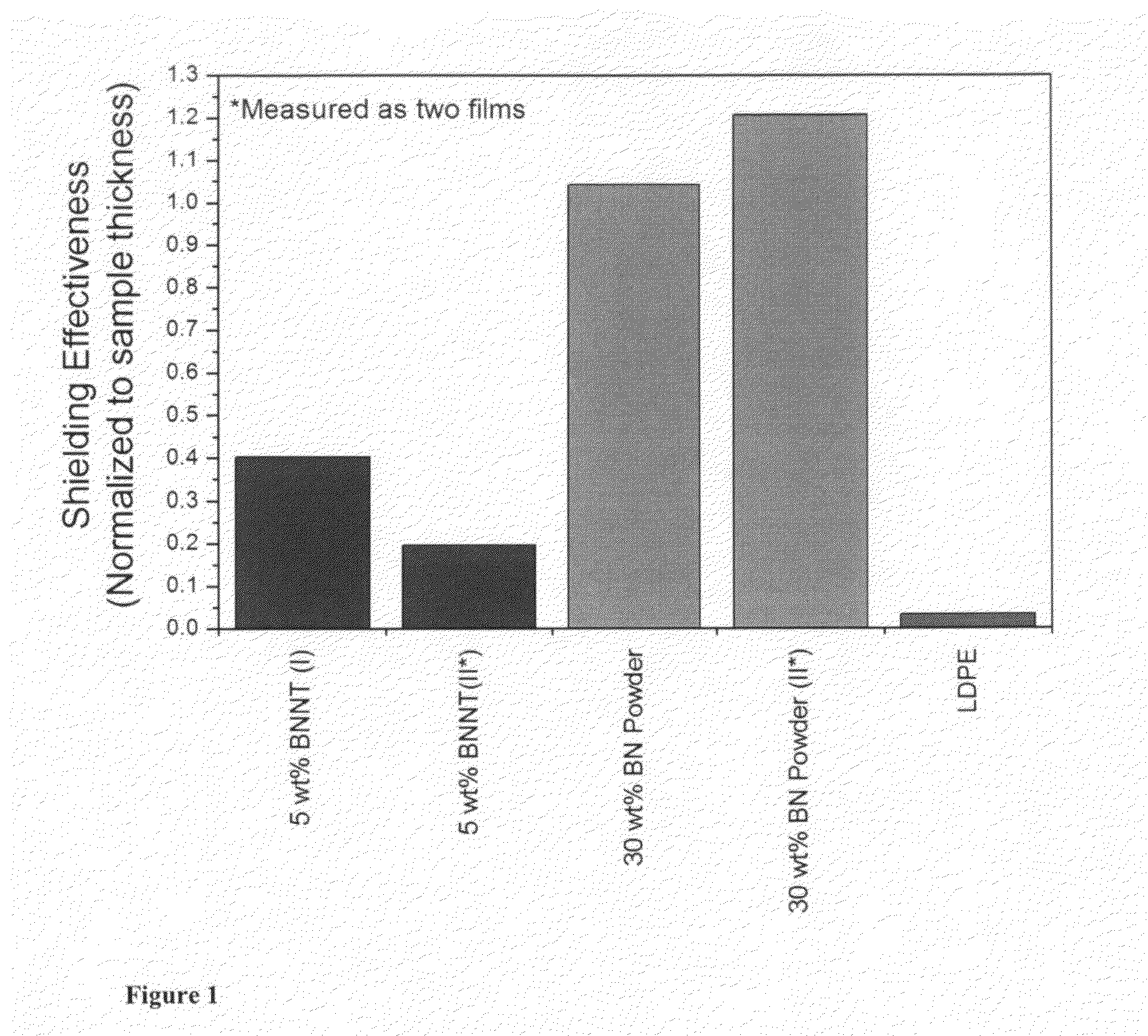

Boron nitride and boron nitride nanotube materials for radiation shielding

Effective radiation shielding is required to protect crew and equipment in various fields including aerospace, defense, medicine and power generation. Light elements and in particular hydrogen are most effective at shielding against high-energy particles including galactic cosmic rays, solar energetic particles and fast neutrons. However, pure hydrogen is highly flammable, has a low neutron absorption cross-section, and cannot be made into structural components. Nanocomposites containing the light elements Boron, Nitrogen, Carbon and Hydrogen as well dispersed boron nano-particles, boron nitride nanotubes (BNNTs) and boron nitride nano-platelets, in a matrix, provide effective radiation shielding materials in various functional forms. Boron and nitrogen have large neutron absorption cross-sections and wide absorption spectra. The incorporation of boron and nitrogen containing nanomaterials into hydrogen containing matrices provides composites that can effectively shield against neutrons and a wide range of radiation species of all energies without fragmentation and the generation of harmful secondary particles.

Owner:JEFFERSON SCI ASSOCS LLC +1

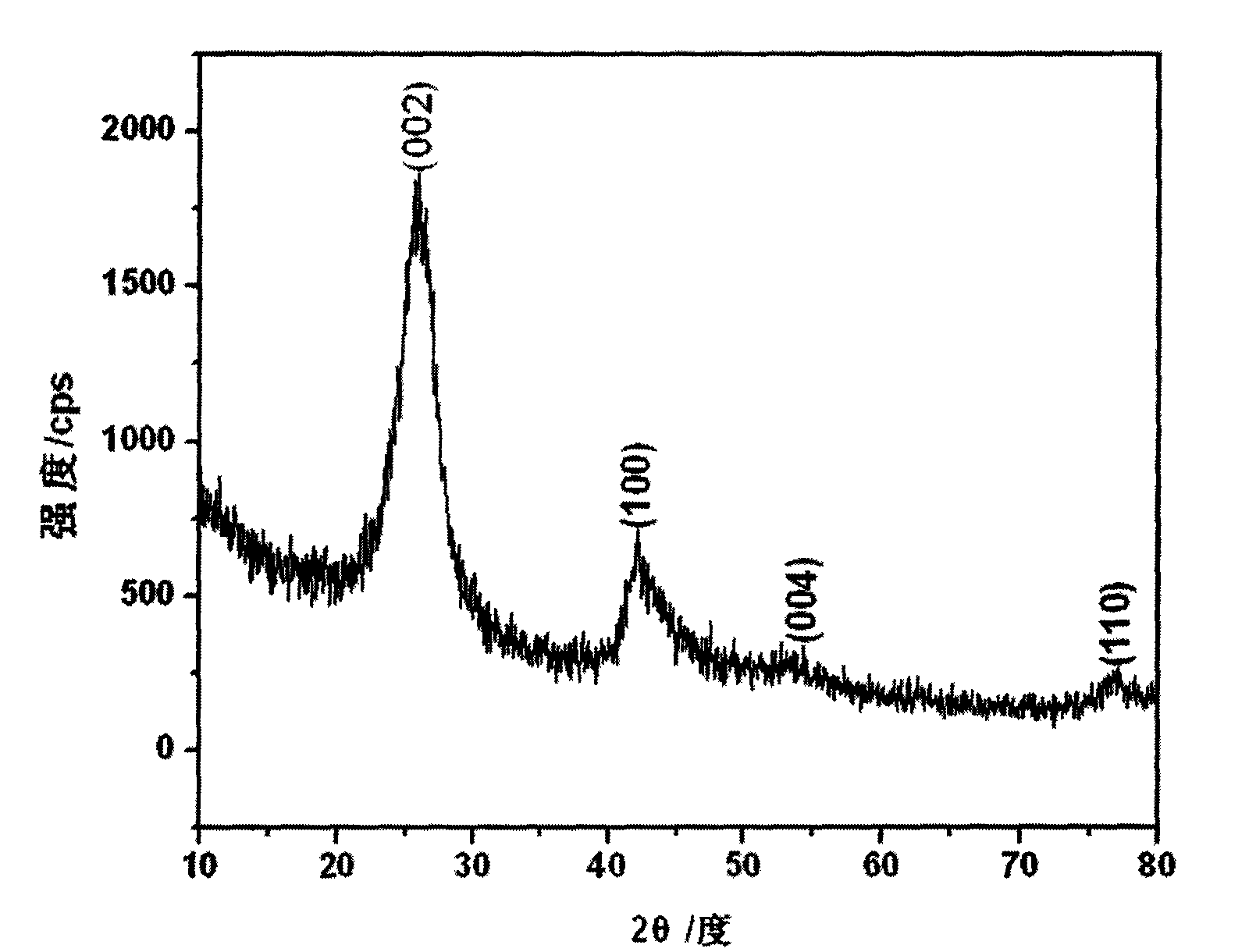

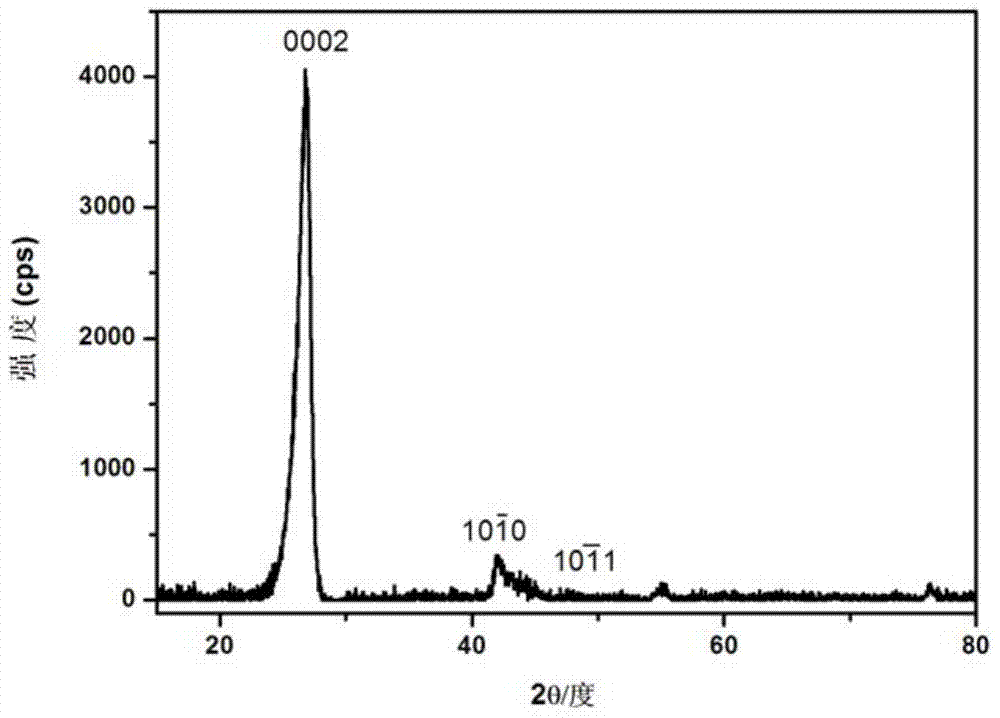

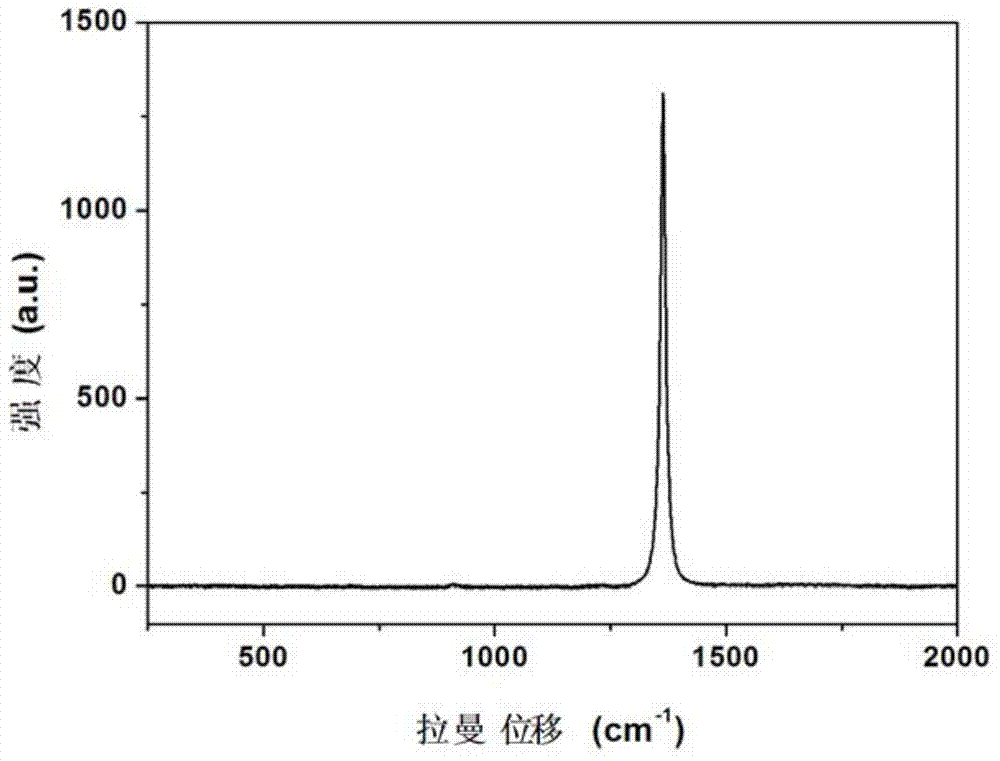

Preparation method of boron nitride nano tube

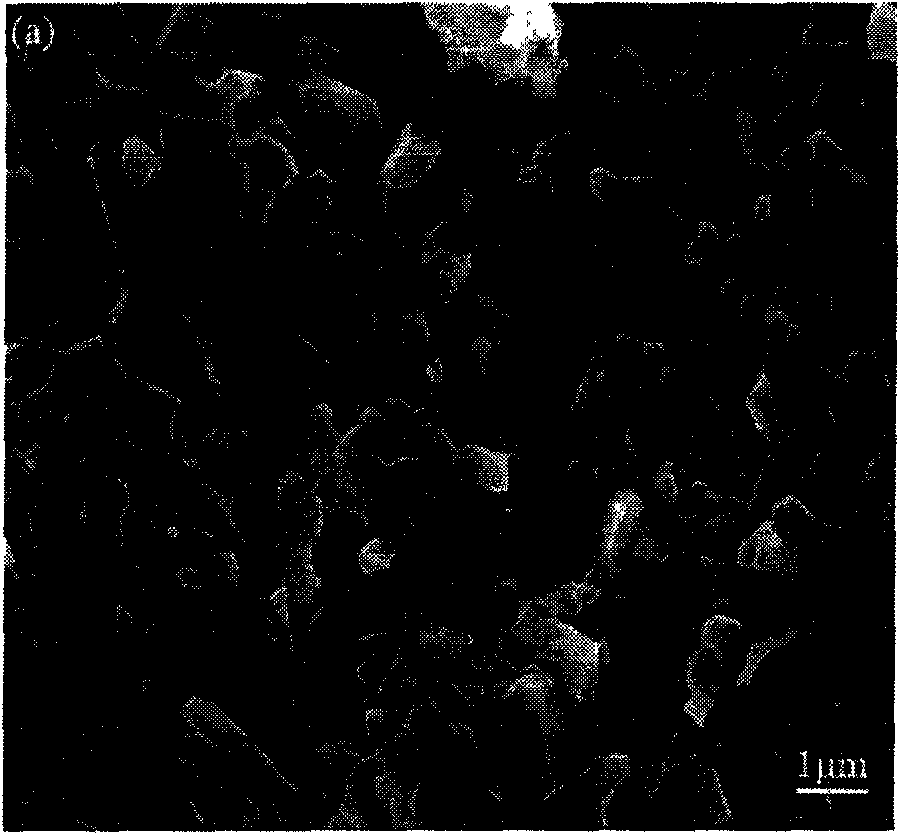

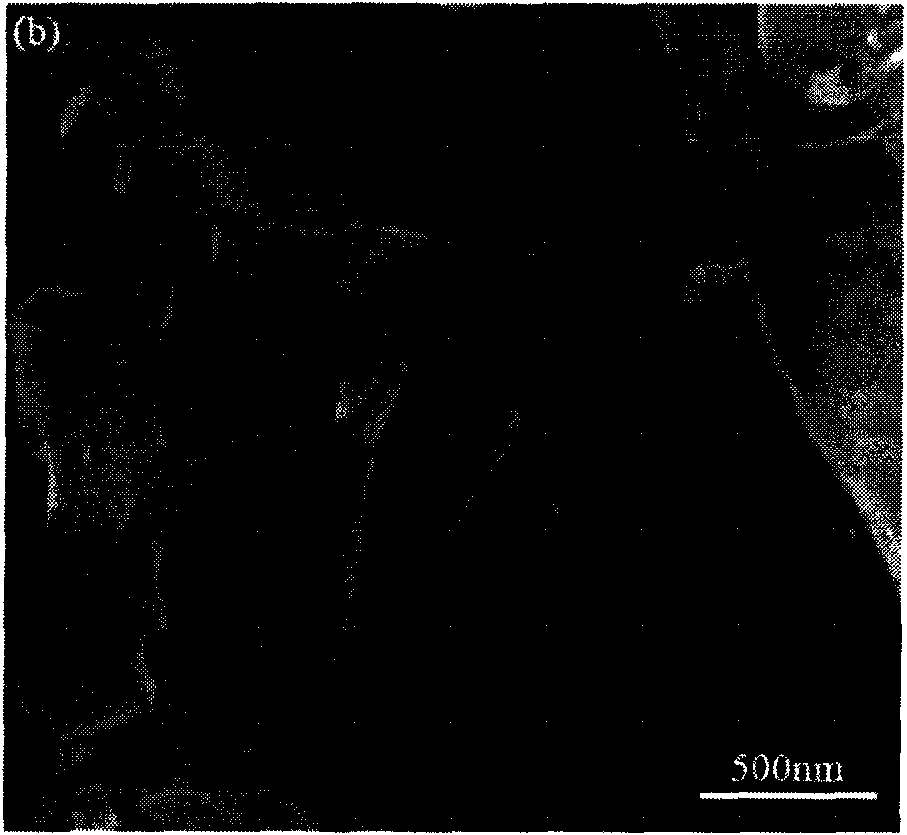

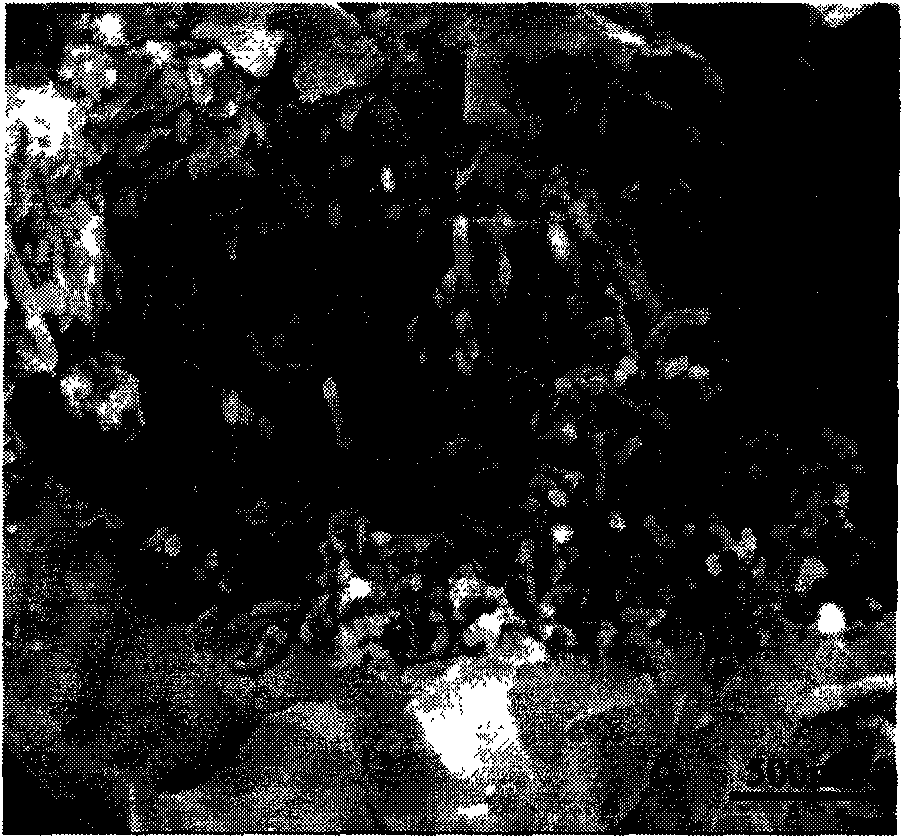

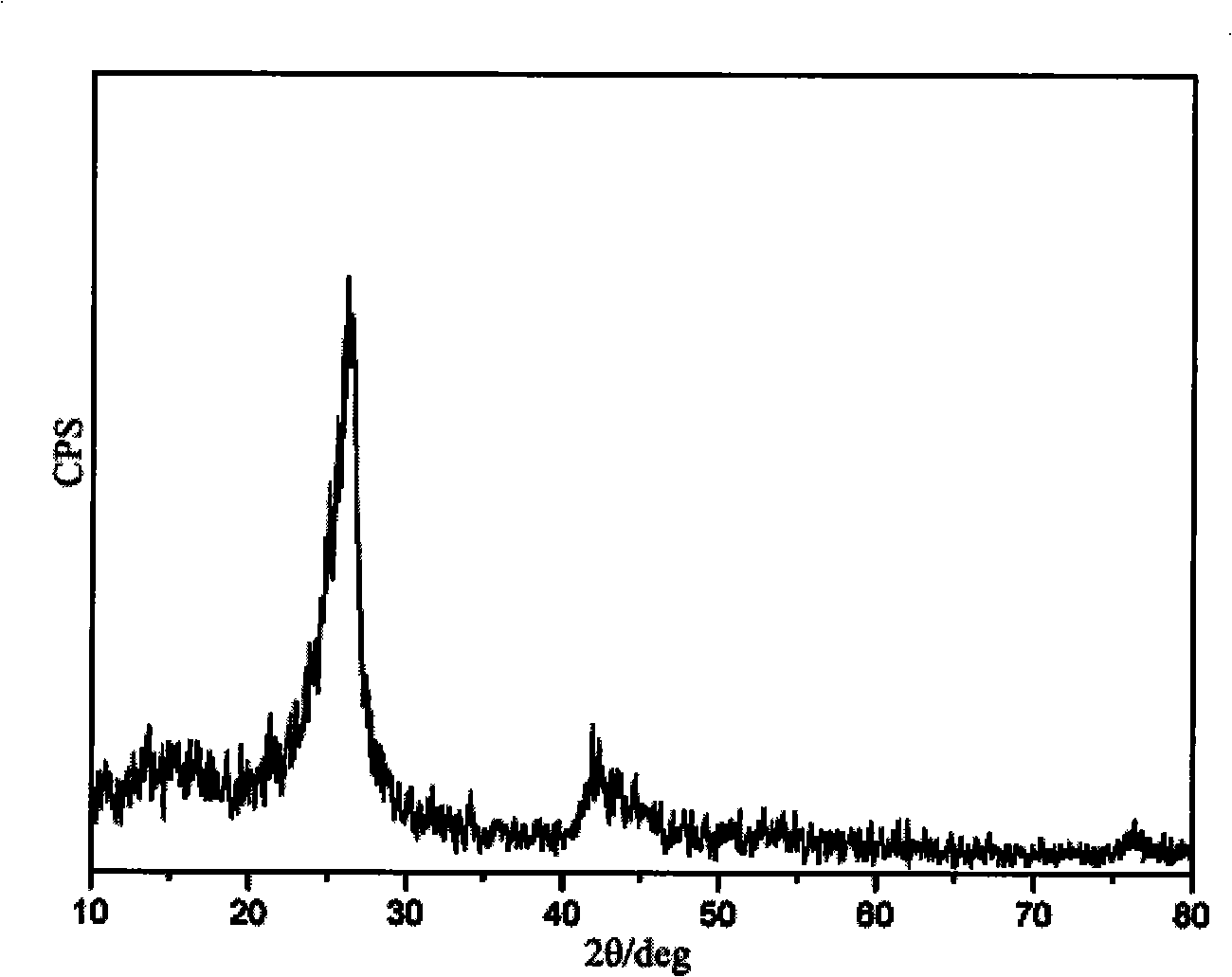

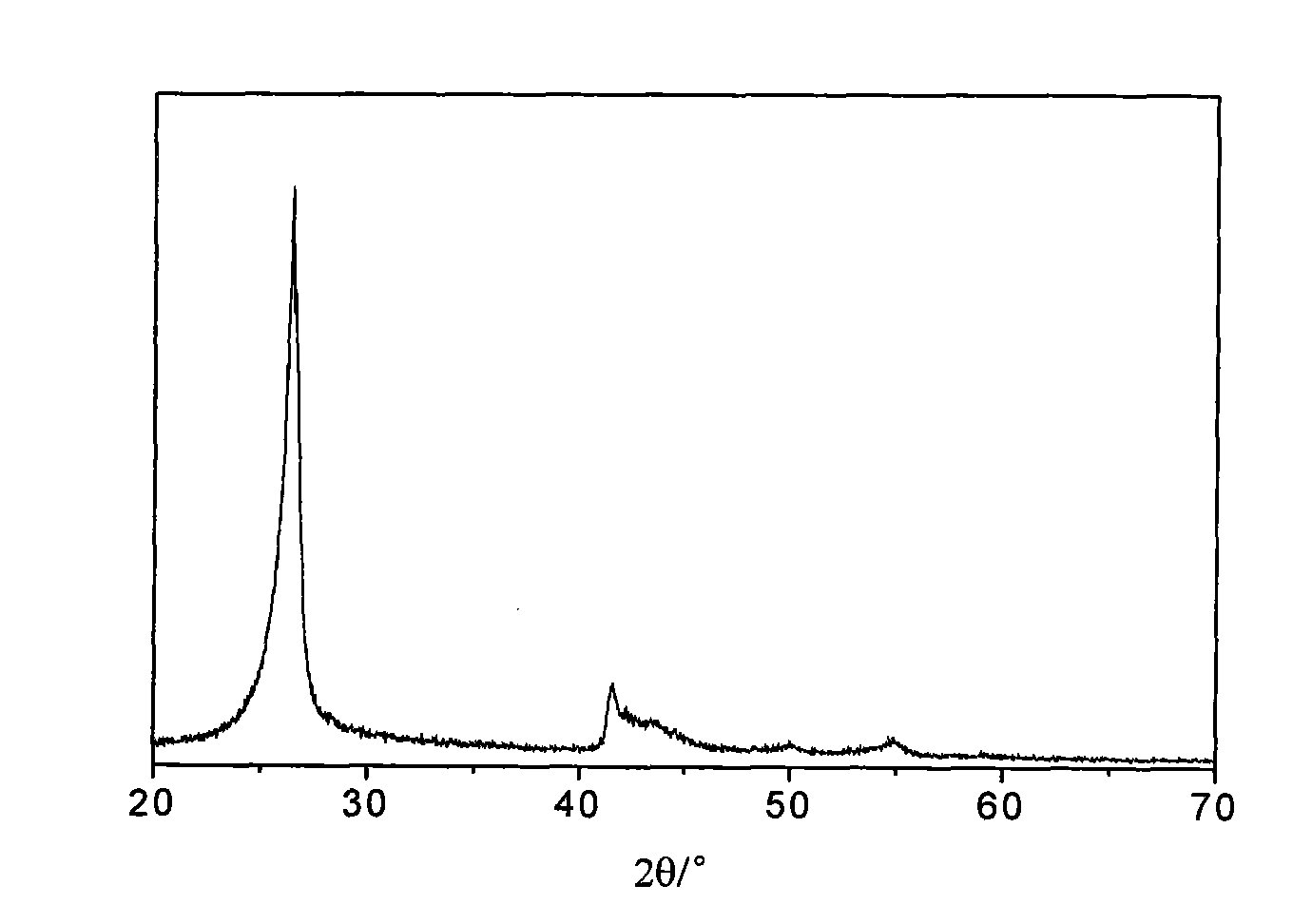

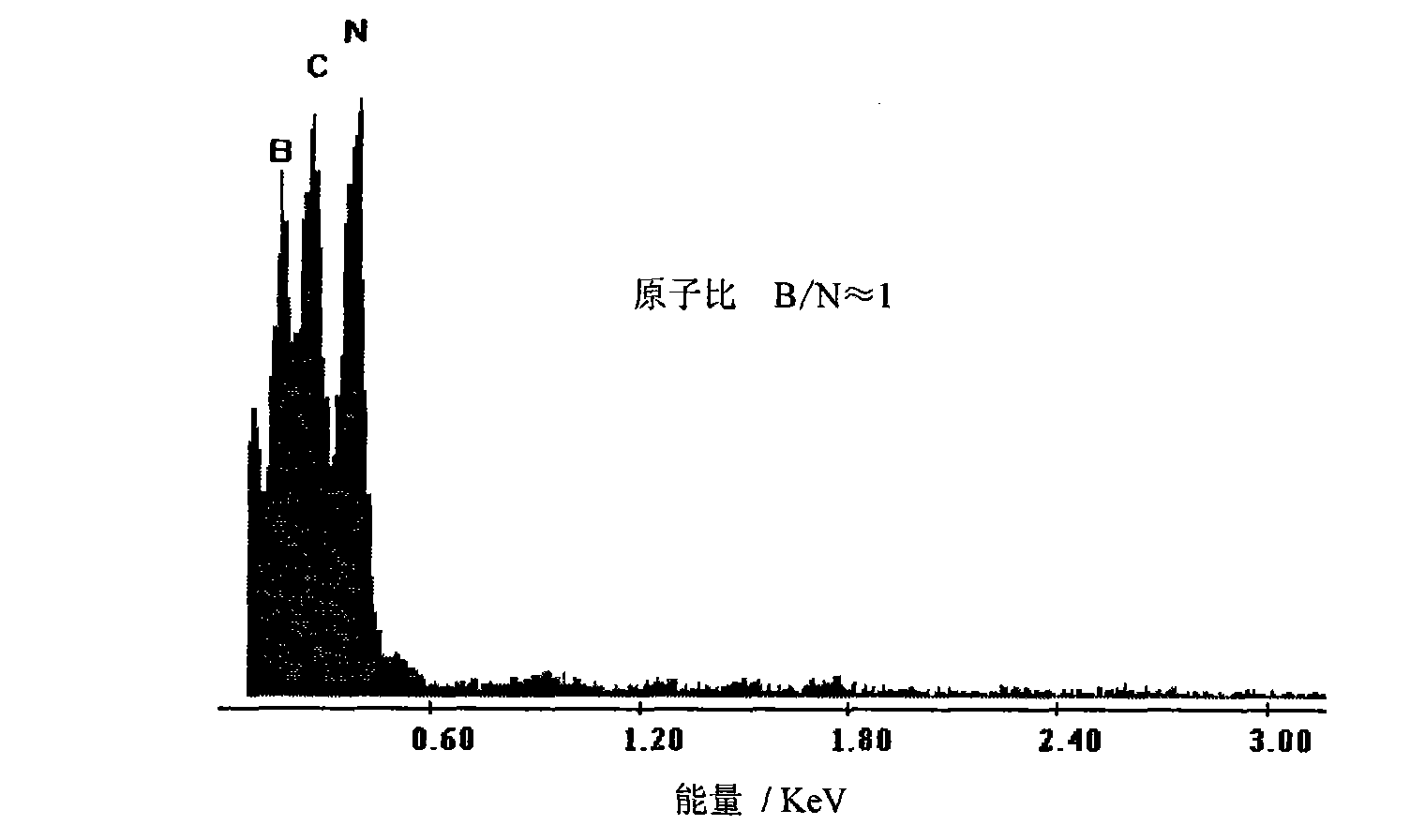

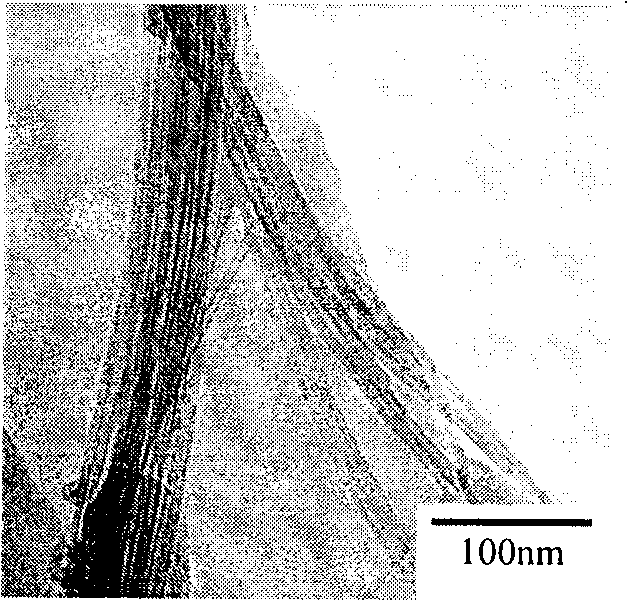

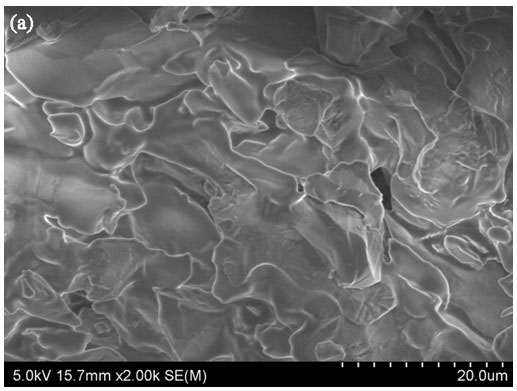

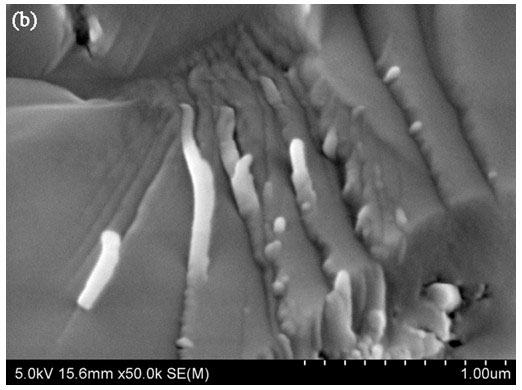

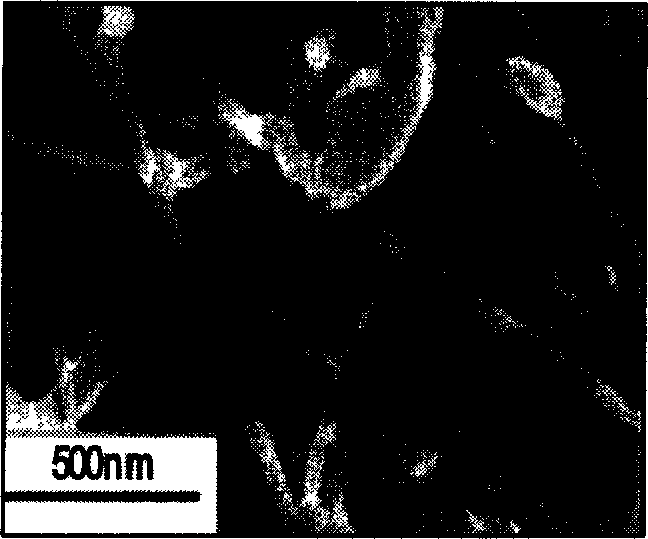

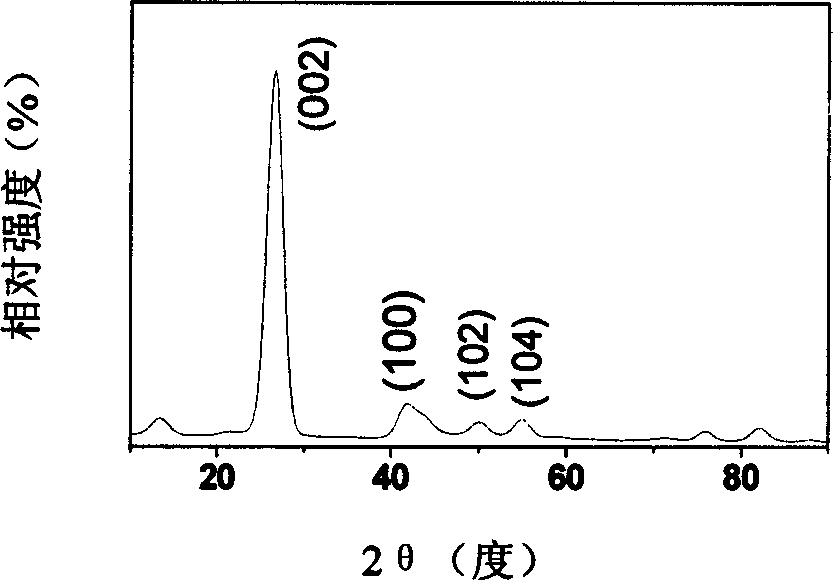

InactiveCN103922295AHigh diffraction intensityHigh degree of crystallizationNitrogen compoundsBoron nitrideBall mill

The invention relates to a preparation method of a boron nitride nano tube. The method comprises the steps of carrying out ball milling on metal magnesium powder and low-cost boron oxide as a boron source instead of B to prepare a precursor; preparing the pure-phase boron nitride nano tube with a high length-diameter ratio in high-temperature ammonia gas atmosphere in a vertical induction heating furnace. According to the invention, used raw materials are boron oxide powder and metal magnesium powder which both belong to ordinary chemical raw materials which are industrially produced, are low and easily available and non-toxic; the synthesized boron nitride nano tube is high in purity, large in length-diameter ratio, little in defect and uniform in morphology; the method is non-toxic, reliable and suitable for synthesis on large scale; the prepared boron nitride nano tube can be applied to the fields of nanoelectronics, electronic heat dissipation elements, solid / liquid lubricants, nano composite materials, high-temperature structure members and the like.

Owner:HEBEI UNIV OF TECH

High-thermal conductivity flame-retardant epoxy resin pouring sealant and preparation method thereof

InactiveCN107779153AFlame retardantGood dispersionNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyBoron nitride

The invention discloses a high-thermal conductivity flame-retardant epoxy resin pouring sealant. The heat conductivity coefficient of the pouring sealant reaches 3.0W / mK-5.0W / mK, and the flame-retardant grade is UL94 V-0. The pouring sealant contains a component A and a component B, wherein the component A is mainly prepared from epoxy resin, an inorganic fillings, a dispersing agent, a defoamingagent and an active diluent; the component B is mainly prepared from a curing agent and an accelerant; the inorganic fillings are selected from at least two of boron nitride nanotubes, boron nitride nanosheets, aluminum nitride, aluminum oxide and silica powder; and the mass ratio of the component A to the component B is (10-15) to 1. The invention further discloses a preparation method of the epoxy resin pouring sealant. The heat conductivity coefficient of the pouring sealant reaches 3.0W / mK-5.0W / mK, and the flame-retardant grade is UL94 V-0.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Preparation method of boron nitride nano tube with controllable dimension

InactiveCN101633498AHigh yieldEasy to purifyNanostructure manufactureNitrogen compoundsBoron nitrideNitrogen gas

The invention belongs to the field of inorganic nano material. The prior preparation method of a boron nitride nano tube has the problems of low production rate, high cost, complicated technology, difficult dimension control and the like. The preparation method comprises the steps: putting boron and a catalyst on the basis of weight ratio of 1 to (0.01 to 0.05) into a plastic bottle; using a nonaqueous solvent as a medium; ball-milling the boron and the catalyst for 8 to 24 hours; sieving the boron and the catalyst in a screen of 100 meshes after drying; heating a sieved mixture under the protection of argon gas; stopping leading the argon gas and leading nitrogen gas or the mixed gas of ammonia gas and the nitrogen gas when the temperature reaches 1000 DEG C to 1300 DEG C; keeping the temperature for 0.5 to 5 hours; reducing the temperature to room temperature after the constant temperature is finished; adding an obtained product to nitric acid for ultrasonic processing; removing the remained catalyst; and obtaining the boron nitride nano tube. The preparation method has the advantages of low cost, simple preparation technology, good repeatability and easy control and amplification of reaction; and the obtained boron nitride nano tube has the advantages of high production efficiency, easy purification, controllable tube diameter, controllable length and the like.

Owner:BEIJING UNIV OF TECH

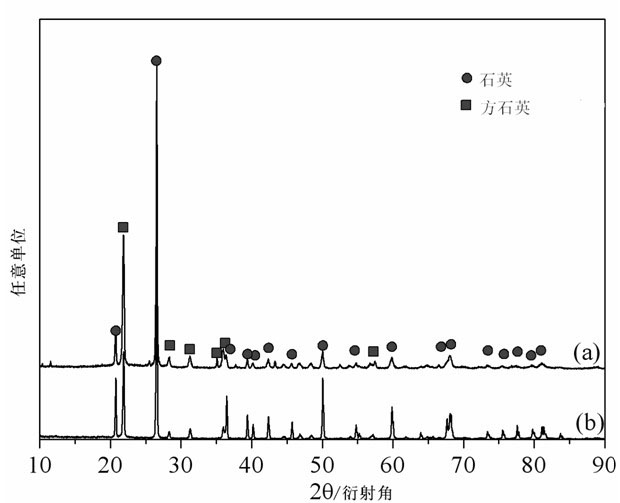

Preparation method of boron nitride nanotube-intensified silicon oxide ceramic

The invention relates to a preparation method of a boron nitride nanotube-intensified silicon oxide ceramic, which comprises the following steps of: A. pre-treating boron nitride nanotubes; B. weighing the boron nitride nanotubes and nano-grade and micron-grade silicon oxides; C. treating with different surface active agents; D. adding to a ball-milling pot, and compounding; E. drying, and screening; F. carrying out the hot pressed sintering in a multifunctional high-temperature sintering furnace in the shielding gas atmosphere; G. maintaining the temperature, then stopping heating, and naturally cooling to the room temperature; and H. machining the sintered ceramic block, and then testing the performance. The invention is a method which effectively improves the mechanical property of the silicon oxide, and greatly improves the mechanical property of the silicon oxide. The bend strength of the boron nitride nanotube-intensified silicon oxide ceramic is up to 130MPa, and is 6.5 times higher than that of the pure silicon oxide ceramic (19.6MPa).The process improves the mechanical property of the silicon oxide ceramic, and has the advantages of simple process, stability, high safety, easy operation and large scale production.

Owner:SHANDONG UNIV

Process for preparing boron nitride nano tube

InactiveCN1587030AGood workmanshipLow heat treatment temperatureNitrogen compoundsBoron nitrideNitrogen gas

The present invention relates to the process of preparing boron nitride nanotube, and relates to inorganic nanometer material. Non-toxic boron compound, such as boron chloride, boric acid, etc. as material is first ball ground for certain time, and then heated to over 800 deg.c in flowing ammonia or nitrogen and maintained for over 0.5 hr. The product after being cooled is cleaned in dilute hydrochloric acid, distilled water and alcohol and dried to obtain white powder as the boron nitride nanotube product. The process is simple, mild in condition and suitable for mass production, and has yield over 80 %. The prepared boron nitride nanotube is semiconductor and may be used in nanometer electronic device, nanometer structural ceramic material, hydrogen storing material, etc.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

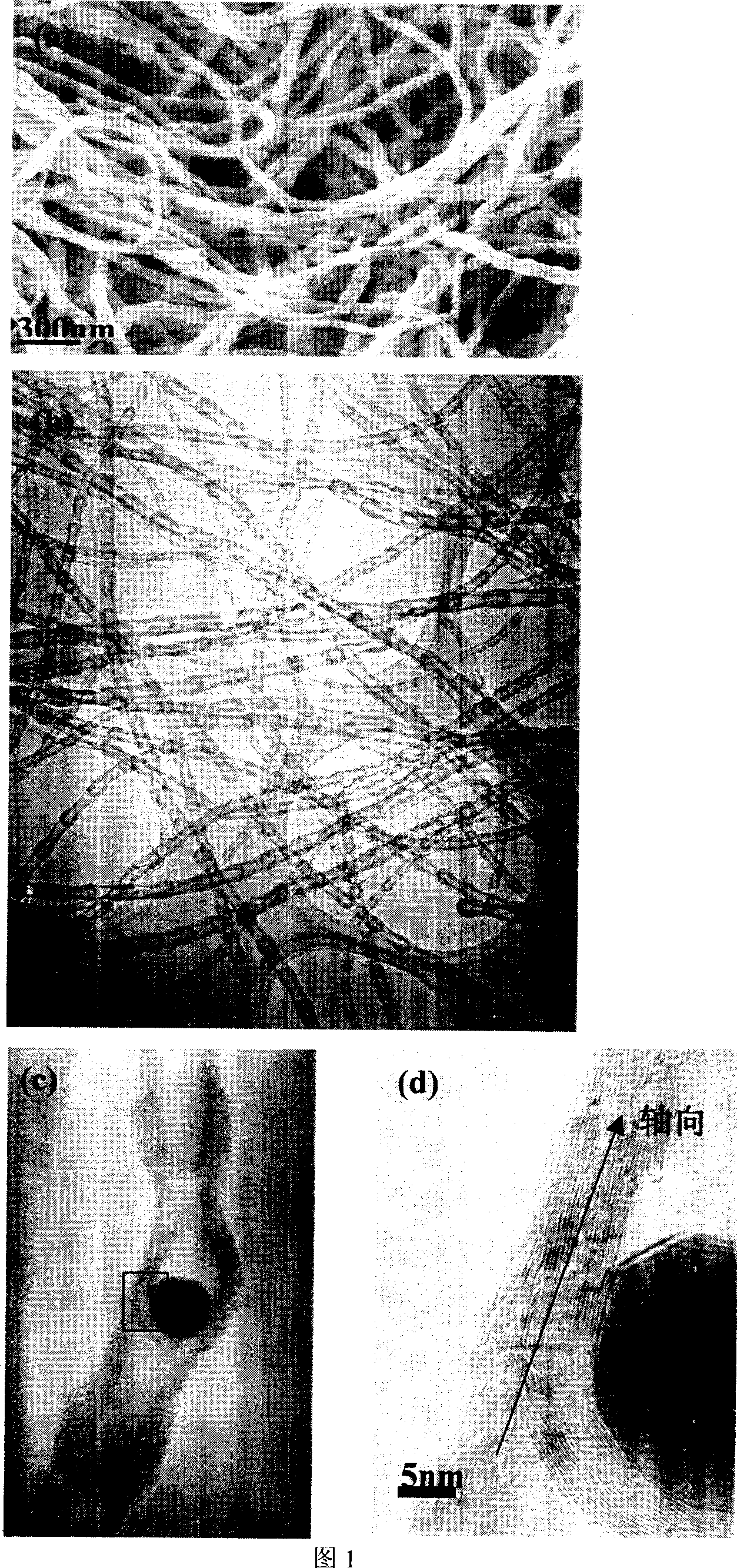

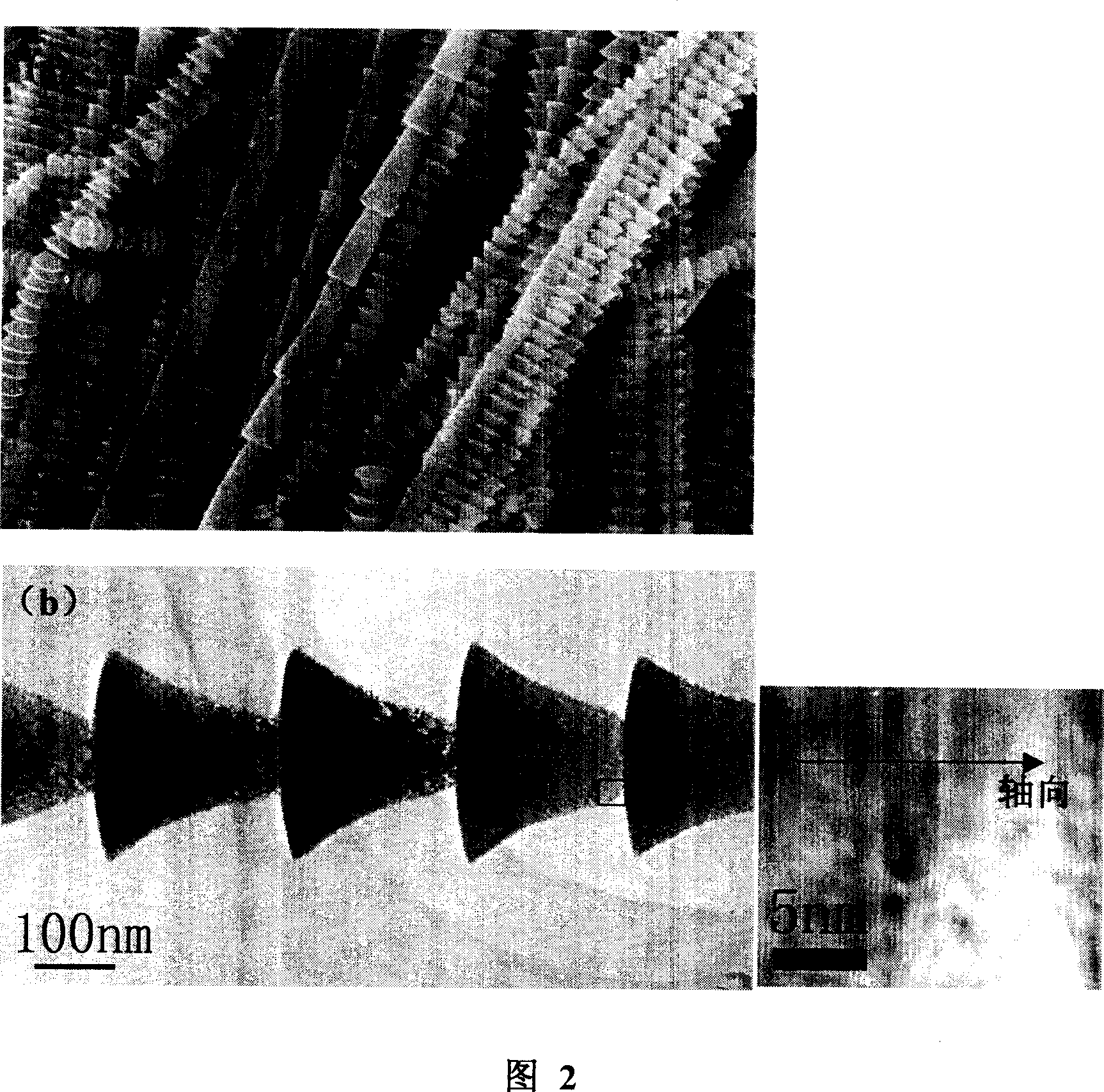

Preparation method of quasi one-dimensional boron nitride nanostructure

The invention discloses a controlled preparing method of pseudo one-dimensional boron nitride nanometer structure through adjusting preparation parameter to control diverse pseudo one-dimensional boron nitride nanometer structure, which comprises the following steps: choosing bis nickel, bis ferrum, bio cobalt or the mixture as suspended activator forerunner body; volatilizing in the low temperature region; carrying through gas-carrier to high-temperature region; disintegrating to metallic catalyst; accelerating B2O2 vapour generated through mixing boron powder and boron oxide to react with ammonia gas; generating the product; getting boron nitride nanometer thread and bamboo joint state boron nitride nanometer pipe with diverse diameter and outlook through controlling component, time, temperature of the activator. The structure of the boron nitride nanometer thread and pipe possesses essential difference, which the front (0002) face grow vertically and the back (0002) face parallel-grows.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com